Professional Documents

Culture Documents

MSPX

Uploaded by

Marc van der LindeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSPX

Uploaded by

Marc van der LindeCopyright:

Available Formats

Sludge Treatment System MSPX 303

Cleaning system for oily waste from oil treatment systems

The Alfa Laval MSPX 303 system offers a fully integrated and modularized system for the de-oiling and de-sludging of oily waste. The reduction of oil content with this system secures the efficient operation of your bilgewater system. Application The MSPX 303 Sludge Treatment System is designed to handle sludge from oil treatment systems in diesel engine installations. The sludge consists of a mixture of water, oil and solids. In the MSPX 303 separator this mixture is separated into its main constituents. System concept The key components of the MSPX 303 Sludge Treatment System are: MSPX 303 separator. HEATPAC EHMS electric heater or S/T heater. EPC 41 control unit. Feed pump. Starters for separator and feed pump. Double strainer. Conditioning module MP 205 (optional).

Features MSPX 303 separator Separation of oil, water and solids simultaneously from oil sludges of varying composition and density without adjustment. Integral paring disc pumps for continuous discharge of separated oil and water. Unique separator bowl design. Separate outlets for oil, water and solids. Automatic start and stop sequence. Benefits Substantial savings in total sludge handling cost. Maximum separation of water prior to discharge to the collecting tank. Maximum recovery of oil for direct use in boiler or for incinerator disposal. Minimum sludge accumulation in bowl ensures long intervals between service. Throughput capacity The throughput capacity of the system is from 200 l/h to 500 l/h dependent on the use of separation conditioner MP 205.

System working principle Sludge is pumped from the sludge tanks and fed via the heater to the MSPX 303 separator. An eccentric screw pump is used to ensure the optimal feed rate to the separator. As an option to enhance the performance of the system a dosing unit for injection of separation conditioner MP 205 is used. The MP 205 is fed directly before the feed pump in the MSPX System. By doing this, the MP 205 will be thoroughly mixed into the feed as it passes through the feed pump and the heater. We recommend dosing MP 205 at a rate of 250500 ppm of the feed flow when dosing directly into the feed. A constant temperature of 95C is maintained by the HEATPAC heater with an accuracy of 1C. The MSPX 303 separator and the MP 205 dosing unit are connected to an EPC 41 control unit for fully automatic operation and designed for intermittent discharge of separated solids during operation. Water and oil are removed continuously, solid impurities intermittently. Since the MSPX 303 system is supplied as three complete modules with a total footprint of approximately 2 m3 it can easily be installed onboard any vessel or in any power plant.

Operations A preventive maintenance program is available with three versions of spare parts kits corresponding to three levels of service: Intermediate service kit every third to fourth month. Major service kit once a year. Three year service kit every third year. System manual includes detailed information in electronic format or paper copy: Installation instructions. Operating instructions. Alarm & fault finding. Service & spare parts. Commissioning & technical service is available from all Alfa Laval offices to start-up the system and to advise about operations & maintenance. Training in all aspects of oil treatment, fresh water generation and cooling is available. All services are incorporated in specially tailored Nonstop Performance packages, details are available from local Alfa Laval offices.

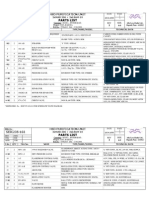

Schematic installation of a sludge treatment plant

11 10

2 3

9 12 1 8 5

System equipment 1. MSPX 303 separator with electric motor, hoses and tools 2. EPC 41 control unit 3. Combined starter for separator and pump 4. Valve block for water 5. Feed pump with electric motor

6. Duplex strainer 7. HEATPAC EHMS 15 kW or S/T preheater 8. Constant pressure valve 9. Three-way-valve 10. Valve block for air 11. Starter for dosing unit (optional) 12. Dosing unit MP 205 (optional)

EMD00018EN 0307

Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval Contact details for all countries are continually updated on our web site. Please visit www.alfalaval.com to access the information direct.

