Professional Documents

Culture Documents

Studies On Solid Desiccant Based Hybrid Air-Conditioning Systems

Uploaded by

Lim Hai MengOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Studies On Solid Desiccant Based Hybrid Air-Conditioning Systems

Uploaded by

Lim Hai MengCopyright:

Available Formats

Applied Thermal Engineering 21 (2001) 119134

www.elsevier.com/locate/apthermeng

Studies on solid desiccant based hybrid air-conditioning systems

P.L. Dhar*, S.K. Singh

Department of Mechanical Engineering, I.I.T. Delhi, New Delhi 110 016, India Received 3 August 1999; accepted 27 February 2000

Abstract Desiccant based air-conditioning systems oer a promising alternative to conventional airconditioning systems using vapour compression refrigeration especially under conditions involving high latent loads. The desiccant can be used either in a stand-alone system or coupled judiciously with a vapour compression system to achieve high performance over a wide range of operating conditions. In this paper, the results of a detailed study of solid desiccant-based hybrid air-conditioning systems are presented. The literature review revealed that various authors dier in their evaluation of the ecacy of these systems. This seems to be due to dierent methods of modelling of dehumidier and dierences in the operating conditions of the cycles employed. Accordingly, the performance of four hybrid cycles (which include a new proposed cycle) for typical hot-dry and hot-humid weather conditions has been evaluated using a detailed procedure for the analysis of rotary dehumidier, the most commonly employed industrial dehumidier, based on the analogy method of Maclaine-Cross and Banks [I.L. Maclaine-Cross, P.J. Banks, Coupled heat and mass transfer in regenerators predictions using an analogy with heat transfer, Int. J. of Heat and Mass Transfer 15 (1972) 12251241]. Eect of room sensible heat factor, ventilation mixing ratio, and regeneration temperature has also been studied. The results show that solid desiccant-based hybrid air-conditioning systems can give substantial energy savings as compared to conventional vapour compression refrigeration based air-conditioning systems in most commonly encountered situations. 7 2000 Elsevier Science Ltd. All rights reserved.

Keywords: Solid desiccant; Hybrid air-conditioning system; Rotary dehumidier

* Corresponding author. Tel.: +91-11-685-7753; fax: +91-11-686-2037. E-mail address: pldar@mech.iitd.ernet.in (P.L. Dhar). 1359-4311/01/$ - see front matter 7 2000 Elsevier Science Ltd. All rights reserved. PII: S 1 3 5 9 - 4 3 1 1 ( 0 0 ) 0 0 0 3 5 - 1

120

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

Nomenclature CMMSUP MOD.VEN-HTX NO. OF DEHUM QHTR RECIR-CON RSHF TEVAP VC CYCLE VEN-CON WCOMP W.E. CONS. 1. Introduction In any air-conditioning system two types of loads have to be met, viz. the sensible load arising from heat transfer into the space and the latent load arising from moisture generated within the space. The conventional systems use vapour compression refrigeration to meet both these loads. To meet the latent load, air must be dehumidied by cooling it below its dew point. Higher the latent heat load, lower is the evaporator temperature required. But there is a limitation on the evaporator temperature too since it must not go below 08C, the freezing point, and a very low supply temperature of air can create situations of draft in the airconditioned space. Therefore, in conventional systems reheat is often required in high latent heat load application, which implies very poor energy eciency. In addition to it, large mass ow rates are maintained because moisture removal per unit mass of air is limited. Simple desiccant systems are well suited to meet latent heat loads. Here the process air is brought in contact with a material with high anity for water. Moisture is absorbed/ adsorbed by this desiccant material and the heat of absorption/adsorption released in the process heats the air. The air is thereafter cooled by heat exchanger(s) and evaporative cooler(s). Now if the system has to meet sensible heat load too, the process air should be over-dried to permit its further cooling by direct evaporation after its sensible cooling through heat exchange with the surrounding air. This overburdens the dehumidier, especially in hot and humid climates, and it therefore needs a large quantity of heat to remove the moisture picked up resulting in poor performance of simple desiccant cycles in these climates. Clearly, a more ecient process would result if a vapour compression machine and a desiccant system were combined. This is termed as desiccant-based hybrid air-conditioning system (Fig. 1). Here the desiccant removes the moisture ingress into the space, and the heat supply air ow rate (m3/min) ventilationheat exchanger cycle number of dehumidiers heater input (kW) recirculationcondenser cycle room sensible heat factor evaporator temperature (8C) conventional system using vapour compression refrigeration for the cooling coil ventilation condenser cycle compressor work (kW) weighted energy consumption (kW, Heat)

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

121

Fig. 1. Schematic diagram of typical hybrid desiccant cooling system.

exchanger/indirect evaporative cooler and vapour compression system share the sensible heat load. For the purpose of comparison all the above mentioned systems are plotted together on a psychometric chart (Fig. 2). In the conventional system the air is directly cooled and dehumidied from state M (i.e., a mixture of return air and fresh ventilation air) to state O by passing it over a coil through which chilled water or refrigerant are circulated. However, in

Fig. 2. Plot of simple desiccant cooling cycle, simple vapour compression cycle and typical hybrid cycle on psychrometric chart.

