Professional Documents

Culture Documents

Adfm 201002508 SM Suppl

Uploaded by

Arun BoseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adfm 201002508 SM Suppl

Uploaded by

Arun BoseCopyright:

Available Formats

CopyrightWILEYVCHVerlagGmbH&Co.KGaA,69469Weinheim,Germany,2010.

SupportingInformation

forAdv.Funct.Mater.,DOI:10.1002/adfm.201002508 AMicrofluidic,ReversiblyStretchable,LargeAreaWirelessStrainSensor ShiCheng*andZhigangWu*

Submitted to

Electronic Supplementary Information

Microfluidic Reversibly Stretchable Large-Area Wireless Strain Sensor

Shi Cheng1, and Zhigang Wu2,

1

Advanced Technology, Laird Technologies, Box 1146, SE 164 22, Kista, Sweden

Microsystems Technology, Department of Engineering Sciences, Uppsala University, Box 534, The Angstrom Laboratory, SE 751 21, Uppsala, Sweden

To whom correspondence should be addressed (Shi.Cheng@ieee.org and Zhigang.Wu@angstrom.uu.se)

Submitted to

1. Principles and Implementation

1.1. RF Transmitter and Receiver Sub-Modules

a)

C1

PT

NC

GND

O/P

GND

GO1555

GND

GND VCC

VCTR

Control voltage

DC power supply

C1=1 nF, NC=No connection

b)

DC power supply To microvolt digital multimeter (DMM)

C2

C3

GND PR C1 L1 RF

C4

Power detector (L5534)

VCC

VOUT GND EN

C1=1 nF, C2=100 pF, C3=0.1 F, C4=1.5 pF, L1=19 nH

Figure S1. Circuit schematics of a) the RF transmitter sub-module in the integrated strain sensor (coupling capacitor: C1), and b) the RF power detection unit in the PC-assisted receiver (decoupling capacitors: C2 and C3, coupling capacitor: C1, matching capacitor: C4, matching inductor: L1). The simplified RF transmitter in the integrated wireless sensor device is composed of a voltage controlled oscillator (VCO) (Gennum, GO1555), and a coupling capacitor (C1), on a flexible laminate of 13 mm 10 mm in size, cf. Figure S1(a). The choice of the VCO is based on its proper oscillation frequency range, miniaturized package size, relatively low power

Submitted to consumption, as well as sufficient RF output power. The chosen VCO generates stable continuous wave (CW) RF signals around 1.5 GHz when a supply voltage in the range of 2.25-2.75V and a control voltage ranging from 1.0V to 1.5V are applied. Moreover, it only draws a maximum supply current of 8 mA. This factor implies that this RF transmitter circuitry can be effectively powered by two serially connected commercially available AA or other types of standard portable batteries.

Figure S1(b) shows the circuit schematic of the RF power detection sub-module in the PCassisted receiver. In addition to an RF power detector (Linear Technology, LT 5534), this unit also contains two decoupling capacitors (C2 and C3), one coupling capacitor (C1), one matching capacitor (C4), and one matching inductor (L1), all soldered on a small piece of FPCB with a size of 10 mm 20 mm. The integrated RF power detection circuitry is capable of precisely converting the injected RF signals, in a decibel scale ranging from -60 dBm to 0 dBm, into DC voltage in a linear scale around 1.5 GHz.

Submitted to 1.2. Strain Sensor Contained Liquid Metal Antenna

Top replica Inlet 1

a)

Bottom replica Outlets Inlet 2

Top and bottom PDMS elastomer patterned by replica molding, with punched holes for inlets 1&2, and outlets

Top replica

b)

Blank sheet Top replica & blank sheet Inlet 3

Top replica bonded to a blank PDMS sheet

c)

Bottom replica

Punch out a hole for inlet 3 & seal to bottom replica

Top replica & blank sheet & bottom replica

d)

Seal inlet 3 with adhesive tape

e)

