Professional Documents

Culture Documents

Final Design r2

Uploaded by

mazumdar_satyajitOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Design r2

Uploaded by

mazumdar_satyajitCopyright:

Available Formats

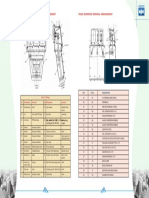

30 METER SELF SUPPORTING CHIMNEY Design Data: Total Height of Chimney: Design Codes: 30 meters IS 6533 (Part 1 &

2) IS 875 (Part 3) IS 800 Self-Supporting Chimney Mild Steel for Chimney Shell

Type of Chimney: Material of Construction: Inputs: Height of Chimney: Range of Zone 1: Length of Zone 1: Range of Zone 2: Length of Zone 2: Range of Zone 3: Length of Zone 3: Range of Zone 4: Length of Zone 4: Range of Zone 5: Length of Zone 5: Range of Zone 6: Length of Zone 6: Size Requirement: As per Clause 7.2.4 of I.S. 6533 Part 2, Minimum Height of Flared Portion

30 meters 25 m to 30 m 5m 20 m to 25 m 5m 15 m to 20 m 5m 10 m to 15 m 5 m. 5 m to 10 m 6m 0 m to 5 m 5m

Total Height Total Height Total Height Total Height Total Height Total Height

5m 5m 15 m 20 m 25 m 30 m

= 1/3 (Total Height) = 1/3 (30) = 10.00 m. = 1.6(OD at Top) = 1.6(0.512) = 0.8192 m.

Minimum OD of Flared Portion at Shell Base

Wind Pressure Calculations: Basic Wind Speed: Vb (m/sec) Risk Co efficient K1 Risk Co efficient K2 (category 1, Class B) Topography Factor K3 (assumed Flat Ground) Calculations: Vz = Design Wind Velocity =(Vb x K1 x K2 x K3) =(33 x 1 x 1.13 x 1) =37.29 m/sec. =0.6 x Vz 2 =0.6 x 37.29 2 = 834 N/sqm =83.4kg/sq. m =0.7 = 33.00 =1.00 =1.10 =1.00

Design Wind Pressure

Safe Factor for Circular Exposed Surface

Calculations for Wind Moment and Checking for Stresses: As Per I.S 6533 (part-2 ) Cl 8.2.2 of I.S.6533-part2, to determine the wind force acting at different heights of the chimney, the chimney shall be divided in to five Zones. Zone 1: Thickness of Shell (cm.) Outside Diameter (OD) Inside Diameter (ID) Calculations: Moment of Inertia I =(3.142/64) x (OD4 ID4) =0.049 x (51.24 504) =30475.4360 cm4 =I x (2/OD) =30475.4360 x (2/51.2) =1190.44 cm3 =0.6 =51.2 cm =50.0 cm

Modulus of Section Z

For wind force on ladder, 20% of ladder dia. is considered for calculation and ladder dia. is 0.7 m. Wind Moment at 20 m. from Base M =[OD x Design wind pr. x safe factor x (sq of height of zone) / 2] + [dia. of ladder x Design wind pr. x 20% dia. of ladder x (sq of height of zone) / 2] x 105

=[0.512 x 83.4 x 0.7 x (52/2)] + [0.7 x 83.4 x 0.2 x 0.7 x (52/2)] x 102 =47580.00 kg cm Self-Weight of Stack and Ladder P Cross Sectional Area of Chimney (sq. cm) A =1900 kg. =(3.142/4) x OD2 =0.7855 x (51.2)2 =2059.14 sq. cm. =(M/Z) + (P/A) =(47580/1190.44)+ (1900/2059.14) =40.89kg/sq.cm =Height/Mean Dia. =5/0.506 =9.88 =Diameter/Thk. =0.506/0.006 =84.33

Stress at 20 m. from base (Kgs/cm2)

Height to Dia. Ratio

Diameter to Thickness Ratio

Refer to table -3 of I.S 6533 (part-2 ). Maximum Permissible Stress for steel = 1260 Kgs/sq. cm.. Maximum Permissible Stress for steel = 1/t x ((M/Z) + (P/A)) t =0.32mm Assume corrosion allowance 3 mm. Total thickness reqd = 0.32+3 = 3.23 mm say 6.0 mm

