Professional Documents

Culture Documents

Torsional Resistance of High-Strength Concrete Beams

Uploaded by

Mohammad ImranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torsional Resistance of High-Strength Concrete Beams

Uploaded by

Mohammad ImranCopyright:

Available Formats

Torsional resistance of high-strength concrete beams

T. Hossain & P. Mendis

University of Melbourne, Victoria, Australia

T. Aravinthan & G. Baker

University of Southern Queensland, Queensland, Australia

ABSTRACT: This paper aims to explore theoretical models for evaluating the torsional behaviour of reinforced concrete beams. This paper aims to explore theoretical models for evaluating the torsional behaviour of reinforced concrete beams. The paper investigates the applicability and extension of existing analytical models and constitutive relationships developed for normal strength concrete to high-strength concrete. The verification models include the space truss model, skew-bending theory and softening truss model theory. The paper presents an assessment of the present Australian Standard AS3600 for the torsional capacity of highstrength reinforced concrete beams in order to make suggestions on how to extend the code to cover the HSC range. Recommendations for the torsional design of HSC beams based on lattice model are also presented.

1 INTRODUCTION In recent years, many theories have been developed for calculating the torsional strengths of members with both longitudinal steel and stirrups. The most recognized theoretical models are the space truss model and the skew-bending theory. It is found that the skew-bending theory overestimates the cracking strength of the torsion of RC beams by considering the contribution of concrete (Fang & Shiau 2004). Collins & Mitchell (1974, 1980) extended the truss model to include the capacity of concrete and the orientation of the compression concrete members, and named this the diagonal compression field theory. One key assumption of their theory was that for a solid section subjected to torsion, the concrete core does not contribute to the torsional resistance. Accordingly, this model does not consider the advantage of the use of HSC. Hsu & Mo (1985) further developed the space truss model to the softened truss model, which accounts for the softening of the cracked concrete. For a low-strength concrete, their model gives a good description of the ascending branch and the first part of the descending branch of the uniaxial stress-strain curve (Rasmussen & Baker 1995b). However, the uniaxial stressstrain curve for concrete changes dramatically when comparing a NSC to a HSC. Hence, it is not obvious that the model can be extrapolated from NSC to the HSC range. Similarly, aggregate interlock is not included in any of these above models, which is a very important phenomenon in HSC. This is because

high-strength concretes are much more brittle than normal strength concretes, with less load carrying capacity once the peak load is reached. Due to the similarity of the strengths in aggregates and that of the surrounding concrete, the failure surfaces are smooth and devoid of aggregate interlock, which reduces the shear resistance in the case of HSC (Attard & Mendis 1993). While HSC has been recently and increasingly used in bridges and buildings, the available theoretical models regarding the behaviour and design code provisions of torsion in AS3600-2001 are primarily based on limited experimental work on low strength concrete beams. Therefore, more work is required to safeguard the related designs when the available information is extrapolated to the design of torsional members made of higher strength concrete. Verification of the applicability of the available theoretical models to higher-strength concrete is also required. Following reviews of the three theoretical models, consisting of skew-bending theory, space truss model, and softening truss model, and other experimental works on pure torsion of reinforced concrete beams, this paper presents an assessment of the present AS3600 for the torsional design of members made of higher-strength concrete. An advanced method of analysis based on the lattice model will also be discussed in this paper. The technique has been successfully applied for both normal and highstrength concrete beams subjected to shear, and can inherently take into account some major influential factors; the reduced aggregate interlocking shear