122

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

high latent load applications, the state O does not lie on room sensible heat factor (RSHF) line and therefore reheating of this cold air (OS) has to be done to meet the load requirements properly. In the simple desiccant system the mixed air at M is dehumidied to a very low moisture content level D2 in the dehumidier. The air which gets heated in the dehumidication process is then sensibly cooled to state C using indirect evaporative cooling (IEC) and nally brought to the same supply state S using direct evaporative cooling. No reheating is needed. In the hybrid system the air is dried to a smaller extent (point D1) and thereafter sensibly cooled upto the supply state S, partly by IEC (D1E) and partly by a refrigerant circulating through a cooling coil (ES). Clearly, here the dehumidier duty is much lesser than that of a simple desiccant system, but there is a load on the refrigeration coil, though much lesser than that of a simple refrigeration system. Since the evaporator temperature required to do sensible cooling (ES) is higher than that needed for conventional cooling and dehumidication (OS), the power consumption per ton of cooling is also lower. But there is an additional requirement of heat energy for regenerating the dehumidier. It is obvious that without detailed calculations it is not possible to predict which of these systems would be superior from the point of view of energy consumption and initial cost. This would depend on factors like performance of the dehumidier, the indirect evaporative cooler, the vapour compression system, the type of hybrid cycle employed, the RSHF, the indoor and outdoor DBT, and specic humidity values.

2. Literature review One of the earliest comprehensive studies on solid desiccant-based hybrid cooling systems was done by Burns et al. [1]. They studied three hybrid system congurations for supermarket applications (high latent load) and a comparison of their performance with conventional airconditioning system was made. The cycles termed as ventilationcondenser cycle, recirculation condenser cycle and ventilationheat exchanger cycle are shown in Figs. 35, respectively. In the ventilationcondenser cycle only the ventilation air (at state 1) is passed through the dehumidier. The dehumidied air (2) is cooled by indirect evaporative cooling (23) before mixing it with the recirculated room air (6). The mixed air (4) is then further cooled sensibly in a chilled water coil (45) till it reaches the RSHF line. To regenerate the desiccant, waste condenser heat is used to preheat the ambient air (17). Any further heating needed (78) is provided by some auxiliary heat source. The regenerative air stream is cooled and humidied as it passes through the desiccant and then exhausted to the outside, state (9). The recirculationcondenser cycle (Fig. 4) diers from the ventilation cycle in that, here the mixture of recirculated air and the ventilation air (state 2) is passed through the dehumidier. Consequently, the dehumidier size is larger since it has to handle larger volumes of air but as is evident on comparing Figs. 3 and 4, the quantity of moisture to be removed per kg of air is much smaller. Therefore, the regeneration temperature needed is lesser than that needed in the ventilationcondenser cycle. The Heat Exchanger cycle (Fig. 5) is a variant of the ventilation cycle. The hot dehumidied air is cooled with the help of ambient air in a heat exchanger; no indirect

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

123

Fig. 3. Schematic diagram and plot of ventilation/condenser cycle.

124

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

Fig. 4. Schematic diagram and plot of recirculation condenser cycle.

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

125

Fig. 5. Schematic diagram and plot of heat exchanger cycle.