Calculations for Wind Moment and Checking for Stresses: As Per I.S 6533 (part-2 ) Cl 8.2.2 of I.S.6533-part2, to determine the wind force acting at different heights of the chimney, the chimney shall be divided in to five Zones. Zone 2: Thickness of Shell (cm.) =0.6 Outside Diameter (OD) =51.2 cm Inside Diameter (ID) =50.0 cm Calculations: Moment of Inertia I =(3.142/64) x (OD4 ID4) =0.049 x (51.24 504) =30475.4360 cm4 =I x (2/OD) =30475.4360 x (2/51.2) =1190.44 cm3

Modulus of Section Z

For wind force on ladder, 20% of ladder dia. is considered for calculation and ladder dia. is 0.7 m. Wind Moment at 20 m. from Base M =[OD x Design wind pr. x safe factor x (sq of height of zone) / 2] + [dia. of ladder x Design wind pr. x

20% dia. of ladder x (sq of height of zone) / 2] x 105 =[0.512 x 83.4 x 0.7 x (102/2)] + [0.7 x 83.4 x 0.2 x 0.7 x (102/2)] x 102 =190318 kg cm Self-Weight of Stack and Ladder P Cross Sectional Area of Chimney (sq. cm) A =1900 kg. =(3.142/4) x OD2 =0.7855 x (51.2)2 =2059.14 sq. cm. =(M/Z) + (P/A) =(190318/1190.44)+ (1900/2059.14) =160.79kg/sq.cm =Height/Mean Dia. =10/0.506 =19.76 =Diameter/Thk. =0.506/0.006 =84.33

Stress at 20 m. from base (Kgs/cm2)

Height to Dia. Ratio

Diameter to Thickness Ratio

Refer to table -3 of I.S 6533 (part-2 ). Maximum Permissible Stress for steel = 1260 Kgs/sq. cm.. Maximum Permissible Stress for steel = 1/t x ((M/Z) + (P/A)) t =1.28 mm Assume corrosion allowance 3 mm. Total thickness reqd = 1.28+3 = 4.27 mm say 6.0 mm

Therefore Section is Safe Zone 3: Thickness of Shell (cm.) Outside Diameter (OD) Inside Diameter (ID) Calculations: Moment of Inertia I = (3.142/64) x (OD4 ID4) =0.049 x (51.24 504) =30475.4 cm4 =I x (2/OD) =30475.4 x (2/51.2) =1190.44 cm3 =0.6 =51.2 cm =50.0 cm

Modulus of Section Z

For wind force on ladder, 20% of ladder dia. is considered for calculation and ladder dia. is 0.7 m. Wind Moment at 15 m. from Base M =[OD x Design wind pr. x safe factor x (sq of height of zone) / 2] + [dia. of ladder x Design wind pr. X 20% dia. of ladder x (sq of height of zone) / 2] x 102 =[0.512 x 83.4 x 0.7 x (152/2)] + [0.7 x 83.4 x 0.2 x 0.7 x (152/2)] x 102 =428216.5 kg - cm =3047 kg. =(3.142/4) x OD2 =0.7855 x (51.2)2 =2059.14 sq. cm. =(M/Z) + (P/A) =(428216.5/1190.44)+ (3047/2059.14) =361.19 =Height/Mean Dia. =1600/60.6 =24.75 =Diameter /Thk. =0.606/0.008 =75.75

Self Weight of Stack and Ladder P Cross Sectional Area of Chimney (sq. cm) A

Stress at 15 m. from base (Kgs/cm2)

Height to Dia. Ratio

Diameter to Thickness Ratio

Refer to table -3 of I.S 6533 (part-2 ). Maximum Permissible Stress for steel = 1260 Kgs/sq. cm.. Maximum Permissible Stress for steel = 1/t x ((M/Z) + (P/A)) t =2.86 mm Assume corrosion allowance 3 mm. Total thickness reqd = 2.86+3 = 5.86 mm say 8.0 mm

Therefore Section is Safe Zone 4: Thickness of Shell (cm.) Outside Diameter (OD) Inside Diameter (ID) Calculations: Moment of Inertia I = (3.142/64) x (OD4 ID4) =0.049 x (71.64 704) =111309.25 cm4 =I x (2/OD) =111309.25 x (2/71.6) =3109.19 cm3 =0.8 =71.6 =70.0

