Professional Documents

Culture Documents

Protection Tubes and Assemblies

Uploaded by

EliasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protection Tubes and Assemblies

Uploaded by

EliasCopyright:

Available Formats

W A T L O W

Accessories

Protection Tubes and

Assemblies

Protecting Tube Application Data

Max. Flexural Thermal

Use Strength Conduct. Thermal Shock Typical

Material Grade Air (X103 psi) W/m.K 1475°K Resistance Remarks Applications

Hexoloy SA® Sintered 1650°C 67 54.0 Excellent Maintains strength to 1650°C Incineration, molten alu-

(3000°F) (3002°F), exceptional minum and non-ferrous

corrosion resistance, does metals, flue gas, hydro-

not creep, attacked by fluoric and sulfuric acids,

halides, fused caustics and bauxite calcining

See page 154 ferrous metals

Silicon Oxide 1650°C 15-20 Good Permeable Non-ferrous metals

Carbide Bonded (3000°F)

See page 151

Alumina 99.9% 1900°C 50 6.3 Fair-preheating to Creeps (sags) at 1900°C Barium, crown glass;

(3450°F) 482°C (900°F) (3452°F) ferrous metals, non-ferrous metals;

recommended dry H2 gas-tight protection for

noble metal thermo-

couples in excess of

1316°C (2400°F)

96% 1700°C 49 5.4 Same as above Creeps at 1900°C (3452°F)

See page 150 (3100°F)

Mullite — 1700°C 12 2.1 Poor—must be pre- Creeps at 1700°C (3092°F), Non-ferrous metals;

(3100°F) heated to 482°C attacked by halides— gas-tight protection for

(900°F) contains silica base metal thermo-

couples to 1316°C

Accessories

See page 150 (2400°F)

Metal LT-1 1400°C 45 29.0 Must be preheated Not recommended in car- Molten non-ferrous

Ceramic (2500°F) (R.T.) to 482°C (900°F) burizing, nitrogen atmos- metals; calcining kilns,

before immersion pheres, high vacuum oxidizing atmospheres

into molten metal or in molten aluminum up to 1400°C (2552°F)

at 1093°C (1999°F)

See page 151 or higher

Coated 760°C Excellent Do not exceed 760°C Molten aluminum, zinc

Protection (1400°F) (1400°F) and galvanizing; maxi-

Tubes mum operating temper-

(1100 SERIES) ature 745°C (1373°F)

See page 152

* Hot face temperature

* Note: Other mounting fittings available; please consult factory.

Note: All accessories subject to

minimum purchase quantities.

149

Accessories

Protection Tubes and

Assemblies L

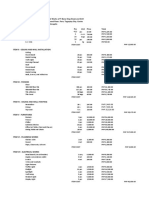

Ceramic Protecting Tubes Mullite or Alumina Protecting Tube, Plain End

Order - Part No.

Code - Length

Example: 1152-12 L

1152-N-12 Mullite or Alumina Protecting Tube with TH-43 or TH-50 Ferrule

1153-191-24 1/2 in. NPT

(12.7 mm) 3 4/ in. NPT

(19 mm)

L

1 3/4 in.

(12.7 mm)

Mullite or Alumina Protecting Tube with TH-190 or TH-191 Fitting (3⁄4 inch of Tube Enters Fitting)

Mullite Protecting Tubes*

Code I.D. X O.D. Construction Length

No. in. in.

1152- ⁄4 x 3⁄8

1

1153- 7

⁄16 x 11⁄16

1154- 3

⁄4 x 1 Plain end

12,18, 24,

1155- 1 x 1 1⁄4

30, 36, 42,

1152-N- 1

⁄4 x 3⁄8 With TH-50 ferrule ⁄8 - 27 threads

7

48, 54, 60

1153-N- 7

⁄16 x 11⁄16 With TH-43 ferrule 7⁄8 - 27 threads

1153-190- 7

⁄16 x 11⁄16 With TH-190 1⁄2” x 3⁄4” brass

1153-191- With TH-191 1⁄2” x 3⁄4” steel

Alumina (99% Minimum Purity) Protecting Tubes

Order - Part No. Code I.D. X O.D. Construction Length

Code - Length No. in. in.

