Professional Documents

Culture Documents

BHEL

Uploaded by

Nageswara Reddy GajjalaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BHEL

Uploaded by

Nageswara Reddy GajjalaCopyright:

Available Formats

Vol.

28

No. 3

September 2005 and trained personnel, the COE will cater to a wide variety of BHEL's products of the power and industrial sectors. CFD in Hydro Power Plants : CFD is extensively applied in the design of hydro turbine components in the water path ,like spiral casing, stay vanes, guide vanes, runner blades and draft tube. Accurate prediction of losses and design analysis aid in optimization of the performance of a hydro turbine. CFD in Thermal Power Plants : CFD analysis is used in performance improvement of various thermal power plant components like boiler furnace, electrostatic precipitator (ESP), bowl mill, steam turbine blading, exhaust hood, pumps and fans. CFD in Industrial Equipment / Components : CFD is increasingly used in industrial equipment such as centrifugal compressors, heat exchangers, electrical machines to improve their performance with respect to fluid flow and heat transfer . Facilities at COE-CFD : Software CFX TASCFLOW CFX 5.7 l FLUENT 6.1 l STAR - HPC - CD 3.15 l CFX - TURBOGRID l CFX - BLADEGEN+ l PHONICS l

CENTRE OF EXCELLENCE FOR C O M P U TAT I O N A L FLUID DYNAMICS ESTABLISHED IN BHEL BHEL, long ago, identified application of Computational Fluid Dynamics (CFD) for improvement of performance as well as generation of know-how and know-why information with reference to many of its products. CFD softwares, today, have emerged as important tools capable of giving valuable insights to the designer to analyse the behaviour of fluid flow in complex geometries. These softwares cut down the cost and time which are otherwise required for physical modeling and experimentation. To further enhance its capabilities in this field, BHEL has recently established a Centre of Excellence for CFD (COE-CFD) at its Corporate R&D Division. Equipped with advanced software and hardware and manned by technically capable

The Centre of Excellence for Computational Fluid Dynamics the interior view

l l l l

ICEM CFD HYPERMESH I-DEAS AutoCad

Hardware l High-performance computing (HPC) cluster with 32 CPU IBM Power 4+, 64-bit processor on Gigabit LAN, 64 GB RAM, 2.4 TB internal storage with additional external NAS of 1 TB with back-up server and LTO tape library.

l

40 high-end workstations as network client, networked peripherals

bearing and its consequent lubrication requirements. iii) State-of-the-art VPI (Vacuum Pressure Impregnation) high-voltage insulation system has been used, which ensures a long electrical, mechanical, thermal and chemical life of the winding, thus making the machine c o m p a c t w i t h ex c e l l e n t o p e r a t i n g parameters. iv) The optimal design of the generator has brought down the size of the machine, thus resulting in saving of precious raw materials like magnetic steel, copper and insulation materials. This has resulted in reduction of manufacturing cycle time. v) The higher efficiency of the generator will result in considerable saving in energy cost to the power plants. BHEL has already secured orders for supply of five machines of this type.

Pressure distribution of a typical low-head Francis runner

DEVELOPMENT OF 1550 kVA UPRATED MODULAR BG AC EMU TRANSFORMER FOR INDIAN RAILWAYS AN MoU PROJECT BG AC EMU (Broad Gauge AC Electrical Multiple Units) trains are used for mass public transport purpose in all metro cities in India. For these EMUs, the requirement is of a main transformer, choke units and other accessories like conservator, cooling pipe work, oil cooler and pump. Looking at the increasing passenger load, Indian Railways /RDSO entrusted BHEL with a developmental project to increase the rating of the present transformer from 1050 kVA to 1550 kVA. Further, they desired that the complete transformer alongwith its choke unit and other accessories be made as one modular unit to be mounted under the motor coach. The overall weight of the complete uprated modular transformer was also required to be limited to 5 tonnes (as against the present weight of 6 tonnes). This developmental project, also an MoU Project for the year 2004-05, has been successfully

