Professional Documents

Culture Documents

Summer Project On Al

Uploaded by

Jenifer PriyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Summer Project On Al

Uploaded by

Jenifer PriyaCopyright:

Available Formats

COMPANY PROFILE:

Ashok Leyland is the leading manufacturer of trucks, buses, special application vehicles and engines in India. The products of Ashok Leyland are at par with the best in the world. Ashok Leyland is the leaders in the Indian bus market, offering unique models such as CNG, Double Decker and Vestibule bus. More than 80% of the State Transport Undertaking (STU) buses come from Ashok Leyland. The company is a pioneer in multi axle trucks and tractor-trailers. Ashok Leyland is the largest provider of logistic vehicles to the Indian army. It also manufactures diesel engines for Industrial, Genset and Marine applications, in collaboration with technology leaders.

HISTORY: The origin of Ashok Leyland can be traced to the urge for self-reliance, felt by independent India. In 1948, Ashok Motors was set up in what was then Madras, for the assembly of Austin Cars. The Company's destiny and name changed soon with equity participation by British Leyland and Ashok Leyland commenced manufacture of commercial vehicles in 1955. Since then Ashok Leyland has been a major presence in India's commercial vehicle industry with a tradition of technological leadership, achieved through tie-ups with international technology leaders and through vigorous in-house R&D. Access to international technology enabled the Company to set a tradition to be first with technology. Be it full air brakes, power steering or rear engine busses, Ashok Leyland pioneered all these concepts. Responding to the operating conditions and practices in the country, the Company made its vehicles strong, over-engineering them with extra metallic muscles. "Designing durable products that make economic sense to the consumer, using appropriate technology", became the design philosophy of the Company, which in turn has moulded consumer attitudes and the brand personality.

The Hinduja Group is a transnational conglomerate that provides a wide range of products in

over fifty countries worldwide. Today, the Hinduja Group has become one of the largest transnational business conglomerates in the world. The Group employs over 25,000 people and has offices in many key cities of the world and all the major cities in India. Ashok Leyland vehicles have built a reputation for reliability and ruggedness. The 5,00,000 vehicles we have put on the roads have considerably eased the additional pressure placed on road transportation in independent India. In the populous Indian metros, four out of the five State Transport Undertaking (STU) buses come from Ashok Leyland. Some of them like the double-decker and vestibule buses are unique models from Ashok Leyland, tailor-made for high-density routes. In 1987, the overseas holding by Land Rover Leyland International Holdings Limited (LRLIH) was taken over by a joint venture between the Hinduja Group. Ashok Leyland embarked on a major product and process upgradation to match world-class standards of technology. For over five decades, Ashok Leyland has been the technology leader in India's commercial vehicle industry, moulding the country's commercial vehicle profile by introducing technologies and product ideas that have gone on to become industry norms. From 18 seater to 82 seater double-decker buses, from 7.5 tonne to 49 tonne in haulage vehicles, from numerous special application vehicles to diesel engines for industrial, marine and genset applications, Ashok Leyland offers a wide range of products. Eight out of ten metro state transport buses in India are from Ashok Leyland. With over 60 million passengers a day, Ashok Leyland buses carry more people than the entire Indian rail network. standard. This tradition of technological innovations and leadership was achieved through years of vigorous in-house research and development.

Manufacturing plant Ashok Leyland has seven manufacturing plants Ennore Plant, Chennai. Hosur Plants Unit I, Unit II and Unit II A.

Alwar, Rajasthan. Bhandara, Maharashtra. Pantnagar, Uttarakhand . The total covered space at these seven plants exceeds 650,000 sq m and together employ over 11,500 personnel Ennore Spread over 135 acres, Ashok Leyland Ennore is a highly integrated Mother Plant accounting for over 40% ALL production. The plant manufactures a wide range of vehicles and house production facilities for important aggregates such as Engines, Gear Box, Axles and other key inhouse components. Hosur unit 1 Established in 1980, Hosur-I is the engine-manufacturing center within the Ashok Leyland production system. Apart from producing various types of diesel engines (including the engines manufactured under license from Hino of Japan) and CNG engines, the plant also manufactures and assembles heavy duty and special vehicles, Axles, AGBs, Marine Gear Box, etc. The facility is spread over 103 acres and is innovatively laid out, optimising the use of all resources. Hosur unit 2 Ashok Leyland established this state-of-the-art production facility in 1994 at Hosur. Spread over 236 acres, Hosur II houses finishing and assembly facilities including sophisticated painting facilities. The complex also houses one of the largest press facilities in India for pressing frame side members. Laid out with an eye for the future, Hosur II has won acclaim from several automotive experts who have visited the facility. Hosur unit 2a Ashok Leylands brand new Cab Panel Press Shop is an imposing addition to the industrial skyline of Hosur. At 800 m above sea level, it is also the tallest in the Hosur industrial belt.This state-of-the-art facility is housed in a 99-acre expanse with a built up area of over 15,000 sq.m.

