Professional Documents

Culture Documents

New Bridge 2902 Tech Manuel

Uploaded by

ckean_ngOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Bridge 2902 Tech Manuel

Uploaded by

ckean_ngCopyright:

Available Formats

Update to 2902 MainStreet Technical Practices Release 1.

0 95-4676-01-00-A

Issue 1 February 1999

Update Instructions and Update History 2902 MainStreet Technical Practices Release 1.0 90-2906-01-B

Update instructions This update lists changes to the 2902 MainStreet Technical Practices. Chapter

1.1 3.1 3.3 4.2 5.1 8.2 8.3 8.4 Index

Reason for update

Added information about the E1 HDSL LIM2. Added information about the E1 HDSL LIM2. Corrected Figure 3.3-3. Corrected date and time information in section 4.2.2. Added information about the E1 HDSL LIM2. Corrected Table 8.2-1 and Figure 8.2-2. Corrected Figure 8.3-3. Added information about the E1 HDSL LIM2. Added entries for the E1 HDSL LIM2.

Replace

Pages 1.1-1 to 1.1-8. Pages 3.1-1 and 3.1-2. Pages 3.3-1 and 3.3-2. Pages 4.2-5 and 4.2-6. Entire chapter. Entire chapter. Pages 8.3-9 and 8.3-10. Pages 8.4-17 to 8.4-20. Pages IN-3 to IN-6.

Update history Date

February 1999 October 1997

Issue

2 1

Part number of update

95-4676-01-00-A 95-1820-01-00-B

Reason for update

This update incorporated PTS fixes and documentation of the new E1 HDSL LIM2. Original release of 2902 MainStreet Technical Practices Release 1.0.

Please retain for your records.

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

1.1 Introduction Issue 2, February 1999

1.1

Introduction

This chapter introduces the 2902 MainStreet Multiservice NTU.

1.1.1

Product Overview

The 2902 MainStreet Multiservice NTU is a high-speed NTU for data devices. The 2902 MainStreet NTU also provides CEPT voice bypass capability. It supports two E1 primary rate interfaces and two data interface modules. HDSL technology allows connection to E1 lines using twisted copper pairs, without repeaters. The 2902 MainStreet Multiservice NTU gives customers access to public and private switched networks. It can be used in point-to-point, or drop and insert configurations. The unit also features circuit protection switching, bypass operation, subrate and super-rate connections, system diagnostics, statistics collection, line and circuit maintenance testing, alarm collection, and database management functions. The HDSL and Optical LIMs allow the 2902 MainStreet NTU to serve as a high-speed NTU, providing low-cost, high-speed X.21 or V.35 circuits for LAN interconnection. E1 G.703 LIMs can also provide high-speed connections to an E1 network. Additionally, an E1 G.703 LIM can be used as a tributary connection to a PBX, allowing voice bypass connections to an HDSL, Optical, or another E1 G.703 LIM. Figure 1.1-1 shows the exterior of a desktop unit. The unit can be placed on a desktop or, with the appropriate hardware, adapted for a rack. Physical connections to primary rate lines can be made through BNC or RJ45 connectors.

Figure 1.1-1: 2902 MainStreet Multiservice NTU

2902 MainStreet

Network Termina tion Unit

Power Event Status System Status

Processor Out of Sync 1 Out of Sync 2

8827

1. Pre-installation

(200)

1.1-1

1.1 Introduction Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

The system uses customer-installed modules to connect to E1 lines and data devices. E1 lines connect to a 2902 MainStreet node through the following line interface modules:

E1 G.703 LIM E1 HDSL LIM E1 HDSL LIM2 E1 Optical LIM

Data devices connect to a 2902 MainStreet node through the following data interface modules:

RS-232 DCM V.35 DCM X.21 DCM Codirectional DCM DNIC module 2B1Q module

1.1.2

Physical Components

The 2902 MainStreet system has three major physical components:

chassis power supply Control card

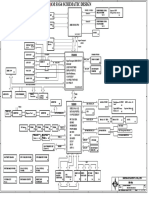

Figure 1.1-2 identifies the components for the unit.

1.1-2

(200)

1. Pre-installation

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

1.1 Introduction Issue 2, February 1999

Figure 1.1-2: 2902 MainStreet Unit (Interior, Rear View)

Data interface modules position (1) position (2) P2 P1 Primary rate interface (P2) modules (P1) EDG and Sig/Gnd Control card

Slot 2 Personality modules Slot 1

Slot 2

P1 P2

Slot 1 Rx-1 Tx-1 Rx-2 Tx-2 Line-1 Line-2 EDG Sig/Gnd

I

O

Modem Termina l

Alarm

Power supply

Loop U1 2 Displa y Status

Rx-1

Tx-1 Rx-2 Tx-2 Modem Line-2 Line-1 Terminal Alarm

Power receptacle Protective earth

Loopback LEDs

Power switch

Fuse holder Status LED

Seven-segment display

9058

Chassis

The chassis acts as a mechanical base for the Control card, power supply and connectors. The top is attached with screws and, once removed, provides access to the Control card, its modules and the power supply. The front panel has LEDs that indicate the status of the power supply, the alarms, the processor and the primary rate links. The rear panel has LEDs that indicate the status of the Control card and loopbacks, and a seven-segment display that indicates the number of major alarms. All power and signal connections are made at the rear panel.

Power supply

The power supply is a self-contained unit mounted inside the unit, above the Control card. It receives its power connection from the power connector module, which contains an EMI filter, fuse holder and power switch.

Control card

The Control card is a multi-layered printed circuit board that performs functions common to the entire system. It contains the system software and configuration memory, and supports up to two E1 primary rate LIMs and up to two data interface modules. Figure 1.1-3 shows the location of the modules.

1. Pre-installation

(200)

1.1-3

1.1 Introduction Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

The Control card provides connectors for network interfaces, data devices, serial ports and external alarm devices. It also supports several LED indicators that can be seen from the back panel (see Figure 1.1-2).

Figure 1.1-3: Control Card Modules

EPROMS 1 2 3 4 Interface module (position 2)

Interface module (position 1) LIM (P1)

LIM (P2) Personality modules (Slot 2/Slot 1)

8840

E1 primary rate line interface modules A LIM provides the line interface to a primary rate line. It contains the drivers and receivers, coupling transformers, and fuses needed for line buffering, impedance matching, isolation and protection. It also provides transmit and receive shield grounding. There are positions for two E1 primary rate LIMs on the Control card, labelled P1 and P2 in Figure 1.1-3. An E1 module must be installed to enable a network port on the 2902 MainStreet system. The unit supports four types of LIMs:

E1 G.703 LIM E1 HDSL LIM E1 HDSL LIM2 E1 Optical LIM

There are two E1 G.703 LIM variantsone for 75 network termination and the other for 120 termination. The 75 G.703 LIM connects to the network through BNC connectors; the 120 G.703 and HDSL LIMs connect through RJ45 connectors. The E1 Optical LIM connects to the network through FC_PC connectors. You can install any combination of primary rate LIMs on the Control card. One LIM is required for each E1 link.

1.1-4

(200)

1. Pre-installation

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

1.1 Introduction Issue 2, February 1999

Data interface modules There are locations for two data interface modules on the Control card, as shown in Figure 1.1-3. Physical position 1 on the Control card maps to logical position M01 on the NMTI, while physical position 2 on the Control card maps to logical position M09 on the NMTI. Logical positions M02 to M08, and M10 to M16 on the NMTI cannot be configured and can only be reserved. All NMTI operations pertaining to physical position 2 are performed through logical position M09. See chapter 4.3 in Configuration for more information. All data modules except the Codirectional DCM support synchronous and asynchronous transmissions. The Codirectional DCM supports local G.703 64 kb/s NTU connections. External device connectors (Slot 1 and Slot 2) Slot 1 and Slot 2 connectors on the Control card provide the access points for user-changeable adapter modules (called personality modules). Each personality module presents the appropriate connector to the external data device and transfers signals between its DCM and the device. There is a personality module for each DCM. Slot 1 and Slot 2 connectors are stacked, with Slot 2 above Slot 1. The personality module in Slot 1 connects to the data interface module in physical position 1 (NMTI logical position M01). The personality module in Slot 2 connects to physical position 2 (NMTI logical position M09). Primary rate link connectors (Rx-1, Tx-1, Rx-2, Tx-2, Line-1, Line-2, P1 and P2) The BNC connectors labelled Rx-1, Tx-1, Rx-2 and Tx-2 are for 75 E1 network termination. Rx-1 and Tx-1 connect to LIM P1; Rx-2 and Tx-2 connect to LIM P2. The RJ45 connectors labelled Line-1 and Line-2 are for 120 E1 or HDSL network termination. Line-1 connects to LIM P1; Line-2 connects to LIM P2. The FC_PC connectors labelled P1 and P2 are for optical network connections. P1 connects to LIM P1; P2 connects to LIM P2. Serial port connectors (Modem and Terminal) The two RJ45 connectors labelled Modem and Terminal are RS-232 serial port connectors. The Terminal connector is configured for a direct connection to node management equipment. The Modem connector is configured for an indirect (or remote) connection to node management equipment through a modem. External alarm connector (Alarm) The connector labelled Alarm is an RJ11 connector. Through the Alarm connector, the 2902 MainStreet system can monitor external equipment for alarm conditions and can signal an alarm condition to an indicating device (such as a light or buzzer).

