Professional Documents

Culture Documents

U.T Procedure

Uploaded by

dedicatemindsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U.T Procedure

Uploaded by

dedicatemindsCopyright:

Available Formats

Owner: KPIC

Costumer: Namvaran

Stack-4201

namvaran Consulting Engineers

Managers

Location: Kermanshah- Iran

Document No.: SEC-PJ045-ST-IFP-0008-2

K.P.I.C.

SEC-Project No.: PJ045

Ultra Sonic Test Procedure

Owner: Purchaser: Unit No.:

Purchaser review and comment shall not be assumed to indicate either responsibility or liability for accuracy and completenes of this document or to alter any contractual terms and conditions. Item Numbers: S-4201 Purchasers Disposition No Comments Comments as Noted Rejected

Date

Name

Initial

SDRL Code A60

Purchase Order No. I-41D1-B213-01

Document No.

Rev.

SEC-PJ045-ST-IFP-0008-2 02

02 01 Rev.

02.08.2004 20.06.2004 Issue Date

COMMENT AS NOTE ISSUED FOR COMMENT

DESCRIPTION

M.Z H.H

PRD. BY

M.Z M.Z

CHKD. BY

M.S.KH M.S.KH

APPR. BY

DISCIPLINE

Quality Assurance System U.T. Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 2 of 10

Contents 123456789Purpose Scope Responsibility Reference Standard Description Acceptance Standard Documentation Sound Beam Propagton Reporting

10- Appendix 11- Personal Qualification

Quality Assurance System U.T. Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 3 of 10

Ultrasonic Test Procedure

1- Purpose: This procedure describe the performance of the ultra sonic test for welds. 2- Scope The following procedure covers the general requirement for ultrasonic test of all corner weld type. 3- Responsibility All nondestructive examinations shall be performed by personnel certified in accordance with level II of American society for non-destructive testing (SNT-TC-1A) 4a) b) c) d) Reference Standard project specification ASME V Article 4 & 5 the latest version ASME SEC. VIII Div. 1 Appendix 2 the latest version . API 661

5- Description Type of equipment: sitescan 130 Messers. SONA TEST Test probe: Variable Frequency: 1MHZ-5MHZ SA5-10x8 ANGLE 60 SA-10x8 ANGLE 45 CDF5-15 (T/R)

(see appendix-3)

Coupling agent: sonagel W1 or grease or oil, Method Contact: Yes Immersion: No Shoes: No Wedge: No 5.1- Test Object Longitudinal corner weld connection corner welds. 5.2- Method of calibration Calibration block refer to appendix 2. standard reference block in ultrasonic testing all discountinuty indication are compared to a reference standard.

Quality Assurance System U.T. Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 4 of 10

Ultrasonic standard reference blocks, often called test block, are used in ultrasonic testing not only to calibrate the ultrasonic equipment but principally to evaluate the discontinuity indication. Standardization means two things it verifies that the instrument/ probe combination is performing as required calibration it establishes a sensitivity (or grain) level. Evaluation of discontinuities within a piece is accomplished by comparing the indications from them with the indication from an artificial discontinuity of known size, at the same depth in a standard reference block of the same material to be tested. DAC calibration curve shall be draw as follow. 1. To make calibration block as per appendix 2. 2. Find the hole that give the highest amplitude & set in 80% of the full screen height. 3. Mark the peak of indication from 1/4, 1/2, 3/4 & connect all point to each other for drawing of distance amplitude corrective on curve. 5.3- Test Scope According to welding & NDT plan (100%) UT. See drawings No. AC01-118-09-00 6- Acceptance Standard As per ASME code SEC. VIII Div.1 appendix 12 and project specification. 7- Documentation Original certificates remain in quality department. One copy to Namvaran Co. 8- Sound Beam Propagation For sound beam propagation see appendix 4. 9- Reporting Operator/ inspector shall provide a test report (appendix 1) after performing each test and send to client authorized inspector for approval. 10- Appendix See appendix 1, 2, 3, 4, 5, 6 Personal Qualification The qualification of NDE personnel shall be in accordance with their employers written practice which must be in accordance with one of SNT-TC-1A , ANSI/ASNT CP-189 , national or international central certification progress.

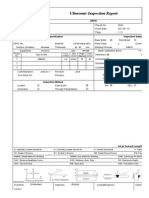

Quality Assurance System U.T. Procedure

Plant Examination acc to: Drawing no.: Testing requirement TASK TO: Examination after H.T. Test Equipment: CALIBRATION RECORD (DAC DATA) Sound path (mm) Amplitude (dB) Ref. Block No. W ithout: Befor H.T.

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 5 of

Plant dentification: Material: Heat No.: Order No.: Dimention: Condition of Exam. Surface:

10

Joint No.

