Professional Documents

Culture Documents

Profile

Uploaded by

Rupen SinghalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Profile

Uploaded by

Rupen SinghalCopyright:

Available Formats

RELIANCE INDUSTRIES LIMITED

( VADODARA MFG. DIVISION )

Company Profile

Reliance Industries Limited (RIL) is worlds leading and Indias no: 1 Private Ltd. Company. RIL group is a highly diversified group and is in to multiproduct business like oil / gas exploration, retail of transportation sectors. RIL, Vadodara Mfg. Div. was earlier part of the Indian Petrochemicals Corporation Ltd. (IPCL) with Management control by Govt. of India. In 2002, due to divestment of the equity, the management control went in the hands of Reliance Petroinvest Co. of RIL group. On 5th Sept., 2007, IPCL got merged with RIL. RIL, Vadodara Mfg. Div. multi-product mfg. portfolio includes Polymers, Synthetic Rubber, Synthetic Fibre & Fibre Intermediates, Solvents and Industrial Chemicals. It has several distinctions to its credit. Accredited earlier for Best performance award among petrochemicals companies worldwide (CI London), FICCI Awards, ICMA Awards, National Energy Awards and several awards from National Safety Council, USA and British Safety Council, UK. Infact it has Integrated Management System in place comprising of ISO-9001, ISO-14001 and OSHAS-18001 Certification for all the plants and depts. of the Site. petro / consumer products and mfg. of Also, in to infrastructure and petrochemical / refining and textile products.

ENERGY MANAGEMENT POLICY The mission of RIL is :

To be the lowest specific energy consumer in our industry. To widen the options for energy source and To minimize the adverse impact of our operations on the environment.

We plan to achieve the above within the framework of sustaining the business by:

Integrating energy management with the business management and establishing performance drive goals. Upgrading hardware, deploying new technologies and improving our practices to increase energy efficiency, reduce greenhouse gas emissions and minimize environmental impacts. Supporting scientific research and technological efforts to deliver new sources of energy including renewable and alternate fuels. Carrying out regular audits and training employees to promote energy conservation as a culture across the entire business functions. Continuously benchmarking our energy efficiency and energy productivity against others. Promoting awareness on energy conservation among all members of the RIL family and the community at large.

Energy Consumption

Baroda Complex energy consumption rate is around 45 MT of fuel oil equivalent i.e. 450 Million KCal per hour. 65 % of total energy consumed is purchased energy and balance 35 % energy is met through fuel gas, CBFS and Mixed oil generated in the process internally and through various waste heat recovery and energy saving schemes implemented.

Specific Consumption Details :

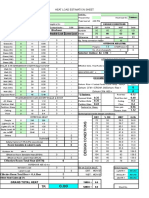

Parameter Annual Production Overall Specific Energy Consumption Thermal Energy Electrical Energy Energy Cost as % of Mfg. Cost Graphical Representation of Specific Energy Consumption MMKcal/MT KWH / MT % 3.24 524 13.84 3.08 508 12.45 2.78 462 11.20 Unit MT MMKcal/MT 2004-05 1004059 4.47 2005-06 984656 4.35 2006-07 1037979 3.82

Energy Index

5 4.5 4 3.5

MMKCAL/MT

Production

1100 1050 1000 950 900 850 800 750 700 650 600 1038 1004 946 909 985

4.65

4.67

4.47

4.35 3.82

3 2.5 2 1.5 1 0.5 0 2002-03 2003-04 2004-05 2005-06 2006-07

('000MT)

2002-03

2003-04

2004-05

2005-06

2006-07

Electrical Energy

6 700 600

(KWH/MT)

Thermal Energy

543

544

534

5 508

(MMKcal/MT)

