Professional Documents

Culture Documents

Japanese Aerospace Industry-2011

Uploaded by

raghava4343Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Japanese Aerospace Industry-2011

Uploaded by

raghava4343Copyright:

Available Formats

2011.

04

Japanese Aerospace Industry

Presented by The Society of Japanese Aerospace Companies 2011

THE SOCIETY OF JAPANESE AEROSPACE COMPANIES (SJAC)

The Society of Japanese Aerospace Companies

1-1-14 NOF Tameike Bldg. 2F

Akasaka, Minato-ku

Tokyo, Japan 107-0052

Telephone: (+81) 3-3585-0511

Facsimile: (+81) 3-3585-0541

http:/ / www.sjac.or.jp

www.sjac.or.jp

Tabl e of Cont ent s

Cont i nuous Ex pansi on of

J apanese Aer ospac e I ndust r y2

1. Signifcance of Aerospace Industry

2. Aircraft-Related Activities

3. Space-Related Activities

4. Japanese Aerospace Industry Sales

J apanese Ai r c r af t I ndust r y6

Ai r c r af t f or Nat i onal Def ense 6

1. Support Fighters of the Highest

Global Standards

2. Aircraft Development

Ci vi l Ai r c r af t f or St eady Gr ow t h

Ex pec t at i ons8

1. Increases in Demand for Passenger and

Transport Aircraft

2. Japans Role in Multinational

Development

3. Domestic Development of Civil Aircraft

Hel i c opt er s and St at e-of -t he-Ar t

Tec hnol ogi es 10

1. Civil Helicopters

2. Defense Aircraft

Ai r c r af t Engi nes 12

1. Civil Engines

2. Defense Engines

Japan' s Hi ghl y Rel i abl e Ai r c r af t

Equi pment 14

1. Hydraulic Systems

2. Cabin Pressure and Air Conditioning

Systems

3. Avionics and Flight Control Systems

4. Power Supply Systems

5. Landing Gear Systems

6. Other Systems

Cabi n and I nt er i or Syst ems f or

I n-Fl i ght Comf or t 16

Advanc ed Ai r c r af t Mat er i al s 17

J apanese Spac e I ndust r y 18

Wor l d-Cl ass Roc ket s 18

1. Liquid Propellant Rockets

2. Solid Propellant Rockets

3. Launch and Control Facilities

Sat el l i t e Devel opment 20

1. Weather Satellites

2. Communication & Broadcasting Satellites

3. Quasi-Zenith Satellite Systems

4. Remote Sensing

5. Other Projects

Cont r i but i on t o t he I nt er nat i onal

Spac e St at i on 22

1. International Space Station

2. H- B and HTV contribute to deliver

supplies to ISS

The Soc i et y of Japanese

Aer ospac e Compani es 24

1. Industrial Policies Promotion

2. Industrial Foundation Buildup and

Maintenance

3. Cooperation with Overseas Aerospace

Industries

4. Japan International Aerospace Exhibition

5. Other Activities

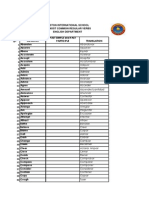

SJAC MEMBER COMPANI ES 28

Tabl e of Cont ent s

Cont i nuous Ex pansi on of

J apanese Aer ospac e I ndust r y2

1. Signifcance of Aerospace Industry

2. Aircraft-Related Activities

3. Space-Related Activities

4. Japanese Aerospace Industry Sales

J apanese Ai r c r af t I ndust r y6

Ai r c r af t f or Nat i onal Def ense 6

1. Support Fighters of the Highest

Global Standards

2. Aircraft Development

Ci vi l Ai r c r af t f or St eady Gr ow t h

Ex pec t at i ons8

1. Increases in Demand for Passenger and

Transport Aircraft

2. Japans Role in Multinational

Development

3. Domestic Development of Civil Aircraft

Hel i c opt er s and St at e-of -t he-Ar t

Technol ogi es 10

1. Civil Helicopters

2. Defense Aircraft

Ai r c r af t Engi nes 12

1. Civil Engines

2. Defense Engines

Japan' s Hi ghl y Rel i abl e Ai r c r af t

Equi pment 14

1. Hydraulic Systems

2. Cabin Pressure and Air Conditioning

Systems

3. Avionics and Flight Control Systems

4. Power Supply Systems

5. Landing Gear Systems

6. Other Systems

Cabi n and I nt er i or Syst ems f or

I n-Fl i ght Comf or t 16

Advanc ed Ai r c r af t Mat er i al s 17

J apanese Spac e I ndust r y 18

Wor l d-Cl ass Roc ket s 18

1. Liquid Propellant Rockets

2. Solid Propellant Rockets

3. Launch and Control Facilities

Sat el l i t e Devel opment 20

1. Weather Satellites

2. Communication & Broadcasting Satellites

3. Quasi-Zenith Satellite Systems

4. Remote Sensing

5. Other Projects

Cont r i but i on t o t he I nt er nat i onal

Spac e St at i on 22

1. International Space Station

2. H- B and HTV contribute to deliver

supplies to ISS

The Soc i et y of Japanese

Aer ospac e Compani es 24

1. Industrial Policies Promotion

2. Industrial Foundation Buildup and

Maintenance

3. Cooperation with Overseas Aerospace

Industries

4. Japan International Aerospace Exhibition

5. Other Activities

SJAC MEMBER COMPANI ES 28

2 3

3. Space-Related Activities

Japanese space-related projects are comparable to the

world standard. We have successfully developed launch

vehicles such as the M- and H-A, and also in the

satellite feld, we have contributed to the development of

various engineering test satellites, observation satellites,

global navigation satellites, etc. The development

technologies of H-A were transferred to a private

sector. The company has received a commercial

order to launch South Korean satellite on an H-A

rocket: expectations are mounting for launch of more

commercial satellites in the future. Meanwhile, the H-

B rocket, an upgrade model of the H-A, has been

developed. It was first production used in a successful

launch of the H-Transfer Vehicle (HTV) in September

2009. The HTV, an unmanned cargo transporter, carries

supplies to the International Space Station (ISS).

The second launch of H-B was also successful in

January 2011.

In recent years, space exploration and usage have

become a major part of the overall industry activities.

Japanese producers now strive to increase reliability and

reduce costs in order to compete in the global market.

Launch of H-B NO.1 (JAXA)

Wideband InterNetworking engineering test and Demonstration

Satellite "KIZUNA" (WINDS) (JAXA)

Advanced Land Observing Satellite "DAICHI" (ALOS) (JAXA)

Cont i nuous Ex pansi on of

J apanese Aer ospac e I ndust r y

After the end of the Second World War, expansion of the aerospace industry in Japan

steadily relied for its defense demands on other countries, and in recent years, international

joint development of civil aircraft has further increased. In space operations, development of

transportation and satellite systems has been promoted and increased. In this way, the Japanese

aerospace industry is being continually advanced to stand alongside those in the US and EU.

1. Signifcance of Aerospace Industry

The aerospace industry is characterized by the following

strategic components.

By integrating advanced technologies with high-grade

materials and components, the aerospace industry

utilizes a wide range of supporting industries, and

its technology also spreads to other industries, thus

benefting the economy as a whole.

Through hi gh- speed t ranspor t at i on, di sast er

prevention and other similar activities, this industry

contributes to improve the daily lives of the people of

Japan.

As one of the most important components of defense,

the aerospace industry is directly linked to national

security.

2. Aircraft-Related Activities

For a certain period after the end of the war, Japan was

forbidden from any activities related to the development

and production of aircraft, and our aerospace industry

thus fell behind those of the US and Europe. Starting

with the licensed production of defense aircraft, national

development and production systems have grown. The

development and manufacture of defense aircraft was

the base of the Japanese aerospace industry, and in

recent years the F-2 fighter (a joint Japan-US project),

the OH-1 observation helicopter, the T-7 trainer US-2

amphibious search & rescue flying boat have been

successfully developed and produced in this country.

The P-1 Fixed-Wing Maritime Patrol Aircraft is being

delivered.

Delivery of the XC-2 Next-Generation Transport Aircraft

will start in 2011.

With a steady increase in passenger transportation,

Japanese producers are fur ther devel opi ng and

manufacturing civil aircraft, and the importance of this

industry has thus risen. In the 1960s, Japan focused on

the YS-11 transport aircraft and other similar projects.