transfer mechanism in HSC; the softening of concrete in compression; tension; and shear. 2 REVIEW OF THEORETICAL MODELS 2.1 Skew-bending theory The skew-bending theory was initially proposed by Lessig in 1958 (1959), and had subsequent contributions from several researchers in the field. Hsu (1968) made a major contribution to the development of this theory as it presently stands. He presented the expressions for evaluating the torsional strength of rectangular sections according to the PCA tests. The basic approach of the skew-bending theory is that the failure of a rectangular section in torsion occurs by bending about an axis which is parallel to the wider face of the section and inclined at about 45 to the longitudinal axis of the beam. The torsional strength of reinforced concrete members is contributed to by both concrete, Tc and torsional reinforcement, Ts. But, from the PCA tests by Hsu (1968) on hollow and solid rectangular beams, it was observed that the concrete core does not contribute to the ultimate torsional strength. Later he concluded that the concrete contribution Tc was mainly due to the shear resistance of the diagonal concrete struts. Based on this approach, the torsional resistance proposed by Hsu (1979) includes the contribution of shear resistance of diagonal concrete struts, axial forces of stirrups, and the dowel forces of the longitudinal bars, and can be evaluated as follows: x1 y1 At f sy Tn = Tc + t (1) s where Tc = x2 y 2.4 f c (in lb-in.) 3

2.2 Space truss model with spalling of concrete cover The most recognized theoretical mode of pure torsion in reinforced concrete is the space truss model, which was first developed by Rausch (1929), and consists of diagonal struts in the concrete restrained by tension in the stirrup and longitudinal reinforcement. After the cracking of a reinforced concrete member subjected to pure torsion, the diagonal cracks separate the concrete into a series of concrete struts. In the space truss model the torsion is resisted by compression diagonals, which consist of the concrete between cracks that spiral around the beam at a constant angle. Based on an assumed strain distribution in the beam, Collins & Mitchell (1974, 1980) extended the truss model and developed a theory to describe the torque-twist response. Mitchell & Collins (1974) observed that the increase in the thickness of the concrete cover caused spalling and a reduction in the torsional strength. According to this assumption of concrete cover spalling, the ultimate torsional capacity of the member is based on the strength of the spalled section. In their theory, based on the knowledge of the uni-axial stress-strain curve, a parabolic stress-strain curve of the concrete was given by the following equation: 2 f c = f c2 c c (2) 0 0 where fc = stress in concrete corresponding to the strain c f'c = compressive strength of concrete c = strain in diagonal concrete struts 0 = strain at maximum concrete compressive stress The detailed derivation of the equations and the solution technique for the ultimate torsional capacity can be found elsewhere (Mitchell and Collins 1974). 2.3 Softening truss model The softening truss model, developed by Hsu & Mo (1985), is similar to the space truss model described above, except that it utilizes the full concrete cross-section and takes the softening of the concrete into consideration. The softening of concrete is based on an assumed effective transverse compressive stress component, which is used to predict the torsional behaviour of reinforced concrete. The model was developed according to the fundamental principles of the mechanics of materials, stress equilibrium, strain compatibility, and the constitutive law of materials. In this model, the constitutive law of materials is given in terms of the stress-strain curve of the softened concrete shown in Figure 1. The equation for the ascending portion of the stressstrain curve of normal-strength concrete is modelled as:

t = m

f ly y 1 + 0.2 1 1.6 f sy x1

x1 = shorter centre-to-centre dimension of closed stirrup; y1 = longer centre-to-centre dimension of closed stirrup At = area of one leg of a torsional closed stirrup s = spacing of stirrups fly = yield strength of longitudinal bars fsy = yield strength of closed stirrups m = ratio of volume of longitudinal bars to volume of stirrups Al s = 2 At ( x1 + y1 )

Al = cross-sectional area of longitudinal bars within the shear-compression zone

f c = f c2 c o

1 c o

(3)

where fc = average compressive stress in the diagonal concrete struts c = compressive strain in the diagonal concrete struts o = strain at maximum stress of non-softened concrete taken as 0.002 for NSC 1 = softening coefficient = l + s + 2 d 0.3