Modulus of Section Z

For wind force on ladder, 20% of ladder dia. is considered for calculation and ladder dia. is 0.7 m. Wind Moment at 22 m. from Base M =[OD x Design wind pr. x safe factor x (sq of height of zone) / 2] + [dia. of ladder x Design wind pr. X 20% dia. of ladder x (sq of height of zone) / 2] x 102 =[0.716 x 83.4 x 0.7 x (202/2)] + [0.7 x 83.4 x 0.2 x 0.7 x (212/2)] x 102 =999465 kg-cm =4001 kg. =(3.142/4) x OD2 =0.7855 x (71.6)2 =4024.34 sq. cm. =(M/Z) + (P/A) =(999465/3190.19)+ (4001/4024.34) =314.28 =Height/Mean Dia. =2000/70.8 =28.2 =Diameter/Thk. =0.708/0.008 =88.50

Self Weight of Stack and Ladder P Cross Sectional Area of Chimney (sq. cm) A

Stress at 10 m. from base (Kgs/cm2)

Height to Dia. Ratio

Diameter to Thickness Ratio

Refer to table -3 of I.S 6533 (part-2 ). Maximum Permissible Stress for steel = 1116 Kgs/sq. cm Maximum Permissible Stress for steel = 1/t x ((M/Z) + (P/A)) t =2.8 mm Assume corrosion allowance 3 mm. Total thickness reqd = 2.8+3 = 5.81 mm say 8.0 mm Therefore Section is Safe

Zone 5: Thickness of Shell (cm.) Outside Diameter (OD) Inside Diameter (ID) Calculations: Moment of Inertia I = (3.142/64) x (OD4 ID4) =0.049 x (91.64 904) =234783.35 cm4 =I x (2/OD) =234783.35x (2/91.6) =5126.27 cm3 =1.0 cm =91.6 cm =90 cm

Modulus of Section Z

For wind force on ladder, 20% of ladder dia. is considered for calculation and ladder dia. is 0.7 m. Wind Moment at 5 m. from Base M =[OD x Design wind pr. x safe factor x (sq of height of zone) / 2] + [dia. of ladder x Design wind pr. X 20% dia. of ladder x (sq of height of zone) / 2] x 102 =[0.816 x 83.4 x 0.7 x (252/2)] + [0.7 x 83.4 x 0.2 x 0.7 x (252/2)] x 102 =2382112.5 =6200 kg. =(3.142/4) x OD2 =0.7855 x (91.6) 2 =6590.78 sq. cm. =(M/Z) + (P/A) =(2602126/5126.27)+ (6200/6590.78) =465.62 =Height/Mean Dia. =2500/90.1 =27.74 =Diameter (mean)/Thk. =0.910/0.010 =90.10

Self-Weight of Stack and Ladder P Cross Sectional Area of Chimney (sq. cm) A

Stress at 11 m. from base (Kgs/cm2)

Height to Dia. Ratio

Diameter to Thickness Ratio

Refer to table -3 of I.S 6533 (part-2 ). Maximum Permissible Stress for steel = 1116 Kgs/sq. cm.. Maximum Permissible Stress for steel = 1/t x ((M/Z) + (P/A)) t =4.17 mm Assume corrosion allowance 3 mm.

Total thickness reqd = 4.17+3 = 7.17 mm Therefore Section is Safe Zone 6: Thickness of Shell (cm.) Outside Diameter (OD) Inside Diameter (ID) Calculations: Moment of Inertia I

say 8.0 mm =0.8 cm =111.6 cm =110 cm

= (3.142/64) x (OD4 ID4) =0.049 x (111.64 1104) =426597.17 cm4 =I x (2/OD) =426597.17 x (2/111.6) =7645.11 cm3

Modulus of Section Z

For wind force on ladder, 20% of ladder dia. is considered for calculation and ladder dia. is 0.7 m. Wind Moment at Base M =[OD x Design wind pr. x safe factor x (sq of height of zone) / 2] + [dia. of ladder x Design wind pr. X 20% dia. of ladder x (sq of height of zone) / 2] x 102 =[1.116 x 83.4 x 0.7 x (302/2)] + [0.7 x 83.4 x 0.2 x 0.7 x (302/2)] x 102 =3299637.6 =8400 kg. =(3.142/4) x OD2 =0.7855 x (111.6)2 =9783.056 sq. cm. =(M/Z) + (P/A) =(3299637.6/7645.11)+ (8400/9783.056) =442.32 =Height/Mean Dia. =3000/111.6 =26.88 =Diameter (mean)/Thk. =1.108/0.008 =138.5

Self Weight of Stack and Ladder P Cross Sectional Area of Chimney (sq. cm) A

Stress at base (Kgs/cm2)

Height to Dia. Ratio

Diameter to Thickness Ratio

Refer to table -3 of I.S 6533 (part-2 ). Maximum Permissible Stress for steel = 1116 Kgs/sq. cm. Maximum Permissible Stress for steel = 1/t x ((M/Z) + (P/A)) t =3.96 mm Assume corrosion allowance 3 mm.