126

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

evaporative cooler is used and the condenser heat is also not utilised. This ambient air is further heated to the regeneration temperature in the auxiliary heater. Burns et al. [1] reported that these cycles would give energy savings, in comparison to the conventional air-conditioning systems, ranging from 56.5 to 66% at moderate ambient conditions of 308C, 0.016 kg/kg da, RSHF of 0.35 and space conditions of 248C, 0.0104 kg/kg da. These calculations were based on the concept of weighted energy consumption, with one unit of electrical energy weighted twice that of thermal energy. Sheridan and Mitchell [5] investigated the performance of a hybrid desiccant cooling system for hot-humid and hot-dry climates. The system studied was similar to recirculationcondenser cycle. In high sensible heat load, SHF was over 0.9 and in high latent load, SHF varied from 0.3 to 0.5. In high sensible heat load applications the energy savings ranged from 24 to 40% for these two climates. However, they also found that the hybrid cycle saved more energy in a hot and dry climate than it did in a hot and humid climate, where it may even use more energy than a conventional system. Here, 1 kW of electrical energy was taken to be equivalent to 3.33 kW of thermal energy. Maclaine-Cross [4] studied the feasibility of gas red hybrid desiccant cooling systems for medium to large general air-conditioning projects. It was suggested that engine drive for vapour compression plant could halve the energy costs for Australian conditions if waste heat was recovered to regenerate the desiccant. Worek and Moon [8] investigated the performance of a rst generation prototype desiccant integrated hybrid system. The results showed that at the same level of dehumidication, 60% performance improvement over vapour compression system was obtained at ARI design conditions. The performance of hybrid system decreased as the outdoor humidity ratio was increased. Nevertheless, over the range investigated, the performance improvement varied from 74 to 44%. The performance improvement increased as outdoor temperature was increased keeping humidity constant; over the range of outdoor temperature investigated the hybrid system had a performance improvement of 2080% over the conventional vapour compression system. Singh et al. [7] in a recent work have analyzed the afore-mentioned three hybrid cycles for Indian climatic conditions. Modelling of the dehumidier operating at a xed regeneration temperature of 1358C, and regeneration to process air mass ow rate of 0.33, is done using the performance data from a manufacturer. It is reported that energy savings ranging from 30% to 50% can be easily achieved at higher latent heat load applications. On the basis of literature review, it is evident that in high sensible load applications, large energy savings are possible by using hybrid systems instead of conventional air conditioning systems. But for high latent heat load application, there is inconsistency in the results of dierent authors. Some have claimed that considerable energy saving would be possible but others have concluded that a hybrid system might use more energy than a vapour compression system. Further, most of the studies have been done at ARI design conditions which are very ``mild'' compared to the ambient conditions actually encountered in tropical climates. Singh et al. [7] have studied the performance for such conditions, but have used a very simple empirical model of the dehumidier which does not permit investigation of the inuence of basic design

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

127

parameters (like regeneration temperature, ratio of the mass ow rates of process to regeneration air, etc.) on the system performance. Accordingly, an attempt has been made in the present work to investigate the suitability of solid desiccant-based hybrid systems for air-conditioning applications in typical hot-dry and hot-humid climatic conditions by incorporating a detailed model for simulating the performance of the rotary desiccant wheel. 3. Computer modelling of hybrid systems The most important component of a hybrid air-conditioning system using solid desiccants is the rotary desiccant wheel. Its mathematical modelling needs solution of coupled partial dierential equations, but Maclaine-Cross and Banks [3] showed that these equations can be transformed into two sets of equations of the same form as those of a rotary sensible heat regenerator. The performance of the rotary desiccant wheel has been determined by using this analogy, following the formulation given by Jurinak [2]. The model has been validated over a wide range of operating conditions by comparing the predictions of the computer programme based on this method with the rated performance of two types of wheel manufactured in India. A satisfactory agreement was observed, with the predicted outlet humidity values generally exceeding the actual values by about 1 gm/kg da (for details, see [6]). The performance of all other components (various heat exchangers and evaporative coolers) has been predicted by assuming suitable values for their eectiveness. The condenser temperature of the vapour compression system has been assumed to be 158C higher than the ambient DBT, and, following Burns et al. [1], its COP has been taken as 46% of the COP of the corresponding Carnot cycle between the condenser and evaporator temperatures. Besides the afore-mentioned three cycles, the analysis has also been done for a modied heat exchanger cycle, shown in Fig. 6, where the exhaust from the air-conditioned space is used, instead of the ambient air, for pre-cooling the dehumidied air in the heat exchanger. The analysis has been done for typical comfort conditions (258C DBT and 10 g/kg da moisture content) with: hot-dry outdoor conditions of 43.28C DBT and 7.26 g/kg da moisture content, and hot-humid conditions of 38.68C DBT and 16.14 g/kg moisture content; two RSHF values of 0.35 and 0.75; and two values of ventilation air to supply air ratio: 0.1 and 0.2. The analysis presumes that the latent heat load has to be met by the dehumidier and the

Fig. 6. Schematic diagram of proposed cycle.