1. Pre-installation

(200)

1.1-5

1.1 Introduction Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

LED indicators A Control card status LED, a seven-segment display, and a group of four loopback LEDs are mounted on the edge of the Control card. These provide information about card and module status and indicate activated loopbacks.

1.1.3

HDSL LIM Overview

HDSL is a technology that provides transport of E1 service over two pairs of unconditioned copper loops, allowing service providers and private network users to take advantage of their installed base of copper facilities. HDSL delivers bidirectional (full-duplex) 2.048 Mb/s transmission capability over two non-loaded, two-wire metallic pairs. This eliminates the need for additional conditioned lines and repeaters to achieve similar distances. The E1 HDSL LIM and E1 HDSL LIM2 can help to significantly reduce carrier provisioning cost, improve service response times and enhance transmission quality. Line conditioning is simplified, since bridge taps and mixed cable gauge concerns are eliminated. Also, binder separation is no longer required. The E1 HDSL LIMs pass all defined ETSI loops. For example, the LIMs can acheive a maximum reach of 3700 m with zero noise using 0.4 mm wire, or 2850 m with 0 dB ETSI noise. Impairments such as noise, cross-talk, bridge taps, and splices can affect the quality of the signal and loop length. The 2902 MainStreet system supports two E1 HDSL LIMs, each providing separate HDSL transmission. A module is used at both ends of an E1 HDSL link to increase the distance between midspan repeaters in a carrier service area. Each loop carries 16 DS0s as well as overhead information. The modules use full duplex, 2B1Q line coding and continuous adaptive echo cancellation to improve loop reach and BER (bit error rate) performance. Note The E1 HDSL LIM and E1 HDSL LIM2 are not end-to-end compatible. Both ends of an E1 HDSL link must have the same type of HDSL LIM installed.

Bidirectional data is transmitted and received on each pair at a rate of 1168 kb/s. The data from both pairs are combined to form a DS1. The 1168 kb/s rate includes 1024 kb/s of timeslot information and 144 kb/s of HDSL overhead (see Figure 1.1-4).

1.1-6

(200)

1. Pre-installation

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

1.1 Introduction Issue 2, February 1999

Figure 1.1-4: HDSL Technology

HDSL loop 1 30 DS0s E1 interface E1 2.048 Mb/s HDSL master 1168 kb/s 1168 kb/s HDSL loop 2

7661

HDSL slave

E1 2.048 Mb/s

E1 30 DS0s interface

The Control card on a 2902 MainStreet system supports E1 HDSL LIMs in the same way that it supports E1 G.703 LIMs. The E1 HDSL LIMs provide the same service as the E1 G.703 LIMs, except that they use HDSL technology, and that they do not provide the monitoring or bypass functions that are available on the E1 LIMs. Figure 1.1-5 shows a typical application for E1 HDSL LIMs.

Figure 1.1-5: Typical E1 HDSL LIM or E1 HDSL LIM2 Application

Ethernet LAN

Router X.21/V.35 X.21/V.35 2902 MainStreet NTU Slave

E1 HDSL LIM or E1 HDSL LIM2 3700 m (12 139 ft) 0.4 mm wire, zero noise Master 3600 MainStreet Bandwidth Manager

Video conferencing

E1

Centrex/PBX

11868

Performance specifications

The E1 HDSL LIM and E1 HDSL LIM2 meet the performance specification for ETSI ETR 152.

1.1.4

Optical LIM Overview

The E1 Optical LIM converts electrical signals to optical signals. The E1 Optical LIM supports up to 32 DS0s, with one DS0 (timeslot 0) used for synchronization. The 31 DS0s available for data transmission provide a bidirectional bandwidth of 2.048 Mb/s over a distance of 15 km (9 mi), using a 1300 nm single-mode fibre.

1. Pre-installation

(200)

1.1-7

1.1 Introduction Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Full-duplex transmission between two E1 Optical LIMs on separate nodes is achieved by sending data in one direction at a time, making the E1 Optical LIM immune to unwanted optical reflections. This method allows a simplex single-mode cable to be used in a full-duplex application. The E1 Optical LIM emulates an E1 G.703 LIM; however, the monitor and bypass modes on the E1 Optical LIM are not supported. The E1 Optical LIM operates transparently with the node software and has the same configuration and maintenance functions as the E1 G.703 LIM. Figure 1.1-6 shows the E1 Optical LIM in a point-to-point application. Figure 1.1-7 shows a feeder node application.

Figure 1.1-6: E1 Optical LIM Point-to-point Application

2902 MainStreet NTU 2902 MainStreet NTU

DNIC Data X.21 E1 G.703 LIM (P2) E1 Optical LIM (P1) 15 km (9 mi) Fibre cable

DNIC X.21 E1 E1 Optical G.703 LIM LIM (P1) (P2) Data

Video

Video

PBX

PBX

10450

Figure 1.1-7: E1 Optical LIM Feeder Node Application

2902 MainStreet NTU

DNIC Data X.21 E1 E1 G.703 Optical LIM LIM (P1) (P2) Video 15 km (9 mi) Fibre cable

Optical network

PBX

10451

1.1-8

(200)

1. Pre-installation

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

3.1 Connecting to the Network Issue 2, February 1999

3.1

Connecting to the Network

This chapter describes connecting primary rate links to the network.

3.1.1

Primary Rate Connections

Primary rate connections are made through connectors on the rear panel: RJ45 connectors for twisted pair (connectors Line-1 and Line-2), optical connectors for fibre cables (connectors P1 and P2) and BNC connectors for coaxial cables (connectors Rx-1, Tx-1, Rx-2 and Tx-2). Connectors Rx-1 and Rx-2 receive network transmissions; Tx-1 and Tx-2 transmit. Figure 3.1-1 identifies the connectors. The cable impedance and the primary rate module termination impedance must match. Use the RJ45 connectors for twisted pair, 120 termination and the BNC connectors for coaxial cable, 75 termination.

Figure 3.1-1: Primary Rate Connectors

P1 First E1 link

P2 Second E1 link

EDG Sig/Gnd Slot 2 P1 P2

Slot 1

Rx-1

Tx-1

Rx-2

Tx-2

Line-1

Line-2

Modem

Terminal

Alarm Loop U 1 2 Display Status

Rx-1

Rx-2 Tx-2 Tx-1 Line-1 First E1 link

Line-2 Second E1 link

First Second E1 link E1 link

10423

3. Physical Connections

(200)

3.1-1

3.1 Connecting to the Network Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Primary rate module pin and signal assignments

Figures 3.1-2 and 3.1-3 identify the RJ45 connector pin and signal assignments for the 120 G.703 and HDSL LIMs respectively. Figure 3.1-4 identifies the BNC connector pin and signal assignments.

Figure 3.1-2: RJ45 Network Connectors (Line-1 and Line-2) for the 120 G.703 LIM

1 2 3 4 5 6 7 8 Receive Receive Shield Transmit Transmit Shield nc nc

nc = no connection

8847

Figure 3.1-3: RJ45 Network Connectors (Line-1 and Line-2) for the HDSL LIMs

1 2 3 4 5 6 7 8 Pair 1b Pair 1a nc Pair 2b Pair 2a nc nc nc

nc = no connection

10470

Figure 3.1-4: BNC Network Connectors (Rx-1, Tx-1, Rx-2 and Tx-2)

Transmit (+) Receive (+)

Transmit (-) TX BNC (Tx-1 and Tx-2)

Receive (-) RX BNC (Rx-1 and Rx-2)

8849

3.1-2

(200)

3. Physical Connections

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

3.3 Connecting Node Management Equipment Issue 2, February 1999

3.3

Connecting Node Management Equipment

This chapter describes connections for node management equipment.

3.3.1

Node Management Equipment Connections

Node management equipment connects to the 2902 MainStreet system through one of two serial ports. The ports use RJ45 connectors, labelled Modem and Terminal. Figure 3.3-1 identifies these connectors.

Figure 3.3-1: Serial Port Connectors

EDG Sig/Gnd Slot 2 P1 P2

Slot 1

Rx-1

Tx-1

Rx-2

Tx-2

Line-1

Line-2

Modem

Terminal

Alarm Loop U 1 2 Display Status

Modem

Terminal

10424

Node management equipment connects directly to the Terminal connector. The NMTI refers to Terminal as serial port 1. The default setting for the Terminal connector is DCE. Node management equipment connects indirectly to the Modem connector (through a modem). The NMTI refers to Modem as serial port 2. The default setting for the Modem connector is DTE. Once you have established a node management session, you may change the serial port configuration for the 2902 MainStreet system. For information on establishing a node management session, see chapter 4.1 in Configuration. Note If you plan to manage the 2902 MainStreet system from a MainStreetXpress 46020 Network Manager, consult the network manager documentation for instructions on installing network management equipment.

3. Physical Connections

(200)

3.3-1

3.3 Connecting Node Management Equipment Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Modem connector pin and signal assignment

Figure 3.3-2 shows the pin and signal assignment of the Modem connector. The arrows indicate signal direction.

Figure 3.3-2: Pin and Signal Assignment for the Modem Connector

1 2 3 4 5 6 7 8 CTS RTS RXD TXD SGND* DTR DSR

*RS-232 signal ground

8991

Terminal connector pin and signal assignment

Figure 3.3-3 shows the pin and signal assignment of the Terminal connector. The arrows indicate signal direction.