Probe

Dimension Sound Position

Echo Haight

Remark

Judgement Acc. Test Specification

Acceptable Reflectors No Recordable Reflectors

Not Accept. Reflectors

REMARKS:

Inspector Signature Date

OPERATOR

API

CLIENT (A.I)

Quality Assurance System U.T. Procedure Appendix (f2)

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 6 of 10

Weld Thickness t

1 in. or less over 1 in. through 2 in. over 1 in. through 4 in. Over 1 in. through 6 in. Over 1 in. through 8 in. Over 1 in. through 10 in. Over 10 in.

Basic Calibration Block Thickness T

3/4 in. or t 1-1/2 in. or t 3 in. or t 5 in. or t 7 in. or t 9 in. or t t=1 in.

Hol Diameter

3/32 in. 1/8 in. 3/16 in. 1/4 in. 5/16 in. 3/8 in. Note (1)

Notch Size

Width= 1/8 in. to 1/4 in. Depth = 2% T or 0.04 in. Diameter is greater into the Based mate

Length=2 in. min.

Quality Assurance System U.T. Procedure Appendix 3 (Sample)

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 7 of 10

Quality Assurance System U.T. Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 8 of 10

Appendix 4 Sound Beam Propagation (Sample)

Type SA5-60 SA-45 CDF5-15

MHZ 4.3 4.3 5

Element Dimension (mm) 10x8 10x8 2x13x5

Quality Assurance System U.T. Procedure Appendix 5 Sound Beam Propagation (Sample)

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 9 of 10

Quality Assurance System U.T. Procedure Appendix (6) Sound Beam Propagation

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 10 of 10

You might also like

- M022 Jsa For Magnetic Penetration TestDocument4 pagesM022 Jsa For Magnetic Penetration TestYahafis MaulanaNo ratings yet

- The Eddy Current Inspection Method Pt4Document4 pagesThe Eddy Current Inspection Method Pt4vrapciudorianNo ratings yet

- Inspection Technologies Brochure English 5Document19 pagesInspection Technologies Brochure English 5Agus WiyantoNo ratings yet

- Iso 17640-2010-UtDocument1 pageIso 17640-2010-Utsdmkl85No ratings yet

- Ultrasonic Thickness Gaging: by Tom NelliganDocument4 pagesUltrasonic Thickness Gaging: by Tom NelliganCarlos BustamanteNo ratings yet

- Inspection Trends (January 2013 Vol. 16 No. 1)Document28 pagesInspection Trends (January 2013 Vol. 16 No. 1)Patrick DominguezNo ratings yet

- Echo To Echo (Holloway NDT Article)Document4 pagesEcho To Echo (Holloway NDT Article)pjhollowNo ratings yet

- Ultra Sound Testing: Opic:-Test Methods and TechniquesDocument23 pagesUltra Sound Testing: Opic:-Test Methods and TechniquesVarun MalanNo ratings yet

- 243 Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes.Document7 pages243 Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes.Ali MohsinNo ratings yet

- In House NDT Examination Fundamental General Examination Leak TestingDocument2 pagesIn House NDT Examination Fundamental General Examination Leak Testingvsnaiduqc100% (1)

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- B-Scan Buggy Demo ProcedureDocument12 pagesB-Scan Buggy Demo ProcedureJuan Ricardo Villanueva ReañoNo ratings yet

- Apt Inspection TechnologiesDocument6 pagesApt Inspection TechnologiesArunNo ratings yet

- Steps For Audit. of NDT ReportsDocument10 pagesSteps For Audit. of NDT Reportsjpvtv100% (1)

- 0455e - Welding Inspector Visual Acuity Record PDFDocument1 page0455e - Welding Inspector Visual Acuity Record PDFAbu HanifaNo ratings yet

- API 1104 ComplateDocument24 pagesAPI 1104 ComplateAwale UdinNo ratings yet

- Ultrasonic Thickness GaugeDocument5 pagesUltrasonic Thickness GaugecarlosNo ratings yet

- tt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFDocument20 pagestt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFelmek jayaNo ratings yet

- NDT Application FormDocument4 pagesNDT Application FormAhmed Shaban KotbNo ratings yet

- Clad MeasurementDocument6 pagesClad MeasurementSunny SaparNo ratings yet

- Overtime Claim Form: Name: Project: MonthDocument1 pageOvertime Claim Form: Name: Project: MonthPermadi SandinantoNo ratings yet

- Amigos Technical Services (S) Pte LTD Operating Procedure Ultrasonic TestingDocument27 pagesAmigos Technical Services (S) Pte LTD Operating Procedure Ultrasonic TestingHoque AnamulNo ratings yet

- SMS-603-UT-003 Ultrasonic - API 1104 - B31.8 - Rev 3 PDFDocument20 pagesSMS-603-UT-003 Ultrasonic - API 1104 - B31.8 - Rev 3 PDFDewAngga YudistiraNo ratings yet

