Professional Documents

Culture Documents

Vol9num4 A6

Uploaded by

reyad03Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vol9num4 A6

Uploaded by

reyad03Copyright:

Available Formats

Determination of Moulding Properties of Locally Available Clays for Casting Operations

Abolarin M. S., Olugboji O. A. and Ugwuoke I. C.

Department of Mechanical Engineering, Federal University of Technology Minna, Niger State, Nigeria

Abstract

Our researched focused on determining the molding properties of two locally available clays used in casting operations. Samples of clays were collected from three locations in Nigeria and experimental tests were carried out as regards their physical and bulk properties. From the experimental findings it was discovered that Ire clay (golden), Ire (purple) and Erusu clay showed appreciable moisture contents ranges from 1.20% - 4.26%. Also for the chemical composition, all the samples fall under Aluminosilicate type of clay because of their high value of Aluminum Oxide and Silicon Oxide. Lastly, the suitability of these clays for better casting quality were determined, as well as recommendation for its various uses in moulding operation was also considered. Keywords: Visual inspection, sieve analysis, refractoriness, cold crushing strength, moisture content, porosity.

Introduction

Apart from petroleum, gas and coal resources, the exploration, mining and exploitation of Nigeria mineral resources have not received sufficient attention. Delving into geological survey of Nigeria soil, it was reported that clay as one of the major Nigeria minerals deposits cover an estimated proven reserves of billions of tones, and these days mineral are discovered all over the states in the country (Raw Material Research and Development Council Lagos 1990 First Edition). One of the best-known applications of clay is in the manufacture of such articles as pottery. Another major application of kaolinite is in the paper industry where it may be used either as filler or for coating paper. The metallurgical industry employs clay mixed with sand to form moulds that are used for casting operation. In the oil industry, clays are used in the drilling of oil wells and also as important constituent of catalyst for refining petroleum and also in the separation of gasoline, gas and coke. A lot of project research has been carried out about the conversion of clays for industrial uses. A material is refractory in nature if it has 238

a very high melting point in addition to its physical, chemical, mechanical and thermal properties that make it suitable for use in furnaces, kilns, reactors, and other high temperature vessels. Omowumi (2001) in his investigation concluded that the properties of refractory clay samples from Onibode, AraEkity, Ibamajo and Ijoko compare favourably with imported fire clay refractories. Hassan and Adewara (1993) found that Onibode refractory clays are suitable for the production of refractory bricks for furnace building. Matthew (1977) investigated the properties and processing of synthetic foundry mixtures prepared from Kankara clay. He found that Kankara clay was suitable for use in preparation of synthetic foundry sand. Akinbode (1996) carried out an investigation on the properties of termite hills as refractory material for furnace lining. In his report, Matthew observed that the refractory properties of termite hill possesses a close relationship between porosity, density, dimensional change and permeability of the known refractory materials for furnace lining. Aniyi and Adewara (1986) investigated the refractory properties of clay from Kankara and found that the clay was suitable for the production of

refractory bricks possessing good shrinkage. Abolarin et al. (2004) investigated the properties of local refractory materials from Kuru, Alkaleri, Barkin-ladi and Bauchi locations in Nigeria. They discovered that refractory clays from Alkaleri and Barkin-ladi are suitable for furnace construction due to higher thermal shock resistance, crushing strength, bulk density and refractoriness values. Research work by Irabor (2002) revealed that kaoline clays from Kankara, Jos and Oshiele are of the residual variety suitable for paper, paint and pharmaceutical manufacture. Experimental analysis on the refractory properties of local clay materials for furnace building by Obi (1995) revealed that all the clay samples were classified as low alumina with kaolinitic nature. An investigation carried out by Hussani (1997) on the refractory properties of bricks produced from five Nigerian clays revealed that all the samples were found to possess good refractoriness (P.C.E) with excellent firing shrinkage value that fall within 3-5% range of the imported bricks. Work done by Agha (1998) on the refractory properties of six samples of Nigerian clays revealed that the clays were high in silica content and low in alumina content. They also exhibit different refractory characteristics with respect to thermal shock resistance, refractoriness, porosity, permeability, bulk density, modulus of rupture and water absorption. Hassan (1985) investigated the effect of additives like saw dust, graphite and asbestos on Kankara clay. He discovered that a good thermal insulating fire clay brick could be produced from this clay by the addition of graphite and saw dust (15%). Loto and Akeju (1994) determined the durability of the bonding property (that is the number of time that the synthetic moulding sand could be reused). Additives such as sodium carbonate, cassava floor and coal dust were added in order to determine their synergetic effect on the clays bonding durability performance.