A 60,000-sqm lawn and the 2,500 saplings planted recently in the premises will give the Shop a cool, green cover Alwar Established in 1982,the Alwar unit in Rajasthan is an assembly plant for wide range of vehicles with an emphasis on passenger chassis,including CNG nuses,situated clos to the northern market. Bhadara Ashok leylands Bhandara Unit houses manufacturing and assembly facilities for sophisticated synchromesh transmission and also has facilities for assembly of vehicles. Pantnagar Set over 190 scenic acres, the Pantnagar plant of Ashok Leyland is also its largest and one of the most integrated manufacturing facilities in Indian commercial vehicle industry. The shop floors receive the maximum natural light and ventilation while the insulated high roof reduces the inside temperature by up to 8oC in the summer months. Designed on lean manufacture principles, process control for high quality of output and flexibility to manage variety with quick changeovers are built into the machine and process selection. The factory boasts of latest generation equipment sourced from global leaders in Japan, USA, Europe and India.

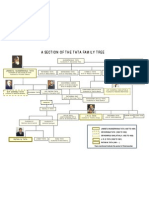

The management team at Ashok Leyland. Mr. Vinod K Dasari Mr. A R Chandrasekharan Mr. Anup Bhat Mr. A K Jain Mr. Jayendra parikh Mr. R R G Menon Mr. Per Gustav Nilsson Mr. Rajive Saharia Mr. Shekar Arora

Mr. K.Sridharan Mr. Venkata Subramaniam

Product range of the company includes:

Buses Trucks Engines Defence & Special Vehicles

The Five AL Values are: 1.International 2.Speedy 3.ValueCreator 4.Innovative 5. Ethical Milestones:

1966 - Introduced full air brakes 1967 - Launched double-decker bus 1968 - Offered power steering in commercial vehicles 1979 - Introduced multi-axle trucks 1980 - Introduced the international concept of integral bus with air suspension 1982 - Introduced vestibule bus 1992 - Won self-certification status for defence supplies 1993 - Received ISO 9002 1997 - India's first CNG powered bus joined the BEST fleet 2001 - Received ISO 14001 certification for all manufacturing units 2002 - Launched hybrid electric vehicle

Major Achievements of Hinduja Group

In 1993, became first Indian Auto Company to receive ISO 9002 certification. Received ISO 9001 certification in 1994, QS 9000 in 1998, and ISO 14001 certification for all vehicle manufacturing units in 2002.

Became the first Indian auto company to receive the latest ISO/TS 16949 Corporate Certification (in July 2006).

First company to introduce full air brakes, power steering and rear engine busses in India.

ASSOCIATE COMPANIES: Automotive Coaches & Components Ltd (ACCL) Lanka Ashok Leyland Hinduja Foundries IRIZAR TVS Ashok Leyland Project Services Ltd Gulf Ashley Motors Ltd Ennore Foundries Ltd

CLIENTS (Not exhaustive): IndianArmy. USArmy. HondurasArmedForces(HAF). TamilnaduStateTransportCorporation(TNSTC). MetropolitanTransportCorporation(MTC),Chennai. StateExpressTransportCorporation(SETC),Tamilnadu. KeralaStateRoadTransportCorporation. MaharashtraStateRoadTransportCorporation(MSRTC). AndhraPradeshStateRoadTransportCorporation(APSRTC). ParveenTravels. Sharma Transport

The chief competitors of the company are; Mahindra Volvo Tata Motors

VISION

Achieving leadership in the medium/heavy duty segments of the domestic commercial vehicle market and a significant presence in the world market through transport solutions that best anticipate customer needs, with the highest value -to-cost ratio.

MISSION

-Identifying with the customer. -Being the lowest cost manufacturer. -Global benchmarking our products, processes and people, against the best in the industry.