500 400 300 200 100 0

2002-03 2003-04 2004-05 2005-06

462

4 3.01 3 2 1 0 3.01

3.42

3.24

3.08

2.78

2006-07

2001-02

2002-03

2003-04 2004-05

2005-06

2006-07

Energy Conservation Commitment, Policy and Setup Energy Conservation Cell set up at RIL, Vadodara Mfg. Div. was initiated quite early after commissioning and stabilisaiton of the Cracker and few downstream plants way back in 1982. Since, then the Cell has been playing a very vital role for the organization. The Cell is headed by General Mgr. (Central Technical Services) and assisted by a team comprising of full time a Sr. Mgr. & a Mgr. (Central Technical Services) for carrying out various activities of the Cell. The group works in tandem with all the nominated Energy Coordinators (19 nos.) for each and every plant for Monitoring, Motivating and Implementation of the various schemes in the Complex. It is Committed to saving Energy every year to the tune of minimum 2% every year through de-bottlenecking, technology upgradation, detailed audit studies by Experts / in-house, Optimising of Energy inputs by consuming plants / Utilities Generators and good upkeep through better and proactive Maintenance practices. The Organogram of our Complex w.r.t Energy Conservation Cell is as under :

ORGANISATION STRUCTURE

( w.r.t Energy Management )

Whole Time-Director Board Level

Sr. Vice President (Operations)

Sr. Vice President (Materials)

Sr. Vice President (CTS)*

Sr. Vice President (CES)**

Vice President (Pers. & Admn.)

Asst. Vice President (Medical Services)

All Plants

Energy Coordinators ( All Plants )

General Manager (CTS) -Energy Cell

One Sr. Manager (CTS) & One Mgr. (CTS) Energy Cell

* Central Technical Services ** Central Engineering Services

Energy Conservation Achievements

RIL, Vadodara Mfg. Div. has implemented various schemes big and small, some of them quite innovative and thereby had been successful every year in reducing the Specific Energy Consumption. The year 2006-07 had been quite successful on Energy front. Revenue Saving due to various measures carried out during the year is Rs. 3200 Lakhs. Major Energy Conservation Projects implemented during the 2006-07 are as under :

i. SRT Heater Efficiency Improvement

SRT Heater Efficiency improvement through additional convection bank and installation of WHRB. Heat recovery of 9.0 MMKCAL/hr and efficiency improvement of 9% Total Annual savings : 1181 Rs. Lakhs Total investment : 800 Rs. Lakhs Payback period : 9 months

ii. Trimming of Oxygen in Superheater Cracker Plant In Superheater H 107, trimming of oxygen done. Thermal efficiency improved from 84 to 86.6% Total Annual savings : Rs. 38 Lakhs Total investment : NIL, rigorous monitoring, follow up & proper sealing of convection bank doors. Payback period : Immediate

iii. External Cleaning of SRT Heaters External cleaning of SRT heaters: H 102 & H 104 of convection bank resulted in reduction of stack temperature by more than 30 Deg C. Total Annual savings : Rs. 38.0 Lakhs Total investment : Rs. 2.0 Lakhs. Payback period : 1 month

iv. Diversion of waste gases to fuel gas system In FPU plant, waste gases from column C-702, diverted to fuel gas system instead of flaring. The quantity of waste gas diverted is 20 kg/hr. Total Annual savings : Rs. 25.0 Lakhs. Total investment : Internal Pipings & Instrumentations used Payback period : Immediate

v. Re-engineering of steam and condensate system Re-engineering of steam and condensate system of PPCP, with improved condensate recovery and steam saving. Also, installation of new De-superheater system. Total Annual savings : Rs. 66.00 Lakhs Total investment : Rs. 14.0 Lakhs Payback period : 2.4 months

vi. Detailed CW Network study Detailed CW network study of the whole Integrated Utility plant by an expert resulted in stoppage of 1 CWRP. Total Annual savings : Rs. 144.00 Lakhs Total investment : Rs. 6.0 Lakhs Payback period : 1.0 month

vii. Saving of Atomising Steam by using plant air Use of plant air in place of atomizing steam in Boilers in view of gas firing Total Annual savings : Rs. 66.0 Lakhs Total investment : Change in Operation methodology Payback period : Immediate

Boilers of Utilities

viii. Detailed Steam trap audit Detailed steam trap audit by an Expert for the whole of Vadodara Mfg. Site. Total Annual savings : Rs. 141.0 Lakhs Total investment : Rs. 25.0 Lakhs Payback period : 1.0 Month

Other schemes of 2006-07 are ix. Installation of VFD in LAB plant for fin fan cooler. x. Stoppage of Service water pump for ACN plant CT make up through hook-up with another pump. xi. Major overhaul of Mitsubishi air compressor resulting in improved heat transfer of exchangers and improved efficiency. xii. Condensate recovery from PBR I plant drying unit resulting in reduction of DM water usage. xiii. Installation of high lumen tubelights and louvertec reflectors for Engineering Services & Training centre Buildings. xiv. Trimming of excess O2 in VCM EDC heater and Auxiliary Boilers.