128

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

sensible heat load by the IEC and the vapour compression refrigeration system. A provision has been made in the computer program that if one dehumidier is unable to lower the process air specic humidity below room humidity, then additional dehumidiers are used with intercooling in between them. Also, provision for direct evaporative cooling has been made wherever necessary. This type of situation arises when the dehumidier exit humidity is low, and the RSHF is high, as illustrated in Fig. 7. Here the supply air state needed to reach the RSHF line only through sensible cooling (i.e., point 5) has a DBT lower than the dew point temperature, which is not physically possible. Therefore, a suitable check has been incorporated in the computer program and a provision is made for direct evaporative cooling (44') of the air leaving the cooling coil. The evaporator temperature is assumed to be 58C higher than the dew point temperature and the state of air after the evaporator (4) is calculated as usual from its eectiveness. 4. Results of analysis The performance parameters at the design regeneration temperature of 1358C, for dierent combinations of parameters mentioned above, are given in Tables 1 and 2 for hot-dry conditions. The weighted energy consumption has been calculated by giving a weightage of 3 to the electrical energy in comparison to the thermal energy. The following conclusions can be drawn from these results: 1. For ventilationcondenser, ventilationheat exchanger and modied ventilationheat exchanger cycles, the supply air ow rate required is very high compared to that in the recirculationcondenser cycle and conventional systems using the vapour compression cycle (VC cycle). In these cycles, only ventilation air is passed through the desiccant wheel, which

Fig. 7. Plot of recirculation condenser cycle at high sensible heat factor and summer design conditions.

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

129

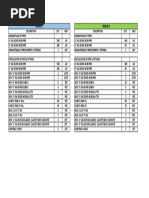

Table 1 Performance of hybrid and conventional VC cycles, at hot-dry conditions, mixing ratio of 0.1 and the design regeneration temperature of 1358C RSHF CMMSUP QHTR (kW) TEVAP (8C) NO. OF DEHUM WCOMP (kW) W.E. CONS. (kW) 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 VC CYCLE 15.08 11.49 3.262 0 6 9.3 2.90 1.425 11.96 4.275 VEN-CON 73.94 28.43 2.962 1.139 23.35 17.13 1 1 0.4818 0.8829 4.407 3.788 VEN-HTX 73.94 28.43 2.77 1.066 21.44 14.92 1 1 1.268 1.288 6.574 4.93 MOD.VEN-HTX 74.31 28.58 2.966 1.1406 23.192 17.00 1 1 0.5817 0.9368 4.711 3.951 RECIR-CON 9.51 8.14 3.81 3.26 12.69 8.879 1 1 0.5997 0.7092 5.609 5.3876

is only 10% or 20% of the supply air. In contrast, in the recirculationcondenser cycle all the supply air is passed through the desiccant wheel and hence a much larger amount of moisture is removed, even if the change in the air specic humidity in the dehumidier is small. 2. Auxiliary heater input is the highest for the recirculationcondenser cycle because the ow rate of regeneration air is much more than that in other hybrid cycles. 3. As the SHF increases, the load on the desiccant wheel diminishes, and so the supply air ow rate reduces for all the cycles. However, there is a corresponding increase in the sensible heat load which reects in the increase in load on the refrigeration system. 4. Compressor work is lower for ventilationcondenser and recirculationcondenser cycles than

Table 2 Performance of hybrid and conventional VC cycles, at hot-dry conditions, mixing ratio of 0.2 and the design regeneration temperature of 1358C RHSF CMMSUP QHTR (kW) TEVAP (8C) NO. OF DEHUM WCOMP (kW) W.E. CONS. (kW) 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 VC CYCLE 13.71 12.31 2.629 0 6.0 9.0 2.7594 1.5518 10.91 4.6553 VEN-CON 36.97 22.59 2.96 1.81 21.7 16.74 1 1 0.5076 0.7839 4.483 4.1617 VEN-HTX 36.97 27.63 2.77 2.0714 18.27 16.74 1 1 1.381 1.321 6.913 6.0344 MOD.VEN-HTX 37.15 23.274 2.96 1.8574 21.38 16.759 1 1 0.615 0.8504 4.807 4.408 RECIR-CON 2.247 7.93 3.704 3.1762 12.34 18.502 1 1 0.6056 0.71362 5.5208 5.317