More recently, international joint development has

become main stream due to the enlargement of the

airline industry in general, which has gone global, and

thus the risks have increased as well. Currently, Japan is

participating in the development of aircraft such as the

B767, B777 and B787, and engines such as the V2500,

TRENT1000, GEnx, etc.

V2500 Turbofan Engine (Japanese Aero Engines Corporation)

T-4 Intermediate Jet Trainer (Kawasaki Heavy Industries, Ltd.)

Memorial First Shipment of B787 Dreamliner Components from Centrair

Airport in Nagoya (Boeing)

2 3

3. Space-Related Activities

Japanese space-related projects are comparable to the

world standard. We have successfully developed launch

vehicles such as the M- and H-A, and also in the

satellite feld, we have contributed to the development of

various engineering test satellites, observation satellites,

global navigation satellites, etc. The development

technologies of H-A were transferred to a private

sector. The company has received a commercial

order to launch South Korean satellite on an H-A

rocket: expectations are mounting for launch of more

commercial satellites in the future. Meanwhile, the H-

B rocket, an upgrade model of the H-A, has been

developed. It was first production used in a successful

launch of the H-Transfer Vehicle (HTV) in September

2009. The HTV, an unmanned cargo transporter, carries

supplies to the International Space Station (ISS).

The second launch of H-B was also successful in

January 2011.

In recent years, space exploration and usage have

become a major part of the overall industry activities.

Japanese producers now strive to increase reliability and

reduce costs in order to compete in the global market.

Launch of H-B NO.1 (JAXA)

Wideband InterNetworking engineering test and Demonstration

Satellite "KIZUNA" (WINDS) (JAXA)

Advanced Land Observing Satellite "DAICHI" (ALOS) (JAXA)

Cont i nuous Ex pansi on of

Japanese Aer ospac e I ndust r y

After the end of the Second World War, expansion of the aerospace industry in Japan

steadily relied for its defense demands on other countries, and in recent years, international

joint development of civil aircraft has further increased. In space operations, development of

transportation and satellite systems has been promoted and increased. In this way, the Japanese

aerospace industry is being continually advanced to stand alongside those in the US and EU.

1. Signifcance of Aerospace Industry

The aerospace industry is characterized by the following

strategic components.

By integrating advanced technologies with high-grade

materials and components, the aerospace industry

utilizes a wide range of supporting industries, and

its technology also spreads to other industries, thus

benefting the economy as a whole.

Through hi gh- speed t ranspor t at i on, di sast er

prevention and other similar activities, this industry

contributes to improve the daily lives of the people of

Japan.

As one of the most important components of defense,

the aerospace industry is directly linked to national

security.

2. Aircraft-Related Activities

For a certain period after the end of the war, Japan was

forbidden from any activities related to the development

and production of aircraft, and our aerospace industry

thus fell behind those of the US and Europe. Starting

with the licensed production of defense aircraft, national

development and production systems have grown. The

development and manufacture of defense aircraft was

the base of the Japanese aerospace industry, and in

recent years the F-2 fighter (a joint Japan-US project),

the OH-1 observation helicopter, the T-7 trainer US-2

amphibious search & rescue flying boat have been

successfully developed and produced in this country.

The P-1 Fixed-Wing Maritime Patrol Aircraft is being

delivered.

Delivery of the XC-2 Next-Generation Transport Aircraft

will start in 2011.

With a steady increase in passenger transportation,

Japanese producers are fur ther devel opi ng and

manufacturing civil aircraft, and the importance of this

industry has thus risen. In the 1960s, Japan focused on

the YS-11 transport aircraft and other similar projects.

More recently, international joint development has

become main stream due to the enlargement of the

airline industry in general, which has gone global, and

thus the risks have increased as well. Currently, Japan is

participating in the development of aircraft such as the

B767, B777 and B787, and engines such as the V2500,

TRENT1000, GEnx, etc.

V2500 Turbofan Engine (Japanese Aero Engines Corporation)

T-4 Intermediate Jet Trainer (Kawasaki Heavy Industries, Ltd.)

Memorial First Shipment of B787 Dreamliner Components from Centrair

Airport in Nagoya (Boeing)

4 5

Engine Component Plant (IHI CO.) Large CFRP Structure Manufacturing Plant (Fuji Heavy Industries Ltd.)

Autoclave for CFRP Structure Manufacturing (Mitsubishi Heavy Industries, Ltd.)

2002 2003 2004 2005 2006 2007 2008 2009

Japan

61 62 62 55 52 42 47 46

United States

47 54 45 45 44 43 44 44

United Kingdom

45 50 51 54 48 48 50 52

France

28 33 32 33 29 27 24 24

0

10

20

30

40

50

60

70

80

Dependence of Defense Contracts on Major Countries

4. Japanese Aerospace Industry Sales

The aerospace industry in Japan has steadily increased

to a total of 1,356 billion yen (with aircraft-related

activities accounting for 1,086 billion yen and space-

related activities accounting for 270 billion yen). As of

2009, a total of 31,561 persons were employed in this

industr y, with 25,220 and 6,341 persons involved in

aircraft-related and space-related activities respectively.

A recent and slight decrease in employment numbers

can be attributed to an increase in overall ef ficiency.

The propor ti on of defense ai rcraft stood at one

time between 80% and 90% of total sales, and export

components of civil aircraft have increased since the

late 1990s along with the promotion of multinational

development projects. Consequently, defense-related

products currently are around 50% of total sales. The

Japanese aerospace industry is compared with those of

foreign countries in the chart right. The United States

is over whelmingly large, and various EU countries,

Canada and Japan follow.

When compared with the automobile, home electric,

computer and other industries in Japan, the aerospace

industr y is still relatively small. Much is therefore

expected of Japanese producers over the coming years.

The trade balance has been in deficit due to the large

amount of airlines procurement of aircraft from abroad.

0

2000

4000

6000

8000

10000

12000

14000

16000

1975 1985 1995 2009

(Units:Billion yen)

Space

Aircraft (civil)

Aircraft (defense)

United States United Kingdom France Canada Germany Japan

0

20

40

60

80

100

120

140

160

180

200

(Units:Billion dollars)

189

33

46

19.4

33

14.5

Japanese Aerospace Industry Sales (FY1975-FY2009)

Aerospace Revenue of Major Countries (2009)

Trade Balance of Major Aerospace Industries (2009)

United States France Japan

-10

0

10

20

30

40

50

60

70

(Units:Billion dollars)

23.7

4.8

56

(%)

4 5

Engine Component Plant (IHI CO.) Large CFRP Structure Manufacturing Plant (Fuji Heavy Industries Ltd.)

Autoclave for CFRP Structure Manufacturing (Mitsubishi Heavy Industries, Ltd.)

2002 2003 2004 2005 2006 2007 2008 2009

Japan

61 62 62 55 52 42 47 46

United States

47 54 45 45 44 43 44 44

United Kingdom

45 50 51 54 48 48 50 52

France

28 33 32 33 29 27 24 24

0

10

20

30

40

50

60

70

80

Dependence of Defense Contracts on Major Countries

4. Japanese Aerospace Industry Sales

The aerospace industry in Japan has steadily increased

to a total of 1,356 billion yen (with aircraft-related

activities accounting for 1,086 billion yen and space-

related activities accounting for 270 billion yen). As of

2009, a total of 31,561 persons were employed in this

industr y, with 25,220 and 6,341 persons involved in

aircraft-related and space-related activities respectively.

A recent and slight decrease in employment numbers

can be attributed to an increase in overall ef ficiency.

The propor ti on of defense ai rcraft stood at one

time between 80% and 90% of total sales, and export

components of civil aircraft have increased since the

late 1990s along with the promotion of multinational

development projects. Consequently, defense-related

products currently are around 50% of total sales. The

Japanese aerospace industry is compared with those of

foreign countries in the chart right. The United States

is over whelmingly large, and various EU countries,

Canada and Japan follow.

When compared with the automobile, home electric,

computer and other industries in Japan, the aerospace

industr y is still relatively small. Much is therefore

expected of Japanese producers over the coming years.

The trade balance has been in deficit due to the large

amount of airlines procurement of aircraft from abroad.