Total thickness reqd = 3.96+3 = 6.96 mm Therefore Section is Safe Checking stress at 1m from bottom level. Zone 7: Thickness of Shell (cm.) Outside Diameter (OD) Inside Diameter (ID) Calculations: Moment of Inertia I

say 10.0 mm

=0.8 cm =111.6 cm =110 cm

= (3.142/64) x (OD4 ID4) =0.049 x (111.64 1104) =426597.17 cm4 =I x (2/OD) =426597.17 x (2/111.6) =7645.11 cm3

Modulus of Section Z

For wind force on ladder, 20% of ladder dia. is considered for calculation and ladder dia. is 0.7 m. Wind Moment at Base M =[OD x Design wind pr. x safe factor x (sq of height of zone) / 2] + [dia. of ladder x Design wind pr. X 20% dia. of ladder x (sq of height of zone) / 2] x 102 =[1.116 x 83.4 x 0.7 x (292/2)] + [0.7 x 83.4 x 0.2 x 0.7 x (292/2)] x 102 =3083328kg-m =8400 kg. =(3.142/4) x OD2 =0.7855 x (111.6)2 =9783.056 sq. cm. =(M/Z) + (P/A) =(3083328/7645.11)+ (8400/9783.056) =404.16 =Height/Mean Dia. =3000/111.6 =26.88 =Diameter (mean)/Thk. =1.108/0.008 =138.5

Self Weight of Stack and Ladder P Cross Sectional Area of Chimney (sq. cm) A

Stress at base (Kgs/cm2)

Height to Dia. Ratio

Diameter to Thickness Ratio

Refer to table -3 of I.S 6533 (part-2 ). Maximum Permissible Stress for steel = 1116 Kgs/sq. cm. Maximum Permissible Stress for steel = 1/t x ((M/Z) + (P/A))

t =3.6 mm Assume corrosion allowance 3 mm. Total thickness reqd = 3.6+3 = 6.96 mm Therefore Section is Safe Total Horizontal Force at Base Plate Level =0.5x10x83.4+0.55x5x83.4+0.65x83.4x5+0.8x6x83.4+1.0x6x83.4 = 1818.12 Kg say 10.0 mm

Design of Base Plate:

Max Compressive Force / unit length = F= (4M / d1 ) + Ws / d 1 F= (4 x 3299637 / x 110 ) + 8400 / x 110 F= 347.4 + 24.28 = 371.66 Kg / cm

2 2

Allowable Bearing stress for M20 grade Concrete = 5 N/mm2 Width of base Plate required = 371.66 / 1.25 x 5 =59.46 mm There fore provide 2 ISA 100 x 100 x 10 are used to transmit the pressure @bottom of the flared portion of the chimney. The length of the base plate beyond angle section =1/2(250 2 x 100 -10) = 20 mm Length of cantilever portion of the base plate up to the critical section xx as shown 20 +100-10 = 110 mm The thickness is designed for allowable pressure instead of actual bearing pressure. The total thickness @ the critical section xx a = l (3 x c / cbc) = 110 x (3x 1.25 x 5 / 1.33 x 185) = 30.36- 10 = 20.36 Provide 24 mm plate thickness Design of Anchor bolts: - F = (4M / d12 ) (Ws / d 1t) = ((4 x 3299637 x 1.5 / x 1102) (8400 / x 110 )) =496.7 Kg/cm For 36 mm dia bolt. Area = 452.16 mm2 Strength of anchor bolt = (10.178 x 1200 x 1.25) = 15267 Kg Spacing of anchor bolt = (15267)/ 806.12 = 18.9 cm Hence provide 24 nos of 36 mm dia bolt. Tensile Capacity of each M36 Bolt As per IS 800 (8.9.4.1) Permissible Shear stress Maximum Shear Capacity Maximum Tensile Force = T = = 10.178 cm2 x 1200 Kg/cm2 = 12219.6 Kg =1000 Kg/cm2 = 10.178 x 1000 = 10178 Kg = (4M / n D) W / n

10

= (4 x 1.5 x 5266759.2/24 x135) 8400/24 = 9403.25Kg Check for Combined Stress for Shear and tension = (9403.25/12213.6) + (2308/10178) = 0.99<1 Hence, Design is Safe. Bolt embedment length in concrete = Ld = x s / 4 x bd bd = Permissible stress in bond 8 Kgs/Cm2 d = 3.6 cms Ld = 135 cms Hence provide a 36 mm dia anchor bolt of 135 cms embedded length in concrete.