This was done to determine the physical appearance of the samples. Sample A dull golden colour, Sample B golden colour and Sample C purple colour. Sieve Analysis Two hundred grams of the ground clay samples were poured into prearranged sieve (of mesh size 850, 710, 500, 300, 180, 125 and 63 microns) on a vibrator. The timer on the vibrator was set at 15 minutes and the motor was switched on. At the end of the sieving period, the mass of the clay retained on each sieve was determined. The percentage retained and passed was then calculated using the following equations: M R = 1 100% M0 and P = 100 R Where, M0 = Mass of each sample of clay M1 = Mass of clay retained on sieve R = Percentage of clay sample retained P = Percentage of clay sample passing through sieve Refractoriness Test Test cones were prepared by mixing each clay sample aggregate with sufficient quantity of water to make the clay become plastic and molded by hand into a cone shape. The samples were dried and fired to a temperature of 900oC in a muffler furnace. Pyrometric cones designed to deform at 1300oC, 1400oC, 1500oC were placed round the samples and the temperature raised to above 1000oC at 10oC per minute. The heating was discontinued when the test cone bent over and leveled with the base of the disc. The pyrometric cone equivalent (P.C.E) of the samples was recorded to be the number of standard pyrometric cone corresponding in the time of softening to the test cone. Cold Crushing Strength Cylindrical test pieces were cut out from each of the original refractory specified 239

Materials and Methods

Visual Inspection

with a cut off wheel, about 50mm wide and 50mm high. They were then air dried for 24 hours and oven dried at a temperature of 110oC for 12 hours and then fired in a furnace at a temperature of about 1200oC for 6 hours. They were then cooled to room temperature. Each specimen was then taken to the tensiometer where load was applied axially to the piece until crack was noticed. The load at which the specimen cracked was noted, which represents the load required for determining cold crushing strength of the test specimen. Cold crushing strength was then determined using equation 5 P C.C.S = A Where, C.C.S = Cold Crushing Strength P = Applied Load A = Area of Load Application Moisture Content

Chemical Analysis

To determine the chemical composition, the method employed was x ray fluorescent. 1 gram of clay sample was added to 10 grams of lithium tetraborate anhydrous solution (Li2B4O7) which act as a fluxing agent. The constituents were mixed inside a crucible which was already cleansed with methylated spirit to prevent contamination and heated up to 500oC for 8 minutes and allowed to cool at room temperature. The fused sample which was a tinted glass was analyzed by the x ray fluorescent and diffraction method.

Loss on Ignition Test (L.O.I)

The clay slabs of the samples were weighed with the container as M11 and then dried for 24 hours after which it was weighed again as M22. The weight of the container is measured as M33. The mass of moisture is taken as (M11 M22)g and mass of dry sample taken as (M22 M33)g. The percentage moisture content was calculated from equation 3. M M 22 %moisture content = 11 100% M 22 M 33 Porosity Test Specimens measuring 6.5 x 6.5 x 4cm were prepared from burn refractory bricks and cleansed from any dust or loose particle. The specimens were then dried in an oven at 110oC to a constant weight (WD) with accuracy of 0.001g. The dried specimens were suspended in water, cooled to room temperature and this weight (WS) noted. The specimens were removed from water and water particles wiped off from their surface by lightly blotting with a wet towel and weighed in air (WA), the apparent porosity (Pa) was then calculated using equation 4. W W D Pa = A 100% W A WS

