Professional Documents

Culture Documents

Double Angle Connection

Uploaded by

runkirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Double Angle Connection

Uploaded by

runkirCopyright:

Available Formats

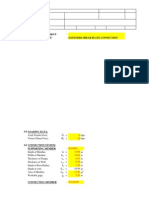

Fu Fy e s Ab d t Du hsc Ns Tb Nb Tu Ag Anv Ae An Ant t1 l

Ultimate stress of the material (Ksi) Yield stress of the material (Ksi) edge distance (in) bolt spacing (in) Load resistance Factor Nominal area of bolt (in2) Nominal diameter of bolt (in) thickness of the critical material mean slip coefficeint multiplier hole factor Number of Slip Planes minimum bolt tension (kips) number of bolts carrying the applied tension

tension force due to LRFD combinations (kips) Gross sectional area (in2) Net area subjected to shear (in2) Effective net area (in2) Net area (in2) Net area subjected to tension (in2) End Projection angle length

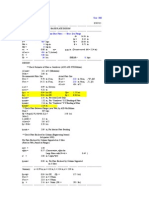

Design strength of bolts

Connection Types

Force Type at Connection

Bolt design strength ( R n)

Shear only a) when e 1.5d, s 3d Bolt holes deformation No Blot shear strength =( Rn) Rn= FnAb Bearing strength at bolt holes =( Rn) For bolt nearsest the edge For remaining bolts b) When e < 1.5d or s < 3d or for a single bolt in line of force. For single bolt hole or the bolt hole nearest the edge when there are two or more bolt holes in the line of force Rn= etFu 2.4dtFu For remaining holes Rn= (s-d/2)tFu 2.4dtFu Rn= etFu 3dtFu Rn= (s-d/2)tFu 3dtFu Yes Rn= 2.4dtFu

Bearing type connections

Tension only

Bolt tensile strength =( Rn) Rn= FnAb

Shear & Tension a) when e 1.5d, s 3d Bolt holes deformation Bolt tensile strength =( Rn) Rn= FnAb Bearing strength at bolt holes =( Rn) No For bolt nearsest the edge For remaining bolts b) When e < 1.5d or s < 3d or for a single bolt in line of force. For single bolt hole or the bolt hole nearest the edge when there are two or more bolt holes in the line of force Rn= etFu 2.4dtFu For remaining holes Rn= (s-d/2)tFu 2.4dtFu Rn= etFu 3dtFu Rn= (s-d/2)tFu 3dtFu Yes Rn= 2.4dtFu

Connection Types

Shear Only

a) when e 1.5d, s 3d Bolt holes deformation

Yes No

Rn= 2.4dtFu

Slip resistance =( Rn)

Rn=D uhsc TbNs

Blot shear strength =( Rn) Rn= FnAb

Bearing strength at bolt holes =( Rn)

For bolt nearsest the edge For remaining bolts b) When e < 1.5d or s < 3d or for a single bolt in line of force. For single bolt hole or the bolt hole nearest the edge when there are two or more bolt holes in the line of force Rn= etFu 2.4dtFu For remaining holes Rn= (s-d/2)tFu 2.4dtFu

Rn= etFu

3dtFu

Rn= (s-d/2)tFu 3dtFu

Slip Critical Connections

Shear & Tension a) when e 1.5d, s 3d Bolt holes deformation Slip resistance =( K sRn)

Rn=D uhsc TbNs

Yes No

Rn= 2.4dtFu

Ks= 1-Tu/(DuTbNb)

Blot shear strength =( Rn) Rn= FnAb

Bearing strength at bolt holes =( Rn)

For bolt nearsest the edge For remaining bolts b) When e < 1.5d or s < 3d or for a single bolt in line of force. For single bolt hole or the bolt hole nearest the edge when there are two or more bolt holes in the line of force Rn= etFu 2.4dtFu For remaining holes Rn= (s-d/2)tFu 2.4dtFu