11

12

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Applied Combinatorics, Second Edition by Fred S Roberts, Barry TesmanDocument889 pagesApplied Combinatorics, Second Edition by Fred S Roberts, Barry TesmanAnil kumarNo ratings yet

- Chimney Calculations 14-7-2003Document4 pagesChimney Calculations 14-7-2003surinder yadavNo ratings yet

- Section 6 Battery SizingDocument54 pagesSection 6 Battery SizingAca ChchNo ratings yet

- CH Design-R1 PDFDocument12 pagesCH Design-R1 PDFmazumdar_satyajitNo ratings yet

- The Normal Distribution and Its PropertiesDocument19 pagesThe Normal Distribution and Its Propertiessherdan genistonNo ratings yet

- Fault Level CalculationDocument43 pagesFault Level Calculationmazumdar_satyajitNo ratings yet

- XML JavascriptDocument62 pagesXML Javascriptanon-506495No ratings yet

- DactylosDocument150 pagesDactylosJay-r Pabualan DacoNo ratings yet

- The Practical Reference Guide ForDocument21 pagesThe Practical Reference Guide ForIgnacio SantiagoNo ratings yet

- Lime Manual PDFDocument60 pagesLime Manual PDFKenny RuizNo ratings yet

- (Nijhoff International Philosophy Series) Stanislaw Lesniewski - S. J. Surma Et Al. (Eds.) - Collected Works. 1, 2-Springer (1991)Document408 pages(Nijhoff International Philosophy Series) Stanislaw Lesniewski - S. J. Surma Et Al. (Eds.) - Collected Works. 1, 2-Springer (1991)Aldana Fontana100% (4)

- Calculation For The Fault CurrentDocument1 pageCalculation For The Fault Currentmazumdar_satyajitNo ratings yet

- Ventilation: Installation ConsiderationsDocument2 pagesVentilation: Installation Considerationsmazumdar_satyajitNo ratings yet

- Ventilation: Thumb Rule For Calculation of Air Flow From An Louvered OpeningDocument1 pageVentilation: Thumb Rule For Calculation of Air Flow From An Louvered Openingmazumdar_satyajitNo ratings yet

- Phase Segregated Terminal Box: Atex / Iecex Gas & Dust CertifiedDocument2 pagesPhase Segregated Terminal Box: Atex / Iecex Gas & Dust Certifiedmazumdar_satyajitNo ratings yet

- Phase Segregated Terminal Arrangement Phase Seperated Terminal ArrangementDocument1 pagePhase Segregated Terminal Arrangement Phase Seperated Terminal Arrangementmazumdar_satyajitNo ratings yet

- PPT6Document1 pagePPT6mazumdar_satyajitNo ratings yet

- General Technical Versions: Motor Terminal BoxesDocument1 pageGeneral Technical Versions: Motor Terminal Boxesmazumdar_satyajitNo ratings yet

- China Nonroad EmissionsDocument6 pagesChina Nonroad Emissionsmazumdar_satyajitNo ratings yet

- Chimney Cost Breakup Details: Base Plate, Comp Ring, Gussets, Flanges Weights and CostsDocument1 pageChimney Cost Breakup Details: Base Plate, Comp Ring, Gussets, Flanges Weights and Costsmazumdar_satyajitNo ratings yet

- 14 Q KG/HR) 0.3 GM/HR 14 0.01998 X (Fuel Rate in G/HR) X (%fuel Sulphur by WT.)Document2 pages14 Q KG/HR) 0.3 GM/HR 14 0.01998 X (Fuel Rate in G/HR) X (%fuel Sulphur by WT.)mazumdar_satyajitNo ratings yet

- Engine Manufacturing COmpanyDocument2 pagesEngine Manufacturing COmpanymazumdar_satyajit0% (1)

- Chimney WT CalculationDocument3 pagesChimney WT Calculationmazumdar_satyajitNo ratings yet

- PE SolarliteKanjanaburi eDocument1 pagePE SolarliteKanjanaburi emazumdar_satyajitNo ratings yet

- Installation of acoustic panels and sound attenuatorsDocument11 pagesInstallation of acoustic panels and sound attenuatorsmazumdar_satyajitNo ratings yet