A 77 MW AIR-COOLED TURBOGENERATOR WITH STATE-OFTHE-ART FEATURES DEVELOPED FOR HINDUSTAN ZINC LIMITED BHEL has designed in-house, manufactured and successfully tested a 77 MW, 11 kV, 3000 rpm aircooled steam turbine-driven generator for M/s Hindustan Zinc Ltd., Chanderia. This generator is significant in many respects: i) The tested efficiency of the generator is 98.65%, which is one of the highest in the world for air-cooled generators of this rating. ii) The generator is equipped with compact overhang type brushless exciter, also developed in-house. The new type of exciter used in the generator is cost-effective, occupies less space and is trouble-free in operation, obviating the necessity of exciter

out using 4-axes CNC programming on 4-axes CNC milling machine Unigraphics NX CAD/CAM software was used to carry out the computer-aided 4-axes part programming for machining of the curved bearing surface of the fir tree root. Tapered end mills were used to open the fir tree slot before using form cutters. The machined fir tree root was then inspected. The dimensional accuracy of fir tree form and surface finish of machined surfaces were found to be satisfactory.

The 1550 kVA uprated modular BG AC EMU transformer

completed : one transformer has been designed, manufactured and tested with the above stringent specifications.

TECHNOLOGY FOR MACHINING OF CURVED INTERNAL FIR TREE ROOT OF BLADES OF 236 MW NUCLEAR TURBINE DEVELOPED 236 MW turbine blades have curved internal fir tree root design and are of state-of-the-art technology. These roots were being machined by Broaching method using imported broaching fixtures. In order to obviate import, BHEL has recently developed a technology for machining of curved internal fir tree root of blades of 236 MW nuclear turbine on available CNC machines. The process developed shall ensure quality of machining as well as reduce the cost of blades by avoiding import. In the absence of suitable Indian supplier to manufacture advanced & highly customized tooling, it was decided to import the form cutters and develop the machining technology. A solid model of the blade root was generated in Unigraphics CAD/CAM software to analyze the amount of material to be removed in different areas, and suitable machining processes were developed. 4axes CNC part programs were developed and special fixture was designed and manufactured. Form cutters were designed to machine the total blade root in three stages. In the first stage, rough machining was carried out for entire form of the fir tree root leaving allowance. In the second stage, finishing of the non-bearing surface of the root was carried out using finishing form cutter for nonbearing surface. In the final stage of blade machining, finishing of bearing surface was carried

Machined blade root

Machining setup

The expertise developed can be used for machining other types of internal curved fir tree. BHELSONIC A STATE-OF-THEART STEAM LEAK DETECTION SYSTEM FOR BOILERS One of the major causes of any boiler outage is tube failure resulting in steam leakage. Hence the detection of steam leakage at an early stage is vital to avoid secondary damage. Conventional methods of steam leak detection used in thermal power plants are operator-dependant and, hence, unreliable. The current technology is to detect the steam

leakage at its nascent stage itself, through detection of acoustic emission of steam leak. BHELSONIC steam leak detection system, developed by BHEL, works on the above principle of acoustic emission detection. The system consists of the following sub-systems: l Sonic tube with sensor assembly l Field amplifier unit l System panel In each zone of the boiler, one sonic tube with sensor is installed, which penetrates the boiler casing and terminates at the edge of the boiler water wall tubing. Sound reaching the sensor assembly is converted into electrical signal and is amplified in the field amplifier unit. The background and combustion noise is filtered in the field amplifier itself. Signal from the field amplifier unit is taken to system panel and processed further to obtain the steam leak information in decibel units and is fed to a PC. Alarm contacts are provided to activate, if steam leak sound level exceeds a preset limit. 4-20mA DC current output is also available. Audio output of steam leak noise is made available in the control room for the operator to cross check. The MMI software provided with the system acquires the sound data, performs engineering unit conversion and presents the steam leak data of various zones of boiler in PC monitor. The presentation format is user-selectable, viz., Bar graph, Mimic, Trend, Group Trend and History. Operator is given a complete picture of processed sound levels in various zones of boiler, indicating steam leak, if any, in the respective zones. The BHELSONIC system is designed in such a way that even in the event of non-availability of PC, the existing steam leak dB readings , 4-20mA current output and alarm status will be available without interruption in the system panel.