Example: 1146-18 1146 1

⁄4 x 3⁄8 Plain end 12, 18, 24, 30, 36, 42, 48

1146-N-36 1147 7

⁄16 x 11⁄16 Plain end 12, 18, 24, 30, 36, 42, 48, 54, 60

1148 3

⁄4 x 1 Plain end 12, 18, 24, 30, 36, 42, 48, 54, 60, 66, 72

1147-190-30

1149 1 x 1 1⁄4 Plain end 12, 18, 24, 30, 36, 42, 48, 54, 60, 66, 72

1146-N 1

⁄4 x 3⁄8 TH-50 ferrule 7⁄8-27 threads 12, 18, 24, 30, 36, 42, 48

1147-N 7

⁄16 x 11⁄16 TH-43 ferrule 7⁄8-27 threads 12, 18, 24, 30, 36, 42, 48, 54, 60

1147-190 7

⁄16 x 11⁄16 With TH-190 1⁄2" x 3⁄4" brass 12, 18, 24, 30, 36, 42, 48, 54, 60

1147-191 7

⁄16 x 11⁄16 With TH-191 1⁄2" x 3⁄4" steel 12, 18, 24, 30, 36, 42, 48, 54, 60

Dimension Tolerance: Up to one inch, ±5 percent or 0.025 inch, whichever is greater; over one inch, ±4

percent or 0.050 inch, whichever is greater.

Note: All accessories subject to

minimum purchase quantities.

150

W A T L O W

Accessories

Protection Tubes and

Assemblies

Silicon Carbide and

Cast Iron Protecting Tubes

Order - Part No. Silicon Carbide Protecting or Target Tube

Code - Length

Example: 1080-18 Silicon Carbide Protecting Tubes—Oxide Bonded

Code I.D. X O.D. Construction Length Weight

No. in. in. per in.

1080 1 x 1 3⁄4 Plain end 12 , 18, 24, 30, 36 0.15 lbs

1081 1 x 1 3⁄4 Collar, 3 inch dia.* 0.17 lbs

*Back edge of flange rounded.

Special Application Metal-Ceramic Protecting Tube Thermocouples can be installed

Protecting Tubes O.D. 7/8 in. I.D. 5/8 in.

directly, eliminating the expense of

(22.2 mm) (15.9 mm) multi-tube assemblies. Metal-

Order - Part No.

ceramics resist surface deformation

Code - Length below the maximum recommended

Example: 1161-36 operating temperature of 1355°C

L (2500°F). They are useful in calcining

/

Accessories

5 8 in.

(15.9 mm)

kilns, for preheat temperature control

of open hearth furnaces, for

Watlow’s SERV-RITE® metal-ceramic continuous immersion in molten

protecting tube is composed of brass, bronze, copper, zinc and lead

metallic chromium and aluminum and in sulphurous gases.

oxide. The metal imparts shock In use, excess thermal or mechanical

resistance and high thermal shock should be avoided. Though

conductivity for fast, precise superior to ceramics, metal-ceramic

readings; the stable ceramic resists tubes are not as shock resistant as

deformation, corrosive attack, metal alloys, and may require

abrasion and oxidizing atmospheres preheating for certain applications.

over 1205°C (2200°F).

Note: Not recommended in molten

aluminum.

Code I.D. X O.D. Construction Length

No. in. in.

1161 5

⁄8 x 7⁄8 Std. 3⁄4 inch conduit connector 12, 18, 24, 30, 36

Note: All accessories subject to

minimum purchase quantities.

151

Accessories

Protection Tubes and

Assemblies SERIES 1100 Protecting Tube

/

3 4 in.

Coated Protecting Tubes (19 mm)

for Molten Aluminum, Zinc

and Galvanizing Applications

Order - Part No.

Code - Length L

Example: 1100-24

With a tough refractory laminated while permitting thermal expansion

coating, SERIES 1100 protecting without damage to the refractory

tubes resist erosion from molten laminate.

aluminum, zinc or galvanizing baths. The 0.493 inch I.D. easily accommo-

They stay strong, even at higher dates up to an eight-gauge beaded

temperatures, and require no washing thermocouple. Stocked for immediate

or maintenance to prolong their shipment. The maximum operating

service life. A special protective cap temperature for the SERIES 1100 is

at the tip provides fast response time, 745°C (1400°F).

