Professional Documents

Culture Documents

Fentons Reagent New

Uploaded by

Stephanus Subagio0 ratings0% found this document useful (0 votes)

141 views3 pagesFenton's process pre-treats a specific 40 GPM wastewater stream to reduce phenols by 90% prior to mixing with higher flow waste streams. Process has consistently achieved >90% removal of phenols from this stream and eliminated bio-toxicity violations and public relations issues. Existing treatment process system (ozone) required significant maintenance and was not providing effective treatment of COD, phenols and other organic compounds in a 15 GPM scrubber blowdown stream.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFenton's process pre-treats a specific 40 GPM wastewater stream to reduce phenols by 90% prior to mixing with higher flow waste streams. Process has consistently achieved >90% removal of phenols from this stream and eliminated bio-toxicity violations and public relations issues. Existing treatment process system (ozone) required significant maintenance and was not providing effective treatment of COD, phenols and other organic compounds in a 15 GPM scrubber blowdown stream.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

141 views3 pagesFentons Reagent New

Uploaded by

Stephanus SubagioFenton's process pre-treats a specific 40 GPM wastewater stream to reduce phenols by 90% prior to mixing with higher flow waste streams. Process has consistently achieved >90% removal of phenols from this stream and eliminated bio-toxicity violations and public relations issues. Existing treatment process system (ozone) required significant maintenance and was not providing effective treatment of COD, phenols and other organic compounds in a 15 GPM scrubber blowdown stream.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Specialty Chemical Manufacturer Louisiana

Problem: Discharge violations (phenols, bio-toxicity) resulting from ineffective treatment

with the existing processes - physical-chemical treatment (DAF unit, coagulation/

precipitation) followed by aerated lagoon.

Treatment Goal: Effectively pre-treat a specific 40 GPM wastewater stream containing

400-600 mg/L phenol compounds and 4000-500 mg/L COD to reduce phenols by 90% prior

to mixing with higher flow waste streams.

Fentons Process Description: The iron catalyst is added to the wastewater stream in-

line (static mixer), with the hydrogen peroxide injected (with mixing) into the first cell of a

baffled reaction vessel. The baffled reaction vessel helps eliminate short-circuiting and

provides sufficient reaction time. The hydrogen peroxide and iron catalyst dosing modules

are interlocked with the wastewater pumps to ensure chemical feed stops with an

interruption in wastewater flow.

Treatment Results (6 years operating): Fentons process has consistently achieved

>90% removal of phenols from this stream and eliminated bio-toxicity violations and public

relations issues.

US Peroxide Contributions: USP personnel worked with a major environmental

consulting firm and the manufacturer on lab scale treatability tests as well as design of

the full-scale process. USP conducted successful 6-month full-scale demonstration of the

technology resulting in optimization of chemical dose requirements. Fentons process is

now a permanent part of the overall facility wastewater treatment process.

US Peroxide supplies the iron catalyst, hydrogen peroxide, and turnkey storage and dosing

systems for both chemicals. Supply scope includes ongoing equipment maintenance,

remote tank monitoring/inventory management, and applications services.

Refinery Southeast US

Problem: The existing treatment process system (ozone) required significant maintenance

and was not providing effective treatment of COD, phenols and other organic compounds in

a 15 GPM scrubber blowdown stream.

Treatment Goal: Effectively pre-treat the stream prior to discharge to on-site biological

treatment.

Fentons Process Description: Catalyst is added to the wastewater stream in-line (static

mixer) with the hydrogen peroxide injected into the wastewater stream in-line (static mixer)

just prior to entry into the reaction vessel. The hydrogen peroxide and catalyst dosing

modules are interlocked with the wastewater pumps to ensure chemical feed stops in the

event of an interruption in scrubber blowdown flow.

Treatment Results (5 years operating): This process has consistently achieved

effective pre-treatment, eliminating upsets to the biological system.

US Peroxide Contributions: USP conducted successful 6-month full-scale demonstration

of the technology resulting in optimization of chemical dose requirements and it is now a

permanent part of the overall facility wastewater treatment process.