HYDRAULIC LOADING SYSTEM FOR BHEL BOWL MILLS BHEL, the country's leading supplier of bowl mills, has recently developed a hydraulic loading system for the bowl mills, to replace the large mechanical springs used to provide grinding pressure to the journal rolls. The hydraulic loading system will improve the grinding efficiency of the mill and useful life of the rolls by reduction of wear. It provides better control on the mill output as the grinding pressure on the rolls can be varied 'online. Such a loading system has been installed in the BHEL-280 mill at Chandrapur STPS, the largest vertical bowl mill in the country, after rigorous testing of the hydraulic cylinders and actuators at high pressure. The system has been working satisfactorily and continuously since its installation in March'05. The advantages of using hydraulic loading system are: i) Control of grinding force applied to rollers according to coal feed rate, type of coal, roller wear etc. online with quick response time, compared to slow and cumbersome manual process of changing the journal spring compression off line; ii) uniform loading in all three rollers, compared to the individual loading of the earlier system; iii) dampening of impact forces generated by large-size nuggets or iron tramps on the bowl which reduces wear of rollers; iv) choice of automatic, semiautomatic or manual control of the grinding pressure.

Scanner

ELECTRONIC MODULES

FIELD AMPLIFIERS

SENSORS

Schematic of BHELSONIC system

The hydraulic loading system assembly

For Private Circulation only

Issued quarterly by the Corporate Office, Bharat Heavy Electricals Limited, BHEL House, Siri Fort, New Delhi-110049, Website : http://www.bhel.com Editor : R.K. Bhattacharya. Associate Editor : D. Roy. Designed & Printed at NIKHIL OFFSET, New Delhi-110020. Phones : 26812316, 26810097, Telefax : 26810458

You might also like

- 1.1 Background of Project 1.2 Assignment & Objectives 1.3 Instruction To Reader 1.4 Limitation 1.5 Organisational ProfileDocument87 pages1.1 Background of Project 1.2 Assignment & Objectives 1.3 Instruction To Reader 1.4 Limitation 1.5 Organisational Profilezerocool86100% (1)

- C& I For SupercriticalDocument93 pagesC& I For SupercriticalPrudhvi RajNo ratings yet

- VHB Presentation (Compatibility Mode) PDFDocument21 pagesVHB Presentation (Compatibility Mode) PDFhirenkumar patelNo ratings yet

- Kawasaki's Presentation on FGD and SCR SystemsDocument20 pagesKawasaki's Presentation on FGD and SCR Systemsjitendrashukla10836No ratings yet

- 1c Low Mass Flux Once Through Boiler Design Application and PDFDocument52 pages1c Low Mass Flux Once Through Boiler Design Application and PDFfrlamontNo ratings yet

- UntitledDocument8 pagesUntitledPMG Bhuswal ProjectNo ratings yet

- Performance Analysis of Surface Condenser in 525MW Thermal Power Plant PDFDocument9 pagesPerformance Analysis of Surface Condenser in 525MW Thermal Power Plant PDFJeeEianYannNo ratings yet

- Final YearDocument51 pagesFinal YearAnand Kumar0% (1)

- 0260-101-01-TR-PVM-U-020-03 Sizing Calculation of FurnaceDocument9 pages0260-101-01-TR-PVM-U-020-03 Sizing Calculation of Furnaceanil peralaNo ratings yet

- Layout and Components of a Supercritical BoilerDocument41 pagesLayout and Components of a Supercritical BoilerLakshmi NarayanNo ratings yet

- CenPEEP Preface and ContentsDocument277 pagesCenPEEP Preface and ContentssridharNo ratings yet