Top replica & blank sheet & bottom replica

Inject upper fluid metal layer, encapsure outlets in top replica with uncured PDMS droplets & seal inlets 1&3 Flip sample & inject lower fluid metal layer, encapsulate inlet 2 and outlets in bottom replica with uncured PDMS droplets Remove adhesive tape on inlets 1&3

f)

Bottom replica & blank sheet & top replica

Top replica & blank sheet & bottom replica

g)

PDMS

Upper fluid metal layer

Bottom fluid metal layer

Adhesive tape for temporarily sealing inlets

Figure S2. Fabrication process steps of the multi-layer microfluidic stretchable patch antenna integrated in the presented wireless strain sensor. Minor modifications have been made to adapt the previously reported fabrication processes to the multi-layer FSRFEs based wireless strain sensor presented in this paper.[1-2] The implementation of the integrated sensor device can be briefly summarized as the following steps: fluidic patch antenna fabrication, active circuit assembly, and hybrid device integration. The latter two resemble the manufacturing and integration processes presented in the previous work. Concerning the antenna fabrication, one more PDMS as well as liquid metal alloy

Submitted to layers have been added to implement multi-layer FSRFEs. More detailed process steps are illustrated in Figure S2 and described as below: First of all, the upper (antenna patch) and lower (ground plane) microfluidic channels were respectively constructed in the top and the bottom PDMS slabs, with a standard soft lithography. And then a few inlets and outlets were punched as depicted in Figure S2. In addition, the blank middle PDMS sheet with a thickness of 1.5 mm was also fabricated. Later, the micro-structured top PDMS layer was bonded to the blank PDMS slab using corona discharging activation, and the inlet 3, cf. Figure S2, was punched on the bonded PDMS sheet. Subsequently, the bottom PDMS slab was bonded to the upper PDMS layers with plasma bonding. After sealing the inlet 3 with a small piece of Scotch tape, the upper microfluidic channels were filled with galinstan fluid, and the ventilation outlets in the top PDMS slab were encapsulated using PDMS prepolymer afterwards. Whereafter, both the inlets 1 and 3 were sealed with Scotch tape, and galinstan alloy was injected into the lower microfluidic channels from the bottom side. All remaining ventilation outlets together with the inlet 2 were encapsulated, and the inlets 1 and 3 were reserved for connecting the RF transmitter circuitry in the hybrid sensor device.

Submitted to

Top View

L ground L patch W ms

Two openings for connecting RF feed cable in the standalone antenna characterizations or RF transmitter sub-module in the integrated device

W ground W patch

x f y z

L inset

Cross View

h middle d Upper fluid metal layer

+

h upper

z h lower h x q y

Lower fluid metal layer

PDMS

Figure S3. Geometric configuration of the elastic fluid metal patch antenna. Dimensions are: Lpatch = 56.0 mm, Wpatch = 50.0 mm, Lground = 110.0 mm, Wground = 80.0 mm, Linset = 16.0 mm, Wms = 3.7 mm, h = 2.5 mm, hupper = 75.0 m, hmiddle = 1.5 mm, and hlower = 75.0 m. Assuming that the PDMS elastomer had the relative permittivity of 3.0 and the dissipation factor of 0.01 around 1.5 GHz, the conductivity of the liquid alloy, galinstan, was about 3.46 106 S/m, and the spacing (hmiddle) and the width (Wpatch) of the patch antenna were 1.5 mm and 50.0 mm, an initial value of 57.3 mm for Lpatch was found, according to the transmission line model of the rectangular microstrip patch antennas.[3] Of course, electrical performance of the patch antenna based on the proposed geometrical configuration must be verified in more accurate numerical simulations, and some minor adjustments are probably needed for 6 6

Submitted to tuning its resonant frequency. Since the thickness of the PDMS membrane on top of the antenna patch is only approximately 425 m, 1/500 of the operational wavelengths at 1.5 GHz, its influence on the antenna electrical performance are negligible.