130

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

the ventilationheat exchanger and modied ventilationheat exchanger cycles. The reason is that in the rst two cycles indirect evaporative cooling is employed while in the latter two, a heat exchanger is used. In hot-dry summer, cooling potential of IEC is very high and so the load on the refrigerated coil is reduced. 5. Weighted energy consumption is lowest for the ventilationcondenser cycle. It is due to the lower heater input and lower compressor work. 6. Energy saving is highest in high latent heat load application (RSHF = 0.35); maximum saving at mixing ratio of 0.1 is 63.15% and at mixing ratio of 0.2 is 58.9% with ventilation condenser cycle. On the other hand for modest latent loads characterized by a high value of RSHF (0.75), the corresponding energy savings are 11.4 and 10.63%, respectively. Other cycles show poorer performance than ventilationcondenser cycle under these hot-dry conditions irrespective of the RSHF and the ventilation air to supply air ratio. The predicted performance under hot-humid ambient conditions is given in Table 3. It can be seen that the ventilationcondenser, ventilationheat exchanger and modied ventilationHeat exchanger cycles need two dehumidiers each to bring process air humidity below the room air humidity. The recirculationcondenser cycle, however, needs only one dehumidier. It also has the lowest weighted energy consumption of all the cycles with an energy saving (in comparison to the conventional system) of 46.6% at high latent load conditions (RSHF = 0.35) when ventilation to supply air ratio is 20%. At low latent heat load (RSHF = 0.75), however, the performance of all the hybrid cycles is poorer than that of the conventional cycle, although the work of compression needed for refrigerated cooling is substantially lower than in the vapour compression cycle. This is mainly due to the fact that reheating is no longer needed in the conventional system, resulting in drastic reduction in its total energy requirements.

Table 3 Performance of hybrid and conventional VC cycles, at hot-humid conditions, mixing ratio of 0.2 and the design regeneration temperature of 1358C RSHF CMMSUP QHTR (kW) TEVAP (8C) NO. OF DEHUM WCOMP (kW) W.E. CONS. (kW) 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 VC CYCLE 18.85 11.97 3.962 0 6.0 8.1 3.588 1.7137 14.728 5.141 VEN-CON 68.08 26.185 11.54 4.4385 22.79 16.04 2 2 0.6224 0.9097 13.407 7.1676 VEN-HTX 68.08 26.185 11.66 4.486 20.31 13.56 2 2 1.4356 1.3367 15.967 8.496 MOD.VEN-HTX 65.23 25.088 11.15 4.2887 22.73 15.69 2 2 0.6051 0.9103 12.96 7.0196 RECIR-CON 13.206 12.085 5.596 5.1213 14.15 12.59 1 1 0.7571 0.79676 7.867 7.51

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

131

5. Inuence of wheel design parameters As mentioned above, in many situations, for recirculationcondenser cycle, the dehumidier outlet humidity was much lower than the room specic humidity, and therefore, direct evaporative cooling had to be incorporated in the system under high RSHF conditions. This clearly suggests that the regeneration temperatures should be lesser than the present design value. Accordingly, the inuence of regeneration temperature on the performance of recirculationcondenser cycle has also been studied. Very interesting results emerge from this study (Table 4). It is seen that under hot-dry conditions the weighted energy consumption reduces drastically with reduction in regeneration temperature. In fact, it seems possible to do wheel regeneration by directly using the air leaving the condenser. Consequently, there is no regeneration heat requirement and the weighted energy consumption decreases by 98% for high latent heat load (RSHF = 0.35) and by about 66% for low latent load (RSHF = 0.75) with 10% ventilation. Of course, energy reduction is not without a price for the supply air ow rate increases considerably, which necessitates a larger dehumidier. Under hot-humid conditions also, the weighted energy consumption decreases with reduction in regeneration temperature but not so drastically (Table 5). At 20% ventilation rate there is now an energy saving over vapour compression cycle of 38.2% at high latent load (RSHF = 0.35). However, at low latent load (RSHF = 0.75) energy consumption of recirculation condenser cycle is still slightly higher than that of a conventional system using vapour compression refrigeration (Table 5). At this high ventilation ratio an interesting result appears. It is seen that the weighted energy consumption falls as the regeneration temperature is reduced from 135 to 808C, but increases (for high latent loads) when regeneration temperature is further reduced to 608C. This is clearly

Table 4 Performance of hybrid recirculationcondenser cycle at reduced regeneration temperatures and hot-dry conditions for 10% ventilation air RSHF VC CYCLE Regeneration temperature 1358C CMMSUP QHTR (kW) TEVAP (8C) NO. OF DEHUM WCOMP (kW) W.E. CONS. (kW) 0.35 0.75 0.35 0.75 0.37 0.75 0.35 0.75 0.35 0.75 0.35 0.75 15.08 11.49 3.262 0 6.0 9.3 2.90 1.425 11.96 4.275 9.51 8.14 3.81 3.26 12.69 8.879 1 1 0.5997 0.7092 5.609 5.386 808C 12.79 10.22 1.99 1.588 17.265 12.28 1 1 0.362 0.548 3.074 3.232 608C 17.44 12.82 0.8063 0.592 19.86 14.25 1 1 0.256 0.512 1.574 2.128 43.28C 27.43 16.87 0 0 22.42 15.97 1 1 0.0837 0.485 0.251 1.456