240

Organic combustible matter present as impurity leads to gas evolution and reduces the refractoriness of the sand. Twenty grams of oven-dried clay from each sample was cooled in the dessicator. The porcelain crucible was cleaned, dried and weighed to an accuracy of 0.001g (M4). The dried test clay sample was weighed to an accuracy of 0.001 (M5). The crucible containing the clay sample was placed in a muffle furnace and heated to a temperature of 800oC. The crucible and its content (test clay) were allowed to cool in desiccators and then weighed to an accuracy of 0.001g (M6). The ignition loss was calculated from the relationship given below: M M6 Loss on ignition = 5 100% M5 M4 Where, M4 = Mass of dried porcelain crucible M5 = Mass of sample clay and porcelain crucible M6 = Mass of heated clay sample and porcelain crucible

Clay Content

A known mass of each clay sample of 25grams was measured and transferred into a beaker of 500cm3. A volume of water was added to each sample to make up to 2/3 of the volume in the beaker. Then the addition of deflocculant Na2CO3 anhydrous solution of about 166ml and the mixture was given a warm temperature. The mixture was stirred

vigorously with a spatular, the deflocculating agent acts as a coagulant of the clay particles and thereby maintain the colloids of the solution. After stirring, it was allowed to settle for about five minutes, the solution of sodium carbonate together with suspended clay particle was siphoned off from the water/clay suspension continuously and allowing for a settling period of about five minutes. This process was continued until perfectly clear water was obtained in the upper region of the beaker. The remaining water just above the residue was completely siphoned. Then the residue was transferred to a filter paper for proper draining and it was further dried on the evaporating dish to about 100oC for some minutes and reweighed. The percentage of clay content was then calculated using this formula. M M8 Percentage clay contents = 7 100% M7 M7 = initial mass of the clay sample M8 = final mass of the clay sample

Besides all, the clay sample withstood casting temperature of aluminum cast products.

Cold Crushing Strength

The values obtained; Sample A 350kg/cm2, Sample B 394.74kg/cm2 and C 256.41kg/cm2 are comparable to standard values of high duty silica bricks. This shows that the bricks have been properly fired. It can transport flange and flux readily without damages to the edges and corners. It also shows the ability of the clay to withstand abrasion and loading.

Chemical Composition

Table 2 shows the chemical composition of the clay samples. From its chemical composition, all the sample fall under Aluminum-silicate type of clay because of their high value of aluminum-oxide and siliconoxide which are highest among other chemical composition of the clay.

Clay Content

Results and Discussion

Sieve Analysis

Sample A was highly retained at the 850m sieve while samples B and C were highly retained at 850m showing good proportion of clay being refined.

Porosity

From clay content test, it was found that specimen C has the highest value of clay followed by specimens A and B. This shows that they all have appreciable clay content and from this the mouldability strength and plasticity can be deduced.

Moisture Content

The apparent porosity was determined, only sample C was found to be in the normal range 20 30% for dense fire bricks, while samples A and B were found to be below the normal range. Samples A and B were good as insulated bricks.

Refractoriness

The plasticity and strength of clay depend on the amount of water present in the clay; water present in a value of 1.2 4.26% activates clay in sand, causing the aggregates to develop strength.

Conclusion

This work went a long way in investigating the molding properties of some locally available clay sample for casting operations. From the overall experimental analysis carried out, it was observed that all the samples have appreciable and reasonable moisture content values. Erusu clay golden 241

The value of samples A and B were found to be exactly 1500oC while sample C was found to be greater than 1500oC. The temperature for sample C is an indication of very good refractoriness, because the normal range for a fire clay brick is 1580oC 1750oC.