0

2000

4000

6000

8000

10000

12000

14000

16000

1975 1985 1995 2009

(Units:Billion yen)

Space

Aircraft (civil)

Aircraft (defense)

United States United Kingdom France Canada Germany Japan

0

20

40

60

80

100

120

140

160

180

200

(Units:Billion dollars)

189

33

46

19.4

33

14.5

Japanese Aerospace Industry Sales (FY1975-FY2009)

Aerospace Revenue of Major Countries (2009)

Trade Balance of Major Aerospace Industries (2009)

United States France Japan

-10

0

10

20

30

40

50

60

70

(Units:Billion dollars)

23.7

4.8

56

(%)

6 7

1. Support Fighters of the Highest Global Standards

Next-generation Fixed-wing Maritime Patrol Aircraft

and Transport Aircraft to be used as successor models

for the P-3C and the C-1, and simultaneous development

activities began in 200l.

By making use of multi-utilization to the utmost, it is

expected that there will be a reduction in the overall

devel opment cost. Next- Generati on Fi xed- Wi ng

Maritime Patrol Aircraft succeeded in the first flight

in September 2007 and delivery to the base started in

2008. Next-Generation Transport Aircraft successfully

completed its frst fight in January 2010 and delivery to

the base will start in 2011.

Unmanned Aerial Vehicles

The Ministr y of Defense is currently developing

unmanned aerial vehicles. Studies to evaluate conversion

of the F-104 Fighter for pilotless operation are underway.

The ministry is also developing an unmanned aircraft

research system whose autonomous flight function

enables automatic landing.

Trainers

The Ministry of Defense is designing and developing

trainers such as the T-4 and T-7 indigenously in Japan.

Both the airframe and engine of the T-4 intermediate

trainer are fully developed and produced in this country.

Making the most of its excellent agility, the aerial-

combat research aircraft (nicknamed Blue Impulse)

appeals to people at airs shows held at various air bases

throughout Japan.

Fur thermore, the outspread applications of such

technical advances not only contributes to the design

and manufacture of civil aircraft, but it also has helped to

form strong technical foundation in other industries.

Advanced Technology Demonstrator (ATD)

In the ATD program, high maneuvering stealth prototype

will be made with advanced technologies such as stealth

form, high maneuvering flight control and advanced

composite material. It will be used to verify the stealth

technology in actual fight environment and establish the

performance needed for the future fghter jet.

P-1 Fixed-Wing Maritime Patrol Aircraft (Kawasaki Heavy Industries. Ltd.)

XC-2 Next-Generation Transport Aircraft (Kawasaki Heavy Industries. Ltd.) Advanced Technology Demonstrator (Full Scale RCS Test Model)

J apanese Ai r c r af t I ndust r y

Ai r c r af t f or Nat i onal Def ense

Japans defense aircraft industry was reborn in 1952 with aircraft such as the F-86F and

T-33 manufactured under license from the United States, in 1958, Japans first jet trainer

was developed and produced. Many significant steps in the advancement of the design and

manufacturing technologies have followed. Today, Japanese aircraft manufacturers have their own

capability to develop, produce and maintain a wide range of defense aircraft, such as fghters,

transporters, patrol planes, trainers and search & rescue vessels, which has thus contributed to

the national defense.

Developed jointly by Japan and the United States, the F-2

support fghter is used in multiple roles, such as tactical

air support and maritime operations, close air support

and defensive counter-air operations. Highly regarded

both at home and overseas, this fghter features a host of

advanced technologies developed indigenously in Japan.

Co-cured composite wings

In order to achieve lightweight aircraft, co-cured

composite material technology was applied for the

first time in wing construction. This technology has

subsequently been transferred to the United States,

and some wings are now produced by American

manufacturers utilizing this technology.

Digital fy-by-wire

Digital fly-by-wire technologies have been adopted to

achieve higher agility - the heartbeat of todays fghter

- and by combining these technologies with lightweight

wings, the worlds highest standards of maneuverability,

acceleration and many other agility-related factors

have been achieved. The carefree digital flight control

allows the F-2 to automatically prevent dangerous fying

conditions, and this has contributed to increase flight

safety.

Active phased-array radar

Radar provides a fighter with eyes, and the F-2 is the

frst fghter in the world to feature active phased-array

radar technology. Thanks to this type of system, it has

been possible to achieve standoff and anti-ship attack

capabilities of the highest standard.

2. Aircraft Development

Japan Ministry of Defense is currently developing, and

delivering following types of aircraft.

Search & Rescue Flying Boat

In l996, development of a successor to the US-1A was

started, and its frst fight was successfully completed in

December 2003. US-2 (former US-1A kai) delivery to the

base started in March 2007.

F-2 Support Fighter (Mitsubishi Heavy Industries, Ltd.) US-2 Amphibious Search & Rescue Flying Boat (ShinMaywa Industries, Ltd.)

T-7 Primary Trainer (Fuji Heavy Industries Ltd.)

Unmanned Aircraft Research System (Fuji Heavy Industries Ltd.)

6 7

1. Support Fighters of the Highest Global Standards

Next-generation Fixed-wing Maritime Patrol Aircraft

and Transport Aircraft to be used as successor models

for the P-3C and the C-1, and simultaneous development

activities began in 200l.

By making use of multi-utilization to the utmost, it is

expected that there will be a reduction in the overall

devel opment cost. Next- Generati on Fi xed- Wi ng

Maritime Patrol Aircraft succeeded in the first flight

in September 2007 and delivery to the base started in

2008. Next-Generation Transport Aircraft successfully

completed its frst fight in January 2010 and delivery to

the base will start in 2011.

Unmanned Aerial Vehicles

The Ministr y of Defense is currently developing

unmanned aerial vehicles. Studies to evaluate conversion

of the F-104 Fighter for pilotless operation are underway.

The ministry is also developing an unmanned aircraft

research system whose autonomous flight function

enables automatic landing.

Trainers

The Ministry of Defense is designing and developing

trainers such as the T-4 and T-7 indigenously in Japan.

Both the airframe and engine of the T-4 intermediate

trainer are fully developed and produced in this country.

Making the most of its excellent agility, the aerial-

combat research aircraft (nicknamed Blue Impulse)

appeals to people at airs shows held at various air bases

throughout Japan.

Fur thermore, the outspread applications of such

technical advances not only contributes to the design

and manufacture of civil aircraft, but it also has helped to

form strong technical foundation in other industries.

Advanced Technology Demonstrator (ATD)

In the ATD program, high maneuvering stealth prototype

will be made with advanced technologies such as stealth

form, high maneuvering flight control and advanced

composite material. It will be used to verify the stealth

technology in actual fight environment and establish the

performance needed for the future fghter jet.

P-1 Fixed-Wing Maritime Patrol Aircraft (Kawasaki Heavy Industries. Ltd.)

XC-2 Next-Generation Transport Aircraft (Kawasaki Heavy Industries. Ltd.) Advanced Technology Demonstrator (Full Scale RCS Test Model)

Japanese Ai r c r af t I ndust r y

Ai r c r af t f or Nat i onal Def ense

Japans defense aircraft industry was reborn in 1952 with aircraft such as the F-86F and

T-33 manufactured under license from the United States, in 1958, Japans first jet trainer

was developed and produced. Many significant steps in the advancement of the design and

manufacturing technologies have followed. Today, Japanese aircraft manufacturers have their own

capability to develop, produce and maintain a wide range of defense aircraft, such as fghters,

transporters, patrol planes, trainers and search & rescue vessels, which has thus contributed to

the national defense.

Developed jointly by Japan and the United States, the F-2

support fghter is used in multiple roles, such as tactical

air support and maritime operations, close air support

and defensive counter-air operations. Highly regarded

both at home and overseas, this fghter features a host of

advanced technologies developed indigenously in Japan.

Co-cured composite wings

In order to achieve lightweight aircraft, co-cured

composite material technology was applied for the

first time in wing construction. This technology has

subsequently been transferred to the United States,

and some wings are now produced by American

manufacturers utilizing this technology.