Code I.D. Nominal O.D. Fitting Tube Length

No. in. in. in. in.

1100 0.493 1 1⁄2 Max. 3

⁄4 NPT 12, 18, 24, 30, 36, 42, 48

SERIES 1101 Protected Thermocouple

Order - Part No. /

3 4 in.

(19 mm)

Code - Length

Example: 1101-12

Watlow’s SERIES 1101 protected complete with 36 inches of high

thermocouple assemblies incor- temperature insulated thermocouple

porate a mineral-insulated stainless wire.

steel sheathed XACTPAK® thermo- Like the 1100, the 1101 assembly

couple hermetically sealed within a requires no washing or maintenance

refractory laminated SERIES 1100 to prolong its service life, yet gives

protecting tube. Standard calibration fast, accurate readings in molten alu-

is Type K (part no. 402-2107), minum, zinc and galvanizing baths.

Code Nominal Lead Tube

No. Calibration O.D. Fitting Length Length

in. in. in. in.

1101 K 1 1⁄2 Max. 3

⁄4 NPT 36 12, 18, 24, 30, 36, 42, 48

Note: All accessories subject to

minimum purchase quantities.

152

W A T L O W

Accessories

Protection Tubes and SERIES 1102 Floating

Assemblies Protected Thermocouple

Coated Protecting Tubes 12 in.

(304.8 mm)

for Molten Aluminum, Zinc

and Galvanizing Applications

Continued

7/8 in. 4 in.

(22.2 mm) (102 mm)

36 in.

(914.4 mm) / in.

1 2

/ in.

5 8

(12.7 mm) (15.9 mm)

A thermocouple that floats! It skimmers. The SERIES 1102 floats

contains a 0.125 inch O.D. easily aside to permit unobstructed

XACTPAK ASTM E 230 Type K skimming.

stainless steel sheathed High temperature, 36 inch insulated

thermocouple for quick, accurate thermocouple wire is standard

temperature indication approximately (optional stainless steel overbraid,

three inches below the surface of the part no. 1112). A metal sleeve with

melt or bath—where control is strain relief spring at the top protects

needed most. This trouble-free unit against molten metal splash and wire

gives you continuous temperature abrasion. The thick, rugged

indication at dip-out depth— refractory laminated thermocouple

regardless of metal level. Chances protecting cone provides rapid heat

of breakage are minimized, thanks to transfer and full physical protection.

a patented buoyant fiber collar that

Accessories

absorbs shock if struck by ladles or

Part Wire Calibration Nominal O.D. Lead Length Stem

No. Type in. in. in. Length

1102-12 Fiberglass

1112-12 Fiberglass

K 4 36 12

with stainless

steel overbraid

Note: All accessories subject to

minimum purchase quantities.

153

Accessories

Protection Tubes and Physical Properties of Hexoloy® Materials—Technical Data

Assemblies

Typical Values Hexoloy® Grade

Hexoloy SA Tubes ®

Physical Properties SA

Composition* (Phases) SiC

Density kg/m3 (g/cm3) 3100 (3.10)

Hardness-Knopp (Kg/mm2) 2800

Flexural Strength 4 pt. @ RT** MPa (x 103 lb/in2) 460 (67)

Flexural Strength 3 pt. @ RT** MPa (x 103 lb/in2) 550 (80)

Compressive Strength RT MPa (x 103 lb/in2) 3900 (560)

Modulus of Elasticity RT GPa (x 106 lb/in2) 410 (59)

Weibull Modulus (2 Parameter) 10

Poisson Ratio 0.14

Fracture Toughness @ RT Double Torsion

and SENB MPa/ √ m (x 103 lb/in2/ √ in) 4.60 (4.20)

Coefficient of Thermal Expansion

RT-700°C (68°-1,292°F)

x 10-6mm/mmK (x 10-6in/in°F) 4.02 (2.20)

Maximum Service Temp. (Air) °C (°F) 1650 (3000)

Mean Specific Heat @ RT (J/gm K) 0.67

* Composition code: Si = Free Silicon Metal; Thermal Conductivity @ RT W/m K (BTU/ft h °F) 125.6 (72.6)

C = Free Graphite; SiC = Silicon Carbide; Thermal Conductivity 200°C W/m K (BTU/ft h °F) 102.6 (59.3)