Figure 3.3-3: Pin and Signal Assignment for the Terminal Connector

1 2 3 4 5 6 7 8 not used not used RXD TXD SGND* not used not used

*RS-232 signal ground

8992

3.3-2

(200)

3. Physical Connections

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

4.2 Node Parameters Issue 2, February 1999

To set the flow control

HOUSE

SER_PORT_1 FLOW_CTRL

SER_PORT_2 FLOW_CTRL

NONE*

XON/XOFF

NONE*

XON/XOFF

DTR

SK000468

where * is the default

4.2.2

Date and Time

The date and time are user-configurable.

Date

No Date appears in the header line until the date is set for the first time or after a system reset or power failure. The format for entering the date is <dd-MMM-yyyy>; the hyphens must be entered. For example, January 9, 1999 is entered as <09-JAN-1999>.

Time

Until the time is set, the time elapsed since the last system reset appears in the header line in the form hh:mmR. For example, 4:03R indicates that 4 hours and 3 minutes have passed since the last system reset. When the time is set, real time appears in 12-hour format, followed by the letter A or the letter P to indicate a.m. or p.m., respectively. The format for entering the time is <hh:mmA> or <hh:mmP>. Time can be entered in either 12-hour or 24-hour format, but is displayed only in 12-hour format. For example, 4:30 p.m. is entered as <4:30P> or <16:30>. If you enter the time in 12-hour format without an <A> or <P>, the system assumes an <A>.

4. System Configuration

(400)

4.2-5

4.2 Node Parameters Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

To set the date and time

HOUSE

DATE <dd-MMM-yyyy>

TIME <hh:mmA> or <hh:mmP>

SK000469

where dd is the date 1 to 31 MMM is the first three letters of the month yyyy is the four digits of the year hh is the hour (1 to 12 or 0 to 23) mm is the minutes (1 to 59)

4.2.3

Node Number and Node Name

A unique node number (CPSS address) identifies each node in a network. The system can also be given a node name. The node number and name are not saved as part of a configuration database backup. That is, when a database is loaded into a node from backup, the number and name return to their default values (unassigned). This helps prevent two or more nodes in a network from having the same number. See chapter 8.7 in Maintenance for more information.

Node number

The node number is the CPSS address used to uniquely identify your unit within a network managed by a Newbridge network manager. If the unit is part of a network managed by a non-CPSS capable network manager, the node number does not need to be set. The node number can be any number from 1 to 999, inclusive. When assigned, it is displayed in the data area. For a node number to take effect, you may have to restart the system; the NMTI displays a message if this is the case. Caution When the system is restarted, all active calls are dropped, in-progress maintenance operations are ended and the NMTI session with the system is ended. The restart does not affect configuration settings.

4.2-6

(400)

4. System Configuration

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

5.1 E1 Module Operating Parameters Issue 2, February 1999

5.1

E1 Module Operating Parameters

This chapter describes the operating parameters for the E1 primary rate modules, including:

network connectors framing format signal earthing (E1 G.703 LIM only) master/slave operation (E1 HDSL and Optical LIMs only) trunk conditioning fault classes alarm declaration and clearing times statistics

5.1.1

The E1 Module Overview

The 2902 MainStreet system supports four 2.048 Mb/s primary rate modules:

E1 G.703 LIM E1 HDSL LIM E1 HDSL LIM2 E1 Optical LIM

There are two E1 G.703 LIM variantsone for 75 network termination and another for 120 termination. The system recognizes whether you have installed a G.703, HDSL or Optical LIM when it powers up. You can install any combination of primary rate LIMs on the Control card. Note 1 The system does not identify E1 G.703 LIM variants. Ensure that you use the network connector that matches the impedance of the LIM. Note 2 It takes approximately 60 seconds for master and slave HDSL LIMs to synchronize. Synchronization is indicated on the front panel Out of Sync LEDs.

Figure 5.1-1 shows an NMTI display with E1 G.703 LIM information. For the E1 HDSL LIMs and E1 Optical LIM, some softkeys differ, as described in this chapter.

5. E1 Primary Rate Configuration

(400)

5.1-1

5.1 E1 Module Operating Parameters Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Figure 5.1-1: E1 G.703 LIM Display

2902 MainStreet # P1 Configured E1 82211-ab-cd Installed E1 Status OOS Alarm:6 Name No Date 3:43R

Options CAS

TS0 channel is unused E1 connector Type : BNC shield levels :

BNC Receive is earthed Transmit is earthed

FAS statistics gathered ANS Alarm Threshold : 5

CONFIG POSITION P1 OPTIONS 1-FRAME_TYPE 62-BNC_SHIELD 7-MORE... 3-RJ45_CONN 8-CANCEL 4-CR4_STATS 9-QUIT 50-

E1 Module IDs

The 2902 MainStreet NMTI identifies E1 LIMs by the module IDs listed in Table 5.1-1. See section 8.3.7 for information about displaying module IDs in the NMTI.

Table 5.1-1: E1 Module IDs

LIM E1 LIM (1) E1 HDSL LIM E1 HDSL LIM2 (2) E1 Optical LIM Module ID $22 $28 $32 $38

Notes 1. The system does not identify E1 G.703 LIM variants. 2. Nodes using software generic 82211-H0-00 or 82211-H0-01 do not display the module type as HDSL for the E1 HDSL LIM2.

5.1.2

Network Connectors

The 2902 MainStreet system can be connected to an E1 network through BNC, RJ45 or FC_PC connectors. The BNC connectors provide 75 termination (according to BS9210:N001:Part 2 specifications). The RJ45 connectors provide 120 termination (according to ISO/IEC 10173:TBR12 specifications).

5.1-2

(400)

5. E1 Primary Rate Configuration

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

5.1 E1 Module Operating Parameters Issue 2, February 1999

The BNC connectors are the default selection for E1 G.703 LIMs. The E1 HDSL LIMs can only connect through RJ45 connectors. The E1 Optical LIM can only connect through FC_PC connectors, and these network connectors are non-configurable. Note For E1 G.703 LIMs, ensure that the impedance of your network connector matches the impedance of your LIM.

When RJ45 connectors are selected for an E1 G.703 LIM, information on signal earthing for BNC shield levels is no longer applicable and does not appear on the display. See section 5.1.4 for more information on signal earthing.

To configure the network connectors for an E1 LIM

CONFIG POSITION <Pp> OPTION RJ45_CONN/BNC_CONN*

where p is 1 or 2 * is the default

5.1.3

E1 Framing Format

The E1 framing options determine the framing structure and the timeslot usage of a 2.048 Mb/s E1 link. The framing type cannot be changed or configured if any circuits are connected. Two framing options are available: CAS and CCS.

Channel associated signalling

With CAS, timeslot 16 is used for channel associated signalling and is not user configurable. Timeslot 0 is used for framing. The rest of the timeslots are used for information. Table 5.1-1 shows the timeslot-to-circuit relationships.

Common channel signalling

With CCS, timeslot 16 is used for circuit 31, which can be configured as an additional 64 kb/s data channel (typically for the transport of common channel signalling messages). Timeslot 0 is used for framing. The rest of the timeslots are labelled as in CAS. Table 5.1-2 shows the timeslot-to-circuit relationships. In Table 5.1-2, a timeslot is the ITU-T specified channel designation of a primary rate channel and a circuit is the node management designation of a primary rate channel. F stands for framing and S stands for signalling.

5. E1 Primary Rate Configuration

(400)

5.1-3

5.1 E1 Module Operating Parameters Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Table 5.1-2: CAS and CCS Timeslot-to-circuit Relationships

Timeslot CAS circuit CCS circuit 0 F F 1 1 1 2 2 2 .... .... .... 15 15 15 16 S 31 17 16 16 .... .... .... 29 28 28 30 29 29 31 30 30

To configure E1 framing format

CONFIG POSITION <Pp> OPTIONS FRAME_TYPE CCS/CAS*

where p is 1 or 2 * is the default

The FRAME_TYPE softkey does not appear if any circuits are connected.

5.1.4

Signal Earthing (E1 G.703 LIM only)

The signal earthing options configure the earth side of the receive and transmit lines as earthed or floating. Transmit shielding can be configured for E1 G.703 LIM variants with 75 termination impedance. The four options are:

receive line earthed (RX_EARTH) receive line floating (RX_FLOAT) transmit line earthed (TX_EARTH) transmit line floating (TX_FLOAT)

Lines earthed When a line is earthed, the earth side of the receive or transmit line is connected to the earth plane of the Control card and, through it, to the telecom safety earth. Normally, both the receive and transmit lines are earthed. Lines floating When a line is floating, the earth side of the receive or transmit line is allowed to float because the differential between the line potential and the telecom safety earth is causing unusually high noise problems.

5.1-4

(400)

5. E1 Primary Rate Configuration

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

5.1 E1 Module Operating Parameters Issue 2, February 1999

To configure signal earthing for E1 G.703 LIMs

If the network connector is configured for RJ45, selecting the BNC_SHIELD softkey is an invalid option that displays the message Invalid option for slot connector type when selected.

CONFIG POSITION <Pp> OPTIONS BNC_SHIELD

RX_EARTH*/RX_FLOAT

TX_EARTH*/TX_FLOAT

SK000678

where p is 1 or 2 * is the default

5.1.5

Master/Slave Operation (E1 HDSL and Optical LIMs only)

To establish a link, the E1 HDSL or Optical LIMs at each end of the link must be configured as either a master or slave LIM. However, both LIMs cannot have the same configuration. The E1 HDSL LIMs do not connect any of the HDSL signal leads to ground (as do the E1 G.703 LIMs) because HDSL is a balanced signal interface. Caution If the E1 HDSL or Optical LIM at each end of a link is configured as the same type (for example, master-to-master or slave-to-slave), the E1 HDSL or Optical LIMs cannot synchronize.

