Professional Documents

Culture Documents

The Effect of PDMS-Based Micro Device Channel Width On Plasmid DNA Transformation Efficiency in E. Coli

Uploaded by

Regine LabogOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effect of PDMS-Based Micro Device Channel Width On Plasmid DNA Transformation Efficiency in E. Coli

Uploaded by

Regine LabogCopyright:

Available Formats

PAPER

University of Calfornia, Berkeley | BioE 121L

Effect of PDMS-based Microdevice Channel Width on Plasmid DNA based Transformation Efficiency in E. coli

Albert Peng,a Simrunn Girn,a Regine Labog,a and Yiqing Zhaoa

Submitted 9th December 2010

5

10

The effect of PDMS-based microdevice channel width on GFP plasmid transformation efficiency based in E. coli was studied in this project. Four different device designs consisting of 50 m, 100 m, 250 m, and 500 m channel widths were used in conjunction with s standard photolithography and soft lithography fabrication techniques to create PDMS microdevices. Multiple chemical transformation trials using optimal macroscale heat shock parameters 1 were performed with these devices, and data was collected from agar plate cultures and subsequently analyzed by the ImageJ ate software package. Although we have successfully demonstrated chemical transformation in a microscale environment, our data suggests that variability in transformation efficiency introduced by experimental error is large enough such that any potential influence channel width may have on l transformation efficiency is masked. that may affect transformation efficiency, such as the channel size in which transformation occurs. For our study a standard chemical transformation procedure is used with chemically competent E. coli cells and GFP. While the results we obtain are specific to the strain of E. coli and GFP plasmid used in these experiments, the results gathered could be useful for future work with other strains of bacteria and plasmids.

15

Introduction

Plasmid DNA transformation is a key molecular biology concept of introducing new functionality to existing bacteria strains by importing desired DNA molecules into cells. DNA transformation in E. coli is generally accomplished by chemical and electrical means, and various studies have been ans, performed to maximize transformation efficiency for both methods. While there are advantages and disadvantages to both techniques, chemical transformation is cheaper and more accessible than electroporation and is the mai focus of this main study. Although heat shock chemical transformation is widely used and accepted,6 it is relatively unclear how it functions. During chemical transformation, it is theorized that ions in a and E. coli solution envelop the cell membrane thus producing a net positive charge on the surface, attracting the negatively charged plasmid DNA. 1,3,4 A heat shock step then opens pores on the cell surface and facilitates passage through the cell membrane due to the close proximity of the plasmid DNA to the cell. An ice incubation step is thought to reduce the thermal motion of the DNA and allow further binding to the cell membrane.1 Finally a warm incubation in rich LB media allows the cells to recover from the previous disturbances to cellular processes and promotes survivability of the culture. In addition, this incubation step could allow further uptake of plasmid into the cell as sort of a second heat shock step. 1 Traditional transformation optimization stud have almost studies always been done at macroscale.5 Applications such as genomic and cDNA library construction typically require transformation with low DNA copy, so it is necessary to find parameters that maximize transformation efficiency. 1 While transformation has been shown to be possible at microscale,2 tion the influence of channel width on transformation efficiency has never been studied. Since the exact mechanism of plasmid DNA uptake in E. coli during chemical transformation is unknown, it is important to study all the possible parameters

60

65

20

60

Materials and Methods

Device Fabrication The design of our 50 m, 100 m, 250 m, and 500 m channel width devices was drawn using AutoCAD and sent to an external manufacturer to produce mylar masks for photolithography (Figure 1). When designing our device we needed to incorporate three functions: an inlet for E. coli and fo GFP loading, a heat shock chamber with the required channel dimensions, and an outlet to collect the pool. S-curves were S chosen for the transformation chamber to maximize volume while maintaining the designated channel widths. In addition, the devices were designed to have identical volumes of 3.4 L e each in order to make channel width the only varying factor between devices. This resulted in fewer S-curves for the larger S channel width devices compared with the smaller channel width devices.

75

25

80

30

85

35

40

45

50

Fig. 1 A 50 m channel width device design

University of California, Berkeley, College of Engineering 2010 o

Bioengineering | 1

Fig. 3 Experimental procedure used for transformation

10

15

A standard contact photolithography procedure with negative SU-8 2035 photoresist was then done using the previously created mylar mask and a 4 silicon wafer. Contact photolithography was used to keep production costs low while maintaining high resolution of features. Spin coating parameters were chosen to create a single final photore photoresist height of 50 m for all devices (Figure 2), and the appropriate , UV exposure times were chosen to accommodate the contact aligner measured UV intensity, which is variable with the age and quality of the UV bulb. After the necessary heat, developing and cleaning treatments, the wafer is then placed into a vacuum chamber for silanizing. Silanizing the wafer allows cured PDMS to be more readily removable from the surface of the wafer and is essential for soft lithography.