TiB = Titanium Diboride

Thermal Conductivity 400°C W/m K (BTU/ft h °F) 77.5 (44.8)

** Test Bar Size: 1⁄8 x 1⁄4 x 2 inch (3.2 x 6.4 x Electrical Resistivitya

50.8 mm), Outer Span = 1.5 inch;

Inner Span = 0.75 inch RT, ohm-cm 0.2 to 300a

a 1000°C, ohm-cm 0.01 to 0.2a

Dependent upon dopants in Hexoloy SA®

Emissivity 0.9

SiC which will decrease electrical resistivity

Max Warpage 0.005/inch

to a desired range

How to Order Cemented mounting fittings are Code O.D./I.D. Lengths

Watlow stocks a wide variety of available for most tubes. Contact No. in. in.

Hexoloy® tubes for immediate the factory or your local Watlow

1040 3

⁄8 x 1⁄4

shipment. To order, specify the sales representative or distributor 1041 5

⁄8 x 3⁄8 6, 12, 18, 24, 30, 36

following part numbers and lengths for further information. 1042 3

⁄4 x 1⁄2

required for your application.

Order - Part No.

Code - Length Tubes with Optional Mounting Fittings

Example: 1040-12 Tube Code No. Head Mount Process Mount Fitting Description Lengths

in.

1040-L 1

⁄2 NPT 1

⁄2 NPT Cemented hex nipple 6, 12,

1041-M 3

⁄4 NPT 3

⁄4 NPT Cemented hex nipple 18, 24,

1042-P 3

⁄4 NPT 3

⁄4 NPT Cemented hex nipple 30, 36

Example: 1041-M-24 is a 5⁄8 x 3⁄8 inch Hexoloy® tube 24 inches long with a single 3⁄4 inch NPT

cemented hex fitting.

Note: Maximum recommended temperature rating of cemented fitting is 538°C

(1000°F) continuous.

Note: All accessories subject to

minimum purchase quantities.

154

You might also like

- Metal-Sheathed Cable XACTPAKDocument9 pagesMetal-Sheathed Cable XACTPAKEliasNo ratings yet

- 17 4PH Spec SheetDocument2 pages17 4PH Spec Sheettrong tan dongNo ratings yet

- Stainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesDocument5 pagesStainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesforuzzNo ratings yet

- 17 4 PH Stainless SteelDocument10 pages17 4 PH Stainless SteelWILLIAN RICARDO DOS SANTOSNo ratings yet

- EN 1 4835 - 1510 Valbruna Nordic EnglishDocument2 pagesEN 1 4835 - 1510 Valbruna Nordic Englishnguyenhuutan91No ratings yet

- High-strength martensitic stainless steel alloyDocument2 pagesHigh-strength martensitic stainless steel alloySuriyachai NiamsornNo ratings yet

- 1.4742 en PDFDocument2 pages1.4742 en PDFArielNo ratings yet

- Forging Materials Specifications GuideDocument1 pageForging Materials Specifications GuideVinothkumarNo ratings yet

- Thermowell SpecificationDocument1 pageThermowell SpecificationNAYEEMNo ratings yet

- A Woodworker's Guide To Tool Steel and Heat TreatingDocument7 pagesA Woodworker's Guide To Tool Steel and Heat TreatingCorneliu CarabellaNo ratings yet

- Thermowell MaterialsDocument2 pagesThermowell Materialswhite9013No ratings yet

- Amari Aerospace LTD Stainless Steel 14542 Bar 100Document5 pagesAmari Aerospace LTD Stainless Steel 14542 Bar 100Ria MustikaNo ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- Duplex Stainless Steel 329 Round Bars ManufacturerDocument2 pagesDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- Heat Input and Thickness Relation-CombinedDocument15 pagesHeat Input and Thickness Relation-CombinedAmanSharmaNo ratings yet

- Stainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicalDocument20 pagesStainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicaljjdNo ratings yet

- TF 43 SystemsDesignDataGuideDocument44 pagesTF 43 SystemsDesignDataGuidespittalokaNo ratings yet

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cNo ratings yet

- Aalco Metals LTD Stainless Steel 14542 174 630 Bar 100Document5 pagesAalco Metals LTD Stainless Steel 14542 174 630 Bar 100LORENA GRIJALBA LEONNo ratings yet

