Professional Documents

Culture Documents

Contents IMN June 08

Uploaded by

Dirgantara Noor InsandamudaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contents IMN June 08

Uploaded by

Dirgantara Noor InsandamudaCopyright:

Available Formats

Shrink Fit:

The High Accuracy Toolholder of Choice

Requirements in the mold industry are much more precise than general machining, so more attention must be paid toward the selection of the appropriate toolholder in regards to its features and benets

ithin the last 10 years, the acceptance and integration of shrink t toolholders in the

reduce or completely eliminate polishing or spotting time on their molds. This can be accomplished in numerous ways including the use of EDM sinker machines, hard milling of steel or cutting closer to net shape from the beginning of the machining process. In order to address this challenge, the mold and die shops have been forced to look at their entire process. For example, choosing the correct machine tool for the

of the toolholder in the machine tool spindle. 2. Accuracy Accuracy comes from minimal run-out at the cutting edge of the cutting tool. 3. Balance Balance comes from a balanced assembly of the toolholder (including all accessories such as pull-studs) and cutting tool combination.

mold and die industry has continued in aiding all world-based mold shops in remaining globally competitive. Toolholding for milling machines in general had often been overlooked by most manufacturing facilities throughout the world especially Asia. However, it was the mold and die industry that was really the rst segment of the manufacturing market to look for more precise toolholder options. Due to numerous inherent benets, shrink t toolholders have predominately become the high accuracy toolholder of choice for the mold and die market. The Challenge As the mold and die industry in Asia has become much more of a globally competitive market, the need to reduce expensive labor intensive practices has become an absolute necessity for shop owners. The goal for most shops is to

22

indometalworking news Vol. 2 / 2008

job is no longer the only consideration. It However, the requirements in the mold is important to investigate and decide on and die industry are much more precise than general machining, so more the appropriate machine control, CAD/ attention must be made toward the cutting tools in order to complete the job selection of the appropriate toolholder for the job. most efciently CAM software package, toolholders and For example, a mold shop often must The Toolholder Solution When looking for toolholder solutions for think of the following: any type of machining, it is always good to rst focus on three main features that a toolholder must bring you: 1. Rigidity Rigidity comes from sufcient taper contact and proper clamping Geometry of toolholder to avoid collisions with the workpiece. In regards to the EDM process, electrodes must be machined accurately and efciently. Often times, deep ribs are required in

the part process and often present challenges. Also, deep cavities such as large door panel or bumper molds require deep reach with extreme clearances. Cleanliness of the toolholder to avoid excessive run-out, especially when machining graphite. Extending cutting tool life since high-end cutting tools are needed to obtain the best performance in the shortest time possible. These cutting tools often have exotic coatings that lend to an expensive price. Finish. Higher speeds and feeds are used with lower depth-ofcuts, which translates into better surface nishes. This makes balance even more important to minimize vibration at the cutting edge of the cutting tool. Also, proper chip evacuation provides better nishes. Based on these additional requirements, most mold shops have found that due to some inherent benets, shrink t toolholders give them the best opportunity to accomplish the job competitively and accurately. Also, the evolution of inductive shrink t machines has made the shrinking process easier, quicker, safer and less costly to invest in this technology up front. Shrink Fit Advantages There are 10 inherent benets that a