Digital fy-by-wire

Digital fly-by-wire technologies have been adopted to

achieve higher agility - the heartbeat of todays fghter

- and by combining these technologies with lightweight

wings, the worlds highest standards of maneuverability,

acceleration and many other agility-related factors

have been achieved. The carefree digital flight control

allows the F-2 to automatically prevent dangerous fying

conditions, and this has contributed to increase flight

safety.

Active phased-array radar

Radar provides a fighter with eyes, and the F-2 is the

frst fghter in the world to feature active phased-array

radar technology. Thanks to this type of system, it has

been possible to achieve standoff and anti-ship attack

capabilities of the highest standard.

2. Aircraft Development

Japan Ministry of Defense is currently developing, and

delivering following types of aircraft.

Search & Rescue Flying Boat

In l996, development of a successor to the US-1A was

started, and its frst fight was successfully completed in

December 2003. US-2 (former US-1A kai) delivery to the

base started in March 2007.

F-2 Support Fighter (Mitsubishi Heavy Industries, Ltd.) US-2 Amphibious Search & Rescue Flying Boat (ShinMaywa Industries, Ltd.)

T-7 Primary Trainer (Fuji Heavy Industries Ltd.)

Unmanned Aircraft Research System (Fuji Heavy Industries Ltd.)

8 9

Mitsubishi Regional Jet (MRJ) (Mitsubishi Aircraft Corporation)

Japan produced the YS-11 60-seater transport aircraft

in 1964 as the first civil aircraft of independent

development The MU-2, FA-200, FA-300 and MU-300

business jets followed during the period until 1980. Full-

fledged development of the Mitsubishi Regional Jet

(MRJ) 70-90 seater, which will have a technological edge

in environmental performance, economical ef ficiency

and the cabin comfort, is proceeding since 2008.

Ci vi l Ai r c r af t f or St eady Gr ow t h Ex pec t at i ons

Aiming at risk reduction and being market oriented, the development of civil aircraft is carried out

in multinational projects. Japan is proactive in the joint development of the B777, B787, and other

models.

The development of the Mitsubishi Regional Jet (MRJ) applying the state-of-the-art technologies

is progressing in Japanese business sector.

1. Increases in Demand for Passenger

and Transport Aircraft

Worldwide demand for passenger aircraft expanded at

a record pace from 2005 after recovering from a low

following the September 11 terror attacks. The demand

was boosted by China, India and other rapidly growing

emerging economies, and by good performance of low-

cost carriers around the world. The demand plunged

again in the aftermath of the global financial crisis in

2008, then, recovering again world wide demand for

passenger aircraft from 2010.

2. Japans Role in Multinational

Development

Japanese companies are active in projects such as those

shown in the following

table, and they play an important role in the global

production of aircraft. Participation in the B767 project

began with the detailed design phase, and Japanese

manufacturers were assigned with responsibility for

the fuselage structure and other components (with a

15% share). In recent projects, such as the B787, Japan

began to participate in the conceptual design phase and

has been assigned with responsibility for the wings and

other complicated components. It has also extended

beyond design and manufacture to the level of testing

and TC acquisition (achieving a 35% share).

The First Flight of the B787 (Boeing)

A380 (Airbus Industries)

Participation in International Projects

Project Area of participation Scope of participation

Boeing B767

Forward fuselage, aft fuselage, main landing

gear door, etc.

15% program partner

Boeing B777

Center section, center fuselage, aft fuselage,

etc.

21% program partner

Boeing B787 Wings, center wings, front fuselage, etc. 35% program partner

Global Express Wings and central fuselage RSP

CRJ 700 / 900

Tail fuselage, nose and main landing gear

system

RSP

Embraer 170 / 190 Wings and center wings RSP

Hawker 4000 Wing structure system RSP

Eclipse Wings RSP

Gulfstream Flaps and landing gear operation devices, etc. Supplier

Airbus A380

Cargo doors, verti cal stabi l i zer structure

material, titanium sheets, carbon fiber, water

tanks, etc.

Supplier

B787 Industrial Participation (Japan Aircraft Development Corporation)

A380 Industrial Participation (Airbus Industries)

3. Domestic Development of Civil Aircraft

Kawasaki Heavy

Industries

forward fuselage

Wheel well

Main wing fxed trailing

edge

Mitsubishi Heavy Industries

main wing box

Fuji Heavy Industries

center wing box

integration of center wing box with

wheel well

(Parts Supplier)

GS Yuasa/Thales (Lithium-ion Battery System)

JAMCO (lavatories, galleys, fight deck door & bulkhead assembly, fight

deck interior panel, storage box)

Sumitomo Precision Products (APU oil cooler)

Tamagawa Seiki (angle sensor, small DC brushless motor)

Toray (TORAYCA, prepreg composites)

Nabtesco/Hamilton Sundstrand (power distribution unit)

Panasonic Avionics (cabin services system, in-fight entertainment system)

Bridgestone (tires)

Boeing 787

8 9

Mitsubishi Regional Jet (MRJ) (Mitsubishi Aircraft Corporation)

Japan produced the YS-11 60-seater transport aircraft

in 1964 as the first civil aircraft of independent

development The MU-2, FA-200, FA-300 and MU-300

business jets followed during the period until 1980. Full-

fledged development of the Mitsubishi Regional Jet

(MRJ) 70-90 seater, which will have a technological edge

in environmental performance, economical ef ficiency

and the cabin comfort, is proceeding since 2008.

Ci vi l Ai r c r af t f or St eady Gr ow t h Ex pec t at i ons

Aiming at risk reduction and being market oriented, the development of civil aircraft is carried out

in multinational projects. Japan is proactive in the joint development of the B777, B787, and other

models.

The development of the Mitsubishi Regional Jet (MRJ) applying the state-of-the-art technologies

is progressing in Japanese business sector.

1. Increases in Demand for Passenger

and Transport Aircraft

Worldwide demand for passenger aircraft expanded at

a record pace from 2005 after recovering from a low

following the September 11 terror attacks. The demand

was boosted by China, India and other rapidly growing

emerging economies, and by good performance of low-

cost carriers around the world. The demand plunged

again in the aftermath of the global financial crisis in

2008, then, recovering again world wide demand for

passenger aircraft from 2010.

2. Japans Role in Multinational

Development

Japanese companies are active in projects such as those

shown in the following

table, and they play an important role in the global

production of aircraft. Participation in the B767 project

began with the detailed design phase, and Japanese

manufacturers were assigned with responsibility for

the fuselage structure and other components (with a

15% share). In recent projects, such as the B787, Japan

began to participate in the conceptual design phase and

has been assigned with responsibility for the wings and

other complicated components. It has also extended

beyond design and manufacture to the level of testing

and TC acquisition (achieving a 35% share).

The First Flight of the B787 (Boeing)

A380 (Airbus Industries)

Participation in International Projects

Project Area of participation Scope of participation

Boeing B767

Forward fuselage, aft fuselage, main landing

gear door, etc.

15% program partner

Boeing B777

Center section, center fuselage, aft fuselage,

etc.

21% program partner

Boeing B787 Wings, center wings, front fuselage, etc. 35% program partner

Global Express Wings and central fuselage RSP

CRJ 700 / 900

Tail fuselage, nose and main landing gear

system

RSP

Embraer 170 / 190 Wings and center wings RSP

Hawker 4000 Wing structure system RSP

Eclipse Wings RSP

Gulfstream Flaps and landing gear operation devices, etc. Supplier

Airbus A380

Cargo doors, verti cal stabi l i zer structure

material, titanium sheets, carbon fiber, water

tanks, etc.

Supplier

B787 Industrial Participation (Japan Aircraft Development Corporation)

A380 Industrial Participation (Airbus Industries)

3. Domestic Development of Civil Aircraft

Kawasaki Heavy

Industries

forward fuselage

Wheel well

Main wing fxed trailing

edge

Mitsubishi Heavy Industries

main wing box

Fuji Heavy Industries

center wing box

integration of center wing box with

wheel well

(Parts Supplier)

GS Yuasa/Thales (Lithium-ion Battery System)

JAMCO (lavatories, galleys, fight deck door & bulkhead assembly, fight

deck interior panel, storage box)

Sumitomo Precision Products (APU oil cooler)

Tamagawa Seiki (angle sensor, small DC brushless motor)

Toray (TORAYCA, prepreg composites)

Nabtesco/Hamilton Sundstrand (power distribution unit)

Panasonic Avionics (cabin services system, in-fight entertainment system)

Bridgestone (tires)

Boeing 787

10 11

2. Defense Aircraft

OH-1 Light Observation Helicopter

The OH-1 is the frst helicopter fully developed in Japan.