Rn= etFu

3dtFu

Rn= (s-d/2)tFu 3dtFu

In all the cases, the design strength

Rn must equal or exceed the required strength Ru

Limiting Design Strength

Connecting Elements Force

Bolts

Shear

Bolt Shear strength =( Rn) Rn= FnAb If If

D/C= Ru / Rn O.K Ru / Rn

1 Review the design

Tension

tensile yielding of angle =( Rn) Rn=FyAg If If Rn Ru O.K Rn < Ru Review the design

tensile rupture of angle =( Rn) Rn=FuAe If If Rn Ru O.K Rn < Ru Review the design

Shear

Angle

Shear yielding of angle =( Rn) Rn=0.6FyAg If If Rn Ru O.K Rn < Ru Review the design

Shear rupture of angle =( Rn) Rn=0.6FuAnv If If Rn Ru O.K Rn < Ru Review the design

a) When F uAnt 0.6FuAnv Rn=0.6FyAgr+FuAnt Block Shear Strength =( Rn) If If Rn Ru Rn < Ru O.K Review the design

b) When FuAnt < 0.6FuAnv Rn=0.6FuAnv+FyAgt If If Rn Ru Rn < Ru O.K Review the design

a) when e 1.5d, s 3d Bolt holes deformation

Yes No

Rn= 2.4dtF u Rn

Ru

Bolt bearing on angles =( Rn)

For bolt nearsest the edge For remaining bolts b) When e < 1.5d or s < 3d or for a single bolt in line of force. For single bolt hole or the bolt hole nearest the edge when there are two or more bolt holes in the line of force Rn= etFu 2.4dtF u For remaining holes Rn= (s-d/2)tF u 2.4dtF u If If Rn Ru O.K Rn < Ru Review the design

Rn= etFu If If

3dtFu Rn Ru O.K Rn < Ru Review the design

Rn= (s-d/2)tF u 3dtFu

Design Check

a) when e 1.5d, s 3d Bolt holes deformation

Yes No

Rn= 2.4dtF u If If Rn Ru O.K Rn < Ru Review the design

Beam

Bolt Bearing on Beam Web =( Rn)

For bolt nearsest the edge For remaining bolts b) When e < 1.5d or s < 3d or for a single bolt in line of force. For single bolt hole or the bolt hole nearest the edge when there are two or more bolt holes in the line of force Rn= etFu 2.4dtF u For remaining holes Rn= (s-d/2)tF u 2.4dtF u If If Rn Ru O.K Rn < Ru Review the design

Rn= etFu If If

3dtFu Rn Ru O.K Rn < Ru Review the design

Rn= (s-d/2)tF u 3dtFu

a) when e 1.5d, s 3d Bolt holes deformation

Yes No

Rn= 2.4dtF u

Bolt Bearing on

For bolt nearsest the edge For remaining bolts b) When e < 1.5d or s < 3d or for a single bolt in line of force. For single bolt hole or the bolt hole nearest the edge when there are two or more bolt holes in the line of force Rn= etFu 2.4dtF u For remaining holes Rn= (s-d/2)tF u 2.4dtF u If If Rn Ru O.K Rn < Ru Review the design

Rn= etFu If If

3dtFu Rn Ru O.K Rn < Ru Review the design

Column

Beam Web =( Rn)

Rn= (s-d/2)tF u 3dtFu

Inputs Units Length force stress Beam End reactions Rd= inch kips ksi

Inputs

Dead load (D) Rl= live load (L) Rw= Wind load (W) Rs= Snow Load (S) Rlr= Roof live load (Lr) Re= Eq. Load (E) Rr= Nominal load due to initial rainwater or ice exclusive of the ponding contribution (R) Ru= as per the load combination defined below

Criteriea

Calculate Bolt design Strength ( Rn)

LRFD Load Combinations 1.4D 1.2D + 1.6L + 0.5(Lr or S or R) 1.2D + 1.6(Lr or S or R) + (0.5L or 0.8W) 1.2D + 1.3W + 0.5L + 0.5(Lr or S or R) 1.2D 1E + 0.5 L + 0.2S 0.9D (1.3W or 1E) Bolt Type Bolt Dia Material Properties Elements Designation Beam Column Angles W36x231 W14x90 2L5x3 1/2 Specifications ASTM A992 ASTM A992 A36 Fy (ksi) 50 50 36 Fu (ksi) 65 65 58 ASTM A325-N 3/4 inch=