132

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

because the supply air ow rate increases drastically as the regeneration temperature is reduced from 80 to 608C (Table 5). It clearly brings out the need for optimisation of the regeneration temperature. 6. Eect of changing other design parameters Jurinak [2] has made some recommendations regarding the wheel operating parameters for optimum performance of desiccant cooling system. To gauge the inuence of these recommendations on the system performance, appropriate changes have been made in the values of the process to regeneration air ow ratio (changed from 3 to 1.25), corresponding wheel face area ratios (changed from 3:1 to 1:1) and the wheel speed (changed to 9 rph). The regeneration temperature has been taken as 808C for all the three cycles, and keeping in view the afore-mentioned results, the recirculationcondenser cycle analysis has also been done for regeneration temperature of 608C. Tables 6 and 7 present a summary of these results. It can be seen that the performance of most of the cycles under these operating conditions is better (both weighted energy consumption and supply ow rate are lesser) than those under the wheel design operating conditions (Tables 2 and 3). The only exception is the proposed cycle which shows slight deterioration in performance under hot-dry conditions but an appreciable improvement of performance under hot-humid conditions. It is also seen that in general, the weighted energy consumption for recirculationcondenser cycle at both regeneration temperatures (80 and 608C) is higher than that obtained at the same regeneration temperatures when other design conditions of the wheel are kept unaltered. This is because of the fact that the ratio of regeneration to process ow rate now is 0.8 while under the design operating conditions this ratio is 0.33. Consequently, even though the total supply air ow rates are

Table 5 Performance of hybrid recirculationcondenser cycle at reduced regeneration temperatures, hot-humid conditions and 20% ventilation RSHF VC CYCLE Regeneration temperature 1358C CMMSUP QHTR (kW) TEVAP (8C) NO. OF DEHUM WCOMP (kW) W.E. CONS. (kW) 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 0.35 0.75 18.86 11.97 3.962 0 6.0 8.1 3.588 1.714 14.728 5.141 13.2059 12.085 5.596 5.1213 14.15 12.59 1 1 0.7571 0.79646 7.867 7.51 808C 26.67 20.71 4.843 3.76 18.94 15.88 1 1 0.798 0.9017 7.24 6.46 608C 88.95 34.21 6.55 2.52 22.14 16.976 1 1 1.372 1.22 10.66 6.18

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134 Table 6 Performance of hybrid cycles at altered wheel operating conditions in hot-dry weather with 20% ventilation

133

RSHF VEN-CON VEN-HTX MOD.VEN-HTX RECIR-CON (808C) RECIR-CON (608C) 0.35 0.75 QHTR (kW) 0.35 0.75 TEVAP (8C) 0.35 0.75 NO. OF DEHUM 0.35 0.75 WCOMP (kW) 0.35 0.75 W.E. CONS. (kW) 0.35 0.75 CMMSUP 36.367 22.25 2.713 1.6597 21.727 16.71 1 1 0.4827 0.766 4.161 3.8598 36.37 27.12 2.41 1.7955 19.43 16.71 1 1 1.2536 1.29 6.168 5.66 39.71 24.08 3.12 1.892 21.62 16.9 1 1 0.6111 0.855 4.95 4.45 7.306 6.154 2.726 2.296 9.70 4.71 1 1 0.5868 0.712 4.486 4.432 9.67 8.01 1.073 0.888 14.01 9.11 1 1 0.4704 0.622 2.4846 2.754

reduced under new operating conditions, the regeneration side ow rates remain higher. The only notable exception is the case of 608C regeneration temperature, 20% ventilation and high latent heat load (RSHF = 0.35). Here, this supply air ow rate reduction is so large (from 88.95 to 25.12 cmm) that the regeneration side ow rate is lower than that under the wheel design conditions (Table 7). Consequently, the weighted power consumption here is 7 kW, which is much less than the corresponding value of 10.66 kW with wheel design conditions unaltered. 7. Concluding remarks It is clear from this study that considerable energy saving can be achieved by using solid

Table 7 Performance of hybrid cycles at altered wheel operating conditions in hot-humid weather with 20% ventilation RSHF VEN-CON VEN-HTX MOD.VEN-HTX RECIR-CON (808C) RECIR-COND (608C) 0.35 0.75 QHTR (kW) 0.35 0.75 TEVAP (8C) 0.35 0.75 NO. OF DEHUM 0.35 0.75 WCOMP (kW) 0.35 0.75 W.E. CONS. (kW) 0.35 0.75 CMMSUP 56.03 21.55 9.766 3.756 22.4 14.2 2 2 0.597 0.4435 11.56 5.587 56.03 21.55 9.395 3.61 21.064 12.86 2 2 1.178 1.254 12.93 7.37 40.763 24.19 7.215 4.28 21.80 16.96 2 2 0.50148 0.7431 8.72 6.51 11.48 10.63 5.00 4.63 12.5 11.16 1 1 0.7957 0.82157 7.39 7.099 25.12 20.31 4.443.59 18.36 15.7 1 1 0.8567 0.9403 7.01 6.41