US Peroxide supplies the catalyst, hydrogen peroxide, and turnkey storage and dosing

systems for both chemicals. Supply scope includes ongoing equipment maintenance,

remote tank monitoring/inventory management, and applications services.

Many metals have special oxygen

transfer properties that improve the

utility of hydrogen peroxide. By far,

the most common of these is iron

(e.g. Fe+2) which, when used in the

prescribed manner, results in the

generation of highly reactive

hydroxyl radicals (

.

OH).

Fentons Reagent is used to treat a

variety of industrial wastes

containing a range of toxic organic

compounds (phenols, formaldehyde,

BTEX, and complex wastes derived

from pesticides, petroleum refining,

wood preservatives, plastics

additives, and rubber chemicals).

The process may be applied to

wastewaters, sludge, or

contaminated soils, with the effects

being:

Organic pollutant destruction

Toxicity reduction

Biodegradability improvement

BOD / COD removal

Odor and color removal

US Peroxide, LLC

500 Bishop St. NW, Suite C-3

Atlanta, GA 30318

www.h2o2.com

Inquiries call 877-346-4262

or email at: info@h2o2.com

FENTONS REAGENT TREATMENT PROCESS

References

Fentons Reagent

Iron-catalyzed

Hydrogen Peroxide

MKG-FEN (06/09) Fentons Reagent Treatment Process References Page 2

Wood Treating Facility Western US

Problem: Discharge violations (NPDES) to a municipal collection and treatment system caused by phenols, napthols and

cresols.

Treatment Goal: Pre-treat this 20 GPM wastewater stream to reduce these compounds by >95%.

Fentons Process Description: The iron catalyst is added to the wastewater stream in-line (static mixer), with the hydrogen

peroxide injected (with mixing) into the first cell of a baffled reaction vessel. The baffled reaction vessel helps eliminate short-

circuiting and provides sufficient reaction time. The hydrogen peroxide and iron catalyst dosing modules are interlocked with the

wastewater pumps to ensure chemical feed stops with an interruption in wastewater flow.

Treatment Results (4.5 years operating): Fentons pre-treatment process has consistently achieved target compound

removal efficiencies, and eliminated inhibition of biomass and discharge violations.

US Peroxide Contributions: USP conducted lab scale treatability tests, followed by a 6-month full-scale demonstration to

optimize chemical dose requirements, as well as design of the full-scale process. The Fentons process is now a permanent part

of the overall facility wastewater treatment process.

US Peroxide supplies the iron catalyst, hydrogen peroxide, and turnkey storage and dosing systems for both chemicals. Supply

scope includes ongoing equipment maintenance, remote tank monitoring/inventory management, and applications services.

Aircraft Painting Stripping and Maintenance Facility Midwest US

Problem: Discharge violations for toxic organic compounds, e.g. methylene chloride, pentachlorophenol, nitrophenols resulting

from ineffective treatment with the existing processes - physical-chemical treatment (chrome reduction followed by

coagulation/precipitation)

Treatment Goal: Effectively pre-treat the paint stripping wastewater stream to reduce targeted toxic organics by >95% prior

to discharge to the municipal wastewater collection system.

Fentons Process Description: The prescribed amount of iron catalyst is added to the stirred batch reaction vessel over a

period of about 5 minutes. The hydrogen peroxide is subsequently added to the stirred batch reaction vessel over a period of

several hours. Peroxide addition is done over a longer period of time to optimize toxic compound oxidation. The hydrogen

peroxide dosing module is interlocked with temperature probes in the reaction tank to ensure chemical feed stops if wastewater

temperatures reach a predetermined level.

Treatment Results: Fentons process consistently achieved >95% removal of toxic organics during the 6-month full-scale

demonstration.

US Peroxide Contributions: USP personnel worked with a major environmental consulting firm and the manufacturer to

conduct pilot treatability tests as well as design of the full-scale batch treatment process. USP conducted successful 6-month

full-scale demonstration of the technology resulting in optimization of chemical dose requirements. Fentons process is being

designed into the permanent upgrade of the facility wastewater treatment process.