- Ultrasonic Testing Training (UT) : Level-IIDocument8 pagesUltrasonic Testing Training (UT) : Level-IIAn IkhrandiNo ratings yet

- Norsok M101 Structural Steel FabricationDocument67 pagesNorsok M101 Structural Steel FabricationbreeeeezzzzzeNo ratings yet

- DMS 2 Thickness Gauge TrainingDocument34 pagesDMS 2 Thickness Gauge TrainingcarlosNo ratings yet

- Thickness ProbesDocument4 pagesThickness ProbesRodrigoNo ratings yet

- G S Earth WireDocument10 pagesG S Earth WiresaratNo ratings yet

- Application Form For CSWIP 5 Year Renewal (Overseas) - v3 1Document7 pagesApplication Form For CSWIP 5 Year Renewal (Overseas) - v3 1Bamarasan ArasanNo ratings yet

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDocument6 pagesLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANo ratings yet

- 8th MENDT Brochure FinalDocument12 pages8th MENDT Brochure FinalAlzaki AbdullahNo ratings yet

- Visual Examination ProcedureDocument23 pagesVisual Examination ProcedureEdAlmNo ratings yet

- Certificate NSL Equipment CertificationDocument1 pageCertificate NSL Equipment CertificationJohn RoshdyNo ratings yet

- E428Document6 pagesE428valentinNo ratings yet

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanNo ratings yet

- Astm A200 PDFDocument3 pagesAstm A200 PDFgaminNo ratings yet

- Partial List of ISO SpecificationsDocument4 pagesPartial List of ISO Specificationsskynyrd75No ratings yet

- Magnetic Particle Process Guide PDFDocument1 pageMagnetic Particle Process Guide PDFdwimukh360No ratings yet

- Eddy Current Testing PDFDocument1 pageEddy Current Testing PDFMai Sỹ HảiNo ratings yet

- NDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Document6 pagesNDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Mark BrailsfordNo ratings yet

- Vacuum Box Test Procedure: PurposeDocument4 pagesVacuum Box Test Procedure: Purposesaravan1891No ratings yet

- Itis NDT MT 01 Rev 06Document19 pagesItis NDT MT 01 Rev 06pandab bkNo ratings yet

- ASNT-TC1A About PDFDocument20 pagesASNT-TC1A About PDFPrashant PuriNo ratings yet

- 344.2 Visual Examination: Para. 344.7Document1 page344.2 Visual Examination: Para. 344.7NDTInstructorNo ratings yet

- 020-NDT - TSE - UT - ASME B31.3 - 20 - Ultrasonic, REV 00 (1) - CompressedDocument35 pages020-NDT - TSE - UT - ASME B31.3 - 20 - Ultrasonic, REV 00 (1) - CompressedPT PUTRA SETIAWAN PRIMANo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Quick Flaw Evaluation in Ultrasonic Testing Using Microprocessor Assisted MethodsDocument4 pagesQuick Flaw Evaluation in Ultrasonic Testing Using Microprocessor Assisted MethodsGustavo Shaw0% (1)

- Itp AsntDocument33 pagesItp AsntSYED FADZIL SYED MOHAMED100% (1)

- Modul 2 FittingDocument19 pagesModul 2 Fittingpetrocamp71No ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- RT ProcedureDocument44 pagesRT Procedureefmartin21100% (1)

- Visual Testing - Level 2 in Ahmedabad & Vadodara - Gulfnde - inDocument1 pageVisual Testing - Level 2 in Ahmedabad & Vadodara - Gulfnde - inGulfnde Industrial ServiceNo ratings yet

- FAQ - What's New in ISO 15614-1 - 2017Document2 pagesFAQ - What's New in ISO 15614-1 - 2017tomasinkaNo ratings yet

- Updated Asnt-Ndt Level - II in RT Ut MT PTDocument4 pagesUpdated Asnt-Ndt Level - II in RT Ut MT PTJason RogersNo ratings yet

- Isq-O&G Ultrasonic Thickness and Corrosion Scanning ProtocolDocument13 pagesIsq-O&G Ultrasonic Thickness and Corrosion Scanning Protocolpon sharonNo ratings yet

- NDT ProcedureDocument29 pagesNDT ProcedureSystem Certifications LimitedNo ratings yet

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalDocument11 pages25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikNo ratings yet

- F5063a-K-003-00 NDT Procedure PDFDocument11 pagesF5063a-K-003-00 NDT Procedure PDFJatmika Budi SantosaNo ratings yet

- Project Owner Contractor Inspection Surveillance Report (Isr)Document20 pagesProject Owner Contractor Inspection Surveillance Report (Isr)destri_742053763No ratings yet