Note Once the HDSL or optical link is connected and the modules are programmed for either master or slave mode, it takes approximately 60 seconds for the HDSL or optical interfaces to synchronize. This time can also apply when loopbacks are applied or the link is in a fault condition.

5. E1 Primary Rate Configuration

(400)

5.1-5

5.1 E1 Module Operating Parameters Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

To configure master/slave operation for E1 HDSL and Optical LIMs

The method you use to configure master/slave operation for the E1 HDSL LIM2 depends on the node software generic you are using. The node software generic does not affect the configuration method for the E1 HDSL LIM or Optical LIM. If you are using an E1 HDSL LIM2 on a 2902 MainStreet node with software generic 82211-H0-00 or 82211-H0-01, you must use the BNC transmit shield option to program the LIM to be a master or slave. By default, the BNC shield option is set to TX_EARTH, which corresponds to the master mode on an E1 HDSL LIM2. To program one of the E1 HDSL LIM2s for slave mode, the BNC transmit shield option must be configured for floating. For E1 HDSL LIM2s on software generic 82211-H0-00 or 82211-H0-01, enter:

CONFIG POSITION <Pp> OPTIONS BNC_SHIELD

RX_EARTH*/RX_FLOAT

TX_EARTH*/TX_FLOAT

SK000678

where p is 1 or 2 * is the default

For E1 HDSL LIM2s on software generic 82211-H0-10 or later, or for E1 HDSL LIMs or Optical LIMs on any software generic, enter:

CONFIG POSITION <Pp> OPTIONS MASTER*/SLAVE

SK000487

where p is 1 or 2 * is the default

5.1.6

Trunk Conditioning

All connections have an information component and a signalling component. When a fault occurs on an E1 link, trunk conditioning defines the type of signal transmitted on the information and signalling paths. Trunk conditioning can be defined for all outgoing transmissions.

5.1-6

(400)

5. E1 Primary Rate Configuration

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

5.1 E1 Module Operating Parameters Issue 2, February 1999

Trunk conditioning can be configured as one-way or two-way for each primary rate module position. It can be enabled or disabled for various classes of link faults, and turned off for individual circuits. You can specify how long a fault must persist before an alarm is raised and how long a fault must be cleared before the alarm is cleared. The trunk conditioning configuration for a primary rate interface can be changed at any time. However, any change disrupts service. If any circuits on the link are cross-connected when the trunk conditioning attributes are being changed, the warning message WARNING: Pressing PROCEED will result in a disruption of service is displayed on the diagnostics line. The two types of trunk conditioning are two-way and one-way. The default is two-way trunk conditioning. Note 1 Super-rate circuits do not support trunk conditioning. Control lead signals are not affected by primary rate circuit failure. Note 2 Primary rate circuits configured to carry CPSS messages have two-way trunk conditioning applied regardless of the type of trunk conditioning selected for them.

Two-way trunk conditioning

When a link is configured for two-way trunk conditioning and a primary rate link fault occurs, the information and the signalling paths are broken in both directions. Figure 5.1-2 illustrates how two-way trunk conditioning is applied to a typical connection. Signalling path Both the primary rate circuit and the connected circuit undergo fault signalling as configured for the primary rate circuit (see section 5.2.2). For the primary rate circuit, the signalling path is driven to idle for 2.5 seconds (which drops any call that may be in progress), then to seized or idle (depending on how the E1 circuit fault signalling is configured). For the connected circuit, the signalling is driven to idle, then to seized or idle depending on how the circuit is configured. For E1 circuits configured with out-of-service A or B fault signalling, the signalling is not driven to idle first. Information path On the information path of a primary rate circuit, the system transmits all ones. On the information path of a connected circuit, the system transmits all ones if the circuit is a primary rate circuit; if not, it transmits all zeros.

5. E1 Primary Rate Configuration

(400)

5.1-7

5.1 E1 Module Operating Parameters Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Example If a primary rate circuit is connected to an X.21 circuit and a fault occurs on the primary rate link, the information path is broken in both directions. On the information path of the primary rate circuit, the node transmits all ones. On the signalling path of the primary rate circuit, it transmits idle signalling, then fault signalling as configured for the primary rate circuit. On the information path of the X.21 circuit, the node transmits all zeros (because it is not a primary rate circuit). On the signalling path of the X.21 circuit, it transmits idle signalling, then fault signalling as configured for the X.21 circuit.

Figure 5.1-2: Two-way Trunk Conditioning

Information All 1s (primary rate circuit) All 0s (not primary rate circuit) Signalling SEIZED or IDLE Fault

Direction of transmission

Fault

Signalling path Information path Connected circuit Information path Signalling path 2902 MainStreet Primary rate circuit

Direction of transmission Signalling 2.5 s SEIZED or IDLE Fault

8842

Information All 1s

One-way trunk conditioning

When a link is configured for one-way trunk conditioning, the information path or the signalling path or both (depending on the fault) are broken in the direction of the fault only. Transmission in the other direction is not affected. One-way trunk conditioning is different for three groups of alarms.

5.1-8

(400)

5. E1 Primary Rate Configuration

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

5.1 E1 Module Operating Parameters Issue 2, February 1999

Group 1 one-way trunk conditioning Figure 5.1-3 shows Group 1 one-way trunk conditioning. For Framing Alarm, Incoming AIS, Framing (FAS) Err Rate Exceeded and Failed State, the information path and the signalling path from the E1 primary rate circuit to the connected circuit are broken in the direction of the fault only. If the connected circuit is a primary rate circuit, the 2902 MainStreet system transmits seized, idle or out-of-service fault signalling (depending on the fault signalling selected for the connected circuit). Unlike two-way trunk conditioning, if the fault signalling is seized, a seized signalling code is transmitted without an idle signalling code first being outputted for a fixed period of time. If the connected circuit is not a primary rate circuit, the node continues to transmit the signalling being outputted. If the connected circuit is not a primary rate circuit, the system transmits all zeros on its information path; if it is a primary rate circuit, it transmits all ones.

Figure 5.1-3: One-way Trunk Conditioning (Group 1)

Signalling Information All 1s (primary rate circuit) All 0s (not primary rate circuit) If primary rate circuit If not primary rate circuit Fault Direction of transmission SEIZED or IDLE Frozen

Fault

Signalling path Information path Connected circuit Information path Signalling path 2902 MainStreet Primary rate circuit

Direction of transmission

8843

Group 2 one-way trunk conditioning Figure 5.1-4 shows Group 2 one-way trunk conditioning. For Multiframe and Incoming TS16 AIS alarms, one-way trunk conditioning breaks only the signalling path in the direction of the fault. The information path is maintained in both directions. If the connected circuit is a primary rate circuit, the system transmits seized or idle fault signalling (depending on the fault signalling selected for the connected circuit).

5. E1 Primary Rate Configuration

(400)

5.1-9

5.1 E1 Module Operating Parameters Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Unlike two-way trunk conditioning, if the fault signalling is seized, the seized signalling code is transmitted without the idle signalling code first being outputted for a fixed period of time. If the connected circuit is not a primary rate circuit, the system continues to transmit the signalling being outputted.

Figure 5.1-4: One-way Trunk Conditioning (Group 2)

Signalling Information All 1s (primary rate circuit) All 0s (not primary rate circuit) If primary rate circuit If not primary rate circuit Fault Direction of transmission SEIZED or IDLE Frozen

Fault

Signalling path Information path Connected circuit Information path Signalling path 2902 MainStreet Primary rate circuit Transmission not affected

Direction of transmission

8844

Group 3 one-way trunk conditioning For Distant alarm and TS16 Distant alarm, one-way trunk conditioning does not result in the information path or the signalling path being broken in either direction. No action is necessary because the fault lies in the transmit path of the primary rate circuit (with respect to the 2902 MainStreet system), not the receive path.

To configure the type of trunk conditioning

This enables trunk conditioning for all primary link faults.

CONFIG POSITION <Pp> OPTIONS MORE TRUNK_COND ONE_WAY/TWO_WAY*

SK000488

where p is 1 or 2 * is the default

You can select classes of alarms that cause trunk conditioning to be applied (see section 5.1.7).

5.1-10

(400)

5. E1 Primary Rate Configuration

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

5.1 E1 Module Operating Parameters Issue 2, February 1999

To disable trunk conditioning for an E1 circuit

If you turn fault signalling off for any E1 circuit, no trunk conditioning is applied to that circuit regardless of how the link is configured for trunk conditioning. That is, the circuit connected to the link stays connected during any red or yellow alarms. See section 5.2.2 for more information on E1 circuit fault signalling.

CONFIG CIRCUIT <Pp-c> FAULT_SIG NONE

where p is 1 or 2 c is 1 to 31

5.1.7

Fault Classes

Trunk conditioning can be enabled or disabled for various classes of primary rate link faults. If trunk conditioning is enabled for an alarm class, one- or two-way trunk conditioning is applied as configured for the primary rate interface when an alarm in that class is raised. If trunk conditioning is disabled for an alarm class, no action is taken when an alarm in that class is raised. Table 5.1-3 lists the four configurable fault classes.