Minimum number of Bolts, n1=Ru / Rn

Assume suitable Number of Bolts (n), edge (e), spacing (s) and gauge (g)

0.75 inch

Assume angle thickness (t)

Design Check

Geometric Properties Beam W36x231 Column Angles Criterias Connection type = Force Type = W14x90 2L5x3 1/2

tw = tf =

0.76 0.71

Design not safe

Bolts

No

n Rn Ru

limiting shear strength of bolt groups (n Rn)

Bearing Type connection Shear and torsion

Yes

Angle

Bolt bearing on angle ( Rn)

Shear yielding ( Rn)

shear rupture ( Rn)

block shear rupture ( Rn)

Design is Safe

Beam

Bolt bearing on Beam Web ( Rn) Bolt bearing on Beam Web ( Rn) Rn Ru

Yes

Design is Safe

Column

No

Design not safe

Design of Double angle connection is complete

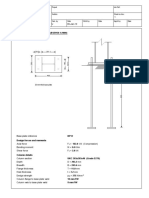

Angle lengthAngle thickness Minimum spacing in any directionMinimum edge distanceAnet= t (W-dh) for single row of bolt t(W-ndh) Anet can never be lesser than 0.85Ag s= g=

Minimum angle length shoud be one half of the "T" dimension of the beam to Pg 1481 b Maximum is 5/8 inch 2 2/3 (2.667) d (AISC J 3.3) Sheared edge is the worst case (from table J 3.4)

LRFD Manual

for n number of bolts across the section

centre to centre spacing of fastener in a row, also called fastner pitch centre to centre spacing of bolts along perpendicular direction to the line of force In lap joint it is the centre to centre distance between rows of fastener ref. Steel Buildings (Green Book) pg 210 total shear strength of the section (Fv) =

Check Shear on net Area of Angles

0.3*FuAv

(when tension is there strength strength is reduced to 30% of the minimum specified tensile strength)

the thickness required for shear=

Fu= Minimum specified tensile strength t=Ru/[Fv(l-ndh)n1] l= length of angle Fv= Shear strength of one angle dh= hole diameter n1= number of angles

8.5 inch

t, Angle Thickness

t1, End Projection e1 e2, edge distance s, bolt spacing

l, Angle length

Beam

e1, end distance

g, gauge

Column

Beam

Beam

Beam

ge distance

You might also like

- ASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishDocument222 pagesASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishAdheith South NgalamNo ratings yet

- Beam Shear ConnDocument26 pagesBeam Shear Connraghav abudhabiNo ratings yet

- Specification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsDocument9 pagesSpecification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsMr Incognito100% (1)

- Endplmc9 AsdDocument25 pagesEndplmc9 AsdmangeshNo ratings yet

- The - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcreteDocument9 pagesThe - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcretejscuencaNo ratings yet

- Circular WeldDocument12 pagesCircular WeldJohn Paul UmaliNo ratings yet

- Flat Slab Punching Shear Check r1Document5 pagesFlat Slab Punching Shear Check r1Usama ChauguleNo ratings yet

- BOLTGRP13Document33 pagesBOLTGRP13NEONo ratings yet

- End Plate Conn 01 - Finite ElementDocument4 pagesEnd Plate Conn 01 - Finite Elementrodriguez.gaytanNo ratings yet

- Calculations of Effective Length of Steel Columns: AS PER IS 800: 2007 (Annex D, Cl. 7.2.2)Document4 pagesCalculations of Effective Length of Steel Columns: AS PER IS 800: 2007 (Annex D, Cl. 7.2.2)Zaki SiddiquiNo ratings yet

- AISC-Extended Shear Plate ConnectionDocument7 pagesAISC-Extended Shear Plate ConnectionMuthukumaran SivalingamNo ratings yet

