Professional Documents

Culture Documents

TR Fastenings Engineering Guide for Plastic Screws

Uploaded by

Andrew GrimesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TR Fastenings Engineering Guide for Plastic Screws

Uploaded by

Andrew GrimesCopyright:

Available Formats

TR Fastenings :: Engineering Knowledge base

Page 1 of 2

Quick Search

Go

Engineering Knowledge base

Products Corporate Site Engineering Support

Monday 15 February 2010

Advanced Search

Home

You are here : - Technical Support > Engineering Knowledge base > Installation Guidelines & Hole Sizes > Screws for Plastic >

Welcome Paul Onions You are now logged in.

Engineering Knowledge base :: Article

KBA040101 - High Performance Screws for Plastic installation guide

This product belongs to: Installation Guidelines & Hole Sizes > Screws for Plastic >

Your Current Project GB1411

View Product Guide View Current Project Load Project Create New Project List All Project Parts Help TR Newsletter Change Your Password This article provides an installation guide for the High Performance Screws for Plastics. The illustrated moulded boss features a 1 Degree inclusive tapered hole. However, it is not a prerequisite. It is commonplace for these screws to be installed into drilled holes also. All data is correct to the best of our knowledge, however TR cannot be held responsible for any errors or omissions Enquire about this article Article

Quick Links :

Screws for Plastics data sheets

Animation

NB: Animation will open in a separate window and requires Flash plugin

Document reference: [ KBA040101 ]

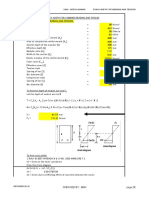

To identify a suitable hole size for a selected screw diameter, choose a material from the boss geometry tables below closest to the application boss type and multiply the value in column A by the nominal external thread diameter. For example:- A 3.0 diameter High Perfomance screw for plastic being installed into ABS would require a 0.8 x 3.0 = 2.4mm guideline hole diameter. (where 'd' = nominal external thread diameter) The inclusion of a counter bore is not important, however, it will prevent damage to the top of the boss, help align the screw in the boss and act as a relief for any material extruded to the head of the screw, allowing flush finishes. To calculate the counter bore diameter, add 0.2mm onto the selected published screw head diameter. All data is correct to the best of our knowledge, however TR cannot be held responsible for any errors or omissions Table 1 Material ABS -A0.80d - B2.00d -C2.00d Table 2 Material PC GF30 -A0.85d -B1.80d -C2.00d

http://tr.trfastenings.com/services/engineering/article/72/64/

15/02/2010

TR Fastenings :: Engineering Knowledge base

Page 2 of 2

ABS/PC ASA PA4.6 PA4.6 GF30 PA6 PA6 GF30 PA6.6 PA6.6 GF30 PBT PBT GF30 PC

0.80d 0.78d 0.73d 0.78d 0.75d 0.80d 0.75d 0.82d 0.75d 0.80d 0.85d

2.00d 2.00d 1.85d 1.85d 1.85d 2.00d 1.85d 2.00d 1.85d 1.80d 2.50d

1.80d 1.80d 1.70d 1.90d 1.70d 1.80d 1.70d 1.80d 1.70d 1.70d 2.20d

LDPE HDPE PET PET GF30 PMMA POM PP PP TF20 PPO PS PVC SAN

0.70d 0.75d 0.75d 0.80d 0.85d 0.75d 0.75d 0.82d 0.75d 0.80d 0.85d 0.77d

2.00d 1.80d 1.85d 1.80d 2.00d 1.90d 1.85d 2.00d 1.85d 1.80d 2.50d 2.00d

2.00d 1.80d 1.70d 1.70d 2.00d 2.80d 1.70d 1.80d 1.70d 1.70d 2.20d 1.90d

All data is correct to the best of our knowledge, however TR cannot be held responsible for any errors or omissions

The High Performance screw for plastic is a direct screw fastener for use in thermoplastics. It's design characteristics include a profiled thread root to assist plastic flow and stress reduction, a 30 Degree flank angle to reduce boss bursting forces and an 8 Degree pitch angle which combine to support low installation torques with high stripping torque values.

low radial stress no material jam in the core area maximium resistance to relaxation no material stress through plastification.

http://tr.trfastenings.com/services/engineering/article/72/64/

15/02/2010

You might also like

- Coco Chanel: The Legend and The Life ExtractDocument24 pagesCoco Chanel: The Legend and The Life ExtractAnonymous ikUR753am75% (4)

- NSL Loler MatrixDocument1 pageNSL Loler MatrixAndrew Grimes100% (1)