QUALITY POLICY

Ashok Leyland is committed to achieve customer satisfaction by anticipating and delivering superior value to the customer in relation to their own business, through the products and services offered by the company and comply with statutory requirements. Towards this, the quality policy of Ashok Leyland is to make continual improvements in the processes that constitute the quality management system, to make them more robust and to enhance their effectiveness and efficiency in achieving stated objectives leading to 1. Superior products manufactured as also services offered by the company. 2. Maximum use of employees potential to contribute to quality and environment by progressive up gradation of their knowledge and skills as appropriate to their functions. 3. Seamless involvement from suppliers and dealers in the mission of the company to address customers changing needs and protection of the environment.

INDUSTRY PROFILE:

AUTOMOBILE INDUSTRY HISTORY:

In the year 1769, a French engineer by the name of Nicolas J. Cugnot invented the first automobile to run on roads. This automobile, in fact, was a self-powered, three wheeler, military tractor that made use of steam engine. The range of the automobile, however, was very brief and at the most, it could only run at a stretch for fifteen minutes. In addition, these automobiles were not fit for the roads as the steam engines made them very heavy and large, and required ample starting time. Oliver Evans was the first to design a steam engine driven automobile in the U.S. The automobile industry finally came of age with Henry Ford in 1914 for the bulk production in cars. This lead to the development of the industry and it first begun in the assembly lines of his car factory. The several methods adopted by Ford, made the new invention ie) car, popular amongst the rich as well as masses. According to the history of automobile industry U.S, dominated the automobile markets around the globe with no notable competitors. However, after the end of Second World War in 1945, the automobile industry of other technologically advanced nations such as Japan and certain European nations gained momentum and within a very short period, beginning in the early 1980s, the U.S automobile industry was flooded with foreign automobile companies, especially those of Japan and Germany. The current trends of the Global automobile industry reveal that in the developed countries the automobile industry are stagnating as a result of the drooping car markets, whereas the automobile industry in the developing nations, such as India and Brazil, have been consistently registering higher growth rates every passing year for their flourishing automobile markets.

INDIAN AUTOMOBILE INDUSTRY:

India is one of the fastest growing automobile industries in the world. After 1960, the automobile industry saw rapid growth and many automotive manufacturers started production. The automobile industry in India is the seventh largest in the world with and annual production of over 2.6 million units in 2009. In 2009, India emerged as Asias fourth largest exporter of automobiles, behind Japan, South Korea and Thailand. By 2050, the country is expected to top the world in car volumes with approximately 611 million vehicles on the nations roads. A well developed transport network indicates a well developed economy. For rapid development a well-developed and well-knit transportation system is essential. As Indias transport network is developing at a fast pace, Indian automobile industry is growing too. Also, the automobile industry has strong backward and forward linkages and hence provides employment to a large section of the population. Thus the role of automobile industry cannot be overlooked in the Indian economy. Indian automobile industry includes manufacture of trucks, buses, passenger cars, defence vehicles ,two wheelers etc.., The industry can be broadly divided into the car manufacturing, two-wheeler manufacturing and heavy vehicle manufacturing units. The major car manufacturers are Hindustan Motors, Maruti Udyog, Fiat India Pvt. Ltd, Ford India Ltd., General Motors Pvt. Ltd., Honda Siel Cars India Ltd., Hyundai Motors India Ltd., Skoda India Pvt. Ltd., Toyota Kirloskar Motor Ltd., to name a few. The two wheeler manufacturing is dominated by companies like TVS, Honda Motorcycle & Scooter India Pvt. Ltd., Hero Honda, Yamaha, Bajaj etc.., The heavy motors like buses, trucks, defence vehicles, auto rickshaws and other multiutility vehicles are manufactured by Tata-Telco, Ashok Leyland, Eicher Motors, Bajaj, Mahindra and Mahindra etc..,

INDIAN AUTOMOBILE MARKET:

Many foreign companies have been investing in the Indian automobile market in various ways such as technology transfers, joint ventures, strategic alliances, exports and financial

collaborations. The auto market in india can boast of attractive finance schemes, increasing purchase power and launch of latest products. Some vital statistics regarding the automobile market in India has been mentioned below: India ranks 2nd in the global two-wheeler market India is the 4th biggest commercial vehicle market in the world India ranks 11th in the international passenger car market India ranks 5th pertaining to the number of bus and truck sold in the world.