good shrink t chuck can offer a mold shop: 1. Unsurpassed accuracy A properly produced shrink t chuck should be able to guarantee 0.00012 (3 microns) maximum run-out at three times the cutting tool diameter. This accuracy is very repeatable from operator to operator. 2. Availability of slim proles Shrink t chucks are available with three-degree draft angles and very slim proles. They can also be modied to be straight walled if needed in order to prevent toolholder collision with the workpiece. 3. Gripping torque A shrink t chuck grips the cutting tool 360 degrees around the shank. This leads to a very high gripping torque that prevents the cutting tool from moving during roughing or nishing operations. This greatly aids in the reduction of scrapped parts. 4. Extended reach options Shrink t chucks can use shrink t extensions that provide the user with many options with standard products. When machining deep cavities, one can place shrink t extensions into standard shrink t chucks, getting unsurpassed toolholder lengths with very little run-out. 5. Balance repeatability and balanceable options Shrink t chucks offer the best balance repeatability of any toolholding system on the market since there are no moving parts. In many cases, if a shop purchases a properly balanced shrink t chuck with correct accessories (such as pull-studs) and uses good cutting tools without inherent unbalance (such as ats) then they can often have good balance characteristics for running at high speeds without doing an additional ne-tune balancing. Of course, if there is a need for additional balancing of the toolholder on a balancing machine after the assembly of the toolholder setup (toolholder plus cutting tool, plus pull-stud or coolant tube) then many shrink t chucks on the market come with simple to use balanceable options already built into the chucks. 6. Reduction of toolchanging time/ less toolholder accessory inventory Nothing beats the tool change time of shrink t chucks if the process is joined with a capable inductive shrink t machine. Tool changes can be done in ve to 10 seconds, and most importantly, consistently. This allows the toolholder assembly to be in the machine making chips more of the time, than out of the machine waiting to be changed. Also, a shop needs very little additional toolholder accessory inventory (i.e., collets, nuts, seal disks, etc.). This simplies the process. 7. Cleanliness of setup A shrink t chuck typically is a sealed system by design. Therefore, the introduction of contaminants in the bore are minimized (such as graphite dust or chips). If contaminants are introduced to the bore of a toolholder, oftentimes run-out accuracy is compromised. 8. Coolant options Shrink t chucks often have clever methods to deliver coolant or air/

indometalworking news Vol. 2 / 2008

23

that sometimes are only available from one manufacturer. Selection of the Proper Shrink Fit Chuck While there are many suppliers of shrink t chucks available, there are good and bad shrink t chucks available. It is important to do research related to the selection of a toolholder for your particular application. oil mist down to the cutting edge of the cutting tool. This helps with the proper removal of chips and can also aid in providing better nishes. In addition, if a mold shop does high precision drilling, a shrink chuck makes an excellent holder for coolant through drills since no accessories or special collets are neededthe Typically, the initial purchase of your toolholders will last the life of your machine tool. Studies have found that the overall expense of toolholders equals less than 0.5 percent of the overall machining process during the life of the machine tool. subscribe to the DIN standards on the nose dimensions so that all cooling options from the shrink t machine side can be utilized. In general, it is recommended to purchase chucks with many options built-in (such as balanced so that there is under 1 gmm of unbalance in the chuck, balanceable design, bore for the data chip, form DIN B coolant delivery option, etc.) so that you are not limited in the future as your operation evolves. Finally, the company making the chucks should be an industry leader, constantly putting further efforts into research and development into new toolholding concepts that can further strengthen the role of shrink t toolholders in the mold market. For example, the recent development

The relationship between the bore of sealed design of the toolholder simply the holder and the taper lead to the allows the coolant to ow through the accuracy of the chuck. It is important to choose a company that truly makes cutting tool. their own product and specializes only 9. Consistency of setup Shrink t holders provide the best repeatability from toolholder setup to toolholder setup. This is especially benecial for those shops running lights out. For example, all toolholder setup operators set the toolholders the same with shrink t holders. There are no variablessuch as over-tightening or under-tightening a collet nut or not cleaning out a chuck sufciently. Also, as mentioned the balance characteristics are the most repeatable. This combination of consistency allows a shop to truly monitor their tool life and understand how many parts they can machine with each toolholder setupagain, this is truly an important part of getting to the point of lights out machining. 10. Availability of shrink chucks Most of the major toolholder builders in the world now offer shrink t chucks as a standard. Therefore, mold shops are not roped into proprietary high precision collets or press t systems

24

indometalworking news Vol. 2 / 2008

in the production of toolholders. This guarantees you the most consistent and accurate toolholder available for your job. The material of the shrink t chucks is also a key element in making the correct selection. If a substandard material is used, one might shorten the life of the shrink t chuck based on limited heating

of a shrink t chuck1 that provides an anti-vibration feature in a shrink chuck. cycles. A shrink t toolholder made of the This feature helps dampen the vibration correct material should remain effective during roughing operations that had at indenitely. one time occurred with standard shrink Also, it is important that the chucks t chucks due to the extreme rigidity of the setup. Summary It is often stated by shop owners and plant managers that shrink t tooling has been the best investment they have made in the past ve years. Acceptance of the use of shrinking technology in the mold and die market has played a vital role in strengthening Asian manufacturing capabilities and preparing it for continued growth.