- Krka National Park - Discover the Unique Power of NatureDocument93 pagesKrka National Park - Discover the Unique Power of NaturenickroroNo ratings yet

- AS2601 Demo STD GuideDocument1 pageAS2601 Demo STD GuideOwen PerrinNo ratings yet

- Lesson 05 - Exterior ElevationsDocument58 pagesLesson 05 - Exterior Elevationsapi-241156742No ratings yet

- PHP MicroservicesDocument18 pagesPHP Microservicestimi_pek0% (2)

- Toyolac ABS CatalogueDocument15 pagesToyolac ABS Catalogueksharidas0% (1)

- BAT54 Series WTE - (L4, L42, L43, L44) (KL1, KL2, KL3, KL4) Tipo SOT23Document5 pagesBAT54 Series WTE - (L4, L42, L43, L44) (KL1, KL2, KL3, KL4) Tipo SOT23z3xa5347No ratings yet

- Disassembly Notebo 2010629133645Document54 pagesDisassembly Notebo 2010629133645Cesar Gabriel BallesterNo ratings yet

- QCS 2010 Section 21 Part 8 TrunkingDocument5 pagesQCS 2010 Section 21 Part 8 Trunkingbryanpastor106No ratings yet

- Grinnell Mechanical Products Mechanical Outlet Coupling Installation / Assembly InstructionsDocument2 pagesGrinnell Mechanical Products Mechanical Outlet Coupling Installation / Assembly InstructionsRay LujanNo ratings yet

- ITT ValvesDocument40 pagesITT Valvesseramon100% (1)

- Pipeline StrainersDocument6 pagesPipeline Strainerssairam2234No ratings yet

- Wilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08Document7 pagesWilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08donsterthemonsterNo ratings yet

- Bapp A4 Stru Bro 2011Document24 pagesBapp A4 Stru Bro 2011Pete SwiftNo ratings yet

- Panduit Contractor CatalogDocument231 pagesPanduit Contractor CatalognumnummoNo ratings yet

- Instructions for Disassembling HP Notebook Models to Remove Components for Selective TreatmentDocument48 pagesInstructions for Disassembling HP Notebook Models to Remove Components for Selective Treatmentdncz69No ratings yet

- Threading Tools (SST Series)Document8 pagesThreading Tools (SST Series)Gilberto ManhattanNo ratings yet

- Diy Build M72 LAW TagInn Airsoft Launcher 70Document5 pagesDiy Build M72 LAW TagInn Airsoft Launcher 70nick wilkinsonNo ratings yet

- HP 620 Notebook PC Disasslembly InstructionsDocument54 pagesHP 620 Notebook PC Disasslembly InstructionsBill MarleyNo ratings yet

- KDL 32 P 3550Document53 pagesKDL 32 P 3550Инж. Хранимир БешковNo ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- Strainer: Range of ApplicationDocument3 pagesStrainer: Range of ApplicationzayerirezaNo ratings yet

- Reservoir Accessories: Filler Breathers, Strainers, Diffusers, Fluid Level/Temperature GaugesDocument15 pagesReservoir Accessories: Filler Breathers, Strainers, Diffusers, Fluid Level/Temperature GaugesPartsGopher.comNo ratings yet

- Dis Assembly Notebook HP 550Document54 pagesDis Assembly Notebook HP 550Alexandros VNo ratings yet

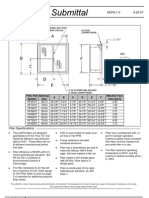

- HEPA Filter Specifications and DimensionsDocument2 pagesHEPA Filter Specifications and DimensionsEnrique Romero SanchezNo ratings yet

- TT2 Welding Joint Control Sheet (N2 Filling System)Document16 pagesTT2 Welding Joint Control Sheet (N2 Filling System)Javier Jaya CamachoNo ratings yet

- FST Technical Manual 2015 Sec04 O-Rings and Static SealsDocument51 pagesFST Technical Manual 2015 Sec04 O-Rings and Static SealsSuresh Kumar Mittapalli100% (1)

- Catalogue: Automatic Control ValvesDocument44 pagesCatalogue: Automatic Control ValvesHeri SetyantoNo ratings yet

- A70072aw009sldasm 02Document4 pagesA70072aw009sldasm 02BalajiNo ratings yet

- ME Pipe Clamp - CatalogueDocument20 pagesME Pipe Clamp - CatalogueRashesh PadiaNo ratings yet