- Clip Steel Connection TableDocument10 pagesClip Steel Connection Tableafloresr01No ratings yet

- Bracing Connection - Rev EDocument32 pagesBracing Connection - Rev EHeberth SanchezNo ratings yet

- Design of Builtup SectionDocument4 pagesDesign of Builtup SectiondsanandaNo ratings yet

- Design of Brace Connection: Input InformationDocument6 pagesDesign of Brace Connection: Input InformationJonatas PrandiniNo ratings yet

- Rigid Connection DesignDocument215 pagesRigid Connection DesignUmer AziqNo ratings yet

- Moment ConnectionDocument7 pagesMoment Connectionkashyap_structuralNo ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- AISC ASD Base Plate Thickness V2016-2Document9 pagesAISC ASD Base Plate Thickness V2016-2yusuf_jtNo ratings yet

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationAlphyl BalasabasNo ratings yet

- Lashing Lug Pedestal Anchor & Concrete DesignDocument23 pagesLashing Lug Pedestal Anchor & Concrete DesignMyunSu GooNo ratings yet

- Base Plate ASDDocument7 pagesBase Plate ASDcataiceNo ratings yet

- Design of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007Document3 pagesDesign of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007sundarNo ratings yet

- HDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Document8 pagesHDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Mohammad Shadab AliNo ratings yet

- Calculations of The Connection: Splice Heb260: General InformationDocument23 pagesCalculations of The Connection: Splice Heb260: General InformationLudovicoVicoNo ratings yet

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelNo ratings yet

- Example J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Document2 pagesExample J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Martin VenichNo ratings yet

- Ext Finplate ConnecDocument78 pagesExt Finplate Connechary9100No ratings yet

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- Beam TabDocument19 pagesBeam Tab45k4No ratings yet

- 1.SHEAR (Or) MOMENT CONNE-GENERALDocument272 pages1.SHEAR (Or) MOMENT CONNE-GENERALbalaNo ratings yet

- Moment To Column WebDocument905 pagesMoment To Column WebAmanpreet SinghNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoNo ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 pagesR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNo ratings yet

- Clipconn All Bolt 13Document22 pagesClipconn All Bolt 13NEONo ratings yet

- Cleat Angle ConnectionDocument38 pagesCleat Angle ConnectionMadhubalan AlagarNo ratings yet

- Plate GirderDocument15 pagesPlate GirderPriodeep ChowdhuryNo ratings yet

- Base Plate Ver Brace Connection - Column FlangeDocument27 pagesBase Plate Ver Brace Connection - Column FlangeAnıl Berk SağırNo ratings yet

- Calculation of End Plate Beam Connection: Data Steel ShapeDocument1 pageCalculation of End Plate Beam Connection: Data Steel ShapeFortunata Citraningrum SukmonoNo ratings yet

- Result Summary - Overall Brace To Gusset Gusset To Column Gusset To Base PlateDocument42 pagesResult Summary - Overall Brace To Gusset Gusset To Column Gusset To Base PlateMichenerparkNo ratings yet

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument11 pages"Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionMustafa RupawalaNo ratings yet

- Beam AnalDocument7 pagesBeam Analgercho23No ratings yet

- Moment Connection - Beam SpliceDocument3 pagesMoment Connection - Beam SpliceSh MNNo ratings yet

- Weld StrengthDocument9 pagesWeld StrengthRUDHRA DHANASEKAR50% (2)

- Circular Sump-Oil DrainDocument24 pagesCircular Sump-Oil DrainSwati ChaudhariNo ratings yet

- Fin Plate-Beam To Beam Inside (AISC-LRFD)Document184 pagesFin Plate-Beam To Beam Inside (AISC-LRFD)AshishNo ratings yet

- WindLoadCalculation SheetDocument8 pagesWindLoadCalculation SheetSher AfganNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- 1.SP2 HEA160 SPLICE-A10%-S60%-M60% (End Plate) BoltedDocument120 pages1.SP2 HEA160 SPLICE-A10%-S60%-M60% (End Plate) BoltedbalaNo ratings yet