You might also like

- Manufacturing Process Assignment 1Document10 pagesManufacturing Process Assignment 1abhishek chibNo ratings yet

- WhitePaper MMTfeatures enDocument3 pagesWhitePaper MMTfeatures enarunNo ratings yet

- Buyer's Guide To Controlled Tolerance StampingsDocument12 pagesBuyer's Guide To Controlled Tolerance StampingsmattgrubbsNo ratings yet

- Dynamic Milling GuideDocument16 pagesDynamic Milling GuidepatrikcncNo ratings yet

- Design Analysis of Personal CNC Mills by TormachDocument13 pagesDesign Analysis of Personal CNC Mills by TormachArjun S RanaNo ratings yet

- ProjectDocument15 pagesProjectpravdivNo ratings yet

- Mickelson, Dale - Guide To Hard Milling and High Speed Machining (2007, Industrial Press)Document251 pagesMickelson, Dale - Guide To Hard Milling and High Speed Machining (2007, Industrial Press)ResearchAssocNo ratings yet

- Cutting and Forming Machine Tools: Customised Machined Seals and Engineered Plastic PartsDocument22 pagesCutting and Forming Machine Tools: Customised Machined Seals and Engineered Plastic Partsfiroz2404No ratings yet

- High Feed Milling by SECODocument48 pagesHigh Feed Milling by SECObangash1975No ratings yet

- Core Handling EquipmentDocument20 pagesCore Handling EquipmentAnjas HardiansyahNo ratings yet

- Chapter - I, Company ProfileDocument12 pagesChapter - I, Company ProfileeswariNo ratings yet

- GOS WP HardTurning F PDFDocument26 pagesGOS WP HardTurning F PDFNhan LeNo ratings yet

- Guide To Welding AutomationDocument14 pagesGuide To Welding Automationdadisetiawan73No ratings yet

- Basic Machining Processes ReportDocument11 pagesBasic Machining Processes Reportedgarinox.davidNo ratings yet

- CNC Cutting Tool Live Monitoring and Cost ReductionDocument10 pagesCNC Cutting Tool Live Monitoring and Cost ReductionKodali Rithvik0% (2)

- Parts Cut To Length: Ted SlezakDocument8 pagesParts Cut To Length: Ted SlezaksolquihaNo ratings yet

- Literature Review On Hammer MillDocument6 pagesLiterature Review On Hammer Millea84e0rr100% (1)

- Self Locking TapsDocument7 pagesSelf Locking Tapscamohunter71100% (1)

- Industrial Training ReportDocument19 pagesIndustrial Training ReportRam PandeyNo ratings yet

- Micro MachiningDocument25 pagesMicro MachiningVishalNaranjeNo ratings yet

- General Design Principles For Manufacturability PDFDocument13 pagesGeneral Design Principles For Manufacturability PDFrrameshsmitNo ratings yet

- Soft Vs Hard ToolingDocument17 pagesSoft Vs Hard ToolingSurya Raghavendar100% (1)

- What's in A BurrDocument6 pagesWhat's in A Burrdecio ventura rodrigues miraNo ratings yet

- Basic Machining Processes ReportDocument11 pagesBasic Machining Processes Reportedgarinox.davidNo ratings yet

- Basic Techniques For Polishing MoldsDocument32 pagesBasic Techniques For Polishing Moldskailashparmar150% (6)

- H - Additional MachiningDocument51 pagesH - Additional MachiningedsaregNo ratings yet

- Page 66-68 Die and Mould NTTF GibsonDocument3 pagesPage 66-68 Die and Mould NTTF GibsonRahul NambiarNo ratings yet

- Designing &manufacturing of Fixture of Cage Cum Differential BrakeDocument34 pagesDesigning &manufacturing of Fixture of Cage Cum Differential BrakeKIRAN YADAVNo ratings yet

- Mold Machining Methods, Part 1Document22 pagesMold Machining Methods, Part 1Edenilson FadekNo ratings yet

- Assignment No. 1 FINALDocument60 pagesAssignment No. 1 FINALCel LuviaNo ratings yet