- BIBUS METALS Land Based Gas Turbines LowResDocument2 pagesBIBUS METALS Land Based Gas Turbines LowResMahsaNo ratings yet

- Soldering: / JoiningDocument5 pagesSoldering: / JoiningKasia MazurNo ratings yet

- Nichrome Alloys For HeatingDocument10 pagesNichrome Alloys For HeatingRajaram GanesanNo ratings yet

- Specification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelDocument2 pagesSpecification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelBalaji RGNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Aisi 4130Document2 pagesAisi 4130ravivelamarthyNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- Materials Selection Considerations Thermal Process Equipment BestpracticesDocument8 pagesMaterials Selection Considerations Thermal Process Equipment BestpracticesMandeep SinghNo ratings yet

- 1.4742 enDocument2 pages1.4742 enGoran ErakovicNo ratings yet

- AISI 4130 Alloy Steel Guide - Properties, Applications, Heat TreatmentDocument2 pagesAISI 4130 Alloy Steel Guide - Properties, Applications, Heat TreatmentRavi Chaitanya VelamarthyNo ratings yet

- Hoja de Especificaciones Del Acero T-410Document2 pagesHoja de Especificaciones Del Acero T-410cristobal_tl2277No ratings yet

- Product information on RWL 34 stainless knife steelDocument4 pagesProduct information on RWL 34 stainless knife steeljose cuervoNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- Summary Note For CSWIP 3.1Document9 pagesSummary Note For CSWIP 3.1Muhamad ShakyreenNo ratings yet

- Specification Sheet: Alloy 410 Stainless SteelDocument2 pagesSpecification Sheet: Alloy 410 Stainless SteelThomasJolyNo ratings yet

- X17Crni 16-2: C: 0,19 - 0,22 CR: 15,5 - 17,0 Ni: 1,5 - 2,5Document2 pagesX17Crni 16-2: C: 0,19 - 0,22 CR: 15,5 - 17,0 Ni: 1,5 - 2,5Aadhya engineering ServicesNo ratings yet

- 410 Spec SheetDocument2 pages410 Spec SheetGumersindo MelambesNo ratings yet

- Al321 PDFDocument10 pagesAl321 PDFJean-Noël LerouxNo ratings yet

- Stainless Steels: Types 321, 347 and 348Document9 pagesStainless Steels: Types 321, 347 and 348Lei WuNo ratings yet

- Amie Material Science Notes PDFDocument276 pagesAmie Material Science Notes PDFAlok KulkarniNo ratings yet

- Inconel 718 Composition, Properties & UsesDocument2 pagesInconel 718 Composition, Properties & UsesPrathyusha RamadurgamNo ratings yet

- 17 4 Technical DataDocument4 pages17 4 Technical DataBalakrishnan MeikandasivamNo ratings yet

- Ferrotherm 4742Document2 pagesFerrotherm 4742Özlem KarataşNo ratings yet

- Armco 17-4 PH PDB Euro Final Secured 89Document24 pagesArmco 17-4 PH PDB Euro Final Secured 89naeem akramNo ratings yet

- Thermowell Material SelectionDocument3 pagesThermowell Material SelectionJp NairNo ratings yet

- Heat Treating of Uranium and Uranium Alloys : Reaffirmed by Robert Hackenberg, Los Alamos National LaboratoryDocument11 pagesHeat Treating of Uranium and Uranium Alloys : Reaffirmed by Robert Hackenberg, Los Alamos National LaboratoryAmin AminiNo ratings yet

- Outokumpu Therma Range DatasheetDocument16 pagesOutokumpu Therma Range Datasheetcehamos882No ratings yet

- Metal HardeningDocument3 pagesMetal HardeningNohemie MaaloufNo ratings yet

- Ceramics For KilnsDocument19 pagesCeramics For KilnsDemira BedakNo ratings yet

- Ferrous Alloys: Fe C CR MoDocument34 pagesFerrous Alloys: Fe C CR MosunsirNo ratings yet

- Saarstahl 18CrNiMo7-6 steel sheet specsDocument1 pageSaarstahl 18CrNiMo7-6 steel sheet specsAdrian-Ciprian SandaNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Ferrous: Revised: December 1982 Author: Kattus FeuhDocument46 pagesFerrous: Revised: December 1982 Author: Kattus FeuhsunsirNo ratings yet