US Peroxide supplied the iron catalyst, hydrogen peroxide, and turnkey storage and dosing systems for both chemicals for the 6-

month demonstration. Supply scope included ongoing equipment maintenance, remote tank monitoring/inventory management,

and applications services.

DRINKING WATER TREATMENT

Hydrogen Peroxide Pre-Oxidant

FENTONS REAGENT TREATMENT PROCESS

References

MKG-FEN (06/09) Fentons Reagent Treatment Process References Page 3

Emergency Treatment of Phenol Contaminated Wastewater at Chemical Plant Alabama

Problem: In 2008, a large chemical manufacturing plant in Southern Alabama had over three million gallons of process

wastewater contaminated with 200-300 mg/L of phenols. Due to the elevated phenol levels, the wastewater could not be

directly pumped to the on-site activated sludge treatment system due to bio-toxicity concerns. The wastewater was diverted to

several large storage tanks until a pretreatment solution could be implemented. Finding and implementing a temporary

pretreatment solution quickly was critical, as the volume of contaminated wastewater nearly exhausted all of the plants

stormwater storage capacity

Treatment Goal: Reduce phenol levels to the 0.2 mg/L plant mandated goal to allow discharge to the on-site biological

treatment plant as soon as possible.

Fentons Process Description: Addition of the ferric chloride catalyst and hydrogen peroxide was done sequentially over a 2-

day period, using temporary peroxide and iron storage and dosing equipment supplied by USP. Chemicals were added using

the mixing/recirculation system in the large stormwater (wastewater) storage tanks.

Treatment Results: After allowing the Fentons reaction to proceed overnight (~12 hours), the plant laboratory confirmed

that phenol levels had been reduced to below the 0.2 mg/l goal. The treated wastewater was subsequently pumped to the

biological treatment plant with no treatment upsets or discharge violations. The entire emergency treatment process

(equipment installation, chemical injection/oxidation, equipment demobilization) was completed in less than 5 days.

US Peroxide Contributions:

US Peroxide supplied the hydrogen peroxide; iron catalyst; temporary peroxide and ferric storage & dosing equipment; piping to

the injection point; equipment system installation, start-up and operational oversight; equipment demobilization upon

completion of the project; portable safety shower/eyewash; on-site applications support; and hydrogen peroxide and ferric

chloride safety training for customer operations personnel.

FENTONS REAGENT TREATMENT PROCESS

References

You might also like

- Emerging Technologies and Biological Systems for Biogas UpgradingFrom EverandEmerging Technologies and Biological Systems for Biogas UpgradingNabin AryalRating: 5 out of 5 stars5/5 (1)

- AS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection StandardsDocument7 pagesAS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection Standardslastwest1No ratings yet

- Li 2017Document8 pagesLi 2017zibaNo ratings yet

- Master Drawing List For GE - All Ge DrawingsDocument7 pagesMaster Drawing List For GE - All Ge DrawingsSulaiman JafferyNo ratings yet

- Delta Industrial Knife Gate ValvesDocument28 pagesDelta Industrial Knife Gate ValvesAlin AllinNo ratings yet

- Bha Coil Tubing Tools PDFDocument35 pagesBha Coil Tubing Tools PDFJose Leonardo Materano Perozo100% (2)

- Chemistry ProjectDocument4 pagesChemistry ProjectJuliana PardoNo ratings yet

- Diseño de Experimentos en Tratamiento de AguasDocument10 pagesDiseño de Experimentos en Tratamiento de AguasLucas RossiniNo ratings yet

- Oxidation of Acetaminophen by Fluidized-Bed Fenton Process: Optimization Using Box-Behnken DesignDocument12 pagesOxidation of Acetaminophen by Fluidized-Bed Fenton Process: Optimization Using Box-Behnken DesignOswar MungkasaNo ratings yet

- Chemical Engineering AssignmentDocument1 pageChemical Engineering AssignmentfinchdogeNo ratings yet

- Pós OzonizaçãoDocument6 pagesPós Ozonizaçãojose buenoNo ratings yet

- OzonoDocument8 pagesOzonoDaniella CelisNo ratings yet

- 03 Review of LiteratureDocument10 pages03 Review of Literaturesahil masulkarNo ratings yet