Table 5.1-3: Fault Classes and Alarms

Fault Class Frame Alarms Framing Alarm Incoming AIS Multiframe Alarm Incoming TS16 AIS Distant Alarm TS16 Distant Alarm Failed State Description Includes alarms associated with frame alignment or multiframe alignment. Includes alarms that are received from the equipment at the far end of the primary rate link. Includes only the Failed State alarm. This alarm is raised when 10 severely errored seconds in a row have occurred. Includes only the Framing Err Rate Exceeded alarm. It is raised when the FAS error rate exceeds approximately 10-3 for a period of 4 to 6 seconds. Clearing Cleared when frame alignment or multiframe alignment is regained. Cleared when the remote equipment is no longer transmitting the alarm. Cleared when 10 non-severely errored seconds have occurred in a row. Cleared when the FAS error rate is below approximately 4 x 10 -4 for 9 to 11 seconds.

Distant

Failed

Error

Framing (FAS) Err Rate Exceeded

5. E1 Primary Rate Configuration

(400)

5.1-11

5.1 E1 Module Operating Parameters Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

To configure fault classes

Softkeys with the suffix _OFF disable trunk conditioning for their fault class; those with the suffix _ON enable trunk conditioning.

CONFIG POSITION <Pp> OPTIONS MORE TRUNK_COND FRAME_OFF/ FRAME_ON* DIST_OFF/ DIST_ON* FAILED_OFF/ FAILED_ON* ERROR_OFF/ ERROR_ON*

SK000489

where p is 1 or 2 * is the default

5.1.8

Alarm Declaration and Clearing Times

Both ends of a primary rate link should use the same alarm declare time because it is desirable for both ends of the link to initiate and terminate trunk conditioning at approximately the same time. The alarm declare and clearing times can be configured for Frame and Distant faults, but not for Failed and Error faults, which have fixed times.

Alarm declare time

The alarm declare time determines how long a fault must persist before an alarm is declared. A longer alarm declaration time is useful when the primary rate link is subject to frequent short outages. A shorter alarm declaration time is useful when an alternate path exists so that the length of time that service is disrupted is minimized. The declaration time ranges from 0.1 to 30 seconds in 0.1 second increments (the default is 0.8 seconds).

Alarm clear time

The alarm clear time determines how long a fault must be cleared before a raised alarm is cleared. A longer alarm clear time is useful when an alternate route exists so that connections to the primary rate link that declared the fault are not restored until it appears that the link is stable again. A shorter alarm clear time is useful when no alternate path exists so that the length of time that service is disrupted is minimized. The clearing time ranges from 0.1 to 30 seconds in 0.1 second increments (the default is 10 seconds).

5.1-12

(400)

5. E1 Primary Rate Configuration

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

5.1 E1 Module Operating Parameters Issue 2, February 1999

To set the alarm declaration and clearing times

CONFIG POSITION <Pp> OPTIONS MORE ALARM_TIME DECLARE <n> CLEAR <n>

SK000490

where p is 1 or 2 n is 1 through 300, 1 equals 0.1 seconds

5.1.9

E1 Statistics

You can configure the primary rate link to collect FAS or CRC4 statistics. See chapter 8.5 in Maintenance for more information on E1 statistics.

To configure the statistics type

CONFIG POSITION <Pp> OPTIONS FAS_STATS*/CRC4_STATS

SK000491

where p is 1 or 2 * is the default

5. E1 Primary Rate Configuration

(400)

5.1-13

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.2 Alarms Issue 2, February 1999

8.2

Alarms

This chapter describes alarms, including:

viewing alarm queues acknowledging alarms in a queue deleting alarms from a queue reclassifying configurable alarms logging alarms setting external alarms

8.2.1

Alarms and Alarm Queues

The 2902 MainStreet system continuously monitors itself for abnormal conditions or significant events. When an abnormal condition is detected or a significant event occurs, an alarm is recorded in one of the three alarm queues:

Major/Prompt (event alarms) Minor/Deferred Diagnostic/In Station

Each alarm queue can hold up to 64 alarms. For some alarms, you can configure in which queue the alarm is recorded. When an alarm is recorded in the Major/Prompt queue, the Event Status LED on the front panel lights. The LED remains lit until the alarm is acknowledged. See section 8.1.2 for more information about the Event Status LED. The 2902 MainStreet system has an external alarm function that allows you to monitor or activate an external device (see section 8.2.7). Note 1 Maintenance on the module in physical position M2 is accessed through NMTI module position 9. Note 2 Maintenance information on module position 9 is not available when position 9 is disabled by position 1 (during a super-rate connection). See section 6.3.11 in Configuration for details.

8. System Monitoring

(500)

8.2-1

8.2 Alarms Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Alarm codes and clearing codes

Each alarm in an alarm queue includes information such as date and time of the alarm, as well as an alarm code. The alarm code is a brief description of the nature of the alarm. Some alarms codes have corresponding clearing codes, which inform you that the alarm condition no longer exists. Clearing codes are added to the appropriate alarm queue. Clearing codes have names that are similar to their corresponding alarm codes but include terms such as cleared, removed, restored and normal. For example, the alarm code AIS - All Ones has the clearing code AIS - All Ones Cleared, while the alarm code Busy Out Applied has the clearing code Busy Out Removed. Table 8.2-1 lists and describes the alarm codes. Alarm codes marked with an asterisk (*) have a corresponding clearing code. Some alarm codes have subcodes and parameters that are used by Newbridge field service representatives. Subcodes and parameters that are useful to maintenance functions are given in the table.

Table 8.2-1: Detailed Alarm Descriptions

Alarm Code AIS - 8K* AIS - All Ones* Board Self Test Failed Busy Out Applied* Card Activity Change CPU Self Test Failed Device Failed Distant/Yellow Alarms* DX Self Test Failed E1 Framer Self Test Failed External Alarm Raised* Description of Alarm 8 kHz timing has been received by the Codirectional DCM. An all ones pattern has been received by the Codirectional DCM. This alarm is used only during the production and factory testing of the 2902 MainStreet unit. A MainStreetXpress 46020 Network Manager has forced the link specified in the first parameter to be busied out. A primary rate link has been switched from a preferred link to a protecting link. The CPU self-test described in Table 2.2-3 has failed. The background or directed diagnostics have detected a failed module. Locate and replace the module. The far end has lost frame alignment on a primary rate link. Check the first parameter of the subcode to identify the primary rate link. The Control DX memory self-test described in Table 2.2-3 has failed. One of the E1 Framer loopback self-tests described in Table 2.2-3 has failed. If the external alarm is enabled as an open circuit, this alarm means the circuit has opened. If the external alarm is enabled as a closed circuit, this alarm means the circuit has closed. A primary rate link has experienced 10 consecutive severely errored seconds and may have been taken out of service as a result. The first parameter identifies the failed link. The E1 link error threshold was exceeded. Frame alignment has been lost on an E1 link. Check the first parameter of the subcode to identify the module, then check the cable connections to the module and the E1 link. One of the HDLC presence or HDLC loopback self-tests described in Table 2.2-3 has failed.

Failed State*

Framing Err Rate Exceeded* Framing/AIS/Red Alarms*

HDLC Self Test Failed

8.2-2

(500)

8. System Monitoring

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.2 Alarms Issue 2, February 1999

Alarm Code Interrupt Self Test Failed LIM position 1 failed LIM position 2 failed LIS Alarm* Module Dead Module Failure

(1)

Description of Alarm The SMAC interrupt self-test described in Table 2.2-3 has failed. The Loopback (LIM 1) self-test described in Table 2.2-3 has failed. The Loopback (LIM 2) self-test described in Table 2.2-3 has failed. Loss of input signal on a Codirectional DCM circuit. A module has been marked as dead. A module is either not responding to the system or it failed the start-up diagnostics on common circuitry. Check the first parameter to identify the module. A module was inserted. The first parameter identifies the module. A module was removed. The first parameter identifies the module. A module on the Control card has been reset. The E1 multiframe alignment has been lost. The Control card has a problem in the non-volatile RAM. Record the alarm subcode and parameters, then run directed test #3 (see section 8.3.3). After the test, record any information displayed when you enter MAINT NVM_DATA. One of the power rails does not have power. The Address Bus self-test described in Table 2.2-3 has failed. The Control card and software versions are mismatched, or a necessary Control card module is missing. Check the second parameter in the subcode to identify the details of the mismatch as follows: 0 - unknown reason 1 - the card and software are incompatible

Module Inserted Module Removed Module Reset Multiframe Alarm / Incoming TS16 AIS* NVM Error

(1)

Power Rail Failed* RAM Self Test Failed Revision/Feature Mismatch

ROM Self Test Failed SEEP Self Test Failed Signalling Fault Synch Source Changed Synch Source Failure Synch Src Recovery Failed System Advisory (DA)

The EPROM checksum self-test described in Table 2.2-3 has failed. The SEEP self-test described in Table 2.2-3 has failed. An over-active device has caused a signalling fault. The timing source has changed. The timing source has been lost. The system attempted to recover a lost timing source but did not succeed. This is a diagnostic software alarm related to Device Administration. If you are reporting any problems to your Newbridge representative, make sure you include this alarm as it can help to identify a failure mechanism. This is a diagnostic software alarm related to System Administration. If you are reporting any problems to your Newbridge representative, make sure you include this alarm as it can help to identify a failure mechanism. The connection between a DNIC or 2B1Q module and a DTU or DSU has been lost. The first parameter identifies the module. This alarm is not raised if the module is removed from its position. Locate the trouble and reconnect or replace the equipment as necessary. The Thermometer self-test described in Table 2.2-3 has failed.