cording to the torsion provision of AS3600, the ultimate strength of a reinforced concrete beam is derived from the thin-walled tube analogy, assuming it is directly proportional to the amount of reinforcement as follows: As f ys T p = 2 Ao cot 0.08 f'c b2 h (5) s where Ao = area enclosed by shear flow path = xoyo As = area of one leg of closed stirrup fys = yield strength of closed transverse torsional reinforcement s = spacing of stirrup = angle of compression diagonals b, h = smaller and larger outer dimensions of the cross-section respectively xo, yo = horizontal and vertical distance between the centre line of the longitudinal corner bars respectively Thus the concrete contribution is ignored after torsional cracking in AS3600, which makes no distinction between the behaviour of normal and highstrength concretes; i.e., there is no advantage in using higher concrete strengths in resisting ultimate torsion. 4 REVIEW OF PAST WORK ON TORSION OF RC BEAMS

l = strain in ordinary longitudinal steel s = strain in stirrups The equation of the descending portion of the stress-strain curve is given as: 2 k f c = f k 1 c (4) 2 o k where fk = f'c = peak softened compressive strength k = o = softened strain corresponding to peak softened compressive strength fc

Equation 3 Equation 4

Figure 1. Stress-strain curve for softened concrete

The torque is obtained from equilibrium equations. The detailed derivation of the equations and the solution technique for the ultimate torsional capacity can be found elsewhere (Hsu & Mo 1985, Hsu 1988). 3 AS3600-2001 TORSION DESIGN CRITERIA The design of reinforced concrete beams subjected to pure torsion according to the AS3600 is based on the space truss model, and does not operate with a variable wall-thickness dependent on the concrete strength and the degree of reinforcement. Ac-

In the past, there have been some investigations conducted which study the behaviour of RC beams under pure torsion. Reid & Bridge (1990) have carried out theoretical and experimental investigations to assess the behaviour of pre-stressed concrete edge beams heavily loaded in shear and torsion. Their theoretical investigation indicated that torsion would greatly reduce the load-carrying capacity of the beams, and the combined torsion and shear would result in brittle failures. The effect of concrete compressive strength on the torsional behaviour of reinforced concrete beams was investigated by Rasmussen & Baker (1994, 1995a, 1995b). The results of that investigation showed a significant effect of concrete strength on crack width, torsional stiffness, and torsional capacity of the test beams. Koutchoukali & Belarbi (2001) studied the effect of high-strength concrete on the torsional behaviour of RC beams under pure torsion. They found from their study that the torsional capacity of under-reinforced beams is independent of concrete strength, and the amount of longitudinal reinforcement was more effective in controlling crack width than the amount of transverse reinforcement. Fang & Shiau (2004) experimentally studied the torsional behaviour of normal and high-strength concrete beams under pure torsion. Their test results showed that the HSC beams had higher torsional strength and cracked stiffness

than the NSC beams which were designed with the same amount of reinforcement. Results of several investigations on the torsional behaviour of normalstrength concrete beams have also been reported (Hsu 1968; Mitchell & Collins 1974; Hsu & Mo 1985). However, no rational method to incorporate the concrete contribution to ultimate torsional strength is proposed in these past works. 5 PARAMETRIC STUDY ON PURE TORSION To examine the applicability of the three theoretical models for high-strength concrete, the experiments carried out by Rasmussen & Baker (1995a) and Fang & Shiau (2004) were analyzed. The test specimens were of solid rectangular beams failing in pure torsion, and represent all possible reinforcement situations and a significant variation in geo-

metric and material parameters. Their experimental results are considered in the correlation between the test and the predicted torsional capacity from the theoretical models, and the effect of concrete strength on ultimate torsional strength. Table 1, Figure 2 and Figure 3 compare the experimental results with the predicted torsional strength of the tested beams from the literature, using the aforementioned theories. On the basis of observations and results reported in this paper, it can be seen from Figure 2 and Figure 3 that AS 3600 always overestimates the experimental torsional capacity. Due to the spalling of the concrete cover, the area enclosed by the centre line of the thickness reduces, resulting in a reduced torsional capacity of the section. But the present AS3600 does not operate with this variable wall thickness, which may result in an unconservative