- Flust-Extended End Plate ConnectionDocument8 pagesFlust-Extended End Plate ConnectionamachmouchiNo ratings yet

- Design of End Plate ConnectionDocument2 pagesDesign of End Plate ConnectionAndro RebuyasNo ratings yet

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- Star Column Coordinates For StaadDocument5 pagesStar Column Coordinates For StaadShriniwas NaikNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document5 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- Fixed - Base PLT - AISCDocument22 pagesFixed - Base PLT - AISCNapoleon ShanNo ratings yet

- Design of Chequered Plate DesignDocument2 pagesDesign of Chequered Plate DesignadihindNo ratings yet

- UC Bracing Gusset - ASDDocument14 pagesUC Bracing Gusset - ASDFunny & InformativeNo ratings yet

- AISC Tension MemberDocument3 pagesAISC Tension Membermodulor3dNo ratings yet

- Engelhardt Steel Notes VI - ConnectionsDocument29 pagesEngelhardt Steel Notes VI - ConnectionsJorge SanchezNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- AITC-H - Compression Strength of Individual Bricks (15!09!14)Document9 pagesAITC-H - Compression Strength of Individual Bricks (15!09!14)runkir100% (1)

- The Projection and Construction of New SchoolsDocument2 pagesThe Projection and Construction of New SchoolsrunkirNo ratings yet

- AITC-H - Direct Shear Strength Test (15!09!14)Document9 pagesAITC-H - Direct Shear Strength Test (15!09!14)runkirNo ratings yet

- AITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)Document8 pagesAITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)runkirNo ratings yet

- AITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)Document8 pagesAITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)runkirNo ratings yet

- New Classrooms ConstructionDocument4 pagesNew Classrooms ConstructionrunkirNo ratings yet

- 03DiI 03Document26 pages03DiI 03runkirNo ratings yet

- Bentley CodeDocument1 pageBentley CoderunkirNo ratings yet

- AITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)Document8 pagesAITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)runkirNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Nikon BrochureDocument9 pagesNikon BrochureMihaela ScarlatNo ratings yet

- Data SheetDocument4 pagesData SheetrunkirNo ratings yet

- Fire Resistance Durability Test Impact Test Green LabelingDocument1 pageFire Resistance Durability Test Impact Test Green LabelingrunkirNo ratings yet

- Bridge Design Eurocodes Worked Examples Annex OnlyDocument150 pagesBridge Design Eurocodes Worked Examples Annex OnlyAhmed AjelNo ratings yet

- Lump MassDocument10 pagesLump Masspkshrawal1976No ratings yet

- In-Plane Cyclic Shear Performance of Interlocking Compressed EartDocument144 pagesIn-Plane Cyclic Shear Performance of Interlocking Compressed EartrunkirNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Adb Nep Kiran Jnbs v1Document8 pagesAdb Nep Kiran Jnbs v1runkirNo ratings yet

- ASCE31 and ASCE41 What Good Are They FinalDocument8 pagesASCE31 and ASCE41 What Good Are They FinalrunkirNo ratings yet

- AITC-Alphaland Makati-UHS (20130904)Document2 pagesAITC-Alphaland Makati-UHS (20130904)runkirNo ratings yet

- Laptop Contract Agreement: If I Am An EmployeeDocument1 pageLaptop Contract Agreement: If I Am An EmployeerunkirNo ratings yet

- ResidentialDocument2 pagesResidentialrunkirNo ratings yet

- Quakeguard Earthquake Early Warning System: January 17, 1994Document2 pagesQuakeguard Earthquake Early Warning System: January 17, 1994runkirNo ratings yet

- Behaviour of Masonry Wall Constructed Using Interlocking Soil Cement BricksDocument7 pagesBehaviour of Masonry Wall Constructed Using Interlocking Soil Cement BricksrunkirNo ratings yet

- Hem Engineering StructureDocument1 pageHem Engineering StructurerunkirNo ratings yet