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocument24 pagesTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranNo ratings yet

- EID PARRY TURBINE POOR VACUUMDocument4 pagesEID PARRY TURBINE POOR VACUUMCharu ChhabraNo ratings yet

- Sliding Pressure Operation in Combined CyclesDocument5 pagesSliding Pressure Operation in Combined CyclesJeeEianYannNo ratings yet

- Scaph Sizing CalculationDocument2 pagesScaph Sizing Calculationanil peralaNo ratings yet

- 500mw Checking and Setting of Hydraulic and ElectroDocument15 pages500mw Checking and Setting of Hydraulic and Electrothangarajm1984No ratings yet

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDocument41 pagesBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNo ratings yet

- Slagging in Steam Generators: Root Cause AnalysisDocument8 pagesSlagging in Steam Generators: Root Cause AnalysispiyushagaNo ratings yet

- Steam Turbine Control & Instrumentation: Vinod Kumar, SR - Mgr. / CIE BHEL, HaridwarDocument50 pagesSteam Turbine Control & Instrumentation: Vinod Kumar, SR - Mgr. / CIE BHEL, HaridwarAhemad100% (1)

- Boiler & Its Auxiliaries Gyanendra Sharma Npti DelhiDocument36 pagesBoiler & Its Auxiliaries Gyanendra Sharma Npti DelhiNPTINo ratings yet

- Lalitpur Superthermal Power Project - 3 X 660 MWDocument10 pagesLalitpur Superthermal Power Project - 3 X 660 MWpramod_nandaNo ratings yet

- Reducing Boiler Cooling Time Saves Rs. 13.5 Crore AnnuallyDocument16 pagesReducing Boiler Cooling Time Saves Rs. 13.5 Crore Annuallyjp mishraNo ratings yet

- Spiral Wound Gasket SpecificationDocument54 pagesSpiral Wound Gasket SpecificationRamalingam PrabhakaranNo ratings yet

- Chapter 12Document12 pagesChapter 12bhaskarNo ratings yet

- Dec 09Document35 pagesDec 09Krishnan SanthanarajNo ratings yet

- Boiler Protection Gyanendra Sharma NPTI DelhiDocument24 pagesBoiler Protection Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- 1st Amendment Operating Frequency Range CERCDocument19 pages1st Amendment Operating Frequency Range CERCashish jainNo ratings yet

- Turbine Working & ItsComponentsDocument88 pagesTurbine Working & ItsComponentsHimanshu spoliaNo ratings yet

- Flexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCDocument27 pagesFlexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCLakshmi NarayanNo ratings yet

- Cost & Cost ConceptsDocument51 pagesCost & Cost ConceptsEzhil Vendhan PalanisamyNo ratings yet

- Asld PresentDocument50 pagesAsld PresentAakanksha GahlautNo ratings yet

- Digital Control System of Plant Gyanendra Sharma NPTI DelhiDocument128 pagesDigital Control System of Plant Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Comparison of BHEL Vs DOOSANDocument12 pagesComparison of BHEL Vs DOOSANParveen NakwalNo ratings yet

- Industrial Lubricants Product GuideDocument29 pagesIndustrial Lubricants Product GuideChandra Kaladhara Rao KuntamukkalaNo ratings yet

- Ash Handling System OverviewDocument24 pagesAsh Handling System Overviewnetygen1No ratings yet

- SSTPS LMI On Optimaization of Ash Water Utilaization Revision-2 - Agupta SirDocument18 pagesSSTPS LMI On Optimaization of Ash Water Utilaization Revision-2 - Agupta SirGautamupadhyayNo ratings yet

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDocument23 pagesSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINo ratings yet

- APH Seal LeakagesDocument17 pagesAPH Seal LeakagesBhargav ChaudhariNo ratings yet

- 02 FSSS Logic SystemDocument51 pages02 FSSS Logic SystemSam100% (3)