Table 1. Comparison of experimental and calculated torsional strength Beam fc MPa B30.1 B30.2 B30.3 B50.1 B50.2 B50.3 B70.1 B70.2 B70.3 B110.1 B110.2 B110.3 H06-06 H06-12 H12-12 H12-16 H20-20 H07-10 H14-10 H07-16 N06-06 N06-12 N12-12 N12-16 N20-20 N07-10 N14-10 N07-16 41.7 38.2 36.3 61.8 57.1 61.7 77.3 76.9 76.2 109.8 105.0 105.1 l % t % Tu(cal)/Tu(exp) AS SkewSpace bending 3600 truss kN-m theory model Rasmussen & Baker (1995a) 16.62 1.32 1.76 1.32 15.29 1.37 1.91 1.23 15.25 1.33 1.92 1.01 19.95 1.33 1.50 0.89 18.46 1.39 1.61 1.12 19.13 1.38 1.56 0.88 20.06 1.40 1.50 1.14 20.74 1.35 1.44 1.10 20.96 1.35 1.44 1.07 24.72 1.24 1.24 0.94 23.62 1.30 1.30 0.96 24.77 1.23 1.24 0.98 Tu(exp) Fang & Shiau (2004) 92.0 1.25 115.1 1.01 155.3 1.50 196.0 1.15 239.0 1.40 126.7 0.91 135.2 1.35 144.5 0.80 79.7 1.12 95.2 0.95 116.8 1.55 138.0 1.27 158.0 1.64 111.7 0.81 125.0 1.13 117.3 0.77 1.03 0.90 0.88 0.88 1.07 0.84 1.13 0.73 1.03 0.97 1.07 1.16 1.54 0.86 1.14 0.82 0.88 0.93 0.95 0.98 1.11 0.86 1.03 0.93 0.96 1.05 1.15 1.12 1.14 0.85 0.92 0.85 Softened truss model

4.0

1.1

1.01 0.98 0.91 0.81 1.05 0.86 0.91 0.95 1.03 0.93 0.90 0.93 1.01 1.04 1.05 0.97 0.97 0.97 1.15 0.97 1.02 1.01 0.99 0.88 0.85 0.78 0.79 0.79

78.5

68.4

35.5

33.5

0.6 1.2 1.2 1.6 2.0 1.0 1.0 1.6 0.6 1.2 1.2 1.6 2.0 1.0 1.0 1.6

0.6 0.6 1.2 1.2 2.0 0.7 1.4 0.7 0.6 0.6 1.2 1.2 2.0 0.7 1.7 0.7

T(ca l)/T(exp)

1.5 1

and unsafe prediction of the ultimate torsional ca0. Also, the concrete contribution, is ignored afpacity. 5 ter torsional cracking in AS3600, and is directly 0 proportional to the amount of transverse reinforce0 0 ment. The angle of 4compression80diagonals 120 also is c kept constant with the shearf'formula.

2.5 2

T(cal)/T(exp)

AS3600-2001 Skew-bending theory Space truss model Softening truss model

It can be seen from Table 1 that for beams with the same reinforcement ratio, the ultimate torsional strength of HSC beams increases approximately 1.2 times than that of NSC beams when the compressive strength of concrete increases from approximately 35 to 78 MPa. This further verified the effect of fc on the ultimate torsional capacity. It exhibits that the ultimate torsional strength of RC beams increases as the compressive strength of concrete increases.

Table 2. Comparison of calculated and experimental cracking strength Beam fc MPa Tcr(exp) kN-m AS3600 Tcr(cal) Skewbending theory Tcr(cal) Tcr(cal)/ Tcr(exp) 7.58 7.25 7.07 9.22 8.87 9.22 10.32 10.29 10.24 12.29 12.02 12.02 90.45 90.45 90.45 90.45 90.45 84.43 84.43 84.43 60.82 60.82 60.82 60.82 60.82 59.09 59.09 59.09 1.06 1.20 1.16 1.24 1.38 1.32 1.11 1.11 1.10 1.07 1.33 1.05 1.23 1.21 1.17 1.14 1.19 1.20 1.37 1.29 1.41 1.17 1.23 1.07 1.11 1.42 1.41 1.48