System Advisory (SA)

Tail Circuit Gone*

Temperature Self Test Failed

8. System Monitoring

(500)

8.2-3

8.2 Alarms Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Alarm Code Timer Self Test Failed Too Many Alarms TS16 Distant Alarm* UART Self Test Failed Wrong Interface Card Wrong Module in Position

Description of Alarm The 4 ms timer or 125 s timer self-test described in Table 2.2-3 has failed. An alarm queue has overflowed. Delete some or all alarms. This is an E1 alarm that indicates that there has been a timeslot 16 multiframe alarm at the far end. One of the UART presence or UART send/receive self-tests described in Table 2.2-3 has failed. The installed interface card and the configuration do not correspond. A module position is configured for a module type other than the type installed. Check the first parameter to determine the position number. Either reconfigure the position to match the module type installed or install the type of module for which the position is configured.

(2)

Wrong/No Module Installed

The installed module and the configuration do not correspond or no module has been installed.

Notes 1. An abnormal operating condition has occurred which may or may not affect system operation. To verify that system operation is not negatively affected, advise the nearest Newbridge field support office of the circumstances leading to this alarm and the details displayed with it. 2. This alarm is not generated for module position 9 when position 9 is reserved for a super-rate connection by position 1.

8.2.2

Viewing Alarm Queues

Alarm queues are displayed with the most recent alarm at the top of the list. If there are too many alarms in the list for the data area to show them all, you can scroll through the list to view earlier or later alarms. Each queue holds up to 64 alarms. If the number of alarms in the queue exceeds 64, a Too Many Alarms alarm occurs and additional alarms are not recorded in the queue until some or all of the alarms are deleted. The number of alarms in the queue is indicated in the header line. Figure 8.2-1 is an example showing four alarms in the Major/Prompt alarm queue. The column headings for the alarms are described in Table 8.2-2.

8.2-4

(500)

8. System Monitoring

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.2 Alarms Issue 2, February 1999

Figure 8.2-1: Alarm Queue Display Example

2902 MainStreet # 4 3 2 1 Date No No No No Date Date Date Date Time 0:17R 0:00R 0:00R 0:00R 82211-ab-cd Stat U U U U Id 4 3 2 1 Alarms:4 Code Module Inserted Framing Alarm Module Inserted Synch Source Changed No Date 4:21R

SubCode Parameters M01 P1 P1 1,0,0 11,0,0 5,14,0

ALARMS MAJ/PROMPT 1-ACK_All 6273-DELETE_ALL 8- CANCEL 4-DELETE 9-QUIT 5-ACK 0-

Table 8.2-2: Description of an Alarm in an Alarm Queue

Column Heading # Description The queue number. The item at the top of the list is the most recent alarm in the queue. Use the alarm queue number when acknowledging or deleting an alarm. Numbers are updated each time an alarm is added or deleted. The date on which the alarm occurred. If No Date appears in the Date column, it indicates that the system has been reset and that the date has not yet been set (see section 4.2.2 in Configuration). The time that the alarm occurred: A for a.m., P for p.m., and R for hours since the last system reset. The status of the alarm: U (unacknowledged) or A (acknowledged). The unique identification number for each alarm code. Unlike the queue #, the Id number does not change. A brief description of the abnormal condition or significant event. A complete list of alarm codes and detailed descriptions are included in Table 8.2-1. Each alarm code has a unique Id number. The alarm subcode and parameters, if any. Subcodes and parameters are used by Newbridge field service personnel only. However, some subcodes and parameters are relevant to maintenance operations, as detailed in Table 8.2-1.

Date

Time Stat Id Code

Subcode and Parameters

8. System Monitoring

(500)

8.2-5

8.2 Alarms Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

To view an alarm queue

ALARMS

MAJ/PROMPT

MINR/DEFER

DIAG/INSTN

EARLIER

LATER

SK000527

8.2.3

Acknowledging Alarms

Alarms can be acknowledged without clearing or deleting them from their respective queues. When an alarm is acknowledged, the letter in the Status column changes from U (unacknowledged) to A (acknowledged), and the alarm remains in the queue. You can acknowledge a specific alarm or all alarms in a queue.

To acknowledge alarms

ALARMS

MAJ/PROMPT

MINR/DEFER

DIAG/INSTN

ACK <alarm number>

ACK_ALL

SK000528

where alarm number is the number (in the # column) of the alarm you want to acknowledge

8.2-6

(500)

8. System Monitoring

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.2 Alarms Issue 2, February 1999

8.2.4

Deleting Alarms

You can delete a specific alarm or all the alarms in a queue. Alarm queue numbers are updated when an alarm is deleted.

To delete alarms

ALARMS

MAJ/PROMPT

MINR/DEFER

DIAG/INSTN

DELETE <alarm number>

DELETE_ALL

SK000529

where alarm number is the number (in the # column) of the alarm you wish to delete

8.2.5

Reclassifying Configurable Alarms

Configurable alarms allow you to determine which queue the alarm is recorded in. In the default configuration, all configurable alarms are classified as Major/Prompt. You may want to configure alarms that need attention but are not an immediate threat to service as Minor/Deferred, or alarms that are advisory as Diagnostic/In Station. Figure 8.2-2 shows a display of alarm codes for configurable alarms and their current classification (listed under Priority). Use the numbers in the # column to identify the alarm code that you wish to reclassify. Press <Esc> before selecting CANCEL, QUIT, PAGE_UP or PAGE_DOWN.

8. System Monitoring

(500)

8.2-7

8.2 Alarms Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Figure 8.2-2: Reclassifying a Configurable Alarm

2902 MainStreet 82211-ab-cd Alarms:4 No Date 4:29R

# Code Priority ------------------------------------1 System Advisory MAJ/PROMPT 2 Wrong Module In Position MAJ/PROMPT 3 NVM Error MAJ/PROMPT 4 Framing/AIS/Red Alarms MAJ/PROMPT 5 Distant/Yellow Alarms MAJ/PROMPT 6 External Alarm Raised MAJ/PROMPT 7 Synch Source Failure MAJ/PROMPT 8 Wrong/No Module Installed MAJ/PROMPT 9 Wrong Interface Card MAJ/PROMPT 10 Device Failed MAJ/PROMPT 11 Framing Err Rate Exceeded MAJ/PROMPT 12 Synch Source Changed MAJ/PROMPT 13 Synch Src Recovery Failed MAJ/PROMPT 14 Revision/Feature Mismatch MAJ/PROMPT ALARMS CONFIG ? Enter the alarm number. 162-PAGE_UP 738- CANCEL

# Code Priority --------------------------------------15 Module Failure MAJ/PROMPT 16 Module Removed MAJ/PROMPT 17 Tail Circuit Gone MAJ/PROMPT 18 Power Rail Failed MAJ/PROMPT 19 Failed State MAJ/PROMPT 20 Card Activity Change MAJ/PROMPT 21 Busy Out Applied MAJ/PROMPT 22 Signalling Fault MAJ/PROMPT 23 Module Reset MAJ/PROMPT 24 Module Dead MAJ/PROMPT 25 RAM Self Test Failed MAJ/PROMPT 26 ROM Self Test Failed MAJ/PROMPT 27 HDLC Self Test Failed MAJ/PROMPT 28 DX Self Test Failed MAJ/PROMPT

49-QUIT

50-

Note An alarm code cannot be reclassified if it has any entries in an alarm queue.

To reclassify an alarm

ALARMS CONFIG <alarm number>

MAJ/PROMPT

MINR/DEFER

DIAG/INSTN

SK000530

where alarm number is the number (in the # column) of the alarm code you wish to reclassify

8.2-8

(500)

8. System Monitoring

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.2 Alarms Issue 2, February 1999

8.2.6

Logging Alarms

The 2902 MainStreet system offers three options for logging alarms:

remotely via CPSS (RMT_ON) remotely via modem (MDM_ON) locally to a device such as a printer (LCL_ON)

All three options are disabled by default and can be enabled concurrently. When two or more options are enabled concurrently, logging priority is as follows: CPSS, then modem, then local printer. Remote logging via CPSS logs alarms to the NOC over the network using CPSS messages. Remote logging via modem logs alarms to the NOC over the PSTN and can serve as a backup method if the network CPSS link to the NOC fails. This option is available only if one of the two serial ports (typically serial port 1) has been configured to accept a modem (see section 4.2.1). Local logging logs alarms to a local device such as a printer. The serial port must be configured to accept a printer (see section 4.2.1).

To log alarms via CPSS

1. 2. Establish CPSS communications over the network. Enter:

ALARMS MORE LOGGING RMT_ON/RMT_OFF*

SK000531

where * is the default

To log alarms via a modem

1. Configure the 2902 MainStreet system serial port type for CPSS_MODEM and establish modem connections between the 2902 MainStreet system and the NOC. Enter:

ALARMS MORE LOGGING MDM_ON/MDM_OFF*

SK000532

2.

where * is the default

8. System Monitoring

(500)

8.2-9

8.2 Alarms Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

To log alarms locally

1. 2. Connect a printer to a serial port and configure the serial port type for PRINTER. Enter:

ALARMS MORE LOGGING LCL_ON/LCL_OFF*

SK000533

where * is the default

8.2.7

External Alarms

The external alarm function allows you to monitor or activate external alarm devices. It is disabled by default. When the function is enabled and a monitored device signals an external alarm, an External Alarm Raised alarm is added to an alarm queue. The function can be disabled while External Alarm Raised alarms are listed in an alarm queue. Connections are made through the Alarm connector (RJ11-type). See chapter 3.4 in Installation for information on connecting external alarm devices.