- Theory of steam turbine rolling temperature profiles and thermal stressesDocument9 pagesTheory of steam turbine rolling temperature profiles and thermal stressesLipika Ghosh BiswasNo ratings yet

- 8 95 01 Weld Procedure Spec ChattanoogaDocument40 pages8 95 01 Weld Procedure Spec ChattanoogaJKKNo ratings yet

- TH 1694Document91 pagesTH 1694buddhivasuNo ratings yet

- WRITE UP ON AUTOMATIC TURBINE TESTERDocument14 pagesWRITE UP ON AUTOMATIC TURBINE TESTERlp mishraNo ratings yet

- Auxiliary Power ConsumptionDocument3 pagesAuxiliary Power ConsumptionNicko LastardaNo ratings yet

- Auxiliary Power Supply System OverviewDocument21 pagesAuxiliary Power Supply System Overviewpramod_nandaNo ratings yet

- Coal Handling and Transportation SystemsDocument40 pagesCoal Handling and Transportation SystemsEzhil Vendhan PalanisamyNo ratings yet

- This Bhel ProjectDocument51 pagesThis Bhel ProjectRaj_005No ratings yet

- Nerator Termination Bus-Bar Arrangement - Design RequirementsDocument8 pagesNerator Termination Bus-Bar Arrangement - Design RequirementsharshNo ratings yet

- Docslide - Us K Karthikeyan Manager Controls Instrumentation Bhel TiruchirappalliDocument97 pagesDocslide - Us K Karthikeyan Manager Controls Instrumentation Bhel TiruchirappallimanojkumarmurlidharaNo ratings yet

- Detergent FlushingDocument36 pagesDetergent FlushingSam100% (1)

- Essential Interlocks and Protections for Feed Water and Condensate SystemsDocument18 pagesEssential Interlocks and Protections for Feed Water and Condensate SystemsSanjay GuptaNo ratings yet

- Role of Maintenance in Boiler Energy ConservationDocument125 pagesRole of Maintenance in Boiler Energy ConservationkkannanmtpsNo ratings yet

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Document74 pagesPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Mohit MalikNo ratings yet

- Jindal Power SOP Load Shedding RelayDocument4 pagesJindal Power SOP Load Shedding RelayChandramani PatelNo ratings yet

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- Objectives: For Cleaner Coal PlantDocument6 pagesObjectives: For Cleaner Coal Plantbarlang123No ratings yet

- Cement Plant Simulation and Dynamic Data PDFDocument8 pagesCement Plant Simulation and Dynamic Data PDFUsman HamidNo ratings yet

- Industrial Seminar on BHEL OverviewDocument45 pagesIndustrial Seminar on BHEL OverviewRaj SinghNo ratings yet

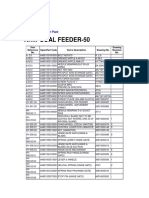

- Raw Coal Feeder-50: Item Reference No. Sparepart Code Item'S Description Drawing No. Drawing Revision NoDocument3 pagesRaw Coal Feeder-50: Item Reference No. Sparepart Code Item'S Description Drawing No. Drawing Revision NoNageswara Reddy GajjalaNo ratings yet

- Companywise Plant ListDocument5 pagesCompanywise Plant ListNageswara Reddy GajjalaNo ratings yet

- Bowl Mill-Feb 2009Document12 pagesBowl Mill-Feb 2009Krishnan SanthanarajNo ratings yet

- Industrial Diesel Hydraulic Crane: TIL LimitedDocument4 pagesIndustrial Diesel Hydraulic Crane: TIL LimitedNageswara Reddy GajjalaNo ratings yet

- Hammer MillDocument11 pagesHammer MillLanre AfolabiNo ratings yet

- Role Played by Digitalization During Pandemic: A Journey of Digital India Via Digital PaymentDocument11 pagesRole Played by Digitalization During Pandemic: A Journey of Digital India Via Digital PaymentIAEME PublicationNo ratings yet