1.5 1 0.5 0 0 40 f'c 80 120

Figure 2. T(cal)/T(exp) versus concrete compressive strength (Rasmussen & Baker 1995b)

AS3600-2001 Skew-bending theory Space truss model Softening truss model

T(ca l)/T(exp)

1.5 1 0.5 0 0 20 40 f'c 60 80 100

B30.1 B30.2 B30.2 B50.1 B50.2 B50.3 B70.1 B70.2 B70.3 B110.1 B110.2 B110.3 H06-06 H06-12 H12-12 H12-16 H20-20 H07-10 H14-10 H07-16 N06-06 N06-12 N12-12 N12-16 N20-20 N07-10 N14-10 N07-16

Figure 3. T(cal)/T(exp) versus concrete compressive strength (Fang & Shiau 2004)

It can be seen from Table 1 that the space truss model with spalling of concrete, and the softening truss model, give the best prediction for the ultimate torsional capacity when compared with the experimental result, with a mean and a standard deviation of 0.9 and 5.8% for the softened truss model, and 1.05 and 6.8% for the space truss model. On the other hand, skew-bending theory gives reasonable predictions for beams tested by Fang & Shiau (2004), but is unconservative for the beams tested by Rasmussen & Baker (1995a). This is because all the beams tested by Rasmussen & Baker (1995a) were over-reinforced where the failure of the beams resulted from the concrete failure. The overestimate of the ultimate strength from the skew-bending theory is because the theory includes the volume of the longitudinal and transverse reinforcements and the concrete contribution.

Tcr(cal)/ Tcr(exp) Rasmussen & Baker (1995) 41.7 7.18 5.46 0.76 38.2 6.05 5.22 0.86 36.3 6.07 5.09 0.84 61.8 7.43 6.64 0.89 57.1 6.41 6.38 0.99 61.7 6.98 6.64 0.95 77.3 9.27 7.43 0.83 76.9 9.27 7.43 0.80 76.2 9.30 7.37 0.79 109.8 11.46 8.85 0.77 105.0 9.05 8.66 0.96 105.1 11.50 8.66 0.75 Fang & Shiau (2004) 70.6 65.12 0.92 75.0 65.12 0.87 78.5 77.1 65.12 0.84 79.3 65.12 0.82 76.0 65.12 0.86 70.5 60.79 0.86 68.4 61.8 60.79 0.98 65.3 60.79 0.93 43.2 43.79 1.01 51.8 43.79 0.85 35.5 49.3 43.79 0.89 57.1 43.79 0.77 55.0 43.79 0.80 41.6 42.54 1.02 33.5 41.8 42.54 1.02 40.0 42.54 1.06

Table 2 provides the comparison of the calculated cracking torque to the experimental data. Cracking occurs when the maximum tensile stress due to torsion reaches the tensile strength of the concrete. It can be seen from Table 2 that the crack load increases as the concrete strength increases, which is apparently due to the higher concrete strength. The mean values of the ratios Tcr(cal)/Tcr(exp) in the HSC