Monitoring a device

To detect an external alarm, the 2902 MainStreet system monitors its Alarm In pins for a change of state. You can configure the external alarm function to assume the Alarm In contacts are normally open or closed. The default setting is normally closed.

Activating a device

If there is an unacknowledged alarm in the major alarm queue, the Event Status LED lights. If an alarm device is properly connected to the external alarm connector and the external alarm function is enabled, the device is activated. If a system problem exists, the System Status LED lights. If an alarm device is properly connected to the external alarm connector and the external alarm function is enabled, the device is activated. See section 8.1.2 for information on system problems.

8.2-10

(500)

8. System Monitoring

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.2 Alarms Issue 2, February 1999

To set the external alarm function

ALARMS EXTNL_ALRM

ENABLE/DISABLE*

OPEN_CCT/CLOSED_CCT*

SK000534

where * is the default

8. System Monitoring

(500)

8.2-11

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.3 System Diagnostics Issue 2, February 1999

To change outgoing signalling leads

MAINT ON_CIRCUIT <pp-c> SET_SIGNAL <signal> <signal state>

SK000540

where pp is 1 or 9, c is A or B signal is the signalling lead you wish to change signal state is 0 (off) or 1 (on)

8.3.7

Displaying Module and Control Card Maintenance Information

If you must contact your Newbridge representative for technical advice about a module or card, you need to provide information from the MAINT ON_MODULE display. A sample display is shown in Figure 8.3-3. When applicable, the display also identifies:

maintenance being performed on the module protecting or protected links To view module information for maintenance purposes

MAINT ON_MODULE <Pp> or <pp> or <CTL>

where p is 1 or 2 pp is 1 or 9

8. System Monitoring

(500)

8.3-9

8.3 System Diagnostics Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Figure 8.3-3: Module Information Display for Maintenance

2902 MainStreet 82211-ab-cd Alarms:6 No Date 1:11R

There is no maintenance being performed on the interface

Module Type Module ID Interface ID Interface Type

: : : :

E1 $28 $14 HDSL LIM

MAINT ON_MODULE P2 1-LOOPBACK 6-RESET_POSN 2-BYPASS 738-CANCEL 49-QUIT 50-

8.3.8

Resetting a Module or the Control Card

If you have problems with a module, for example, if an alarm indicates that there is a module failure, you may want to reset the module. Caution Resetting the Control card resets the node.

To reset a module or the Control card

MAINT ON_MODULE <Pp> or <pp> or <CTL> RESET_POSN

where p is 1 or 2 pp is 1 or 9

8.3-10

(500)

8. System Monitoring

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.4 Loopbacks Issue 2, February 1999

Figure 8.4-17: Equipment Loopback for E1 G.703 and Optical LIMs

2902 MainStreet

E1 G.703 or Optical LIM Control card

E1 LIM

9116

HDSL LIMs When an HDSL LIM is configured for an equipment loopback, the signal is looped back toward the node and passed through to the far end, as shown in Figure 8.4-18. The loopback occurs as close to the HDSL output as possible.

Figure 8.4-18: Equipment Loopback for HDSL LIMs

2902 MainStreet HDSL LIM or HDSL LIM2 Control card

Loop 1 interface HDSL pair 1 Loop 2 interface HDSL pair 2 MUX

11867

8. System Monitoring

(500)

8.4-17

8.4 Loopbacks Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Line loopback

The line loopback is unidirectional with pass-through. It can be initiated on both primary rate links at the same time. E1 G.703 and Optical LIMs Figure 8.4-19 illustrates the line loopback for the E1 G.703 and Optical LIMs. The signal originates from the E1 link, is looped back at the E1 LIM, and passes through to the DX on the Control card.

Figure 8.4-19: Line Loopback for E1 G.703 and Optical LIMs

2902 MainStreet

Primary rate interface DX LIM Control card DX

DX LIM

Primary rate line loopback

8863

HDSL LIMs An HDSL LIM loops the signal received from the HDSL line back to the network, and passes it through to the Control card (see Figure 8.4-20).

8.4-18

(500)

8. System Monitoring

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

8.4 Loopbacks Issue 2, February 1999

Figure 8.4-20: Line Loopback for HDSL LIMs

2902 MainStreet HDSL LIM or HDSL LIM2 Control card

Loop 1 interface HDSL pair 1 Loop 2 interface HDSL pair 2 MUX

11869

To initiate a primary rate loopback

MAINT ON_MODULE <Pp> LOOPBACK

EQUIPMENT

LINE

SK000546

where p is 1 or 2

To remove a primary rate loopback

MAINT ON_MODULE <Pp> UNDO_LPK

where p is 1 or 2

8. System Monitoring

(500)

8.4-19

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Index Issue 2, February 1999

CPSS links and ANS, 4.4-10 Craft Interface, 4.1-1, 4.2-2 CRC4 statistics, 5.1-13, 8.5-3 cross-connections bypass configuration, 7.1-3 disconnecting, 7.1-11 drop and insert configuration, 7.1-2 NMTI circuit display, 7.1-5 RAPID protection switching, 7.1-6 simple, 7.1-2 super-rate, 7.1-3 to configure protection switching, 7.1-10 to connect simple, 7.1-3 super-rate, 7.1-4 to disconnect all circuits, 7.1-11 simple circuits, 7.1-11 super-rate circuits, 7.1-11 types, 7.1-1

D

data area (NMTI screen), 4.1-5 data devices connecting to the node, 3.2-1 data position HCM rate adaption, 6.6-8 to configure HCM rate adaption, 6.6-8 data structure 2B1Q, 6.1-7 DNIC, 6.1-7 RS-232 DCM, 6.2-6 V.35 DCM, 6.3-8 X.21 DCM, 6.3-8 database 9.1-2 backing up, 9.1-1 resetting, 9.1-4 verifying backups, 9.1-2 DCM data circuit loopbacks, 8.4-10 debounce time DNIC, 6.1-15 device gender 2B1Q, 6.1-4 DNIC, 6.1-4 RS-232 DCM, 6.2-3 V.35 DCM, 6.3-4, 6.3-5, 6.3-6 X.21 DCM, 6.3-4, 6.3-5, 6.3-6

device mode 2B1Q, 6.1-3 DNIC, 6.1-3 RS-232 DCM, 6.2-2 V.35 DCM, 6.3-3 X.21 DCM, 6.3-3 diagnostics background diagnostics, 8.3-3 busy-out circuit, 8.3-6 directed diagnostics, 8.3-4 signalling leads, 8.3-7 test descriptions, 8.3-1 viewing test display, 8.3-5 diagnostics line (NMTI screen), 4.1-5 directed diagnostics, 8.3-4 disconnecting cross-connections description, 7.1-11 distant fault class, 5.1-11 DNIC module circuit configuration, 6.1-2 circuit identifier, 4.3-1 circuit operating parameters, 6.1-2 clocking, 6.1-9 control signals, 6.1-6 data structure, 6.1-7 debounce time, 6.1-15 description, 6.1-1 device gender, 6.1-4 device mode, 6.1-3 duplex method, 6.1-4 loopbacks, 8.4-6 multidrop data bridge, 6.1-12 RTS/CTS delay, 6.1-5 signalling leads, 8.3-7 super-rate configuration, 6.1-14 to configure control signals, 6.1-7 data structure, 6.1-9 device gender, 6.1-4 device mode, 6.1-3 duplex method, 6.1-5 multidrop data bridge, 6.1-13, 6.2-10 RTS/CTS delay, 6.1-5, 6.2-4 super-rate speeds, 6.1-14 transmit clock, 6.1-12 drop and insert configuration (cross-connection), 7.1-2 DTUs and 2B1Q modules, 6.1-1 and DNIC modules, 6.1-1 loopbacks (2600 MainStreet series), 8.4-6 loopbacks (2700 MainStreet series), 8.4-3

IN-3

Index Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

duplex method 2B1Q, 6.1-4 DNIC, 6.1-4

E

E1 circuit fault signalling, 5.2-2 signalling type, 5.2-1 to configure E1 fault signalling, 5.2-2 signalling type, 5.2-1 E1 framing format CAS, 5.1-3 CCS, 5.1-3 E1 G.703 LIM installing, 2.3-3 removing, 2.3-4 signal earthing, 5.1-4 E1 HDSL LIMs installing, 2.3-3 master/slave operation, 5.1-5 removing, 2.3-4 E1 LIMs, 5.1-1 E1 modules alarm declaration and clearing, 5.1-12 E1 framing format CAS, 5.1-3 CCS, 5.1-3 E1 G.703 LIM, 1.1-4, 5.1-1 E1 HDSL LIMs, 1.1-4, 5.1-1 E1 Optical LIM, 1.1-4, 5.1-1 fault classes, 5.1-11 network connectors, 5.1-2 overview, 5.1-1 statistics, 5.1-13 to configure alarm declaration and clearing times, 5.1-13 E1 framing format, 5.1-4 fault classes, 5.1-12 network connectors, 5.1-3 signal earthing (E1 G.703 LIMs), 5.1-5 slave/master operation (HDSL and Optical LIMs), 5.1-6 statistics, 5.1-13 trunk conditioning, 5.1-10 trunk conditioning, 5.1-6