50

55

60

competent E. coli was thawed on ice for 30 minutes, after minutes which 2 L GFP plasmid obtained through miniprep was added and mixed by gentle tapping. After incubating on ice for 30 minutes, 5 L of this solution was vacuum loaded into each device. Vacuum loading was done on ice until the entire device was loaded. The devices were then placed on a hot ded. plate set at for 30 seconds as monitored by a thermocouple, and then placed on ice for 2 minutes. A syringe was placed at the inlet of each device and used air pressure to evacuate the device of bacteria, and pool was collected at the outlet and incubated in 50 L LB-Amp media for 1 hour. The Amp appropriate dilutions were made and the culture was plated on agar-Amp plates and allowed to grow overnight. Pictures were Amp taken the following day and colonies were counted by the counte ImageJ software.

Results and Discussion

Prior to performing any transformation experiments, we attempted to vacuum load our devices with E. coli to show that vacuum loading is a viable technique to introduce solutions into microdevices. A picture using phase contrast microscopy was taken demonstrating successful vacuum loading (Figure 4). A total of 28 devices were then ). successfully used in transformation runs and had enough ormation colonies on their corresponding plates to be counted. Transformation efficiency is determined quantitatively as the total colony count on each plate, with higher counts equating to higher transformation efficiencies.

65

70

Fig. 2 Close-up channel dimensions of a 50 m device s

20

25

30

The silanized wafer with all the device features was then used as a mold for PDMS soft lithography. A 10:1 ratio of base to curing agent was weighed out and thoroughly mixed, resulting in a 50 g base: 5 g curing agent mixture. This solution was degassed by vacuum and then poured over the ution clean wafer, and allowed to cure overnight on a hot plate. Once cured, the PDMS layer was carefully peeled off the wafer. Individual devices were cut out from the PDMS sheet and 1 mm holes were punched at the inlet and outlet. hed Devices and microscope glass slides were then both tape cleaned and chemically cleaned by acetone, IPA and DI water, and subjected to UVO treatment to modify the surface chemistry to facilitate bonding. The PDMS devices and sli slides were then bonded together to produce a final useable microdevice. Experimental Procedure After our devices were created, we began running chemical transformation trials (Figure 3). 20 L of chemically .

2 | Bioengineering

65

Fig. 4 Phase microscopy image of E. coli loaded in a 50 m device

The first set of experiments we tried to perform included: 3 x 50 m, 3 x 100 m, 3 x 250 m, and 3 x 500 m channel

University of California, Berkeley, College of Engineering 2010 e

10

width devices. We wanted to do three runs of each channel width in order to average the data from all three and generate more reliable results. Out of these runs only: 1 x 50 m, 2 x 100 m, 2 x 250 m, and 2 x 500 m devices were able to generate any measurable data (Figure 5). Some devices were not able to load completely in a reasonable amount of time and had to be discarded. In addition, our initial batch of 50 m channel width devices were not bonded very well to the glass slides, and popped off when we attempted to use air pressure to empty the device of E. coli.

40

Fig. 6 Colony count data gathered from the second set of transformations

45

50

In a last attempt to obtain coherent data, we performed a third and final set of transformations. For these trials we used: 4 x 50 m, 4 x 100 m, 4 x 250 m, and 4 x 500 m channel width devices. The 50 m and 500 m channel widths performed the best at an average of 250 and 300 colonies respectively, while the 100 m and 250 m channel widths had 100 and 180 colonies each (Figure 7). Unfortunately this data still does not agree with our previous runs, and we must end this project with inconclusive results.

Fig. 5 Colony count data gathered from the first set of transformations

15

20

25

30

35

The data generated using these devices shows that colony count decreases as channel width increases, since the 100 m devices had an average of 900 colonies while the 250 m and 500 m devices had an average of 800 and 600 colonies, respectively. This suggests that smaller channel widths coincide with higher transformation efficiency. However, due to the low number of successful trials for each device, we decided to do more transformations in order to confirm our findings. For the second set of transformation runs we wanted to see if there was a legitimate difference in transformation efficiency between smaller and larger channel widths. Since our data from the first set of runs was relatively sparse due to experimental error, we decided that we should only focus on two channel widths and make sure that we believe our results. We ran trials with 4 x 100 m and 4 x 250 m devices in the same fashion as the first set of runs and gathered the colony data (Figure 6). The data shows that the average colony number from the 100 m and 200 m devices are 1000 and 1200 respectively, which is in direct contradiction of the trend observed in the first set of runs. This new data suggests that there is relatively little difference between the transformation efficiency of the 100 m and 200 m channel width devices. Judging from the extreme variability of the individual trials in the second run (1500 colonies in trial 1 and 400 colonies in trial 4 of the 250 m set), it appeared that our experimental methods were still unable to generate consistent results.