- Micro MachiningDocument25 pagesMicro MachiningYour ChoiceNo ratings yet

- TriformWeb (Good) PDFDocument11 pagesTriformWeb (Good) PDFNhan LeNo ratings yet

- Plastics Processing Technology Lecture 6Document23 pagesPlastics Processing Technology Lecture 6Kyazze SulaimanNo ratings yet

- ANCA - Part 1 - Making Rotary Instruments For SurgeonsDocument6 pagesANCA - Part 1 - Making Rotary Instruments For Surgeonsclivas83No ratings yet

- Cmti 1228918957257618 1Document32 pagesCmti 1228918957257618 1Nhan LeNo ratings yet

- Mapal News 2013 enDocument20 pagesMapal News 2013 ensivanesanmailNo ratings yet

- Literature Study TopicsDocument11 pagesLiterature Study TopicsPreetish DevamaneNo ratings yet

- Briney Tooling Systems 2012Document81 pagesBriney Tooling Systems 2012brineytoolingNo ratings yet

- Mould Maintenance A KumarDocument40 pagesMould Maintenance A KumarprashanthNo ratings yet

- Quick Die Change in HammersDocument16 pagesQuick Die Change in HammersBalram JiNo ratings yet

- Sitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Document24 pagesSitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Rudra DasNo ratings yet

- Everything You Need To Know About Flatteners and Levelers For Coil Processing-Part 4 - The FabricatorDocument7 pagesEverything You Need To Know About Flatteners and Levelers For Coil Processing-Part 4 - The FabricatorSIMONENo ratings yet

- Rotary TableDocument12 pagesRotary TableNakul Devaiah50% (2)

- How To Buy Forgings: The Design ConferenceDocument6 pagesHow To Buy Forgings: The Design ConferencekkamalakannaNo ratings yet

- MPS5a - GrindingDocument2 pagesMPS5a - GrindingMark julius garciaNo ratings yet

- Project 2Document4 pagesProject 2api-3001969550% (4)

- Casting Design: Cost Factors & ReductionDocument7 pagesCasting Design: Cost Factors & ReductionSantosh DabholeNo ratings yet

- Limits & Fits - Types of Fits Explained & Tolerance Charts - FractoryDocument10 pagesLimits & Fits - Types of Fits Explained & Tolerance Charts - FractoryMangesh KetkarNo ratings yet

- Design For Manufacture - Assembly (Dfma)Document136 pagesDesign For Manufacture - Assembly (Dfma)calvin100% (2)

- Proto Copy Finale DraeteDocument60 pagesProto Copy Finale DraeteAjinkya MoreNo ratings yet

- Die Maintenance. Die Repair. - The FabricatorDocument8 pagesDie Maintenance. Die Repair. - The FabricatorSIMONENo ratings yet

- Heads MNF For BeginnersDocument6 pagesHeads MNF For BeginnersFELIXENGIPLASCOMNo ratings yet

- Internship Report EditedDocument28 pagesInternship Report EditedRohanRayNo ratings yet

- ReamerDocument8 pagesReamerEirick Wayne Zuñigga De-Itzel100% (2)

- ASU Design and Manufacturing BOOKLETDocument0 pagesASU Design and Manufacturing BOOKLETIndranil BhattacharyyaNo ratings yet

- Gear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDocument1 pageGear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDhruv SutharNo ratings yet

- DFM 6Document21 pagesDFM 6Shreya UppuNo ratings yet

- Camworks Dragster CHTP 1Document15 pagesCamworks Dragster CHTP 1Mayrym Rey ConNo ratings yet

- Literature Review of Pipe Bending MachineDocument7 pagesLiterature Review of Pipe Bending Machinec5pbp8dk100% (1)

- History of Cauayan IsabelaDocument18 pagesHistory of Cauayan IsabelaLisa MarshNo ratings yet

- Creating Product and Process Control SystemsDocument35 pagesCreating Product and Process Control SystemsNeydi DávilaNo ratings yet

- Divya Pandya NNDocument29 pagesDivya Pandya NNKrishnaNo ratings yet

- TLEDocument3 pagesTLEJennifer AñesNo ratings yet

- Cod1410 3110Document11 pagesCod1410 3110Tj TalhaNo ratings yet

- National Income MCQsDocument6 pagesNational Income MCQsZeeshan Afzal100% (1)