1.3. Integrated Wireless Strain Sensor

a)

e)

GO1555

b) d) c)

GO1555

GO1555

f)

C

Upper fluid Lower fluid PDMS metal layer metal layer

Copper

Kapton foil

Metallic pin Capacitor Anode Cathode

VCO chip

Solder

Figure S4. Schematic drawings of the integration procedure for the demonstrated microfluidic stretchable wireless strain sensor. In brief, two tin-plated contact pins resembling cantilevers were first soldered to the RF output and the ground pads on the FPCB of the RF transmitter, respectively. And then a semispherical solder ball was mounted to the bottom surface of each pin at the other end. Whereafter, three thin wires were respectively soldered to the supply voltage, the control voltage, and the ground pads of the RF transmitter circuitry for external power supply connection, as observed in Figure 1. Subsequently, this RF transmitter sub-module was attached to the top surface of the previously fabricated liquid metal patch antenna, and each solder ball at the end of the contact pin was directly immersed in the fluid metal enclosed in

Submitted to the micro-structured elastomeric channels, via the two opening in the upper PDMS membrane, cf. Figures 1, S3 and S4. In the end, the complete RF transmitter including the two contact pins were locally encapsulated in a PDMS LSC for protecting from stretching.

Submitted to 1.4. System Demonstration

Horn antenna Microfluidic elastic antenna RF amplifier

PT PR

DC power supply DC power supply

Tunable attenuator RF power detector Microvolt DMM PC

Voltage-controlled osillator (VCO) Flexible circuitry DC power supply

5m

Integrated Wireless Strain Sensor

Remote Monitor

Figure S5. Schematic illustration of the system demonstration setup for remotely sensing mechanical strains in real-time, using the integrated sensor device. Besides the self-contained sensor device, a custom-designed PC-assisted RF receiver has also been implemented for remote monitoring in the system demonstration, as illustrated in Figure S5. Of course, similar receiving function can also be realized using commercially available RF measurement instruments, for instance, spectrum analyzers or RF power meters, but the intention here was to remove all costly and bulky RF test equipment, and replace them with cost-effective modules. Figure S5 displays the schematic illustration of the system demonstration setup for remotely sensing high tensile mechanical strains in real-time, of which the receiver part consists of a standard gain horn (Flann Microwave, 08240-10), a coaxial amplifier (Mini-circuits, ZKL-2R5), a tunable HP attenuator (HP, 8495A), a Keithley 197A autoranging microvolt digital multimeter, a laptop, a DC power supply, and an RF power detection unit powered by four serially connected AA rechargeable batteries with a DC supply voltage of 5.23V.

Submitted to

2. Results and Discussion

2.1. RF Power Detection Unit

2.5

2

Output DC Voltage (V)

1.5

0.5

0 -70

-60

-50 -40 -30 -20 Input RF Power (dBm)

-10

Figure S6. Measured output DC voltages of the RF power detection sub-module in the custom-designed RF receiver versus varying input RF power around 1.5 GHz.

[1] S. Cheng, Z.G. Wu, Lab Chip. 2010, 10, 3227. [2] S. Cheng, Z.G. Wu, P. Hallbjorner, K. Hjort, A. Rydberg, IEEE T. Antenn. Propag. 2009, 57, 3756. [3] C. A. Balanis, Antenna Theory, 2nd ed, John Wiley & Sons, New York, 1997.