- Carrosuel 2000Document7 pagesCarrosuel 2000Khang TrầnNo ratings yet

- Chemical Engineering Journal: A. Durán, J.M. Monteagudo, J. Gil, A.J. Expósito, I. San MartínDocument9 pagesChemical Engineering Journal: A. Durán, J.M. Monteagudo, J. Gil, A.J. Expósito, I. San MartínDanilo RodriguesNo ratings yet

- Envirmonement Source ReportDocument19 pagesEnvirmonement Source Reportمهيمن الابراهيميNo ratings yet

- Industrial wastewater treatment case study fertilizer industryDocument11 pagesIndustrial wastewater treatment case study fertilizer industryisquare77No ratings yet

- EPRI's Phosphate Continuum and Caustic Treatment GuidelineDocument59 pagesEPRI's Phosphate Continuum and Caustic Treatment GuidelineDian PiresNo ratings yet

- علي غانم خضير PDFDocument29 pagesعلي غانم خضير PDFAli AlibrahimiNo ratings yet

- Anaerobic Pre-Treatment of PharmaceuticalDocument6 pagesAnaerobic Pre-Treatment of PharmaceuticalZulhasri WahapNo ratings yet

- Electro FentonDocument5 pagesElectro FentonTônHưngNo ratings yet

- Paper 19Document6 pagesPaper 19Editor IJSETNo ratings yet

- Chemical Method For Wastewater Management Developments of Fenton ProcessDocument15 pagesChemical Method For Wastewater Management Developments of Fenton ProcessIJARP PublicationsNo ratings yet

- 10.1007@s11356 017 0746 ZDocument12 pages10.1007@s11356 017 0746 ZFarah TalibNo ratings yet

- Sustainability 09 00244Document14 pagesSustainability 09 00244Israel SaavedraNo ratings yet

- Optimization of Fenton's Oxidation of Chemical Laboratory Wastewaters Using The Response Surface MethodologyDocument9 pagesOptimization of Fenton's Oxidation of Chemical Laboratory Wastewaters Using The Response Surface MethodologyravenNo ratings yet

- Reduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. DevadasanDocument5 pagesReduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. Devadasanjmrozo3No ratings yet

- Fenton ReactionsDocument30 pagesFenton Reactionssong1088100% (1)

- 1 s2.0 S2666016423001366 MainDocument10 pages1 s2.0 S2666016423001366 MainChan Yong SoonNo ratings yet

- Chemical Engineering Journal Optimizes Phenol DegradationDocument12 pagesChemical Engineering Journal Optimizes Phenol DegradationFarah El ShahawyNo ratings yet

- Ding2016 Article BiologicalTreatmentOfActualPetDocument10 pagesDing2016 Article BiologicalTreatmentOfActualPetPraveen KumarNo ratings yet

- BiomassDocument10 pagesBiomassSasi DevanNo ratings yet

- Q. Enumerate The Undesirable Characteristics of Industrial Wastewater??????Document14 pagesQ. Enumerate The Undesirable Characteristics of Industrial Wastewater??????Sudipta kumar muduliNo ratings yet

- lixiviados vertederosDocument10 pageslixiviados vertederosSanchez LauraNo ratings yet

- Fenton Oxidation Post-Treatment Winery WastewaterDocument4 pagesFenton Oxidation Post-Treatment Winery Wastewatervenessa cabrillosNo ratings yet

- Phenolic Based Pharmaceutical Contaminated WastewaDocument5 pagesPhenolic Based Pharmaceutical Contaminated WastewaAri AdriantoNo ratings yet

- Ozone Based Waste Water TreatmentDocument10 pagesOzone Based Waste Water TreatmentZafar BukhariNo ratings yet

- Application of Hydrodynamic Cavitation ReactorsDocument24 pagesApplication of Hydrodynamic Cavitation ReactorsJeffery TaylorNo ratings yet

- Document PDFDocument2 pagesDocument PDFOki Andri Oktaviana0% (1)