4.26%, Ire clay golden 2.06% and Ire clay purple 1.20%. The sintering temperature for Erusu clay, Ire clay golden and Ire clay purple were 1500oC, 1500oC and > 1500oC respectively. This implies that Erusu and Ire clay golden can be used to melt metals not exceeding 1500oC while sample C is recommended for construction of furnace because it possesses a refractoriness temperature above 1500oC.

References

Abolarin, M.S.; Olugboji, O.A.; and Ugwuoke, I.C. 2004. Experimental investigation on local refractory materials for furnace construction. Proc. 5th Ann. Eng. Conf., Federal University of Technology, Minna, Nigeria, pp 82-85. Agha, O.A. 1998. Testing of local refractory clays for producing furnace lining bricks. M. Eng. Thesis, Department of Mechanical Engineering, Federal University of Technology, Minna, Nigeria. Akinbode, F.O. 1996. An investigation on the properties of termite hill as refractory material for furnace lining. Indian Foundry J. 42(9): 10-3. Aniyi, J.A.; and Adewara, J.O.T. 1986. Refractory properties of Kankara clay. Proc. Ann. Conf. Nigeria Metal. Soc. Table 1. Property of Clay Samples Property Sieve Analysis Refractoriness Cold Crushing Strength Porosity Loss on Ignition Clay Content Moisture Content A 35.10 1500oC 350kg/cm2 9.97% 11.82 72.44% 4.26%

Hassan, S.B. 1985. Effect of certain additives on some refractory properties of Kankara clay. B. Eng. Project, Department of Metallurgical Engineering, Ahmadu Bello University, Zaria, Kaduna, Nigeria. Hassan, S.B; and Adewara, J.O.T. 1993. Refractory properties of some Nigerian clays. Nigerian Soc. Eng. Trans. 28(3): 21-5. Hussani, E. 1997. Experimental determination of local refractory properties for furnace building. B. Eng. Project, Department of Mechanical Engineering, Federal University of Technology, Minna, Nigeria. Irabor, P.S.A. 2002. Physical and chemical investigation on some Nigerian kaoline clays for use in the ceramic and allied industries. Nigerian J.Eng. Res. Devel.. 1(1): 54-9. Loto, C.A.; and Akeju, E.A 1994. Durability of Igbokada clay and cilica sand as synthetic moulding sand. Department of Mechanical Engineering, University of Lagos, Akoka, Nigeria. Matthew, P. 1977. Investigation of the properties and processing of synthetic foundry sand mixture prepared from local material. B. Sc Project, Ahmadu Bello University, Zaria, Kaduna, Nigeria, Omowumi, O.J. 2001.Characterization of some Nigerian clays as refractory materials for furnace lining. Nigerian J. Eng. Manage. 2(3): 9-13. .

B 30.00 1500oC 394.74kg/cm2 18.61% 7.81 61.44% 2.06%

C 32.88 >1500oC 256.41kg/cm2 29.4% 9.81 79.64% 1.20%

Table 2. Chemical Composition of Clay Samples Sample A B C Locality Erusu Clay Ire Clay Golden Ire Clay Purple Al2O3 17.32 15.94 18.19 242 SiO2 51.53 55.14 56.96 Fe2O3 7.19 7.59 6.39

You might also like

- Orgieva 1Document6 pagesOrgieva 1reyad03No ratings yet

- 1 PBDocument8 pages1 PBreyad03No ratings yet

- Writing A SOPDocument3 pagesWriting A SOPreyad03No ratings yet

- NothingDocument1 pageNothingreyad03No ratings yet

- Li Batteries PDFDocument9 pagesLi Batteries PDFVandam65No ratings yet

- Character certificate for Md. Ashiqur Rahman July 2010Document1 pageCharacter certificate for Md. Ashiqur Rahman July 2010reyad03No ratings yet