And, it has been honored with the Howard Hughes

Award by the American Helicopter Society. Featuring an

all-composite, bearing-less rotor system, it benefts from

extremely high maneuverability.

SH-60K Anti-Sub Patrol Helicopter

In addition to a newly developed high-performance

rotor system and a ship-landing assist system, the SH-

60K features a longer fuselage, and despite being an

upgrade, it represents almost a complete redevelopment

of the SH-60J.

AH-64D Fighting Helicopter

The AH-64D, which has distinguished information and

fghting capabilities, is the successor model to the AH-

IS, and it is expected to be the core of the combat of the

network-centered type in the future.

Under License Production.

MCH-101 Airborne Mine Countermeasures missions

and transportation Helicopter

The MCH-101 is the successor of the current MH-53E,

and it is based on the EH-101. It is used for Airborne

Mi ne Count er measures (AMCM) mi ssi ons and

transportation.

Under License Production.

In addition, Japanese manufacturers produce helicopters

under license, such as for the CH-47 (Boeing, heavy

transpor t helicopter) and the UH- 60J (Sikorsky,

multipurpose helicopter).

SH-60K (Mitsubishi Heavy Industries, Ltd.)

OH-1 (Kawasaki Heavy Industries, Ltd.)

MCH-101 (Kawasaki Heavy Industries, Ltd.)

AH-64D (Fuji Heavy Industries Ltd.)

Hel i c opt er s and St at e-of -t he-Ar t Technol ogi es

As the largest user of helicopters after the US and three other countries, Japan develops and

manufactures fuselages, engines and all other helicopter components. The technologies used

in fuselage and transmission production in this country have an excellent reputation throughout

the world. The rotor system is the most important part of these components, and Japan has

successfully developed and produced a composite-material, bearing-less version of this system

that makes full use of cutting-edge technologies. The Japanese aerospace industry is also

proactively participating in multinational development projects.

1. Civil Helicopters

BK117

The BK117 has been developed jointly with MBB of

Germany (now part of Eurocopter). A best-seller in both

domestic and overseas markets, this helicopter is used

in fre fghting, fying medical services and many other

applications.

Japanese companies are currently participating in the following multinational development projects.

BA609 (Bell / Agusta)

Participation in design and development of the

fuselage (RSP)

The worlds frst civil, tail-rotor helicopter

MD902 (MD Helicopter) Production of the transmission

BK117C-2 (Kawasaki Heavy Industries, Ltd.)

S-92

The Sikorsky S-92 is a 19-seat, double-engine, large

helicopter developed in an international collaboration

project led by Sikorsky Aircraft Corporation of the

United States. Japan, China, Spain, Brazil and Taiwan

are part of the project. Dubbed the Helibus, the aircraft

is used for commuting and offshore oil development.

S-92 (Mitsubishi Heavy Industries, Ltd.)

10 11

2. Defense Aircraft

OH-1 Light Observation Helicopter

The OH-1 is the frst helicopter fully developed in Japan.

And, it has been honored with the Howard Hughes

Award by the American Helicopter Society. Featuring an

all-composite, bearing-less rotor system, it benefts from

extremely high maneuverability.

SH-60K Anti-Sub Patrol Helicopter

In addition to a newly developed high-performance

rotor system and a ship-landing assist system, the SH-

60K features a longer fuselage, and despite being an

upgrade, it represents almost a complete redevelopment

of the SH-60J.

AH-64D Fighting Helicopter

The AH-64D, which has distinguished information and

fghting capabilities, is the successor model to the AH-

IS, and it is expected to be the core of the combat of the

network-centered type in the future.

Under License Production.

MCH-101 Airborne Mine Countermeasures missions

and transportation Helicopter

The MCH-101 is the successor of the current MH-53E,

and it is based on the EH-101. It is used for Airborne

Mi ne Count er measures (AMCM) mi ssi ons and

transportation.

Under License Production.

In addition, Japanese manufacturers produce helicopters

under license, such as for the CH-47 (Boeing, heavy

transpor t helicopter) and the UH- 60J (Sikorsky,

multipurpose helicopter).

SH-60K (Mitsubishi Heavy Industries, Ltd.)

OH-1 (Kawasaki Heavy Industries, Ltd.)

MCH-101 (Kawasaki Heavy Industries, Ltd.)

AH-64D (Fuji Heavy Industries Ltd.)

Hel i c opt er s and St at e-of -t he-Ar t Technol ogi es

As the largest user of helicopters after the US and three other countries, Japan develops and

manufactures fuselages, engines and all other helicopter components. The technologies used

in fuselage and transmission production in this country have an excellent reputation throughout

the world. The rotor system is the most important part of these components, and Japan has

successfully developed and produced a composite-material, bearing-less version of this system

that makes full use of cutting-edge technologies. The Japanese aerospace industry is also

proactively participating in multinational development projects.

1. Civil Helicopters

BK117

The BK117 has been developed jointly with MBB of

Germany (now part of Eurocopter). A best-seller in both

domestic and overseas markets, this helicopter is used

in fre fghting, fying medical services and many other

applications.

Japanese companies are currently participating in the following multinational development projects.

BA609 (Bell / Agusta)

Participation in design and development of the

fuselage (RSP)

The worlds frst civil, tail-rotor helicopter

MD902 (MD Helicopter) Production of the transmission

BK117C-2 (Kawasaki Heavy Industries, Ltd.)

S-92

The Sikorsky S-92 is a 19-seat, double-engine, large

helicopter developed in an international collaboration

project led by Sikorsky Aircraft Corporation of the

United States. Japan, China, Spain, Brazil and Taiwan

are part of the project. Dubbed the Helibus, the aircraft

is used for commuting and offshore oil development.

S-92 (Mitsubishi Heavy Industries, Ltd.)

12 13

2. Defense Engines

Regarding the Ministr y of Defense, both the F3-

IHI-30 turbofan engine and the TS1-M-10 turbo shaft

engine that were developed in Japan are used in the

T-4 intermediate jet trainer and the OH-1 observation

helicopter respectively. Research and development

ef forts on the XF5-1 demonstration engine, an after-

burning fan engine with a low bypass ratio and capable

of 5,000 kg of thrust with a thrust weight ratio of 8, have

made this engine rival any of the advanced engines in

the US and Europe. Furthermore, the F7-IHI-10 fan

engine, with a bypass ratio of between 8 and 9, has

been selected for use in the Fixed-Wing Maritime

Patrol Aircraft P-1. The engine is being mounted on the

aircraft.

F7 (IHI CO.) F3-30 Engine (IHI CO.)

International Joint Development for Civil Aircraft Engine

Engine Aircraft Components developed Level of participation

TRENT1000 B787

Mid-pressure modules, combustor modules,

low-pressure turbine vanes

RSP 16%

GEnx B787

Low-pressure turbines, high-pressure

compressors, shafts and combustor cases

RSP 15% and

subcontract

TRENT900 A380

Low-pressure turbines vanes, mid-pressure

compressor cases

Subcontract

TRENT500 A340

Mid- & low-pressure turbine vanes,

compressor cases, turbine cases, etc.

RSP 20%

CF34-8/10

CRJ700/900,

EMBRAER170/190,

ARJ21

Low-pressure turbine module, high-

pressure compressor rear stages, fan

rotors, gearboxes, etc.

RSP 30%

PW4000 A310/330/340

Low-pressure turbine vanes, disk,

combustor, active clearance control, etc.

RSP 11% and

subcontract

GE90 B777

Low-pressure turbine rotor vanes disks,

long shafts, etc.

RSP 10%

TRENT700/800 A330, B777

Low-pressure turbine vanes, disks, long

shafts, low-pressure turbine disks, turbine

cases, etc.

RSP 8 to 9%

V2500 A320, MD90

Fans, low-pressure compressors, fan

cases, etc.

Program partner 23%

Ai r c r af t Engi nes

For the development of civil aircraft engines, Japan plays key roles in international joint

development projects for such engines as the CF-34, TRENT 1000, GEnx, etc.