- GF Central Catalog Electrofusion Products Section PDFDocument54 pagesGF Central Catalog Electrofusion Products Section PDFjose03No ratings yet

- O Ring GrooveDocument10 pagesO Ring GrooveArjav Desai100% (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Series LFB6080, LFB6081 Specification SheetDocument2 pagesSeries LFB6080, LFB6081 Specification SheetWattsNo ratings yet

- Constant Current Led DriverDocument27 pagesConstant Current Led DriverSreekanth RaveendranNo ratings yet

- Series IT6300, IS6301 Specification SheetDocument2 pagesSeries IT6300, IS6301 Specification SheetWattsNo ratings yet

- EAO Series 70 Full DataDocument20 pagesEAO Series 70 Full DataAidolan UlrichNo ratings yet

- Series 008PCQT Specification SheetDocument2 pagesSeries 008PCQT Specification SheetWattsNo ratings yet

- 3051CDocument5 pages3051CAntonio FloresNo ratings yet

- Series B6400-SE Specification SheetDocument2 pagesSeries B6400-SE Specification SheetWattsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Sae J51-2004Document11 pagesSae J51-2004khhoseNo ratings yet

- En10028 2Document12 pagesEn10028 2Patilea DanielaNo ratings yet

- Plastiques Dual Laminate Piping PDFDocument20 pagesPlastiques Dual Laminate Piping PDFlitalomp05100% (2)

- 02 Precision Pipe FittingsDocument28 pages02 Precision Pipe FittingsNilesh MistryNo ratings yet

- Ss 01059 eDocument8 pagesSs 01059 eDavid LapacaNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Thomas&Betts PCB DfM Report Highlights IssuesDocument3 pagesThomas&Betts PCB DfM Report Highlights IssuesmellzredNo ratings yet

- MMPQ6700: Quad NPN & PNP General Purpose AmplifierDocument6 pagesMMPQ6700: Quad NPN & PNP General Purpose AmplifierNarendra BholeNo ratings yet

- Product End-of-Life Disassembly InstructionsDocument30 pagesProduct End-of-Life Disassembly InstructionsKarinson LeonelNo ratings yet

- Analysis of Bolt TorquingDocument7 pagesAnalysis of Bolt TorquingAlessandro Serafini100% (1)

- Features: IH IL CCA CC CCDocument15 pagesFeatures: IH IL CCA CC CCDeepa DevarajNo ratings yet

- STAADPro V8i AISC 13th Ed Design Example VerificationDocument103 pagesSTAADPro V8i AISC 13th Ed Design Example Verificationdpk100% (1)

- Stainless Steel Seamless TubingDocument2 pagesStainless Steel Seamless Tubingtoxa0707No ratings yet

- Normal 5f899939a256aDocument3 pagesNormal 5f899939a256aHamzah AlbrakaniNo ratings yet

- Fits & TolerancesDocument6 pagesFits & Tolerancessuperman92makNo ratings yet

- INSERTION Adapter/Fitting For Analytical Devices: (With Reduction) (Plastic) (Stainless Steel)Document8 pagesINSERTION Adapter/Fitting For Analytical Devices: (With Reduction) (Plastic) (Stainless Steel)Manjit SinghNo ratings yet

- Practical Water Distribution Design GuideDocument29 pagesPractical Water Distribution Design GuideUSHAJYOTHISHETTYNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- Bore and Keyway TolerancesDocument8 pagesBore and Keyway TolerancesIgor San Martín PeñalozaNo ratings yet

- B.3.4 Design Calculations For Snap-Fit Joints, FarbigDocument18 pagesB.3.4 Design Calculations For Snap-Fit Joints, FarbigpchannagoudarNo ratings yet

- Structural Bolting GuideDocument24 pagesStructural Bolting GuideJoseph BookerNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Aerotight BrochureDocument2 pagesAerotight BrochureAndrew Grimes100% (1)

- Loler PDFDocument84 pagesLoler PDFErcan AkkayaNo ratings yet

- Beaumont Rag: Banjo, Key of C, Standard TuningDocument2 pagesBeaumont Rag: Banjo, Key of C, Standard TuningAndrew GrimesNo ratings yet

- 15-5 PH Data SheetDocument2 pages15-5 PH Data SheetGarapati MurarjiNo ratings yet

- Self-Tapping Screws How To ChooseDocument3 pagesSelf-Tapping Screws How To ChooseoarmstroNo ratings yet

- Directive 2006-42-CE - Machinery PDFDocument63 pagesDirective 2006-42-CE - Machinery PDFeng13No ratings yet