10

10

You might also like

- FM Bugger CircuitDocument44 pagesFM Bugger CircuitBathrinath 00750% (4)

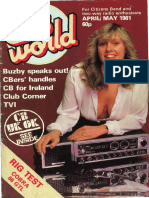

- CBWorld AprilMay1981 PDFDocument56 pagesCBWorld AprilMay1981 PDFbobbyunlockNo ratings yet

- RLC Bandpass Filter 33Document5 pagesRLC Bandpass Filter 33api-257705796No ratings yet

- King KX170170A175175AKY195 Installation & Maintenance ManualDocument587 pagesKing KX170170A175175AKY195 Installation & Maintenance ManualHamza Afado100% (1)

- Memristor - The Fourth Fundamental Circuit ElementDocument19 pagesMemristor - The Fourth Fundamental Circuit ElementArun Bose100% (1)

- PA - Class Work - QuestionsDocument20 pagesPA - Class Work - QuestionsLe Anh Duy100% (1)

- Design Microwave Filters Using Ansoft DesignerDocument50 pagesDesign Microwave Filters Using Ansoft Designersimsook91100% (1)

- Simple Low Cost UHF RFID Reader: Pavel V. Nikitin, Shashi Ramamurthy, Rene MartinezDocument2 pagesSimple Low Cost UHF RFID Reader: Pavel V. Nikitin, Shashi Ramamurthy, Rene MartinezHuỳnh Thanh DưNo ratings yet

- MOS Integrated Circuit DesignFrom EverandMOS Integrated Circuit DesignE. WolfendaleNo ratings yet

- 01 Manual - Detector Metales - MSM-210-MD-01Document194 pages01 Manual - Detector Metales - MSM-210-MD-01Emilio Alejandro Molina Salvo100% (2)

- Manual Traxxas 2238-2208-2209-24GHzDocument4 pagesManual Traxxas 2238-2208-2209-24GHzChefiaNo ratings yet

- How To Build High-Q Coils PDFDocument2 pagesHow To Build High-Q Coils PDFmiguellm5071No ratings yet

- FinfetsDocument27 pagesFinfetsAjay JoshyNo ratings yet

- Microelectronic CircuitDocument696 pagesMicroelectronic CircuitImtiaz AhmedNo ratings yet

- Andre Carpenter 02072014 Tracked VersionDocument6 pagesAndre Carpenter 02072014 Tracked VersionnikhatskhanNo ratings yet

- Modeling of Power Line Communications Using MIMO Coding Scheme For Indoor SystemDocument11 pagesModeling of Power Line Communications Using MIMO Coding Scheme For Indoor SystemNoorianah LollmahamodNo ratings yet

- Analysis of Pre-Emphasis Techniques For Channels With Higher-Order Transfer FunctionDocument12 pagesAnalysis of Pre-Emphasis Techniques For Channels With Higher-Order Transfer FunctionPraveen KumarNo ratings yet

- A 0.35Μm Cmos 1.9Ma Vco-Core With Off-Chip Inductance On Ltcc For System-In-A-Package Solutions Of A 5-Ghz-Wlan TransceiverDocument4 pagesA 0.35Μm Cmos 1.9Ma Vco-Core With Off-Chip Inductance On Ltcc For System-In-A-Package Solutions Of A 5-Ghz-Wlan TransceiverMohamed SaidNo ratings yet

- FinFET Inverter Anlaysis PDFDocument14 pagesFinFET Inverter Anlaysis PDFRakeshNo ratings yet

- Phase 2 ReportDocument59 pagesPhase 2 ReportMurugeswariNo ratings yet

- AN 01eDocument3 pagesAN 01eluisNo ratings yet

- Electromagnetic Interference and CompatibilityDocument2 pagesElectromagnetic Interference and CompatibilityVinod CmNo ratings yet

- Low Power Design and Simulation of 7T SRAM Cell Using Various Circuit TechniquesDocument6 pagesLow Power Design and Simulation of 7T SRAM Cell Using Various Circuit TechniquesseventhsensegroupNo ratings yet

- Online Monitoring of Underground Cables Using Low-Cost SensorsDocument4 pagesOnline Monitoring of Underground Cables Using Low-Cost SensorspipotxNo ratings yet

- Minimizing RF PCB Electromagnetic Emissions: TutorialDocument4 pagesMinimizing RF PCB Electromagnetic Emissions: TutorialsundarvrpNo ratings yet