For the development of both defense and civil engine, several national projects are underway with

the focus on developing advanced technology applications.

1. Civil Engines

Engine development requires an enormous amount

of t i me, money and i ncr easi ng ri sks of bei ng

outperformed against growth requirements. Because

of such difficulties for any single company to endure,

these projects very often become international joint

development projects.

Since the participation in the V2500, we have continued

to be involved in and a key player in these international

collaborative projects, like the GE90, PW4000, TRENT

series and CF-34.

The status of participation has grown: In V2500 - design

of the fan, and in GE90, PW4000, CF34-8 and CF34-10

extended to compressor, combustor, turbine, and

in TRENT series, including design of FADEC (Full

Authority Digital Electronics Control).

Japans technical expertise has been implemented in

almost every area of the engine. Japanese companies

play an important role in the global joint development

of the TRENT 1000, GEnx and other engines for the

B787. Independent research and development of civil

engines within Japan began in 197l with the FJR710, and

an R&D project for environmental compliance engines

for small-sized aircraft started in 2003. With the project

for environmental compliance small-sized aircraft,

participation grows a great deal in R&D projects for both

the fuselage and engine.

TRENT 1000 (Rolls-Royce) Artists Rendition of GEnx (GE)

Artists Rendition of TRENT XWB (Rolls-Royce)

12 13

2. Defense Engines

Regarding the Ministr y of Defense, both the F3-

IHI-30 turbofan engine and the TS1-M-10 turbo shaft

engine that were developed in Japan are used in the

T-4 intermediate jet trainer and the OH-1 observation

helicopter respectively. Research and development

ef forts on the XF5-1 demonstration engine, an after-

burning fan engine with a low bypass ratio and capable

of 5,000 kg of thrust with a thrust weight ratio of 8, have

made this engine rival any of the advanced engines in

the US and Europe. Furthermore, the F7-IHI-10 fan

engine, with a bypass ratio of between 8 and 9, has

been selected for use in the Fixed-Wing Maritime

Patrol Aircraft P-1. The engine is being mounted on the

aircraft.

F7 (IHI CO.) F3-30 Engine (IHI CO.)

International Joint Development for Civil Aircraft Engine

Engine Aircraft Components developed Level of participation

TRENT1000 B787

Mid-pressure modules, combustor modules,

low-pressure turbine vanes

RSP 16%

GEnx B787

Low-pressure turbines, high-pressure

compressors, shafts and combustor cases

RSP 15% and

subcontract

TRENT900 A380

Low-pressure turbines vanes, mid-pressure

compressor cases

Subcontract

TRENT500 A340

Mid- & low-pressure turbine vanes,

compressor cases, turbine cases, etc.

RSP 20%

CF34-8/10

CRJ700/900,

EMBRAER170/190,

ARJ21

Low-pressure turbine module, high-

pressure compressor rear stages, fan

rotors, gearboxes, etc.

RSP 30%

PW4000 A310/330/340

Low-pressure turbine vanes, disk,

combustor, active clearance control, etc.

RSP 11% and

subcontract

GE90 B777

Low-pressure turbine rotor vanes disks,

long shafts, etc.

RSP 10%

TRENT700/800 A330, B777

Low-pressure turbine vanes, disks, long

shafts, low-pressure turbine disks, turbine

cases, etc.

RSP 8 to 9%

V2500 A320, MD90

Fans, low-pressure compressors, fan

cases, etc.

Program partner 23%

Ai r c r af t Engi nes

For the development of civil aircraft engines, Japan plays key roles in international joint

development projects for such engines as the CF-34, TRENT 1000, GEnx, etc.

For the development of both defense and civil engine, several national projects are underway with

the focus on developing advanced technology applications.

1. Civil Engines

Engine development requires an enormous amount

of t i me, money and i ncr easi ng ri sks of bei ng

outperformed against growth requirements. Because

of such difficulties for any single company to endure,

these projects very often become international joint

development projects.

Since the participation in the V2500, we have continued

to be involved in and a key player in these international

collaborative projects, like the GE90, PW4000, TRENT

series and CF-34.

The status of participation has grown: In V2500 - design

of the fan, and in GE90, PW4000, CF34-8 and CF34-10

extended to compressor, combustor, turbine, and

in TRENT series, including design of FADEC (Full

Authority Digital Electronics Control).

Japans technical expertise has been implemented in

almost every area of the engine. Japanese companies

play an important role in the global joint development

of the TRENT 1000, GEnx and other engines for the

B787. Independent research and development of civil

engines within Japan began in 197l with the FJR710, and

an R&D project for environmental compliance engines

for small-sized aircraft started in 2003. With the project

for environmental compliance small-sized aircraft,

participation grows a great deal in R&D projects for both

the fuselage and engine.

TRENT 1000 (Rolls-Royce) Artists Rendition of GEnx (GE)

Artists Rendition of TRENT XWB (Rolls-Royce)

14 15

(2) Navigation Systems

Navigation systems locate the exact position of aircraft

in flight and direct them to their destinations safely,

quickly and without fail. Japanese manufacturers

produce inertial navigation systems and GPS receivers.

(3) Flight Deck Systems

A fight deck system consists of fight instrumentation,

attitude displays and audio and visual warning systems.

Installed in a cockpit, the system is operated by pilots.

Japanese makers supply liquid crystal displays for the

Next-Generation Flight Deck Systems for the B787 and

A380.

4. Power Supply Systems

Power supply systems for todays aircraft require high

voltage and large capacity to meet diversifying needs

and to keep pace with technological advancement in the

industry. Japanese manufacturers have teamed up with

Hamilton Sundstrand to develop power distribution units

for the B787.

5. Landing Gear Systems

The landing gear systems for the Bombardier CRJ700

and CRJ900 have been jointly developed by Japanese

manufacturers and Goodrich. Japanese manufacturers

also supply radial tires for the B777, B787 and A380.

6. Other Systems

Japanese compani es are cur rentl y acti ve i n the

development and production of simulators.

Landing Gear (Sumitomo Precision Products Co., Ltd.)

Flight Conrol Hydraulic System (Nabtesco Corporation)

Japans Hi ghl y Rel i abl e Ai r c r af t Equi pment

Along with the fuselage structure, a wide range of reliable equipment is required for the

construction of an aircraft. In defense applications, Japanese manufacturers provide radar

systems, digital control systems and other products, all of which make use of advanced

technologies. For civil use, Japanese products, which are highly reliable in quality and delivery,

have been well received by overseas OEM and customers. To participate in the international

development project for the B777, Japans parts manufacturers, competing with overseas

manufacturers, have taken orders for actuators, valves and many other types of equipment.

1. Hydraulic Systems

Hydraulic systems are used in flight controls, high-lift

devices and landing gear for remote control operations.

Japanese manufacturers supply B777 electronic flight

control actuation systems, flap drive systems for the

B747-8 and fight control actuation systems.

Head-up Display (Shimadzu Corporation)

2. Cabin Pressure and

Air Conditioning Systems

Cabin pressure and air conditioning systems protect

passengers, crews and on-board equipment from

changes in cabin pressure and temperature, and enable

safe and comfortable fights. The cabin pressure and air

conditioning systems for the Embraer 170 regional jet

have been jointly developed by Japanese manufacturers

and Hamilton Sundstrand.

3. Avionics and

Flight Control Systems

(1) Flight Systems

Modern aircraft deploy flight controls based on active

control technology and a flight management system

that uses advanced electronics. The mainstream flight

control system is an electrically signaled control system

called fly-by-wire. In Japan, the P-1 Next-Generation

Fixed-Wing Maritime Patrol Aircraft has been equipped

with an optically signaled control system called fly-by-

light.

Aerospace Instruments (Yokogawa Electric Corporation)

Cockpit Display(Yokogawa Electric Corporation) Flap Drive System (Shimadzu Corporation) Air Conditioning System (Sumitomo Precision Products/Hamilton Sundstrand)

14 15

(2) Navigation Systems

Navigation systems locate the exact position of aircraft

in flight and direct them to their destinations safely,

quickly and without fail. Japanese manufacturers

produce inertial navigation systems and GPS receivers.

(3) Flight Deck Systems

A fight deck system consists of fight instrumentation,

attitude displays and audio and visual warning systems.