Fig. 7 Colony count data gathered from the third set of transformations

55

60

Different dilution factors were used for each run prior to plating, so the colony counts between runs are very different in our data. However, only the relative difference in colony counts between individual devices within runs matters, and from the three sets of runs that we performed, there was no clear trend indicating the effect of channel width on transformation efficiency. One reason for this could be due to experimental error. The transformation has been shown to be very robust even at a 10x dilution factor across all device widths, indicating that slight errors in experimental procedure such as inexact transfer volumes can result in high variability

University of California, Berkeley, College of Engineering 2010

Bioengineering | 3

in colony counts. For example trial 1 of the 50 m device in run 2 had 600 colonies while trial 2 of the same device in the same run had only 100 colonies, even though they both experienced a 10x dilution before plating. Any effect that channel width may have had on these colony counts would have been masked by the extreme variability introduced by experimental error.

Conclusion

10

15

20

Colony count data collected from three separate runs of multiple transformation trials did not reveal a clear trend between microdevice channel width and transformation efficiency. Transformation was robust amongst all devices even at high dilution factors, suggesting that the effect of channel width is small compared to the inherently high transformation efficiency. Variability in colony counts introduced due to experimental error also contributed to the inability to generate consistent data. Due to limitations in our original device design and time constraints we must end this project with inconclusive results. Future work can be done to improve both device design and the experimental procedure by performing everything on-chip, to minimize compounding errors due to inexact off-chip activities such as E. coli evacuation from the device, dilution factors, and inconsistent plating technique.

25

References

College of Engineering, Bioengineering Department, University of California, Berkeley,CA, 94704, USA. 1 Mahipal Singh, Arpita Yadav, Xiaoling Ma and Eugene Amoah. Plasmid DNA Transformation in Escherichia Coli: Effect of Heat Shock Temperature, Duration, and Cold Incubation of CaCl2 Treated Cells. International Journal of Biotechnology and Biochemistry, Volume 6 Number 4 (2010) pp. 561568. 2 Sha Li, L. Meadow Anderson, Jui-Ming Yanga, Liwei Lin, Haw Yang. DNA transformation via local heat shock. APPLIED PHYSICS LETTERS 91, 2007. 3 W. Edward Swords. Chemical Transformation of E. coli. Methods in Molecular Biology, 2003, Volume 235, 49-53, DOI: 10.1385/159259-409-3:49. 4 Dagert M, Ehrlich SD. Prolonged incubation in calcium chloride improves the competence of escherichia coli cells. Gene. 1979 May;6(1):23-8. 5 Huff JP, Grant BJ, Penning CA, Sullivan KF. Optimization of routine transformation of escherichia coli with plasmid DNA. BioTechniques. 1990 Nov;9(5):570,2, 574, 576-7. 6 Bergmans HE, van Die IM, Hoekstra WP. Transformation in escherichia coli: Stages in the process. J Bacteriol. 1981 May;146(2):564-70.

a

30

35

40

45

4 | Bioengineering

University of California, Berkeley, College of Engineering 2010

You might also like

- (Resume) Regine LabogDocument1 page(Resume) Regine LabogRegine LabogNo ratings yet

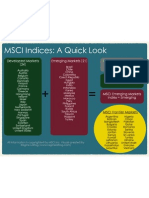

- MSCI Indices - A Closer LookDocument1 pageMSCI Indices - A Closer LookRegine LabogNo ratings yet

- The Impact of Technology in The Gaming IndustryDocument26 pagesThe Impact of Technology in The Gaming IndustryRegine LabogNo ratings yet

- Continuum Bio Mechanics Modeling of Homologue ProteinsDocument5 pagesContinuum Bio Mechanics Modeling of Homologue ProteinsRegine LabogNo ratings yet

- A Novel Microfluidic Device For Rapid Melanoma DiagnosisDocument6 pagesA Novel Microfluidic Device For Rapid Melanoma DiagnosisRegine LabogNo ratings yet

- Aristotle Vs Plutarch - A Comparison of Solonian ReformDocument11 pagesAristotle Vs Plutarch - A Comparison of Solonian ReformRegine LabogNo ratings yet