series are 0.82 for the AS3600 expression, and 1.13 for the skew-bending theory; while for those in the NSC series, the values are 0.88, and 1.23, respectively, from Rasmussen & Bakers (1995a) beams. In the case of Fang & Shiaus (2004) beams, the mean values of the ratios Tcr(cal)/Tcr(exp) in the HSC series are 0.89 for the AS3600 expression, and 1.23 for the skew-bending theory; while for those in the NSC series, the values are 0.93, and 1.25, respectively. So in all cases, whether over-reinforced or under-reinforced, the AS3600 expression underestimates the cracking strength, while skew-bending theory overestimates the cracking torque of reinforced concrete beams. Also, the ratio of ultimate and cracking torsional strength, Tu/Tcr, from Rasmussen & Bakers (1995a) beams is 2.61 for NSC and 2.26 for HSC, while the respective values from Fang & Shiaus (2004) beams are 2.5 and 2.08. This proves that after cracking, the increase in torsional strength for HSC is less than in NSC. This is probably due to the well-known reduced aggregate interlocking shear resistance mechanism in HSC. 6 LATTICE MODEL The lattice model was initially developed by Niwa et al. (1994), and can be expressed using a finite element formulation by smearing out concrete and reinforcement lattices into a continuum. The main characteristic of the lattice model is the possibility to change the direction of the local coordinate (or the inclination angle of the lattice component) in proportion to the progress of fracture in the connection between the stress field of the global and local coordinate system. This model provides the freedom to change the inclination angle of longitudinal reinforcement lattice components. Thus it is possible to evaluate the dowel effect by controlling the inclination angles of the reinforcement lattice components. In addition, it is possible to evaluate the resisting mechanism of transverse reinforcement, which may not be vertical. With regard to the resisting mechanism of concrete, the shear transfer of the crack surface can be evaluated not by using the shear stressstrain relationship, but by using the shear lattice. For each crack surface, two shear lattices S1 and S2 are provided. The shear force along a crack is carried by these shear lattices. The effect of aggregate interlock is dependent on the relative movement of concrete on two sides of the crack and thus S1 and S2 will become active as shown in Figure 4. In this shear transfer mode, the roughness of the crack surface is represented by the roughness angle of the crack surface. Itoh et al. (2000) suggested a value = /3 for NSC based on a comprehensive study comparing the lattice model and the panel test results of Vecchio & Collins (1986). For HSC with smoother crack surfaces, a smaller value of should be

adopted. A value of /4 was proposed by Ngo (2005) for the roughness angle. The technique of the lattice model has been successfully applied for both normal and highstrength concrete beams subjected to shear, by including a fracture energy based damage model as developed by Hossain (2006). The fracture energy based damage model developed in this study is based on the MCFT, reduced fracture energy and variable shear retention factors, which represent the change of material properties due to the higher strength of concrete. A linear decreasing function related to the tensile strain that is normal to the crack plane is proposed in this study, which takes into account the fact that friction due to the roughness of the crack surface decreases as the opening of the crack increases. This improves the damage model, allowing for the correct provision of the secondary mechanisms of shear resistance of a structure and accounting for the well-known experimental observation of the reduced aggregate interlock shear resistance in the case of HSC.

Figure 4. Modelling shear contact area with shear lattices

7 CONCLUSIONS AND RECOMMENDATIONS Based on the assessment of the theoretical models and AS3600 for rectangular beams under pure torsion, the following can be concluded: 1. A higher crack load and higher torsional capacity for a given cross-section are obtained using highstrength concrete both from experimental and theoretical models. 2. Among the three theoretical models used, the space truss model with spalling of the concrete cover and softened truss model give the best estimate of the ultimate torsional strength of test beams. 3. The AS3600-2001 gives an unconservative prediction for the ultimate torsional strength of both normal and high-strength RC beams.

4. HSC provided higher torsional strength than NSC for beams designed with the same amount of reinforcement. Further research effort remains to be implemented to accurately predict the torsional behaviour of high-strength reinforced concrete beams, by taking into account the effects of reduced aggregate interlock shear transfer mechanism due to the smooth crack surface in HSC. An advanced method of analysis based on the lattice model can be developed to carry out a rational analysis for torsion up to the ultimate range, to include the important aspects of aggregate interlock and dowel action, which have been ignored in the past for torsional resistance.