Installed in a cockpit, the system is operated by pilots.

Japanese makers supply liquid crystal displays for the

Next-Generation Flight Deck Systems for the B787 and

A380.

4. Power Supply Systems

Power supply systems for todays aircraft require high

voltage and large capacity to meet diversifying needs

and to keep pace with technological advancement in the

industry. Japanese manufacturers have teamed up with

Hamilton Sundstrand to develop power distribution units

for the B787.

5. Landing Gear Systems

The landing gear systems for the Bombardier CRJ700

and CRJ900 have been jointly developed by Japanese

manufacturers and Goodrich. Japanese manufacturers

also supply radial tires for the B777, B787 and A380.

6. Other Systems

Japanese compani es are cur rentl y acti ve i n the

development and production of simulators.

Landing Gear (Sumitomo Precision Products Co., Ltd.)

Flight Conrol Hydraulic System (Nabtesco Corporation)

J apans Hi ghl y Rel i abl e Ai r c r af t Equi pment

Along with the fuselage structure, a wide range of reliable equipment is required for the

construction of an aircraft. In defense applications, Japanese manufacturers provide radar

systems, digital control systems and other products, all of which make use of advanced

technologies. For civil use, Japanese products, which are highly reliable in quality and delivery,

have been well received by overseas OEM and customers. To participate in the international

development project for the B777, Japans parts manufacturers, competing with overseas

manufacturers, have taken orders for actuators, valves and many other types of equipment.

1. Hydraulic Systems

Hydraulic systems are used in flight controls, high-lift

devices and landing gear for remote control operations.

Japanese manufacturers supply B777 electronic flight

control actuation systems, flap drive systems for the

B747-8 and fight control actuation systems.

Head-up Display (Shimadzu Corporation)

2. Cabin Pressure and

Air Conditioning Systems

Cabin pressure and air conditioning systems protect

passengers, crews and on-board equipment from

changes in cabin pressure and temperature, and enable

safe and comfortable fights. The cabin pressure and air

conditioning systems for the Embraer 170 regional jet

have been jointly developed by Japanese manufacturers

and Hamilton Sundstrand.

3. Avionics and

Flight Control Systems

(1) Flight Systems

Modern aircraft deploy flight controls based on active

control technology and a flight management system

that uses advanced electronics. The mainstream flight

control system is an electrically signaled control system

called fly-by-wire. In Japan, the P-1 Next-Generation

Fixed-Wing Maritime Patrol Aircraft has been equipped

with an optically signaled control system called fly-by-

light.

Aerospace Instruments (Yokogawa Electric Corporation)

Cockpit Display(Yokogawa Electric Corporation) Flap Drive System (Shimadzu Corporation) Air Conditioning System (Sumitomo Precision Products/Hamilton Sundstrand)

16 17

Advanc ed Ai r c r af t Mat er i al s

Composite materials, such as carbon fber reinforced plastic (CFRP) in particular, are expanding

and are becoming widely used.

JAPAN accounts for 70% of the world carbon fber products for CFRP and supplies main wings

and center wing box etc. for B787, which consists of 50% of composite materials.

Titan alloys are also expanding and are becoming widely used following back of the composite

materials, which is used for jet engine components, such as fan casing and turbine blade.

These components are manufactured with the Japanese excellent precision forging and casting

technologies.

The Mitsubishi Regional Jet is under development fully utilizing these advanced aircraft materials.

Carbon Fiber Materials (Toray Industries) Carbon Fiber Materials (Toray Industries)

V2500 Turbofan Engine

V2500 Fan Case (KOBELCO)

Cabi n and I nt er i or Syst ems f or I n-Fl i ght Comf or t

In the field of cabin and interior systems, Japanese manufacturers respond to customer

requirements and apply the latest technologies in the development of the worlds best products.

Japanese manufacturers of products, such as galleys, lavatories, aircraft seats and in-fight AV

systems that optimally match the passengers needs, have an excellent reputation with a large

worldwide market share. Japanese manufacturers can continue to lead the world in terms of

technical achievements for cabin and interior systems.

Aircraft Lavatory (JAMCO Corporation) Aircraft Galley (JAMCO Corporation)

MRJ Interior Mock-up (Mitsubishi Aircraft Corporation)

The composite main spar of the vertical stabilizer for MRJ (actual size test

component) (Mitsubishi Aircraft Corporation)

16 17

Advanc ed Ai r c r af t Mat er i al s

Composite materials, such as carbon fber reinforced plastic (CFRP) in particular, are expanding

and are becoming widely used.

JAPAN accounts for 70% of the world carbon fber products for CFRP and supplies main wings

and center wing box etc. for B787, which consists of 50% of composite materials.

Titan alloys are also expanding and are becoming widely used following back of the composite

materials, which is used for jet engine components, such as fan casing and turbine blade.

These components are manufactured with the Japanese excellent precision forging and casting

technologies.

The Mitsubishi Regional Jet is under development fully utilizing these advanced aircraft materials.

Carbon Fiber Materials (Toray Industries) Carbon Fiber Materials (Toray Industries)

V2500 Turbofan Engine

V2500 Fan Case (KOBELCO)

Cabi n and I nt er i or Syst ems f or I n-Fl i ght Comf or t

In the field of cabin and interior systems, Japanese manufacturers respond to customer

requirements and apply the latest technologies in the development of the worlds best products.

Japanese manufacturers of products, such as galleys, lavatories, aircraft seats and in-fight AV

systems that optimally match the passengers needs, have an excellent reputation with a large

worldwide market share. Japanese manufacturers can continue to lead the world in terms of

technical achievements for cabin and interior systems.

Aircraft Lavatory (JAMCO Corporation) Aircraft Galley (JAMCO Corporation)

MRJ Interior Mock-up (Mitsubishi Aircraft Corporation)

The composite main spar of the vertical stabilizer for MRJ (actual size test

component) (Mitsubishi Aircraft Corporation)

18 19

2. Solid Propellant Rockets

Space of fers mankind the opportunity of unlimited

adventure and knowledge. Japan has developed the

world maximum class M- solid propellant rocket as a

transportation means to support research in the feld of

space science, and this vehicle has achieved success on

a global scale through the launch of solar observation

satellites, astronomical obser vation satellites, etc.

Development of Epsilon Launch Vehicle as a successor

to the M- is currently underway.

3. Launch and Control Facilities

Satellite tracking, command and control in Japan are

carried out at three communication centers and three

tracking centers, the most important of which are the

launch facilities at the Tanegashima Space Center

and the Tsukuba Space Center. Furthermore, these

installations represent a complete system for the launch,

command and control of satellites.

Launching of H-B NO.2 (JAXA)

Tanegashima Space Center Launch Control Room (JAXA)

Tanegashima Space Center (JAXA)

J apanese Spac e I ndust r y

Wor l d-Cl ass Roc ket s

Japan is currently developing a range of different launch vehicles is order to facilitate the

independent development and utilization of space.

Currently, JAPAN operates the H-A, which rivals any of the worlds top-class liquid propellant

rockets, and the M-V, which ranks among the worlds largest solid propellant rockets.

Japans 1st space experiment was conducted in 1955

with the testing of a 20-cm pencil rocket. Since then, we

have fully applied our technical strengths, and this effort

has allowed Japan to take its place among the worlds

leading space-exploration nations.

1. Liquid Propellant Rockets

In 1975, Japan successfully launched the N-with

the assistance of the United States. Following this,

development of the N- and H-was advanced with

the aim of improving both performance and the level

of domestic production; accordingly, 1994 saw the

successful launch of the H- a launch vehicle that was

produced completely in Japan. Using liquid hydrogen as

fuel and liquid oxygen as an oxidizing agent, this rocket

s engine offered extremely high levels of performance.

In 2001,the Japanese H-A was successfully launched,

and in the process, it became this countr ys main

launch vehicle. This rocket was developed by the Japan

Aerospace Exploration Agency (JAXA), and the launch

business were transferred to private companies in 2007.

It is expected that the reliability and cost factors will

improve so that thus allowing Japan to continue to be

active on the global stage.

The first H-B, an upgraded version of the H-A was

successfully launched in September 2009 with the H-

transfer vehicle designed to support the transportation of

supplies to the International Space Station. The second

H-B was also successfully launched in January 2011.