- Topak 2013Document3 pagesTopak 2013Sanjib MandalNo ratings yet

- Cntfet Technology Based Precision Full-Wave Rectifier Using DDCCDocument8 pagesCntfet Technology Based Precision Full-Wave Rectifier Using DDCCresearchinventyNo ratings yet

- A Fully Integrated CMOS DCS-1800 Frequency Synthesizer: Jan Craninckx,, and Michel S. J. SteyaertDocument12 pagesA Fully Integrated CMOS DCS-1800 Frequency Synthesizer: Jan Craninckx,, and Michel S. J. SteyaertgopipatNo ratings yet

- RFReport YazidDocument59 pagesRFReport YazidDyrul SyaznanNo ratings yet

- A 150V Subscriber Line Interface Circuit in A New Bicmos Dmos TechnologyDocument6 pagesA 150V Subscriber Line Interface Circuit in A New Bicmos Dmos TechnologyWang YuNo ratings yet

- Measuring Nano AmperesDocument12 pagesMeasuring Nano Amperesvenustas08No ratings yet

- Implementation Using Power Line Communications in Telephone SystemDocument5 pagesImplementation Using Power Line Communications in Telephone SystemGopinath KudaravalliNo ratings yet

- D-Band Frequency Tripler For Passive Imaging - Final 13th JulyDocument4 pagesD-Band Frequency Tripler For Passive Imaging - Final 13th JulyTapas SarkarNo ratings yet

- 128122-Accelerometer & VelomitorTransducerOperationDocument22 pages128122-Accelerometer & VelomitorTransducerOperationNorman MoralesNo ratings yet

- Nuclear Instruments and Methods in Physics Research BDocument4 pagesNuclear Instruments and Methods in Physics Research BguiburNo ratings yet

- Vibration Monitoring SystemDocument15 pagesVibration Monitoring SystemusmannasrullahNo ratings yet

- Mmwave Submmwave SoC RFIT11Document4 pagesMmwave Submmwave SoC RFIT11workmanjNo ratings yet

- A 3.4dB NF K-Band LNA in 65nm CMOS TechnologyDocument4 pagesA 3.4dB NF K-Band LNA in 65nm CMOS TechnologyJeong-geun KimNo ratings yet

- Electronics: Self-Aligned Metal Electrodes in Fully Roll-to-Roll Processed Organic TransistorsDocument10 pagesElectronics: Self-Aligned Metal Electrodes in Fully Roll-to-Roll Processed Organic TransistorsJorge Mideros ArboledaNo ratings yet

- Ege Ge Egege eDocument8 pagesEge Ge Egege eAjay Kumar PrajapatiNo ratings yet

- 6 ART Banda de TransmisionDocument3 pages6 ART Banda de TransmisionFELIX PARCA ACEVEDONo ratings yet

- RF ConceptsDocument109 pagesRF ConceptssrinidhiNo ratings yet

- Efficient 2.45 GHZ Rectenna Design With High Harmonic Rejection For Wireless Power TransmissionDocument4 pagesEfficient 2.45 GHZ Rectenna Design With High Harmonic Rejection For Wireless Power TransmissionEk RishtaaNo ratings yet

- 2.294dB Noise-Figure RF Wideband PHEMT LNADocument7 pages2.294dB Noise-Figure RF Wideband PHEMT LNAPaul ShineNo ratings yet

- Nature MicroDocument9 pagesNature MicroChandra ShettyNo ratings yet

- Neukomm PDocument15 pagesNeukomm PDiego RodriguezNo ratings yet

- Acoustic Source Localization Based On Time-Delay Estimation MethodDocument5 pagesAcoustic Source Localization Based On Time-Delay Estimation Methodscribd1235207No ratings yet

- Alpha Particle Effect On Multi-Nanosheet Tunneling Field-Effect Transistor at 3-nm Technology NodeDocument11 pagesAlpha Particle Effect On Multi-Nanosheet Tunneling Field-Effect Transistor at 3-nm Technology Node전종욱No ratings yet