- Self-Tapping Screws How To ChooseDocument3 pagesSelf-Tapping Screws How To ChooseoarmstroNo ratings yet

- En13852-1 2004 Offshore Crane StandardDocument84 pagesEn13852-1 2004 Offshore Crane StandardAndrew GrimesNo ratings yet

- PlanquadratDocument115 pagesPlanquadratManish RajpalNo ratings yet

- Green Meadows - Hakimi - 3rd & 5th Floor Plan-REVISEDDocument1 pageGreen Meadows - Hakimi - 3rd & 5th Floor Plan-REVISEDPraveenNo ratings yet

- Haunch BeamDocument4 pagesHaunch BeamRafaArdiSyahrezaNo ratings yet

- Masonry Bridge Assessment With Archie-M: Notes For A Masonry Bridge Masterclass Bill Harvey Associates LTD March 2011Document12 pagesMasonry Bridge Assessment With Archie-M: Notes For A Masonry Bridge Masterclass Bill Harvey Associates LTD March 2011Info Aviron LavalNo ratings yet

- 3 Axially Loaded Vertical Piles and Pile Groups in Layered SoilDocument15 pages3 Axially Loaded Vertical Piles and Pile Groups in Layered SoilaNo ratings yet

- Conf2015 MGough MalwareArchaelogy SecurityCompliance FindingAdvnacedAttacksAnd PDFDocument62 pagesConf2015 MGough MalwareArchaelogy SecurityCompliance FindingAdvnacedAttacksAnd PDFVangelis MitakidisNo ratings yet

- Vijeo Historian V4.20 Collects, Stores and Reports DataDocument2 pagesVijeo Historian V4.20 Collects, Stores and Reports DataAkshay JoshiNo ratings yet

- Oracle Apps Technical ManualDocument81 pagesOracle Apps Technical ManualPJ190289% (9)

- Crackwidth For Wall (Combined Bending and Tension)Document3 pagesCrackwidth For Wall (Combined Bending and Tension)mukhleshNo ratings yet

- Design Optimization of Industrial Portal PDFDocument6 pagesDesign Optimization of Industrial Portal PDFVassil VassilevNo ratings yet

- Lec - 2 Greek City Planning and Urban Design-1Document23 pagesLec - 2 Greek City Planning and Urban Design-1Froile BekeleNo ratings yet

- (PC Game) Anno 2070Document6 pages(PC Game) Anno 2070Kemas Muhandis MancapaniNo ratings yet

- Samridhi SharmaDocument10 pagesSamridhi SharmaSamridhi SharmaNo ratings yet

- What Are The Events in Alvs and Which Events Not Used in Alvs?Document4 pagesWhat Are The Events in Alvs and Which Events Not Used in Alvs?farooqNo ratings yet

- IEEE Standards4Document29 pagesIEEE Standards4Ruchi AgrawalNo ratings yet

- Supertimeline+Splunk: Dorumugs and Yet It Does MoveDocument40 pagesSupertimeline+Splunk: Dorumugs and Yet It Does Moveljdwhiz9719No ratings yet

- FT087-Saracen Strongholds 1100-1500 The Central and Eastern Islamic LandsDocument68 pagesFT087-Saracen Strongholds 1100-1500 The Central and Eastern Islamic Landsab1z100% (6)

- 01 Sap BPC IntroDocument32 pages01 Sap BPC IntroRamesh VaradaNo ratings yet

- Comparison Between Cementitious Vs Epoxy Tile Joint GroutDocument14 pagesComparison Between Cementitious Vs Epoxy Tile Joint Groutannayya.chandrashekar Civil EngineerNo ratings yet

- History, Answer, Quiz 03Document3 pagesHistory, Answer, Quiz 03JARMRANo ratings yet

- BSR Notes IctadDocument14 pagesBSR Notes IctadDavid Web100% (4)

- A Case StudyDocument25 pagesA Case StudyJainam ShahNo ratings yet

- Septic Vault Detail: Trench Drain DetailsDocument1 pageSeptic Vault Detail: Trench Drain DetailsMariel VillagonzaloNo ratings yet

- Inspection Report On A Power Plant in Cement IndustryDocument16 pagesInspection Report On A Power Plant in Cement Industryparthi20065768No ratings yet

- Atmel 11209 32 Bit Cortex M4 Microcontroller SAM G51 DatasheetDocument866 pagesAtmel 11209 32 Bit Cortex M4 Microcontroller SAM G51 Datasheetmsmith6477No ratings yet