- Genon 15 06 10Document6 pagesGenon 15 06 10mazumdar_satyajitNo ratings yet

- Cooling Tower Calculations-TR CapacityDocument10 pagesCooling Tower Calculations-TR Capacitymazumdar_satyajitNo ratings yet

- KEI Cable Price List 2008Document7 pagesKEI Cable Price List 2008mazumdar_satyajitNo ratings yet

- Exhaust System Back Pressure CalculationDocument1 pageExhaust System Back Pressure Calculationmazumdar_satyajitNo ratings yet

- Pid 2Document1 pagePid 2mazumdar_satyajitNo ratings yet

- VMA 1826 Approval Standards Rev 3Document54 pagesVMA 1826 Approval Standards Rev 3mazumdar_satyajitNo ratings yet

- Heat Balance CalculationDocument1 pageHeat Balance Calculationmazumdar_satyajitNo ratings yet

- Calculation of fault current for paralleled generatorsDocument1 pageCalculation of fault current for paralleled generatorsmazumdar_satyajitNo ratings yet

- Room AcousticDocument19 pagesRoom AcousticMenandro AmbanlocNo ratings yet

- HS CodeDocument2 pagesHS Codemazumdar_satyajitNo ratings yet

- Data SheetDocument1 pageData Sheetmazumdar_satyajitNo ratings yet

- E 3Document1 pageE 3mazumdar_satyajitNo ratings yet

- 1910 179bookletDocument12 pages1910 179bookletRichard DeNijsNo ratings yet

- Airy stress function enables determination of stress components in pure beam bendingDocument19 pagesAiry stress function enables determination of stress components in pure beam bendingmaran.suguNo ratings yet

- Install and Configure Computer SystemsDocument18 pagesInstall and Configure Computer SystemsAlbino LarozaNo ratings yet

- Financial Modelling Assignment - Ghizal Naqvi (Attock Petroleum Limited)Document13 pagesFinancial Modelling Assignment - Ghizal Naqvi (Attock Petroleum Limited)Ghizal NaqviNo ratings yet

- NFRC 200-2010Document45 pagesNFRC 200-2010reynolds534100% (1)

- Swat Luu: User ManualDocument13 pagesSwat Luu: User ManualgjferreiraNo ratings yet

- Beyond SVGFDocument66 pagesBeyond SVGFLiliana QueiroloNo ratings yet

- Brown Stock WashingDocument22 pagesBrown Stock Washingtreese2No ratings yet

- PD05P XXX XXX B SeDocument2 pagesPD05P XXX XXX B SemaaoeNo ratings yet

- Understanding the Strength and Limitations of DES EncryptionDocument32 pagesUnderstanding the Strength and Limitations of DES EncryptionArya KumariNo ratings yet

- Academic Performance of Face-to-Face and Online Students in An Introductory Economics Course and Determinants of Final Course GradesDocument13 pagesAcademic Performance of Face-to-Face and Online Students in An Introductory Economics Course and Determinants of Final Course GradesLou BaldomarNo ratings yet

- Adiabatic Logic: An Alternative Approach To Low Power Application CircuitsDocument6 pagesAdiabatic Logic: An Alternative Approach To Low Power Application CircuitsBibartan DasNo ratings yet

- CH-2 Earth DamsDocument18 pagesCH-2 Earth DamssidNo ratings yet

- ES Q2 Mod8Document26 pagesES Q2 Mod8maacovsNo ratings yet

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsDocument4 pages19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RNo ratings yet

- SVCE Seminar Report Format (FINAL)Document6 pagesSVCE Seminar Report Format (FINAL)Vinod KumarNo ratings yet

- ZTE NODE-B ConnectivityDocument19 pagesZTE NODE-B ConnectivitySanjeet Doodi100% (7)

- PI ControllerDocument5 pagesPI Controllerdanuega1No ratings yet

- A Tour Through Mathematical Logic: Robert S. WolfDocument4 pagesA Tour Through Mathematical Logic: Robert S. WolfUrahara JefNo ratings yet

- Materials Refractive Index and Extinction CoefficientDocument276 pagesMaterials Refractive Index and Extinction CoefficientDr-Mandeep SinghNo ratings yet

- Unit 2 MineralogyDocument53 pagesUnit 2 MineralogyEashan Adil100% (1)

- Rudolf Steiner - Warmth Course GA 321Document119 pagesRudolf Steiner - Warmth Course GA 321Raul PopescuNo ratings yet

- Parsing Techniques and Grammars for Compiler DesignDocument102 pagesParsing Techniques and Grammars for Compiler DesignRajakumaran MohanNo ratings yet