- Using CO2 For PH ControlDocument7 pagesUsing CO2 For PH ControlstreamtNo ratings yet

- Chapter 1Document27 pagesChapter 1Isha MeshramNo ratings yet

- ww07 Chem Feed WBDocument74 pagesww07 Chem Feed WBHouseNo ratings yet

- A Review On Fenton-Like Processes For OrganicDocument115 pagesA Review On Fenton-Like Processes For OrganicCarolinaQuimbayaNo ratings yet

- 1999 Andreozzi - Advanced Oxidation Processes AOP For Water Purification and RecoveryDocument9 pages1999 Andreozzi - Advanced Oxidation Processes AOP For Water Purification and RecoveryHerick Bulhões100% (1)

- My Project SeminarDocument19 pagesMy Project SeminarSherry Oma NnadozieNo ratings yet

- Application of Sono-photo-Fenton Process For DegraDocument9 pagesApplication of Sono-photo-Fenton Process For DegraS DNo ratings yet

- Application of The Central Composite Design and Response Surface Methodology To The Advanced Treatment of Olive Oil Processing Wastewater Using Fenton's PeroxidationDocument9 pagesApplication of The Central Composite Design and Response Surface Methodology To The Advanced Treatment of Olive Oil Processing Wastewater Using Fenton's PeroxidationBEANNo ratings yet

- Treatment of Industrial Wastewater Contaminated With RecalcitrantDocument9 pagesTreatment of Industrial Wastewater Contaminated With Recalcitrantfrank2593No ratings yet

- Direct Synthesis of Hydrogen Peroxide in Batch Reactors: Understanding The Kinetics and MechanismsDocument2 pagesDirect Synthesis of Hydrogen Peroxide in Batch Reactors: Understanding The Kinetics and MechanismsSanaNo ratings yet

- Pesticide Chemical OxidationDocument12 pagesPesticide Chemical OxidationIvan OsipovNo ratings yet

- Quality Water Drinking Irrigation Contaminants: Chapters 21 IntroductionDocument10 pagesQuality Water Drinking Irrigation Contaminants: Chapters 21 IntroductionMohd ShakoorNo ratings yet

- 9.7 MLD DPR PDFDocument56 pages9.7 MLD DPR PDFAjay ShindeNo ratings yet

- 10 11648 J Ajche 20160401 11 PDFDocument8 pages10 11648 J Ajche 20160401 11 PDFchristian roldanNo ratings yet

- Archive of SID: Removal of Surfactant From Industrial Wastewaters by Coagulation Flocculation ProcessDocument6 pagesArchive of SID: Removal of Surfactant From Industrial Wastewaters by Coagulation Flocculation ProcessrudymerchoNo ratings yet

- Potable Water From Industrial Wastewater: M. S. AliDocument4 pagesPotable Water From Industrial Wastewater: M. S. AliEr Omkar Ravindra MhatreNo ratings yet

- Application of The Combined Ultrafiltration and Reverse Osmosis For Refinery Wastewater Reuse in Sinopec Yanshan PlantDocument11 pagesApplication of The Combined Ultrafiltration and Reverse Osmosis For Refinery Wastewater Reuse in Sinopec Yanshan PlanteducacionNo ratings yet

- EPA Guide to In Situ Chemical Oxidation for Soil and Groundwater RemediationDocument6 pagesEPA Guide to In Situ Chemical Oxidation for Soil and Groundwater RemediationCarlos AponteNo ratings yet

- Solid Waste: Odor and Dust ControlDocument7 pagesSolid Waste: Odor and Dust ControlDaniela SîrbuNo ratings yet

- Tratarea Deseurilor - MicroorganismeDocument7 pagesTratarea Deseurilor - MicroorganismeDaniela SîrbuNo ratings yet

- Chapter 3 - Water TreatmentDocument21 pagesChapter 3 - Water TreatmentSri SundragomathyvenkateshNo ratings yet

- Anaerobic Biodegradation of Phenol in Wastewater TreatmentDocument30 pagesAnaerobic Biodegradation of Phenol in Wastewater TreatmentCarlos OlveraNo ratings yet