Artists Rendition of Epsilon Launch Vehicle (JAXA)

Principal Japanese Launch Vehicles

No. Specifcations H-A H-B M-

1 Length 53m 57m 30.8m

2 Diameter 4.0m 5.2m 2.5m

3 Gross weight 289t 531t 137.5t

4 LEO launch capability 10t 16.5t 1.85t

5 GTO launch capability 4.0t 9t

Gross weight: Not include payload weights

LEO: Low earth orbit

GTO: Geostationary transfer orbit

18 19

2. Solid Propellant Rockets

Space of fers mankind the opportunity of unlimited

adventure and knowledge. Japan has developed the

world maximum class M- solid propellant rocket as a

transportation means to support research in the feld of

space science, and this vehicle has achieved success on

a global scale through the launch of solar observation

satellites, astronomical obser vation satellites, etc.

Development of Epsilon Launch Vehicle as a successor

to the M- is currently underway.

3. Launch and Control Facilities

Satellite tracking, command and control in Japan are

carried out at three communication centers and three

tracking centers, the most important of which are the

launch facilities at the Tanegashima Space Center

and the Tsukuba Space Center. Furthermore, these

installations represent a complete system for the launch,

command and control of satellites.

Launching of H-B NO.2 (JAXA)

Tanegashima Space Center Launch Control Room (JAXA)

Tanegashima Space Center (JAXA)

Japanese Spac e I ndust r y

Wor l d-Cl ass Roc ket s

Japan is currently developing a range of different launch vehicles is order to facilitate the

independent development and utilization of space.

Currently, JAPAN operates the H-A, which rivals any of the worlds top-class liquid propellant

rockets, and the M-V, which ranks among the worlds largest solid propellant rockets.

Japans 1st space experiment was conducted in 1955

with the testing of a 20-cm pencil rocket. Since then, we

have fully applied our technical strengths, and this effort

has allowed Japan to take its place among the worlds

leading space-exploration nations.

1. Liquid Propellant Rockets

In 1975, Japan successfully launched the N-with

the assistance of the United States. Following this,

development of the N- and H-was advanced with

the aim of improving both performance and the level

of domestic production; accordingly, 1994 saw the

successful launch of the H- a launch vehicle that was

produced completely in Japan. Using liquid hydrogen as

fuel and liquid oxygen as an oxidizing agent, this rocket

s engine offered extremely high levels of performance.

In 2001,the Japanese H-A was successfully launched,

and in the process, it became this countr ys main

launch vehicle. This rocket was developed by the Japan

Aerospace Exploration Agency (JAXA), and the launch

business were transferred to private companies in 2007.

It is expected that the reliability and cost factors will

improve so that thus allowing Japan to continue to be

active on the global stage.

The first H-B, an upgraded version of the H-A was

successfully launched in September 2009 with the H-

transfer vehicle designed to support the transportation of

supplies to the International Space Station. The second

H-B was also successfully launched in January 2011.

Artists Rendition of Epsilon Launch Vehicle (JAXA)

Principal Japanese Launch Vehicles

No. Specifcations H-A H-B M-

1 Length 53m 57m 30.8m

2 Diameter 4.0m 5.2m 2.5m

3 Gross weight 289t 531t 137.5t

4 LEO launch capability 10t 16.5t 1.85t

5 GTO launch capability 4.0t 9t

Gross weight: Not include payload weights

LEO: Low earth orbit

GTO: Geostationary transfer orbit

20 21

4. Remote Sensing

The importance of remote sensing missions such as

global observation and resource surveying is expected

to become ever more important. In terms of the latter,

the monitoring of global surface temperature, heat

radiation and other characteristics is carried out by

the Advanced Spaceborne Thermal Emission and

Reflection Radiometer (ASTER) flying on NASA s

Terra Satellite, and this imaging instrument has been

providing extremely valuable data since 2000. As

part of multinational monitoring activities for global

climate change, the Advanced Land Observing Satellite

"DAICHI" (ALOS) was launched in January 2006, The

Satellite equipped with the sensor PALSAR etc. which

have been widely used for mapping, global observation,

determining the status of disasters, etc.

The Greenhouse Gases Observing Satellite "IBUKI"

(GOSAT) lifted off in January 2009. It is monitoring the

distribution of carbon dioxide and methane, which are

considered greenhouse gases.

5. Other Projects

Japan is also actively involved in ef forts related to

satellites for the observation of astronomical bodies

and the verification of various technologies. In l995,

the Space-Flyer Unit (SFU) carried out a host of

measurements and experiments in space before being

recovered by a Japanese astronaut riding on the Space

Shuttle. The Selenological and Engineering Explorer

"KAGUYA" (SELENE) was launched in September 2007.

It is part of the largest lunar mission since the Apollo

Program. The explorer was put in regular operation

in October of that year. It ended its mission in June

2009 after completing 15 obser vation missions. The

Asteroid Explorer "HAYABUSA"(MUSES-C) launched

in May 2003 successfully landed on Itokawa asteroid in

November 2005 and came back to Earth in June 2010

after travelling over 6 billion kilometers. It ended its

mission with a brilliant achievement after releasing the

capsule containing the asteroid surface sample.

Rising Earth from "KAGUYA" (SELENE) (JAXA / NHK)

Fuji at Night (PALSAR) (METI / JAXA)

"HAYABUSA" Capsule heat Shield (JAXA)

Sat el l i t e Devel opment

The most imperative usage of space is to assure national security, social peace and activities. In

1970, Japan launched its frst satellite, Oosumi, becoming the fourth spacefaring nation to launch

a domestically manufactured satellite using a rocket of her own. Then in 1977, Japan successfully

launched a geosynchronous orbit satellite. With technical capabilities rating among the best in the

world, Japan is currently involved in the development and production of satellite systems, onboard

sensors and components.

1. Weather Satellites

The frst satellite launched for practical use by Japan was

the Himawari weather satellite of l977. Following this, a

total of four weather satellites were put into operation,

allowing valuable weather-related information to be

supplied domestically and throughout the Asian region.

Furthermore, projects have launched Multi-Purpose

Transportation Satellites (MTSAT) as successors to

these earlier satellites for weather monitoring and air-

traffc control.

MTSAT No.1 and 2 were launched in February 2005 and

February 2006, and they are currently in operation.

2.Communication & Broadcasting Satellites

In addition to launching its Sakura series of satellites

for communication and its Yuri series for broadcasting,

Japan has also developed the technologies required to

make practical use of these satellites capabilities. As a

result of the delivered benefts, Japan has also established

technologies for satellite communication and broadcasting;

furthermore, we currently supply satellite systems to

overseas operators of communication systems. Satellites

made in foreign countries used to dominate the Japanese

market, however successes like the receipt of orders for

the Superbird 7 satellite, which is made by a Japanese

company, help to advance Japans competitiveness in

the international market. Currently, the Wideband

InterNetworking engineering test and Demonstration

Satellite "KIZUNA" (WINDS) is being operated. It

performs essential technical demonstrations in order to

speed up and enlarge the capacity of information networks.

Also, Verifying Tests are underway on the Engineering

Test Satellite "KIKU No. 8" (ETS-), which is equipped

with a large deployable antenna in order to achieve high-

speed mobile communication technology.

3. Quasi-Zenith Satellite Systems

Positioning information as presented by vehicle

navigation systems is currently being put to practical

use in a wide range of social fields, and the range of

this usage is expected to increase even further over the

coming years. The Quasi-Zenith Satellite-1 "MICHIBIKI"

was launched in September 2010 and the verifying tests

are underway.

Quasi-Zenith Satellite-1 " MICHIBIKI" (JAXA) Greenhouse gases Observing Satellite "IBUKI" (GOSAT) (JAXA)

"HAYABUSA" (Sample catching) Image CG (JAXA)

20 21

4. Remote Sensing

The importance of remote sensing missions such as

global observation and resource surveying is expected

to become ever more important. In terms of the latter,

the monitoring of global surface temperature, heat

radiation and other characteristics is carried out by

the Advanced Spaceborne Thermal Emission and

Reflection Radiometer (ASTER) flying on NASA s

Terra Satellite, and this imaging instrument has been

providing extremely valuable data since 2000. As

part of multinational monitoring activities for global