134

P.L. Dhar, S.K. Singh / Applied Thermal Engineering 21 (2001) 119134

desiccant-based hybrid air-conditioning cycles instead of conventional systems using refrigerated cooling coils alone, especially in hot-dry weather conditions. In hot-humid weather conditions energy savings are possible only under high latent load conditions. However, there is a great need to optimise the operating parameters of the desiccant wheel for getting the best performance. The relative performance of various cycles depends very strongly on these parameters. Thus, it is seen from the study that in hot-dry weather. The ventilationcondenser cycle performs the best, consuming even lesser energy than a conventional system using vapour compression cycle. In hot-humid weather, however, it is the ventilationcondenser cycle which performs the best at high latent loads, but for low latent loads (RSHF = 0.75) again the conventional system with refrigerated cooling coil performs better. This picture, however, changes when we operate at reduced regeneration temperatures. The recirculationcondenser cycle now performs better even in hot-dry weather. These results also give us a clue to the reasons responsible for conicting statements made in the literature regarding ecacy of hybrid system vis-a-vis vapour compression system. Most desiccant wheels being marketed today have been optimized for dehydration duties, to achieve very low exit moisture content. The requirements for hybrid air-conditioning applications being considerably dierent, the optimum operating parameters for this application are bound to be quite dierent. Consequently, if a desiccant wheel is operated at the usual design conditions (suitable for dehydration duties) while being employed in a hybrid air-conditioning system, the performance would be quite inferior to that obtained when the wheel's operating conditions are optimized. So a proper comparison of the eectiveness of various cycles for given load and weather conditions demands that proper optimisation of the wheel operating parameters be carried out. MaclaineCross and Banks [3] analogy model used in this work seems to be quite suitable for such optimisation. References

[1] P.R. Burns, J.W. Mitchell, W.A. Beckman, Hybrid desiccant cooling systems in super market applications, ASHRAE Trans 91 (Part-1B) (1985) 457468. [2] J.J. Jurinak, Open cycle solid desiccant cooling, component models and system simulations, Ph.D. thesis, University of Wisconsin-Madison, 1982. [3] I.L. Maclaine-Cross, P.J. Banks, Coupled heat and mass transfer in regenerators predictions using an analogy with heat transfer, Int. J. of Heat and Mass Transfer 15 (1972) 12251241. [4] I.L. Maclaine-Cross, Hybrid desiccant cooling in Australia, Australian Refrigeration Air-conditioning and Heating 41 (5) (1987) 1625. [5] J.C. Sheridan, J.W. Mitchell, A hybrid solid desiccant cooling system, Solar Energy 34 (2) (1985) 187193. [6] S.K. Singh, Some studies on solid desiccant-based hybrid air-conditioning systems, M. Tech Thesis, Department of Mechanical Engg., I.I.T. Delhi, 1996. [7] M. Singh, S. Jain, S.C. Kaushik, Energy conservation through hybrid air conditioning cycles: computer modelling studies, unpublished paper, I.I.T. Delhi, 1996. [8] W.M. Worek, C.J. Moon, Desiccant integrated hybrid vapour compression cooling performance sensitivity to outdoor conditions, Heat Recovery Systems and CHP 8 (6) (1988) 489501.

You might also like

- BM Brchapter7Document37 pagesBM Brchapter7Lim Hai MengNo ratings yet

- Assignment 1Document2 pagesAssignment 1Lim Hai MengNo ratings yet

- Assignment 1Document2 pagesAssignment 1Lim Hai MengNo ratings yet

- Green Mark CriteriaDocument136 pagesGreen Mark CriteriaLim Hai MengNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Steam Generation - Distribution 2023Document64 pagesSteam Generation - Distribution 2023Aaqil cassimNo ratings yet

- White Paper Flowmeter AccuracyDocument2 pagesWhite Paper Flowmeter Accuracyธนาชัย เต็งจิรธนาภาNo ratings yet

- Optimum insulation thickness for pipe freeze protectionDocument11 pagesOptimum insulation thickness for pipe freeze protectionjrri16No ratings yet