- Articulos MicrobiologiaDocument17 pagesArticulos MicrobiologiaBrayao95No ratings yet

- Direct Methane to Methanol: Foundations and Prospects of the ProcessFrom EverandDirect Methane to Methanol: Foundations and Prospects of the ProcessNo ratings yet

- Cold Storage 2Document61 pagesCold Storage 2Dhruba Jyoti MalakarNo ratings yet

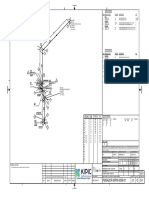

- P055azr 05P00 3059 01Document1 pageP055azr 05P00 3059 01Deshwa SaravananNo ratings yet

- Conveyor installation diagramDocument2 pagesConveyor installation diagramLuis PurisNo ratings yet

- Multistage Air Compressor FinalDocument21 pagesMultistage Air Compressor FinalJames TheeNo ratings yet

- Unimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfDocument2 pagesUnimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfIvana Ilic67% (3)

- Install Guide Spunlite Poles 2015Document6 pagesInstall Guide Spunlite Poles 2015Balaji PalaniNo ratings yet

- WWW - Osha.gov Pre Test Answer Key2Document3 pagesWWW - Osha.gov Pre Test Answer Key2raul_bsu100% (6)

- Outokumpu Dowel BarsDocument2 pagesOutokumpu Dowel BarsAriel NemcoNo ratings yet

- Hydraulic Arm RealDocument14 pagesHydraulic Arm RealVarun S RajanNo ratings yet

- Introduction Electrical MotorDocument36 pagesIntroduction Electrical MotorYajidNo ratings yet

- Ecoflam BurnersDocument40 pagesEcoflam Burnerseuroused100% (1)

- AP Chem Test - Chapter 10,11,13 - Gases, Solutions, Solids, Liquids, Inter Forces (2010-2011)Document12 pagesAP Chem Test - Chapter 10,11,13 - Gases, Solutions, Solids, Liquids, Inter Forces (2010-2011)dlloyd63050% (2)

- Improving The Performance of Fabric Filter Dry Dust Collection EquipmentDocument10 pagesImproving The Performance of Fabric Filter Dry Dust Collection EquipmentDavid GuevaraNo ratings yet

- The Introduction of Sterilization PouchesDocument3 pagesThe Introduction of Sterilization PouchesjarzloniezNo ratings yet

- (RDMP) BQ Piping Smp3 170601 Iti Rev0Document365 pages(RDMP) BQ Piping Smp3 170601 Iti Rev0Fahmy FlipNo ratings yet

- Cane Ite PDFDocument4 pagesCane Ite PDFJim HaigNo ratings yet

- 1kz-Te Cooling System PDFDocument14 pages1kz-Te Cooling System PDFwill meridith100% (2)

- 6.3 - MCB & MCCBDocument25 pages6.3 - MCB & MCCBAnonymous qJXSQDSoE100% (2)

- What To Do When Service Is Needed: C Cu Ua An ND Do o N Ne Ec Ce Es Siitta A S Se Errv Viic Ciio oDocument48 pagesWhat To Do When Service Is Needed: C Cu Ua An ND Do o N Ne Ec Ce Es Siitta A S Se Errv Viic Ciio oJANo ratings yet

- En 1 4547 - 1510 Valbruna Nordic EnglishDocument2 pagesEn 1 4547 - 1510 Valbruna Nordic Englishpinky_y2kNo ratings yet

- Dvm+s+y+joint Mcu+port+twin Submittal 09192018Document3 pagesDvm+s+y+joint Mcu+port+twin Submittal 09192018Luis Fernado PaizNo ratings yet

- A815 PDFDocument8 pagesA815 PDFExport priminoxNo ratings yet

- DC 163Document2 pagesDC 163manox007No ratings yet

- Toyota 8fg Forklift Wiring DiagramDocument10 pagesToyota 8fg Forklift Wiring Diagrammarilyn100% (45)

- Corporate Image enDocument8 pagesCorporate Image enDanfert PinedoNo ratings yet

- LR Tech IntroDocument432 pagesLR Tech Intromagellan_phineas100% (11)