E1 Optical LIM installing, 2.3-4 master/slave operation, 5.1-5 removing, 2.3-8 earthed signal lines, 5.1-4 earthing E1 signal, 5.1-4 empty module positions, 4.3-3 EPROMs replacing, 2.3-12 to replace, 2.3-13 equipment loopback, 8.4-16 error fault class, 5.1-11 event status LED, 8.1-2 external alarm equipment connecting to node, 3.4-1 to connect for activating, 3.4-3 to connect for monitoring, 3.4-3 external alarm function description, 8.2-10 to configure, 8.2-11

F

failed fault class, 5.1-11 failure threshold description, 4.4-8 to assign, 4.4-8 FAS statistics, 5.1-13, 8.5-3 fault classes and alarms, 5.1-11 to configure, 5.1-12 fault signalling and protection switching, 7.1-7 E1 circuit, 5.2-2 floating signal lines, 5.1-4 format E1 framing CAS, 5.1-3 CCS, 5.1-3 frame fault class, 5.1-11 framing format E1 (CAS), 5.1-3 E1 (CCS), 5.1-3 front panel LEDs, 8.1-2 full duplex RS-232 DCM, 6.2-4 fuse testing and replacing, 9.2-3

IN-4

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

Index Issue 2, February 1999

G

grooming CPSS, 8.6-5 ground points EDG, 2.2-1 protective earth, 2.2-1 Sig/GND, 2.2-1 telecom safety earth, 2.2-1 grounding requirements, 1.1-11 grounding the unit, 2.2-2 group 1 one-way trunk conditioning, 5.1-8 group 2 one-way trunk conditioning, 5.1-9 group 3 one-way trunk conditioning, 5.1-10

H

HCM rate adaption description, 6.6-1 to configure data position, 6.6-8 HCM adaption, 6.6-3 interface speed, 6.6-7 signalling, 6.6-5 transport bandwidth, 6.6-4, 6.6-5 HDSL LIMs equipment loopback, 8.4-17 line loopback, 8.4-18 HDSL overview, 1.1-6 header line (NMTI screen), 4.1-4 hop, 8.6-1

personality module pin and signal assignments, 3.2-2 physical positions, 1.1-5, 4.3-1 removing, 2.3-10 resetting a module, 8.3-10 RS-232, 6.2-1 to view module status information, 4.3-6 V.35 DCM, 6.3-1 X.21 DCM, 6.3-1 interface speed HCM rate adaption, 6.6-6 setting super-rate speeds (X.21 and V.35 DCMs) 6.3-14 super-rate for DNIC or 2B1Q, 6.1-14 X.21 or V.35 DCMs, 6.3-13 to configure HCM rate adaption, 6.6-7 inter-sector links, 4.4-10 intra-sector links, 4.4-10

J

J1 and J2 (personality modules) pin and signal assignments, 3.2-2 J11 (external alarm equipment) pin and signal assignment, 3.4-2 J3, J4, J5, J6, J7 and J8 (primary rate) pin and signal assignments, 3.1-2

K

keyboard buffer, 4.1-8

I

installation desktop unit in slide assembly in a rack, 2.1-2 grounding requirements, 1.1-11 power requirements, 1.1-11 site selection, 1.1-10 space requirements, 1.1-11 tool and hardware requirements, 1.1-13 unit, 2.1-1 interface modules 2B1Q, 6.1-1 Codirectional DCM, 6.4-1 DNIC, 6.1-1 general description, 1.1-5 installing, 2.3-9 LEDs, 8.1-6 logical positions, 1.1-5, 4.3-1 maintenance information, 8.3-9

L

LEDs colours, 8.1-1 Control card (rear panel), 8.1-4 front panel, 8.1-2 interface modules, 8.1-6 locations, 8.1-1 start-up sequence, 2.2-6 level 0 access description, 4.2-9 level 1 access description, 4.2-8 level 2 access description, 4.2-8 level 3 access description, 4.2-8 level 4 access description, 4.2-8 level 5 access description, 4.2-8 LIMs E1, 5.1-1 installing, 2.3-3 removing, 2.3-3

IN-5

Index Issue 2, February 1999

2902 MainStreet Technical Practices NNP 95-1820-01-00-B

line loopback, 8.4-18 links inter-sector, 4.4-10 intra-sector, 4.4-10 lockout feature (NMTI), 4.1-2 logging in to NMTI, 4.1-2 logging out of NMTI, 4.1-9 logical module positions, 1.1-5, 4.3-1 loopbacks 2B1Q module, 8.4-3 data circuits (DCMs), 8.4-10 DNIC module, 8.4-6 DTU (2600 MainStreet series), 8.4-6 DTU (2700 MainStreet series), 8.4-3 equipment, 8.4-16 indicators, 8.4-3 line, 8.4-18 overview, 8.4-1 primary rate circuit, 8.4-14 primary rate link, 8.4-16 to remove a specific loopback, 8.4-3 to remove all loopbacks, 8.4-3 types, 8.4-2

installation and removal, 2.3-1 naming a module position, 4.3-7 viewing status, 4.3-4 multidrop data bridge 2B1Q, 6.1-12 DNIC, 6.1-12 RS-232 DCM, 6.2-9 V.35 DCM, 6.3-11

N

network configuration display, 4.4-12 network connections (physical), 3.1-1 NMTI alarm functions, 4.1-6 configuration functions, 4.1-5 general functions, 4.1-7 housekeeping functions, 4.1-6 lockout feature, 4.1-2 logging in, 4.1-2 logging out, 4.1-9 main menu, 4.1-5 maintenance functions, 4.1-6 refreshing the display, 4.1-8 screen display description, 4.1-4 softkey menus, 4.1-7 statistical functions, 4.1-6 NMTI, 4.1-1 NOC telephone number, 4.2-7 node management (overview), 4.1-1 node management equipment to connect to node, 3.3-3 node number, 4.2-6 node parameters access levels, 4.2-8 baud rate, 4.2-3 CPSS node identifier, 4.2-6 date 4.2-5 device type, 4.2-1 flow control, 4.2-4 NOC telephone number, 4.2-7 node name, 4.2-6 node number, 4.2-6 passwords, 4.2-12 time, 4.2-5 to view node information, 4.2-13 NVM and configuration database, 9.1-1 resetting, 9.1-4 viewing information about, 9.1-4

M

M34 cabling (for V.35 DCM connections), 3.2-21 MainStreetXpress 46020 Network Manager, 4.1-1, 4.2-2 master/slave operation HDSL and Optical LIMs, 5.1-5 master/slave operation, 5.1-5 Modem pin and signal assignment, 3.3-2 module circuits naming, 4.3-7 module positions configuring, 4.3-3 empty, 4.3-3 logical, 4.3-1 naming, 4.3-7 physical, 4.3-1 reserved, 4.3-3 to configure, 4.3-4 viewing status, 4.3-4 module status information viewing, 4.3-4 modules Control card

IN-6

You might also like

- Delta Starter Kit ManualDocument178 pagesDelta Starter Kit ManualJonathanRivera100% (1)

- Gravimetric FeederDocument47 pagesGravimetric FeederYousuf Ali67% (3)

- PLC Programming and Control ManualDocument59 pagesPLC Programming and Control Manualyourwish1992No ratings yet

- KTMS 2500Document127 pagesKTMS 2500etchegarayfNo ratings yet

- Prac MCQDocument92 pagesPrac MCQmayur jabare100% (3)

- Alcatel 3AL34277AA 1641SMDocument2 pagesAlcatel 3AL34277AA 1641SMckean_ng50% (2)

- CPU7Document16 pagesCPU7sunnymachoo100% (1)

- GSM Handover Sharing Sharing GuysDocument50 pagesGSM Handover Sharing Sharing GuysAnonymous ofwB20r0sNo ratings yet

- GST200 2Document4 pagesGST200 2Ahmed SweetNo ratings yet

- Alcatel-Lucent OmniPCX Enterprise DPT1Document18 pagesAlcatel-Lucent OmniPCX Enterprise DPT1Hải Đàm100% (1)

- Datis FinalDocument64 pagesDatis FinalVibhore Kumar SainiNo ratings yet

- LVDSDocument35 pagesLVDSRinaldy100% (1)

- UMTS RNC Overview and IntegrationDocument40 pagesUMTS RNC Overview and IntegrationRwayda NadimNo ratings yet

- AEQ TLE-02D Users ManualDocument32 pagesAEQ TLE-02D Users ManualJose Carlos SoaresNo ratings yet

- Flatpack 2 Smartpack MonitoringDocument20 pagesFlatpack 2 Smartpack Monitoringuzef08100% (2)

- Network Interface Converter Net-01X (03X) Owner's Manual 2010-01Document12 pagesNetwork Interface Converter Net-01X (03X) Owner's Manual 2010-01Joshua KaukungwaNo ratings yet

- Ws3000 2dte EngDocument83 pagesWs3000 2dte EngpasupuNo ratings yet

- Nant ADocument12 pagesNant Atran quy don100% (1)

- Mitsubishi fx2n-32ccl Manual - JY992D93201cDocument8 pagesMitsubishi fx2n-32ccl Manual - JY992D93201cssgNo ratings yet

- Megatel MUX ManualDocument60 pagesMegatel MUX ManualkotafiNo ratings yet