- Convocation NoticeDocument1 pageConvocation Noticereyad03No ratings yet

- H07Document5 pagesH07reyad03No ratings yet

- Character certificate for Md. Ashiqur Rahman July 2010Document1 pageCharacter certificate for Md. Ashiqur Rahman July 2010reyad03No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Delhi-Mumbai Industrial Corridor Project OverviewDocument11 pagesDelhi-Mumbai Industrial Corridor Project Overviewer_ankurpareekNo ratings yet

- Logistics BoDocument26 pagesLogistics BomanjupadmaNo ratings yet

- Fazal Cloth Mills LTDDocument24 pagesFazal Cloth Mills LTDYasmeenJahanNo ratings yet

- China ExhibitorsDocument8 pagesChina ExhibitorsYaIpha NaOremNo ratings yet

- Sk6 ToleranceDocument1 pageSk6 Tolerancen1ghtfallNo ratings yet

- Astm F 30 - 96 R02 - RJMWDocument5 pagesAstm F 30 - 96 R02 - RJMWphaindikaNo ratings yet

- Supply Chain Management EssentialsDocument41 pagesSupply Chain Management Essentialsvnewaskar_1No ratings yet

- NASA Bolting Design ManualDocument98 pagesNASA Bolting Design ManualjoshhinesNo ratings yet

- Fuel From Plastic WasteDocument32 pagesFuel From Plastic WasteMANN BATTISE100% (1)

- ASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual ExaminationDocument10 pagesASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual Examinationpsanches25100% (1)

- Flexible ElectronicsDocument21 pagesFlexible ElectronicsNeeraj JawadwarNo ratings yet

- Stainless Steel 304 PipesDocument6 pagesStainless Steel 304 PipesVikas ShahNo ratings yet

- Resume: Personal ParticularsDocument4 pagesResume: Personal ParticularsKaasini MohanNo ratings yet

- Specification For Support and HangerDocument6 pagesSpecification For Support and Hangerdee1985No ratings yet

- Cat. Durochem Bbas. DDocument5 pagesCat. Durochem Bbas. DDavid ManzanoNo ratings yet

- Finalvalue Usb FanDocument9 pagesFinalvalue Usb FanDianne De FranciaNo ratings yet

- Hardening and hardness test methods overviewDocument1 pageHardening and hardness test methods overviewkdalavadi3905No ratings yet

- Al-Si Alloy Casting & Machining ReferencesDocument3 pagesAl-Si Alloy Casting & Machining Referencesreddy rajaNo ratings yet

- TdsDocument4 pagesTdsSatish VishnubhotlaNo ratings yet

- How To Make Your Own Sugru SubstituteDocument19 pagesHow To Make Your Own Sugru Substitutecocorific100% (1)

- ISO 9001 Quality Management System DocumentsDocument33 pagesISO 9001 Quality Management System DocumentsSanjay Rajpal100% (1)

- Asmuss Pipes and FittingsDocument106 pagesAsmuss Pipes and FittingsJohn HarkenNo ratings yet

- Operations Management - Final ExamDocument7 pagesOperations Management - Final ExamMuhammad Ben Mahfouz Al-Zubairi75% (4)

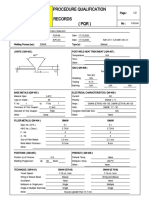

- Procedure Qualification Record PQRDocument2 pagesProcedure Qualification Record PQRWalid BdeirNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Up PDFDocument242 pagesUp PDFMandal Ji TeloNo ratings yet

- MT Series Chamber Furnaces GuideDocument6 pagesMT Series Chamber Furnaces GuideAndyNo ratings yet

- A Seminar On Bharat Pumps & Compressors LTD: Presented by Amit Singh Roll - No. 1110440006Document17 pagesA Seminar On Bharat Pumps & Compressors LTD: Presented by Amit Singh Roll - No. 1110440006madhurauto100% (3)

- MD - Sharif CVDocument3 pagesMD - Sharif CVsharifmunna20022469No ratings yet

- Powercrete J ApplicationDocument2 pagesPowercrete J ApplicationJèfrì PìnémNo ratings yet