- A Review On Microfluidic Immunoassays As Rapid Saliva-Based Clinical DiagnosticsDocument13 pagesA Review On Microfluidic Immunoassays As Rapid Saliva-Based Clinical DiagnosticsRegine LabogNo ratings yet

- (Case Study) Zara Fast FashionDocument8 pages(Case Study) Zara Fast FashionRegine Labog83% (12)

- Confocal MicrosDocument10 pagesConfocal MicrosJames WangNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Password Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Document4 pagesPassword Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Pratiksha SankapalNo ratings yet

- Nanometer CMOS VLSI CircuitsDocument108 pagesNanometer CMOS VLSI CircuitsumakrishnanNo ratings yet

- AKL User ManualDocument678 pagesAKL User Manualmaia.df11No ratings yet

- Disclosure To Promote The Right To InformationDocument39 pagesDisclosure To Promote The Right To InformationA.YOGAGURUNo ratings yet

- XR-P560 - RRV1626 Service ManualDocument21 pagesXR-P560 - RRV1626 Service ManualBarry John FitzGeradNo ratings yet

- Problemas CH6 PDFDocument11 pagesProblemas CH6 PDFJuan227100% (1)

- Training Instrument Technician CourseDocument71 pagesTraining Instrument Technician Coursejbtind0% (1)

- SB370 - SB3100: Contact UsDocument3 pagesSB370 - SB3100: Contact UsYoelNo ratings yet

- Door-Open Alarm PDFDocument2 pagesDoor-Open Alarm PDFjoseph_kachappilly80% (5)

- DBX 266xl SCHDocument9 pagesDBX 266xl SCHFazar AhmadNo ratings yet

- Datasheet OB3350 LED DriverDocument10 pagesDatasheet OB3350 LED DriverEnya Andrea Ribba Hernandez0% (1)

- 1.2A Step-Down Converter With 1.4Mhz Switching Frequency: Ap5100 Ap5100Document2 pages1.2A Step-Down Converter With 1.4Mhz Switching Frequency: Ap5100 Ap5100bilalNo ratings yet

- Chandar An 2010Document4 pagesChandar An 2010Alvaro Balvin VelasquezNo ratings yet

- Ultimate 486 Benchmark ComparisonDocument16 pagesUltimate 486 Benchmark ComparisonDanijela DinNo ratings yet

- Experiment # 1: Figure 1: Circuit DiagramDocument4 pagesExperiment # 1: Figure 1: Circuit DiagramMahnoor Siddiqi100% (1)

- Saferstein CH 04 - Physical Properties Glass and SoilDocument36 pagesSaferstein CH 04 - Physical Properties Glass and SoilLalit AmbasthaNo ratings yet

- Trends in Electric Vehicle Propulsion TechnologyDocument28 pagesTrends in Electric Vehicle Propulsion TechnologyAlex Kariyil50% (2)

- MVAJ 05 Trip RelayDocument9 pagesMVAJ 05 Trip RelayKT MENON100% (1)

- Microelectronic PillsDocument33 pagesMicroelectronic PillsAnu MavelyNo ratings yet

- Irgp 50 B 60 PD 1Document11 pagesIrgp 50 B 60 PD 1pufipufi5No ratings yet

- Piezomechanics An IntroductionDocument32 pagesPiezomechanics An IntroductionGustavo L. GelardiNo ratings yet

- Assignment 2Document5 pagesAssignment 2pappuyadav1996No ratings yet

- High Sensitivity Photodetector For Photon-Counting ApplicationsDocument24 pagesHigh Sensitivity Photodetector For Photon-Counting ApplicationsLong HoàngNo ratings yet

- Panel Ae Solar Ae320p6-72 PDFDocument2 pagesPanel Ae Solar Ae320p6-72 PDFneymarronNo ratings yet

- Human Body As AntennaDocument11 pagesHuman Body As AntennaSaadat RehmanNo ratings yet

- AD624Document17 pagesAD624سعيد ابوسريعNo ratings yet

- PSU GROUP 2 B Semifinal No RDDocument21 pagesPSU GROUP 2 B Semifinal No RDEdwinDuranJr.No ratings yet

- NPN Epitaxial Silicon Transistor: High Voltage General Purpose ApplicationsDocument4 pagesNPN Epitaxial Silicon Transistor: High Voltage General Purpose ApplicationsNam TàoNo ratings yet

- Rain AlarmDocument3 pagesRain AlarmSebastin AshokNo ratings yet

- Applied Thin Films Inc BriefDocument7 pagesApplied Thin Films Inc BriefBruno AgueroNo ratings yet