- Concrete Design AidsDocument20 pagesConcrete Design AidsumtancwNo ratings yet

- MOE OrganogramDocument18 pagesMOE OrganogramrunkirNo ratings yet

- Tie ConnectionDocument1 pageTie ConnectionrunkirNo ratings yet

- Rule of Thumb Concrete DesignDocument54 pagesRule of Thumb Concrete DesignrunkirNo ratings yet

- House Plan (Mezzanine) - 23rd June, 2013Document3 pagesHouse Plan (Mezzanine) - 23rd June, 2013runkirNo ratings yet

- How To Attain Success Through The Strength of The Vibration of NumbersDocument95 pagesHow To Attain Success Through The Strength of The Vibration of NumberszahkulNo ratings yet

- MPPWD 2014 SOR CH 1 To 5 in ExcelDocument66 pagesMPPWD 2014 SOR CH 1 To 5 in ExcelElvis GrayNo ratings yet

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocument20 pagesAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenNo ratings yet

- Tan Vs GumbaDocument2 pagesTan Vs GumbakjsitjarNo ratings yet

- ODF-2 - Learning MaterialDocument24 pagesODF-2 - Learning MateriallevychafsNo ratings yet

- CEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)Document3 pagesCEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)MichaelNo ratings yet

- Shares and Share CapitalDocument50 pagesShares and Share CapitalSteve Nteful100% (1)

- Admission Notice: Weekend Masters Program (WMES)Document4 pagesAdmission Notice: Weekend Masters Program (WMES)masud100% (1)

- Carelink Connect: User GuideDocument41 pagesCarelink Connect: User GuideMiha SoicaNo ratings yet

- Business-Model Casual Cleaning ServiceDocument1 pageBusiness-Model Casual Cleaning ServiceRudiny FarabyNo ratings yet

- Ahakuelo IndictmentDocument24 pagesAhakuelo IndictmentHNNNo ratings yet

- QuestionDocument7 pagesQuestionNgọc LuânNo ratings yet

- Expected MCQs CompressedDocument31 pagesExpected MCQs CompressedAdithya kesavNo ratings yet

- LISTA Nascar 2014Document42 pagesLISTA Nascar 2014osmarxsNo ratings yet

- S SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesDocument3 pagesS SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesMohan PreethNo ratings yet

- Module 5 - Multimedia Storage DevicesDocument10 pagesModule 5 - Multimedia Storage Devicesjussan roaringNo ratings yet

- Opel GT Wiring DiagramDocument30 pagesOpel GT Wiring DiagramMassimiliano MarchiNo ratings yet

- Fast Binary Counters and Compressors Generated by Sorting NetworkDocument11 pagesFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544No ratings yet

- Idmt Curve CalulationDocument5 pagesIdmt Curve CalulationHimesh NairNo ratings yet

- Double Inlet Airfoil Fans - AtzafDocument52 pagesDouble Inlet Airfoil Fans - AtzafDaniel AlonsoNo ratings yet

- Ap06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónDocument9 pagesAp06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónJenny Lozano Charry50% (2)

- bz4x EbrochureDocument21 pagesbz4x EbrochureoswaldcameronNo ratings yet

- Database Management System and SQL CommandsDocument3 pagesDatabase Management System and SQL Commandsdev guptaNo ratings yet

- Basic Electronic Troubleshooting For Biomedical Technicians 2edDocument239 pagesBasic Electronic Troubleshooting For Biomedical Technicians 2edClovis Justiniano100% (22)

- SCHEDULE OF FEES - FinalDocument1 pageSCHEDULE OF FEES - FinalAbhishek SunaNo ratings yet

- Is 778 - Copper Alloy ValvesDocument27 pagesIs 778 - Copper Alloy ValvesMuthu KumaranNo ratings yet

- TATA Power - DDL:ConfidentialDocument15 pagesTATA Power - DDL:ConfidentialkarunakaranNo ratings yet

- Adjectives With Cork English TeacherDocument19 pagesAdjectives With Cork English TeacherAlisa PichkoNo ratings yet

- Pharmaceutical Microbiology NewsletterDocument12 pagesPharmaceutical Microbiology NewsletterTim SandleNo ratings yet