- BT Sin 349Document11 pagesBT Sin 349Ary SudarmantoNo ratings yet

- 279 E317 PDFDocument6 pages279 E317 PDFJubin JainNo ratings yet

- Bias Dependent Attenuation of Coplanar Transmission Lines On SiliconDocument4 pagesBias Dependent Attenuation of Coplanar Transmission Lines On SiliconEssam KhaterNo ratings yet

- A High-Speed Continuous-Time Bandpass VHF Filter in TechnologyDocument4 pagesA High-Speed Continuous-Time Bandpass VHF Filter in Technologyعاطف رضاNo ratings yet

- Design and Simulation of RF Energy Extracting CircuitsDocument28 pagesDesign and Simulation of RF Energy Extracting CircuitsHaresh SinghNo ratings yet

- Fiber Optics LabDocument102 pagesFiber Optics LabVirendra KumarNo ratings yet

- Fiberoptic Transceiver Lab GuideDocument33 pagesFiberoptic Transceiver Lab Guideanasardi93No ratings yet

- Evaluation of Modelling Accuracy of Reconfigurable Patch AntennasDocument4 pagesEvaluation of Modelling Accuracy of Reconfigurable Patch AntennasGordon ArihoNo ratings yet

- 300-GHz CMOS Receiver Module With WR-3.4 Waveguide InterfaceDocument4 pages300-GHz CMOS Receiver Module With WR-3.4 Waveguide InterfaceMarcoNo ratings yet

- 1.5GHz Negative Impedance Converter PaperDocument3 pages1.5GHz Negative Impedance Converter PaperNestor Alberto EscalaNo ratings yet

- 2001 Likharev RSFQ ReviewDocument49 pages2001 Likharev RSFQ Reviewqadqwefsvc34No ratings yet

- A Complete Narrow-Band Power Line Communication Node For AMRDocument6 pagesA Complete Narrow-Band Power Line Communication Node For AMRSudheer KakaniNo ratings yet

- Regular Correspondence: Compact High-Frequency Output Buffer For Testing of Analog CMOS VLSI CircuitsDocument3 pagesRegular Correspondence: Compact High-Frequency Output Buffer For Testing of Analog CMOS VLSI CircuitsSaranya ChakrabortyNo ratings yet

- Agilent Eesof Eda: Overview On Designing A Low-Noise Vco On Fr4Document6 pagesAgilent Eesof Eda: Overview On Designing A Low-Noise Vco On Fr4bayman66No ratings yet

- Extending The SPI Bus For Long Distnce CommDocument7 pagesExtending The SPI Bus For Long Distnce CommFelipe Ademir Aleman Hdez100% (2)

- The Last BarrierDocument13 pagesThe Last BarrierGdv Santhosh KumarNo ratings yet

- Design of Rectangular Microstrip Patch Antennas For The 2.4 GHZ BandDocument7 pagesDesign of Rectangular Microstrip Patch Antennas For The 2.4 GHZ BandkarimbebNo ratings yet

- Application in Mobile CommDocument4 pagesApplication in Mobile CommAnandita MalikNo ratings yet

- ESD Protection: Design and Layout Issues For VLSI Circuits: Ieee 25, 1989Document7 pagesESD Protection: Design and Layout Issues For VLSI Circuits: Ieee 25, 1989Donna AmbalongNo ratings yet

- Principles of Mobile Communication DesignDocument6 pagesPrinciples of Mobile Communication DesignFAHAD KHAN NIAZINo ratings yet

- Stealthy Jam Resistant AnteenaDocument2 pagesStealthy Jam Resistant AnteenaArun BoseNo ratings yet

- Embedded DramDocument23 pagesEmbedded DramAbhi MaheshwariNo ratings yet

- 4g Wireless TechnologyDocument31 pages4g Wireless Technologydivyareddy31No ratings yet

- Silicone Elastomers: Peter JerschowDocument8 pagesSilicone Elastomers: Peter JerschowArun BoseNo ratings yet