Energy Conservation Planned and Target

Planned Specific Energy Consumption Target for the year 2007-08 & 2008-09

Year

Electrical kWh/MT

Thermal MMKCAL/MT

Reduction over the year 2006-07 Electrical % --Thermal % ---

2006-07 (Base Year) 2007-08 2008-09

462 453 444

2.78 2.72 2.67

+2.0 +2.0

+2.0 +2.0

The company has set quantative objectives of minimum 2.0% overall reduction in energy usage every year. Major future plans for energy conservation are as under :

a)

b)

Steam saving in Naphtha Cracker plant due to Heat Integration measures based on Pinch Analysis Study. Estimated Annual saving of Rs. 75.0 Lakhs. Optimisation of steam cons. by the Steam Turbines of the Complex thru rise in temp. and pressure of the header based on Pinch Analysis Study. Estimated Annual saving of more than Rs. 29 Lakhs.

c)

Preheating of fuel gas for Gas Turbine generator based on Pinch Analysis Study. Estimated Annual saving of more than Rs. 35 Lakhs.

d)

Installation of Energy Conservation Turbine at Utility and Acrylonitrile plants for Steam letdown station. Estimated investment is Rs. 90 Lakhs & Rs. 120 Lakhs respectively. Power generation is 700KWH and 1200 KWH respectively. Payback period for both the schemes is less than a Year.

Environment and Safety

a) Environment Conservation RIL, Vadodara Mfg. Div. has taken several environment friendly measures. Infact new plants / expansion have adopted are cleaner and with energy efficient technologies. Meets all CPCB & GPCB statutory regulations for air, water and soil. A multi-purpose incinerator for the disposal of hazardous solid waste is existing. Also existing is the secured landfill site for solid waste disposal. RIL, Vadodara have received several environment excellence awards like FICCI Award for environment preservation and pollution control and GreenTech awards for environment excellence. ISO 14001 Certification has been achieved for all the plants and depts.. of the Site w.e.f. May 2007.

b)

Safety :

RIL, Vadodara Mfg. Div. gives utmost importance to Safety. Safety of human being is considered above all. Safety dept. is well organised, established and well planned for minimising losses caused by unexpected situations. Various safety practices / procedures / rules have been inbuilt in the Company ever since the inception. The Vadodara Site is recipient of no. of prestigious awards for the last three years are listed below:-

i)

Received Runners-up Trophy in Good Housekeeping contest conducted by Baroda Productivity Council (BPC) for 2004-05 for Gujarat State in Refinery & Petrochemicals category.

ii)

Certificate of Honour from Gujarat Safety council for achieving more than 3 Million Man Hours (MWH) Accident Free Spells.

RIL, Vadodara Mfg. Div. has assigned DuPont, USA for detailed safety audit of two important critical plants namely Acrylonitirle (ACN) and Liner Alkyl Benzene (LAB) plants wherein most dangerous polluting gas like hydrocyanic acid and hydrogen fluoride gases respectively are handled. Secondly, it has well established Process Safety Mgmt. group for improving in depth process related safety measures as per the norms of Dupont which has a reputation of high standard of Safety practices in the world. --- x ---

You might also like

- MarketingDocument4 pagesMarketingRupen SinghalNo ratings yet

- Questionnaire On AirtelDocument3 pagesQuestionnaire On AirtelRupen SinghalNo ratings yet

- Questionnaire On AirtelDocument3 pagesQuestionnaire On AirtelRupen SinghalNo ratings yet

- Why Did Subhiksha FailedDocument21 pagesWhy Did Subhiksha FailedRupen SinghalNo ratings yet

- Our Vision,: Reliance Industries LimitedDocument1 pageOur Vision,: Reliance Industries Limitedalokgod807No ratings yet

- Pradeep Singh Without VideoDocument18 pagesPradeep Singh Without VideoRupen SinghalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Energy Audit in Sugar IndustryDocument6 pagesEnergy Audit in Sugar IndustryVikram Porje100% (1)