REFERENCES

AS 3600 2001. Concrete Structures, Standards Association of Australia, Australia. Attard, M. M., & Mendis, P. A. 1993. Ductility of HighStrength Concrete Columns. Australian Civil Engineering Transactions, The Institute of Engineers, Australia, Vol. CE35, No. 4, October 1993, pp 295-306, 295-306. Collins, M. P., & Mitchell, D. 1980. Shear and Torsion Design of Prestressed and Non-Prestressed Concrete Beams. PCI Journal, 25(5), 32-100. Fang, I. K., & Shiau, J. K. 2004. Torsional Behavior of Normal- and High-Strength Concrete Beams. ACI Structural Journal, 101(3), 304-313. Hossain, T. 2006. Shear Behaviour of High-Strength Concrete Beams at Low and High Strain-Rates. PhD Thesis, Department of Civil and Environmental Engineering, University of Melbourne. Australia, 289 pp. Hsu, T. C. 1968. Torsion of Structural Concrete- Behaviour of Reinforced Concrete Rectangular Members. Torsion of Structural Concrete, SP-18, American Concrete Institute, Farmington Hills, Mich., 261-306. Hsu, T. C. 1979. Discussion of Pure Torsion in Rectangular Sections-A Re-examination by McMullen, A. E. and Rangan, B. V. Journal of the American Concrete Institute, Proc., 76(6), 741-746. Hsu, T. C. 1984. Torsion of Reinforced of Concrete. Van Nostrand Reinhold, New York, USA, 1-516. Hsu, T. C., & Mo, Y. L. 1985. Softening of Concrete in Torsional Members-Theory and Tests. ACI Journal, 82(3), 290-303. Hsu, T. C., and Mo, Y. L. (1985). Softening of Concrete in Torsional Members-Design Recommendations. ACI Journal, 82(4), 443-452. Hsu, T. C. 1988. Softened Truss Model Theory for Shear and Torsion. ACI Structural Journal, 85(6), 624-635. Itoh, A., Ishtiaq, A. S., & Tanabe, T. 2000. Expression of the Compression Field Theory Based on the Lattice Equivalent Continua Model. Transactions of the Japan Concrete Institute, 22, 427-432. Koutchoukali, N. E., & Belarbi, G. 2001. Torsion of HighStrength Reinforced Concrete Beams and Minimum Reinforcement Requirement. ACI Structural Journal, 98(4), 462-469.

Lessig, N. N. 1959. Determination of Load-Carrying Capacity of Rectangular Reinforced Concrete Elements subjected to Flexure and Torsion. Concrete and Reinforced Concrete Institute, Trudy No. 5, Moscow, 5-28. Mitchell, D., & Collins, M. P. 1974. Diagonal Compression Field Theory-A rational Model for Structural Concrete in Pure Torsion. ACI Journal, Proc., 71(8), 396-408. Ngo, T. D. 2005. Behaviour of High Strength Concrete subject to Impulsive Loading. PhD Thesis, Department of Civil and Environmental Engineering, University of Melbourne. Australia, 331 pp. Niwa, J., Choi, I. C., & Tanabe, T. 1994. Analytical Study for Shear Resisting Mechanism using Lattice Model. JCI International workshop on Shear in Concrete Structures, Japan, 130-145. Rasmussen, L. J., & Baker, G. 1994. Assessment of Torsional Strength in Reinforced Normal and High-Strength Concrete Beams. Australian Civil Engineering Transactions, IEAust., CE36(2), 165-171. Rasmussen, L. J., & Baker, G. 1995a. Torsion in Reinforced Normal and High-Strength Concrete Beams-Part 1: Experimental Results. ACI Structural Journal, 92(1), 55-63. Rasmussen, L. J., & Baker, G. 1995b. Torsion in Reinforced Normal and High-Strength Concrete Beams-Part 2: Theory and Design. ACI Structural Journal, 92(2), 149-156. Rausch, E. 1929. Design of Reinforced Concrete in Torsion. PhD Thesis, Technische Hochshule, Berlin, 53 pp. Reid, S. G., & Bridge, R. C. 1990. Shear and Torsion in Reinforced Concrete Beams. National Conference Publication, Institute of Engineers, Australia, 90(10), 259-264. Vecchio, F. J., & Collins, M. P. 1986. Modified Compression Field Theory for Concrete Elements Subjected to Shear. ACI Journal, Proceedings, 83(2), 219-231.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 37eb PDFDocument29 pages37eb PDFZikriaKMuhammadNo ratings yet

- Centrifugal CastingDocument266 pagesCentrifugal Castinguzairmetallurgist100% (2)

- Final Cassava Grating MachineDocument7 pagesFinal Cassava Grating Machinenormelyn100% (2)