- Micro Fluid Wireless AntennaDocument116 pagesMicro Fluid Wireless AntennaArun BoseNo ratings yet

- Wireless Sensory For Park in SonsDocument4 pagesWireless Sensory For Park in SonsArun BoseNo ratings yet

- Android Seminar PresentationDocument24 pagesAndroid Seminar PresentationYedu90% (20)

- WSNDocument29 pagesWSNsridevishinasNo ratings yet

- 12BiCMOS TechnologyDocument17 pages12BiCMOS TechnologyAna JundullahNo ratings yet

- Intech Fast Matlab SimulationDocument26 pagesIntech Fast Matlab SimulationJoão RamosNo ratings yet

- Introduction to Marine Single Sideband Radio CommunicationsDocument100 pagesIntroduction to Marine Single Sideband Radio Communicationsnaval_05No ratings yet

- Remote Control Model ManualDocument48 pagesRemote Control Model Manualpaleman62No ratings yet

- Park Air m7x and m7rDocument4 pagesPark Air m7x and m7rPrashanthi PathipatiNo ratings yet

- Mobile Fading-Rayleigh and Lognormal SuperimposedDocument4 pagesMobile Fading-Rayleigh and Lognormal Superimposedأحمد عليNo ratings yet

- STI 6517B Instruction ManualDocument1 pageSTI 6517B Instruction ManualJMAC SupplyNo ratings yet

- BE Free5 English User Manual V1.0 CleanDocument17 pagesBE Free5 English User Manual V1.0 CleanNicholas D'ArcangeloNo ratings yet

- WiFi Jammer CircuitDocument10 pagesWiFi Jammer CircuitSathwik YadalamNo ratings yet

- Aqua Communications Using Modem: Presented byDocument49 pagesAqua Communications Using Modem: Presented byThanvithaNo ratings yet

- BOSCH Projected Smoke D297Document3 pagesBOSCH Projected Smoke D297Antonio EstevezNo ratings yet

- RF Agile Transceiver: Data SheetDocument32 pagesRF Agile Transceiver: Data SheetNga V. DaoNo ratings yet

- Spe 11380 PaDocument6 pagesSpe 11380 PaCavidan IbrahimliNo ratings yet

- Catalogs (4+1)Document68 pagesCatalogs (4+1)Danijel DanicicNo ratings yet

- AM-FM Signal Generators Models 8640A/B SpecificationsDocument13 pagesAM-FM Signal Generators Models 8640A/B SpecificationsdonsterthemonsterNo ratings yet

- Trio Jr599custom ManualDocument34 pagesTrio Jr599custom Manualhaha2012No ratings yet

- CQ-DATV95 May 2021Document30 pagesCQ-DATV95 May 2021Benjamin DoverNo ratings yet

- Analog Communication Course FileDocument37 pagesAnalog Communication Course FilePrachi ParasharNo ratings yet

- Wireless and Mobile Communications Mid Term Question Paper AKDocument10 pagesWireless and Mobile Communications Mid Term Question Paper AKSrikanthNo ratings yet

- EPR420S Lecture Notes - Unit Protection of FeedersDocument50 pagesEPR420S Lecture Notes - Unit Protection of FeedersgeorgeNo ratings yet

- Radio wave propagation problems and solutionsDocument2 pagesRadio wave propagation problems and solutionsSaad ChakkorNo ratings yet

- Ultrasonic Distance Meter MicrocontrollerDocument11 pagesUltrasonic Distance Meter MicrocontrollerHafiz Murtaza100% (3)

- Datasheet NBM-550 ENDocument10 pagesDatasheet NBM-550 ENRodrigo BruniNo ratings yet

- Design and Fabrication of Robotic Trash Boat To Drive and Harvest Floating Trash in DrainagesDocument6 pagesDesign and Fabrication of Robotic Trash Boat To Drive and Harvest Floating Trash in DrainagesTharun KumarNo ratings yet