- Anexo VII PDFDocument1 pageAnexo VII PDFIvo CostaNo ratings yet

- A Woodworker’s Guide to Tool Steel Heat TreatingDocument7 pagesA Woodworker’s Guide to Tool Steel Heat TreatingAnonymous dmhNTyNo ratings yet

- High Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlDocument4 pagesHigh Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlSyed Zakir Hussain ZaidiNo ratings yet

- EN1.4462-0509 Original EngDocument2 pagesEN1.4462-0509 Original Eng4455jappNo ratings yet

- Alloy 330 Spec SheetDocument2 pagesAlloy 330 Spec SheetArman MominNo ratings yet

- Baja Khusus - Kuliah Material 3Document13 pagesBaja Khusus - Kuliah Material 3Ikhsan IkhsanNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Watlow Resistance Temperature SensorsDocument21 pagesWatlow Resistance Temperature SensorsEliasNo ratings yet

- Watlow SERV-RITE WireDocument40 pagesWatlow SERV-RITE WireEliasNo ratings yet

- Watlow Heater Selection MatrixDocument4 pagesWatlow Heater Selection MatrixEliasNo ratings yet

- Watlow Reference DataDocument19 pagesWatlow Reference DataEliasNo ratings yet

- Watlow Thermocouple SDocument62 pagesWatlow Thermocouple SEliasNo ratings yet

- Watlow High Temperature HeatersDocument33 pagesWatlow High Temperature HeatersEliasNo ratings yet

- Watlow Circulation HeatersDocument54 pagesWatlow Circulation HeatersEliasNo ratings yet

- Watlow AccessoriesDocument30 pagesWatlow AccessoriesEliasNo ratings yet

- Watlow Mineral InsulatedDocument13 pagesWatlow Mineral InsulatedEliasNo ratings yet

- Watlow Strip Clamp On HeatersDocument15 pagesWatlow Strip Clamp On HeatersEliasNo ratings yet

- Watlow Immersion HeatersDocument163 pagesWatlow Immersion HeatersEliasNo ratings yet

- Watlow Cartridge HeatersDocument49 pagesWatlow Cartridge HeatersEliasNo ratings yet

- Watlow Radiant HeatersDocument16 pagesWatlow Radiant HeatersEliasNo ratings yet

- Waltlow Specialty HeatersDocument17 pagesWaltlow Specialty HeatersEliasNo ratings yet

- Watlow Flexible HeatersDocument46 pagesWatlow Flexible HeatersEliasNo ratings yet

- Watlow Thermostats and AccessoriesDocument10 pagesWatlow Thermostats and AccessoriesEliasNo ratings yet

- Watlow Air HeatersDocument32 pagesWatlow Air HeatersEliasNo ratings yet

- Watlow Tubular HeatersDocument55 pagesWatlow Tubular HeatersEliasNo ratings yet

- Watlow Band Barrel HeatersDocument13 pagesWatlow Band Barrel HeatersEliasNo ratings yet

- Watlow Agency Heaters CertificationsDocument6 pagesWatlow Agency Heaters CertificationsEliasNo ratings yet

- Watlow Integrated Multi-FunctionDocument45 pagesWatlow Integrated Multi-FunctionEliasNo ratings yet

- Watlow Fluid Delivery HeatersDocument5 pagesWatlow Fluid Delivery HeatersEliasNo ratings yet

- Watlow Data LoggersDocument10 pagesWatlow Data LoggersEliasNo ratings yet

- Watlow Nozzle HeatersDocument5 pagesWatlow Nozzle HeatersEliasNo ratings yet

- Watlow Power Switching DevicesDocument38 pagesWatlow Power Switching DevicesEliasNo ratings yet

- Watlow Limits ScannersDocument24 pagesWatlow Limits ScannersEliasNo ratings yet

- Watlow Temperature and ProcessDocument24 pagesWatlow Temperature and ProcessEliasNo ratings yet

- Watlow Operator InterfacesDocument11 pagesWatlow Operator InterfacesEliasNo ratings yet

- Watlow Controller AccessoriesDocument12 pagesWatlow Controller AccessoriesEliasNo ratings yet