HEAVY VEHICLES MARKET:

Heavy vehicles market in India comprises of trucks, machines, ambulances and school buses. The popular heavy vehicle brands in India are Volvo, Eicher, Tata, Telco, Ashok Leyland and Swaraj Mazda. Following are the major players in the Indian Heavy Vehicles Market: Tata Motors is the largest automobile manufacturing company in India that manufactures a

wide range of heavy vehicles adhering to world class standards. It is the market leader in commercial vehicles in all the segments, be it heavy vehicles, medium size vehicles, small vehicles, buses or defence vehicles. The heavy vehicles manufactured by Tata Motors have highly developed braking structure, high ground authorization, better direction competence and a muscular body. The advanced engine imparted to these heavy vehicles makes them a class apart from the other heavy vehicles running on the Indian roads and Highways. Tata Motors leads this segment with a market share of 61%. . Ashok Leyland is an exclusively heavy vehicle manufacturing company situated in Chennai and was initiated in the year 1948. It is one of Indias biggest producers of heavy vehicles such as trucks, buses, military vehicles and also the second biggest commercial vehicle firm in India heavy vehicle division with a market share of around 27%. Ashok Leyland is also renowned for producing auto spare parts and engines for marine and industrial submission. Eicher Motors was initiated in 3rd September, 1960. The first firm to manufacture

the first tractor in India. The indigenously manufactured tractor was introduced in the Indian market straight from Eichers Faridabad factory. The history of the firm can be traced back to

1948, when Goodearth Company was established for vending and repairs of imported tractors in the nation. Swaraj Mazda, a tie up between Mazda and Swaraj Enterprise, Swaraj Mazda

represents advanced Indian expertise and manufacturing. The firm has Research and Development improvement edge on international scale. The firm manufactures various products such as Bus, Ambulance, Trucks etc.

The modern automobile market in India has been considering key issues in the process of growth: Customer care, and not just service Domestic as well as multi-national investments Searing through cut-throat competition Road safety Anti-pollution norms Co-ordination with government to enable advancement Used vehicle trade

PRODUCT PROFILE (Not Exhaustive):

Ashok Leyland offers a comprehensive product range with trucks from 7.5 tons GVW to 49 tons GVW(Gross Vehicle Weight). From 19 to 80 seaters in passenger transport, a host of special application vehicles and diesel engines for industrial gensets and marine application. Product profile can be broadly split into five categories viz. Buses, Trucks, defence vehicles, special Vehicles and Engines. BUSES LYNX BS-II Viking BS-III Panther (Rear engine) Falcon (Front engine) Viking BS-II Viking AL 12 M Bus-BS II Airport Tarmac Coach Cruiser Stag BS-II Cheetah (Front engine) Vestibule Bus Viking CNG BS-III Double Decker

TRUCKS 4x2 Haulage models Tractor DEFENCE VEHICLES Short Chassis Bus Comet 4x4 Stallion 6x6 SPECIAL VEHICLES Hippo tractor Stallion Mk III Tipper Hippo Tipper Beaver tractor Rapid Intervention Vehicle Beaver Haulage Hippo Haulage Field artillery tractor Topchi field Artillery tractor Stallion truck fire fighting Long Chassis Bus Ecomet Multi Axle vehicles 4x2 and Multi-axle Tipper

ENGINES Genset application Marine application Industrial application DG sets for exports

SALES TURNOVER & PROFIT: YEAR SALES TURNOVER Rs.Crore 2006-07 2007-08 2008-09 2009-10 7168.17 7729.12 5981.07 7244.71 net profit rs.crore 441.28 469.31 190 423.67

Ashok Leyland registered a sales turnover of Rs.7729.12 crores during 2007-08 compared to Rs. 7168.17 Crore in 2006-07 showing an improvement of 7.8% After a sluggish start in 2008, the sales turnover improved by 21% touching crores in 2009-10 compared to Rs.5981.07 crores in the 2008-09. The net profit rose by 6.4% in 2007-08 to touch Rs.469.31 crores compared to crore in 2006-07. Similarly the net profit improved to 123% to touch 423.67 crores in 2009-10 against Rs.190 crores in 2008-09. Rs.441.28 Rs.7244.71

Vehicle sales

YEAR SALES in Units DOMESTIC EXPORTS total sales in units

2006-07 2007-08 2008-09 2009-10

77069 76022 47619 57947

6025 7285 6812 5979

83094 83307 54431 63926

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Syllabus CFA Level 1Document2 pagesSyllabus CFA Level 1Phi AnhNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Document6 pagesCore Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Rob Willestone100% (1)

- TencentDocument2 pagesTencentSumit Suman100% (1)