- Heat Load CalculationDocument1 pageHeat Load CalculationNashit SayyedNo ratings yet

- Roof-Top Solar PV System Project For Home and Office - Bijli BachaoDocument4 pagesRoof-Top Solar PV System Project For Home and Office - Bijli BachaojishnuNo ratings yet

- EBTKE Conex Seminar AgendaDocument2 pagesEBTKE Conex Seminar AgendaAndre IndoNo ratings yet

- Energy Manager Question PaperDocument18 pagesEnergy Manager Question PaperNibyendu Saha100% (1)

- Biomass Heating Systems: Key Points Savings PotentialDocument4 pagesBiomass Heating Systems: Key Points Savings Potentialnmolloy123No ratings yet

- Industrial Sectional DoorsDocument88 pagesIndustrial Sectional Doorsapi-325435569No ratings yet

- New Vario VFS TC 1622 PDFDocument224 pagesNew Vario VFS TC 1622 PDFsebkahnNo ratings yet

- MT8Document2 pagesMT8fahsaiiNo ratings yet

- Wind Diesel Systems by Krishna Raghavan, Arrakis AssociateDocument7 pagesWind Diesel Systems by Krishna Raghavan, Arrakis Associateanhhung80No ratings yet

- Dalmia Cement AriyalurDocument31 pagesDalmia Cement AriyalurMohammed Shafi AhmedNo ratings yet

- EACM B.tech Paper B0 41720 Dec. 2013Document4 pagesEACM B.tech Paper B0 41720 Dec. 2013Madhu ValavalaNo ratings yet

- Abrahamse & Al. (2005) - A Review of Intervention Studies Aimed at Household Energy ConservationDocument19 pagesAbrahamse & Al. (2005) - A Review of Intervention Studies Aimed at Household Energy ConservationRoz KrakraNo ratings yet

- ECG73 Saving Energy in SchoolsDocument12 pagesECG73 Saving Energy in SchoolsIppiNo ratings yet

- Solar Passive ArchitectureDocument56 pagesSolar Passive ArchitectureVinoth Malaikani100% (1)

- Hollandia Power Inc Flat Collector Solar Water Heater SystemDocument3 pagesHollandia Power Inc Flat Collector Solar Water Heater SystemilieoniciucNo ratings yet

- Energy Audit in BuildingDocument188 pagesEnergy Audit in BuildingReema100% (1)

- 1.3kW Spec SheetDocument2 pages1.3kW Spec SheetArkan Ahmed100% (1)

- KAESER FixingLeaksshortcourseDocument32 pagesKAESER FixingLeaksshortcoursecarlosNo ratings yet

- Ect Emergyu Techniqes ManagementDocument6 pagesEct Emergyu Techniqes Managementkaushik9595No ratings yet

- 3 3 4Document3 pages3 3 4api-351481607No ratings yet

- Environmental and Life Cycle Cost Analysis of A Switched Reluctance MotorDocument4 pagesEnvironmental and Life Cycle Cost Analysis of A Switched Reluctance MotorAmgad_A_Salama_239No ratings yet

- Comparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626Document128 pagesComparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626phuongnhsfc100% (1)

- Save Energy Suction TubeDocument2 pagesSave Energy Suction TubeVenkat PrasannaNo ratings yet

- Havells Lamp Catalog 2012Document80 pagesHavells Lamp Catalog 2012Susmit PalNo ratings yet

- Thermal Effect and Cost Estimation of Expanded Polystyrene Insulated Cavity Wall in Buildings of Composite ZoneDocument4 pagesThermal Effect and Cost Estimation of Expanded Polystyrene Insulated Cavity Wall in Buildings of Composite ZoneijsretNo ratings yet

- Calculation Sheet - GSFC, KosambaDocument22 pagesCalculation Sheet - GSFC, KosambaVijay Mishra100% (1)

- Pressure-Controlled Pumps CascadeDocument2 pagesPressure-Controlled Pumps Cascadecc_bauNo ratings yet

- Energy Efficient RatioDocument5 pagesEnergy Efficient RatioNedunuri.Madhav MurthyNo ratings yet

- LBNL 39102Document155 pagesLBNL 39102Vandana YadavNo ratings yet