- Mody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyDocument3 pagesMody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyAtul GaurNo ratings yet

- Structural Health Monitoring: Abin Paul Roll No:4 S7, CE-ADocument34 pagesStructural Health Monitoring: Abin Paul Roll No:4 S7, CE-AAnjana kpNo ratings yet

- Dambrk Modeling MethodologyDocument38 pagesDambrk Modeling MethodologyDevi DephieNo ratings yet

- Preparation of Turkey Red OilDocument16 pagesPreparation of Turkey Red OilHimanshu Jha73% (11)

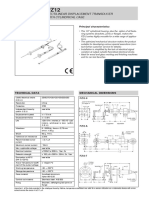

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Installation Operation Maintenance Manual (Harvest Series)Document36 pagesInstallation Operation Maintenance Manual (Harvest Series)berkahharianNo ratings yet

- Digital RF Driver for Laser Intensity ControlDocument2 pagesDigital RF Driver for Laser Intensity ControlGaloppierende ZuversichtNo ratings yet

- Job 1 SksoDocument5 pagesJob 1 SksoFajAr OkTaNo ratings yet

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDocument7 pagesMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94No ratings yet

- Beginner Ansys TutorialDocument114 pagesBeginner Ansys TutorialNGUYEN92% (12)

- Analytical Chemistry & Numerical MCQ Test 3 - Makox MCQsDocument5 pagesAnalytical Chemistry & Numerical MCQ Test 3 - Makox MCQsنونه الحنونةNo ratings yet

- Temperature Regulator With Two Temperature SensorsDocument2 pagesTemperature Regulator With Two Temperature SensorsSandi AslanNo ratings yet

- Electrical Conductivity of Carbon Blacks Under CompressionDocument7 pagesElectrical Conductivity of Carbon Blacks Under CompressionМирослав Кузишин100% (1)

- Design and Analysis of G+8 Commercial Building Using Staad ProDocument8 pagesDesign and Analysis of G+8 Commercial Building Using Staad ProVikaskumar ReddyNo ratings yet

- Marking Scheme Physics Trial SPM SBP 2016 Paper 3Document6 pagesMarking Scheme Physics Trial SPM SBP 2016 Paper 3Anonymous UypCttWNo ratings yet

- PMI Procedure for Verifying Alloy Elements in Metals by XRFDocument2 pagesPMI Procedure for Verifying Alloy Elements in Metals by XRFMohamed NabilNo ratings yet

- M.Prasad Naidu MSC Medical Biochemistry, PH.D Research ScholarDocument31 pagesM.Prasad Naidu MSC Medical Biochemistry, PH.D Research ScholarDr. M. Prasad NaiduNo ratings yet

- Teleportation AbstractDocument2 pagesTeleportation Abstractvishal2988No ratings yet

- 06.-Medidor Cloro CL4000enDocument18 pages06.-Medidor Cloro CL4000enLeonel RubioNo ratings yet

- Partition Coefficients and Their UsesDocument92 pagesPartition Coefficients and Their UsesquelenigNo ratings yet

- CO2 Depressurisation OLGADocument8 pagesCO2 Depressurisation OLGAMaheshNo ratings yet

- Geogrids in Walls and SlopesDocument6 pagesGeogrids in Walls and SlopesYong Cheng Hung100% (1)

- Biological Materials Structure and PropertiesDocument206 pagesBiological Materials Structure and PropertiesDulce Job BenitezNo ratings yet

- Handbook5 PDFDocument257 pagesHandbook5 PDFZAKROUNNo ratings yet

- The Weighted Histogram Analysis Method (WHAM) : Michael AndrecDocument14 pagesThe Weighted Histogram Analysis Method (WHAM) : Michael AndrecWilliam AgudeloNo ratings yet

- 9702 w04 QP 4Document16 pages9702 w04 QP 4api-3706826No ratings yet

- Assignment MetrologyDocument8 pagesAssignment MetrologyPratama sudibyo0% (1)