- IC August 2014Document68 pagesIC August 2014sabah8800No ratings yet

- BembosBurger PDFDocument34 pagesBembosBurger PDFcreynosocNo ratings yet

- TNPL Ratio Analysis Study on Financial PerformanceDocument77 pagesTNPL Ratio Analysis Study on Financial PerformanceJenifer PriyaNo ratings yet

- Rough Draft Wit PG NoDocument59 pagesRough Draft Wit PG NoJenifer PriyaNo ratings yet

- Letter Credit FormatDocument3 pagesLetter Credit FormatSanjay MishraNo ratings yet

- A Study On Organisational Culture in Ashok LeylandDocument13 pagesA Study On Organisational Culture in Ashok LeylandJenifer PriyaNo ratings yet

- Demand ForecastingDocument24 pagesDemand ForecastingJenifer PriyaNo ratings yet

- My Dream Company: Why Join ITC Limited (Under 40 charsDocument9 pagesMy Dream Company: Why Join ITC Limited (Under 40 charsamandeep152No ratings yet

- Cases On CommodatumDocument10 pagesCases On CommodatumAlfons Janssen MarceraNo ratings yet

- New Kyc FormDocument3 pagesNew Kyc Formvikas9saraswatNo ratings yet

- Factors - Influencing Implementation of A Dry Port PDFDocument17 pagesFactors - Influencing Implementation of A Dry Port PDFIwan Puja RiyadiNo ratings yet

- Schneider EnglishDocument134 pagesSchneider EnglishpepitoNo ratings yet

- Adjustment of Contract Prices: Using Cida Formula MethodDocument10 pagesAdjustment of Contract Prices: Using Cida Formula MethodHarshika Prasanganie AbeydeeraNo ratings yet

- Model Trading Standard ExplainedDocument12 pagesModel Trading Standard ExplainedVinca Grace SihombingNo ratings yet

- Aparna Singh 19021141023Document2 pagesAparna Singh 19021141023Aparna SinghNo ratings yet

- TATA Family TreeDocument1 pageTATA Family Treemehulchauhan_9950% (2)

- Performance Review and GoalsDocument3 pagesPerformance Review and GoalsTaha NabilNo ratings yet

- Franchising Expansion Benefits Through Franchisee Capital and Motivated ManagementDocument13 pagesFranchising Expansion Benefits Through Franchisee Capital and Motivated ManagementTirsolito SalvadorNo ratings yet

- E Channel Product FinalDocument100 pagesE Channel Product Finalakranjan888No ratings yet

- Tally PPT For Counselling1Document11 pagesTally PPT For Counselling1lekhraj sahuNo ratings yet

- None 9aa455b5Document10 pagesNone 9aa455b5ANISNo ratings yet

- BT India Factsheet - NewDocument2 pagesBT India Factsheet - NewsunguntNo ratings yet

- Partial Fore Closure Receipt 28 03 2018 1522236048Document1 pagePartial Fore Closure Receipt 28 03 2018 1522236048Shridhar JoshiNo ratings yet

- Presentacion Evolucion Excelencia Operacional - Paul Brackett - ABBDocument40 pagesPresentacion Evolucion Excelencia Operacional - Paul Brackett - ABBHERMAN JR.No ratings yet

- Bir Ruling Da 192-08Document2 pagesBir Ruling Da 192-08norliza albutraNo ratings yet

- MAN Machine Material: Bottle Dented Too MuchDocument8 pagesMAN Machine Material: Bottle Dented Too Muchwaranya suttiwanNo ratings yet

- Case Study 7.5 SPMDocument2 pagesCase Study 7.5 SPMgiscapindyNo ratings yet

- Three Eras of Survey ResearchDocument11 pagesThree Eras of Survey ResearchGabriela IrrazabalNo ratings yet

- 10 Types of Entrepreneurial BMsDocument36 pages10 Types of Entrepreneurial BMsroshnisoni_sNo ratings yet

- Special Meeting TonightDocument48 pagesSpecial Meeting TonightHOA_Freedom_FighterNo ratings yet

- What Makes a Great Product ManagerDocument16 pagesWhat Makes a Great Product Managerpresident fishrollNo ratings yet

- Design Thinking: by Cheryl Marlitta Stefia. S.T., M.B.A., QrmaDocument18 pagesDesign Thinking: by Cheryl Marlitta Stefia. S.T., M.B.A., QrmaRenaldiNo ratings yet