- 04.06 - Architectural Record 2004-06Document421 pages04.06 - Architectural Record 2004-06elainecristi2002100% (1)

- The Effect of Information Satisfaction and Relational Benefit On Consumer's Online Shopping Site CommitmentDocument3 pagesThe Effect of Information Satisfaction and Relational Benefit On Consumer's Online Shopping Site CommitmentRidho Bramulya IkhsanNo ratings yet

- Berjaya GroupsDocument7 pagesBerjaya Groupspretty80No ratings yet

- Eye Tracking As A Tool in Package and Shelf TestingDocument22 pagesEye Tracking As A Tool in Package and Shelf TestingJon WardNo ratings yet

- Dynamic PurchasingDocument12 pagesDynamic PurchasingsinthujaNo ratings yet

- Business Strategy Case 3 Jumia NigeriaDocument2 pagesBusiness Strategy Case 3 Jumia NigeriaGoddy UshieNo ratings yet

- 15-10219 Item 7 PDFDocument33 pages15-10219 Item 7 PDFRecordTrac - City of OaklandNo ratings yet

- Parlux v. Shawn Carter - Complaint PDFDocument20 pagesParlux v. Shawn Carter - Complaint PDFMark JaffeNo ratings yet

- American Association of Wine EconomistsDocument37 pagesAmerican Association of Wine EconomistspecoraroNo ratings yet

- Strategic Analysis of Indian Advertising IndustryDocument34 pagesStrategic Analysis of Indian Advertising Industryprats9No ratings yet

- Personal Expenses As of September 2023Document2 pagesPersonal Expenses As of September 2023aqualinawrsNo ratings yet

- 2003 RLC Business CalcDocument9 pages2003 RLC Business Calcbob smithNo ratings yet

- Elem Toc PDFDocument5 pagesElem Toc PDFKevin Alexis Hinostroza Cardenas100% (2)

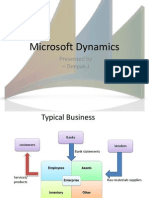

- Microsoft Dynamics: Presented by - Deepak.JDocument20 pagesMicrosoft Dynamics: Presented by - Deepak.JDeepak Prakash JayaNo ratings yet

- Fragmatic: Smell Only Good Phase-3Document9 pagesFragmatic: Smell Only Good Phase-3Udit AgarwalNo ratings yet

- InTouch OFFERS Spring 2022Document10 pagesInTouch OFFERS Spring 2022AlexNo ratings yet

- 10 - Chapter 4 PDFDocument105 pages10 - Chapter 4 PDFAdam CrushNo ratings yet

- 14 ReferencesDocument21 pages14 ReferencespreethiNo ratings yet

- 15.963 Management Accounting and Control: Mit OpencoursewareDocument19 pages15.963 Management Accounting and Control: Mit OpencoursewareTran HueNo ratings yet

- 4D3N Jakarta Bandung Shopping TourDocument1 page4D3N Jakarta Bandung Shopping TourNik AAtoursNo ratings yet

- United Colors of BenettonDocument15 pagesUnited Colors of BenettonMadhukiran KiranNo ratings yet

- American Investor March 2011Document19 pagesAmerican Investor March 2011American Chamber of Commerce in Poland, Kraków Branch / Amerykańska Izba Handlowa w Polsce. Oddział w KrakowieNo ratings yet

- FY2122 Q1 Slide Deck FinalDocument12 pagesFY2122 Q1 Slide Deck FinalMatyas LukacsNo ratings yet

- Roles of A Merchandiser in Garment IndustryDocument5 pagesRoles of A Merchandiser in Garment IndustryRakib Hasan V PNo ratings yet

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyFrom EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyRating: 1.5 out of 5 stars1.5/5 (2)

- Contactless Vital Signs MonitoringFrom EverandContactless Vital Signs MonitoringWenjin WangNo ratings yet

- Design Research Through Practice: From the Lab, Field, and ShowroomFrom EverandDesign Research Through Practice: From the Lab, Field, and ShowroomRating: 3 out of 5 stars3/5 (7)