- Etp ListDocument33 pagesEtp ListMohamed MostafaNo ratings yet

- Coa - Ofx-8040a (H078K5G018)Document2 pagesCoa - Ofx-8040a (H078K5G018)Jaleel AhmedNo ratings yet

- HSPA+ Compressed ModeDocument10 pagesHSPA+ Compressed ModeAkhtar KhanNo ratings yet

- Alexander Lee ResumeDocument2 pagesAlexander Lee Resumeapi-352375940No ratings yet

- Corena s2 p150 - Msds - 01185865Document17 pagesCorena s2 p150 - Msds - 01185865Javier LerinNo ratings yet

- Warranty Information Emea and CisDocument84 pagesWarranty Information Emea and CisHenriques BrunoNo ratings yet

- Fact Sheet Rocket StovesDocument2 pagesFact Sheet Rocket StovesMorana100% (1)

- Syllabus - Mech 3rd YearDocument130 pagesSyllabus - Mech 3rd YearAbhishek AmarNo ratings yet

- Acceptance and Presentment For AcceptanceDocument27 pagesAcceptance and Presentment For AcceptanceAndrei ArkovNo ratings yet

- Renewable and Sustainable Energy ReviewsDocument13 pagesRenewable and Sustainable Energy ReviewsMohammadreza MalekMohamadiNo ratings yet

- Mesa de Trabajo 1Document1 pageMesa de Trabajo 1iamtheonionboiNo ratings yet

- Joint Memorandum Circular (JMC) No. 2021Document49 pagesJoint Memorandum Circular (JMC) No. 2021Nicey RubioNo ratings yet

- Nucleic Acid Isolation System: MolecularDocument6 pagesNucleic Acid Isolation System: MolecularWarung Sehat Sukahati100% (1)

- Product Catalog: Ductless Mini-Splits, Light Commercial and Multi-Zone SystemsDocument72 pagesProduct Catalog: Ductless Mini-Splits, Light Commercial and Multi-Zone SystemsFernando ChaddadNo ratings yet

- Determining Total Impulse and Specific Impulse From Static Test DataDocument4 pagesDetermining Total Impulse and Specific Impulse From Static Test Datajai_selvaNo ratings yet

- 2 - Nested IFDocument8 pages2 - Nested IFLoyd DefensorNo ratings yet

- SC invalidates Ordinance allowing oil depots in Pandacan due to population densityDocument2 pagesSC invalidates Ordinance allowing oil depots in Pandacan due to population densityMigs Raymundo100% (1)

- Vallance - Sistema Do VolvoDocument15 pagesVallance - Sistema Do VolvoNuno PachecoNo ratings yet

- Afar Partnerships Ms. Ellery D. de Leon: True or FalseDocument6 pagesAfar Partnerships Ms. Ellery D. de Leon: True or FalsePat DrezaNo ratings yet

- Manual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteDocument94 pagesManual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteAlexandra DumitruNo ratings yet

- Marketing Management NotesDocument115 pagesMarketing Management NotesKajwangs DanNo ratings yet

- 2.4 Adams Equity TheoryDocument1 page2.4 Adams Equity TheoryLoraineNo ratings yet

- ViscosimetroDocument7 pagesViscosimetroAndres FernándezNo ratings yet

- WEEK 8 HW WS - B - Graphs & ChartsDocument6 pagesWEEK 8 HW WS - B - Graphs & Chartsangela trioNo ratings yet

- FEM IntroductionDocument47 pagesFEM IntroductionShanmuga RamananNo ratings yet

- SHIPPING TERMSDocument1 pageSHIPPING TERMSGung Mayura100% (1)

- Maintenance: ASU-600 SeriesDocument54 pagesMaintenance: ASU-600 SeriesMichael Maluenda Castillo100% (2)

- CONFLICT ManagementDocument56 pagesCONFLICT ManagementAhmer KhanNo ratings yet

- Method StatementDocument11 pagesMethod StatementMohammad Fazal Khan100% (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)