- News - Free Cooling Using Water Economizers PDFDocument8 pagesNews - Free Cooling Using Water Economizers PDFlipi8No ratings yet

- Reciprocating Pump Lab ExperimentDocument3 pagesReciprocating Pump Lab ExperimentParth BisenNo ratings yet

- Reg. No: Year/Dept: IV/CIVIL Date: .08.2018 Reg. No: Year/Dept: IV/CIVIL Date: .08.2018Document1 pageReg. No: Year/Dept: IV/CIVIL Date: .08.2018 Reg. No: Year/Dept: IV/CIVIL Date: .08.2018ganesh15No ratings yet

- W A U K E S H A: 68 FORM 6302 First EditionDocument2 pagesW A U K E S H A: 68 FORM 6302 First Editiondiego yecid millan mendozaNo ratings yet

- (123doc) English For Industrial Machinery and Equipment Tieng Anh Chuyen Nganh May Moc Va Thiet BiDocument65 pages(123doc) English For Industrial Machinery and Equipment Tieng Anh Chuyen Nganh May Moc Va Thiet BiTuan NguyenNo ratings yet

- PIPE LAYING PROJECT (Sent To Ms. Analyn) PDFDocument1 pagePIPE LAYING PROJECT (Sent To Ms. Analyn) PDFJamaica RolloNo ratings yet

- Singapore Underwater CityDocument22 pagesSingapore Underwater CitySuresh DNo ratings yet

- SimplAir EPL BrochureDocument12 pagesSimplAir EPL BrochureHfksosnaaoNo ratings yet

- Matlab ProblemsDocument12 pagesMatlab Problemsganesh naidu dasariNo ratings yet

- Omega - 1384.021-10 - LeafletDocument2 pagesOmega - 1384.021-10 - LeafletJorge VillalobosNo ratings yet

- Monitoreo de Ensuciamiento en IntercambiadoresDocument11 pagesMonitoreo de Ensuciamiento en IntercambiadoresHernan CobaNo ratings yet

- Cycle EfficiencyDocument17 pagesCycle Efficiencyrashm006ranjanNo ratings yet

- Instrumentation FittingsDocument32 pagesInstrumentation FittingsTochukwu OnuohaNo ratings yet

- Anaerobic Treatment of Tequila Vinasses in A CSTR-typeDocument7 pagesAnaerobic Treatment of Tequila Vinasses in A CSTR-typeProyectos Plantas De Tratamiento De AguaNo ratings yet

- Schedule of Mechanical Ventilation Fan: Basement FloorDocument4 pagesSchedule of Mechanical Ventilation Fan: Basement FloorHalem Hafidz KadirNo ratings yet

- Piping and Instrumentation DiagramDocument18 pagesPiping and Instrumentation DiagramMasih Belajar100% (2)

- Department of Mechanical Engineering Nano Fluids and Its ApplicationsDocument23 pagesDepartment of Mechanical Engineering Nano Fluids and Its ApplicationsAshutosh KumarNo ratings yet

- University of Mindanao Civil Engineering Program Physically Distanced but Academically Engaged Self-Instructional Manual (SIM) for Self-Directed Learning (SDLDocument141 pagesUniversity of Mindanao Civil Engineering Program Physically Distanced but Academically Engaged Self-Instructional Manual (SIM) for Self-Directed Learning (SDLSHALOM EMMANUEL OHAONo ratings yet

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksNo ratings yet

- Chapter 9Document48 pagesChapter 9Ahmet KuralNo ratings yet

- Modeling of Gravity Concentration Unit Operations: A. K. MajumderDocument78 pagesModeling of Gravity Concentration Unit Operations: A. K. MajumderSwarnaRakshitNo ratings yet

- Pump and CompressorDocument20 pagesPump and Compressor최승원No ratings yet

- Hydraulics Reviewer For Civil Engineering StudentsDocument2 pagesHydraulics Reviewer For Civil Engineering StudentsKing BangngayNo ratings yet

- Bermad: Level Control and Pressure Sustaining ValveDocument4 pagesBermad: Level Control and Pressure Sustaining ValveMaryoly BlancoNo ratings yet

- Column Flotation Systems With Cavitation TubeDocument8 pagesColumn Flotation Systems With Cavitation TubeRogério Leonardo OliveiraNo ratings yet

- University of Gondar: Institutes of Technology Department of Civil EngineeringDocument56 pagesUniversity of Gondar: Institutes of Technology Department of Civil EngineeringnahomNo ratings yet

- General Arrangement of Ash Handling EquipmentDocument24 pagesGeneral Arrangement of Ash Handling EquipmentPrakashNo ratings yet