- Watlow SoftwareDocument10 pagesWatlow SoftwareEliasNo ratings yet

- Socketweldspacerrings SoluGapBrochureDocument2 pagesSocketweldspacerrings SoluGapBrochureRamzi BEN AHMEDNo ratings yet

- 45° Brick House: Sunrise Society, Vadodara, GujaratDocument21 pages45° Brick House: Sunrise Society, Vadodara, GujaratSneha PatilNo ratings yet

- Fisa Tehnica Robineti Sertar R55Document2 pagesFisa Tehnica Robineti Sertar R55Petrisor FilipNo ratings yet

- Debatosh RoyDocument26 pagesDebatosh RoyDebatosh RoyNo ratings yet

- Compact Enclosures for Machine AutomationDocument28 pagesCompact Enclosures for Machine AutomationDarlyn BayonaNo ratings yet

- Compound Wall South Side - RevisedDocument39 pagesCompound Wall South Side - RevisedRajib MaharjanNo ratings yet

- Cement Concrete Pavement ConstructionDocument6 pagesCement Concrete Pavement ConstructionAmit Singh80% (5)

- Alucoworld E CatalogueDocument22 pagesAlucoworld E CatalogueRicardo Miguel Ayllon CamachoNo ratings yet

- Retrofitting of Building Project ReportDocument144 pagesRetrofitting of Building Project ReportNisanth Thulasidas100% (1)

- Surface-Mounted Horizontal Tank-Type Soap Dispenser: With All-Purpose ValveDocument1 pageSurface-Mounted Horizontal Tank-Type Soap Dispenser: With All-Purpose ValveAndres AguileraNo ratings yet

- Halfen Fixing TechnologyDocument24 pagesHalfen Fixing TechnologybachNo ratings yet

- FABRICS FOR HOT WORKS SAFETYDocument6 pagesFABRICS FOR HOT WORKS SAFETYfcoespinosaNo ratings yet

- Rate Analysis of Banganga NagarpalikaDocument127 pagesRate Analysis of Banganga NagarpalikaKobid KunwarNo ratings yet

- Henry Waterproofing BrochureDocument7 pagesHenry Waterproofing BrochureOgbedande Awo OrunmilaNo ratings yet

- Material ScheduleDocument12 pagesMaterial ScheduleAneeq MustafaNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- Interior Fitting Out Works Bill of MaterialsDocument15 pagesInterior Fitting Out Works Bill of MaterialsAnn MoralesNo ratings yet

- Structural Design of Swimming PoolsDocument12 pagesStructural Design of Swimming Poolsale hopeju200975% (20)

- Unbrako Technical BrochureDocument24 pagesUnbrako Technical BrochureAmirul ShamNo ratings yet

- Construction materials price list from local suppliersDocument6 pagesConstruction materials price list from local suppliersicNo ratings yet

- MetallurgyDocument17 pagesMetallurgyirajfarji2481No ratings yet

- Safety GratingDocument21 pagesSafety GratingAhmed IrakyNo ratings yet

- SoR 2021-22 FInal (Part - I, II, III and IV)Document728 pagesSoR 2021-22 FInal (Part - I, II, III and IV)vk52267% (24)

- Pohokura DeckDocument54 pagesPohokura DeckLynn BishopNo ratings yet

- Written R. PlumbingDocument5 pagesWritten R. PlumbingRia LopezNo ratings yet

- Cablofil Guia TecnicaDocument36 pagesCablofil Guia TecnicaMarisela BelloNo ratings yet

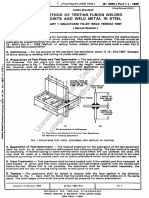

- Licensed To Arun Kumar Das: Method of Testing Fusi0.N Welded Joints and Weld Metal in SteelDocument2 pagesLicensed To Arun Kumar Das: Method of Testing Fusi0.N Welded Joints and Weld Metal in SteelIndira BanerjeeNo ratings yet

- Dortech Direct Product CatalogueDocument29 pagesDortech Direct Product CatalogueAdam YatesNo ratings yet

- Saej 524 V 002Document5 pagesSaej 524 V 002Marcos Verissimo Juca de PaulaNo ratings yet

- Nas 254N: (Uns S32053)Document4 pagesNas 254N: (Uns S32053)munif finumNo ratings yet