ALFA LAVAL and HEATPAC are trademarks registered and owned by Alfa Laval Corporate AB.

You might also like

- Flex Separation Systems P Separators 605 615 PDFDocument4 pagesFlex Separation Systems P Separators 605 615 PDFJoshua MOUNOWAH100% (1)

- Compatible Spare Parts FOR Centrifugal Separators: Alfa LavalDocument4 pagesCompatible Spare Parts FOR Centrifugal Separators: Alfa LavalJerom RonquilloNo ratings yet

- FWG Explained (Autosaved)Document21 pagesFWG Explained (Autosaved)Junehenry YalduaNo ratings yet

- MAB Separator PDFDocument2 pagesMAB Separator PDFSundarNo ratings yet

- 210 прямого действияDocument2 pages210 прямого действияAlexanderNo ratings yet

- Feed Pump Long TypeDocument20 pagesFeed Pump Long TypeSyam NairNo ratings yet

- Afpx 517Document2 pagesAfpx 517banerjeeamlanNo ratings yet

- MAB103Document2 pagesMAB103olhevlaNo ratings yet

- Mab104 MANUALDocument167 pagesMab104 MANUALMiguel PerezNo ratings yet

- Alfa Laval T5: Gasketed Plate-And-Frame Heat Exchanger For A Wide Range of ApplicationsDocument2 pagesAlfa Laval T5: Gasketed Plate-And-Frame Heat Exchanger For A Wide Range of ApplicationsSergio aldoNo ratings yet

- Sondex S7A-S14A-S20A-IDocument2 pagesSondex S7A-S14A-S20A-IEdwin GallegosNo ratings yet

- Compressor 143Document30 pagesCompressor 143James Wayne BarkerNo ratings yet

- SEJC235-102 Parts List: HSD Purification UnitDocument3 pagesSEJC235-102 Parts List: HSD Purification UnitidigitiNo ratings yet

- Instruction For RBP250-3 and RBP300-3: Anti-Heeling PumpDocument13 pagesInstruction For RBP250-3 and RBP300-3: Anti-Heeling PumpJan MaarschalkerweerdNo ratings yet

- SJ 08 - BrochureDocument2 pagesSJ 08 - BrochureCentrifugal SeparatorNo ratings yet

- 9.5 Oil Purifier - Maintenance ManualDocument104 pages9.5 Oil Purifier - Maintenance Manualsumitchandwaniseros equiptransNo ratings yet

- Aldec Decanter CentrifugeDocument4 pagesAldec Decanter CentrifugejailtonpierreNo ratings yet

- MIB 303 Separation System, Module - Installation Instructions - 1997Document24 pagesMIB 303 Separation System, Module - Installation Instructions - 1997Centrifugal SeparatorNo ratings yet

- E70 Whistle SystemDocument31 pagesE70 Whistle SystemHemananth VeerasekaranNo ratings yet

- WSST Oi Ose 5 10 20 40 80 enDocument2 pagesWSST Oi Ose 5 10 20 40 80 enjing qiangNo ratings yet

- Separator Manual High Speed Separator: MMB 305S-11Document164 pagesSeparator Manual High Speed Separator: MMB 305S-11Bima Surya UtamaNo ratings yet

- Purifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsDocument4 pagesPurifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsJohn Lemuel Arquisola0% (1)

- SA - Separation System - Operating Instructions - 2002Document30 pagesSA - Separation System - Operating Instructions - 2002Centrifugal SeparatorNo ratings yet

- Alpacon ALTREAT 400Document2 pagesAlpacon ALTREAT 400ECO Green and BlueNo ratings yet

- Product Range Alfa LavalDocument13 pagesProduct Range Alfa LavalSoficu DanielNo ratings yet

- GEA Separator enDocument4 pagesGEA Separator enApurba Sen SinghaNo ratings yet

- MH - 8 Test Report of Oil PurifierDocument12 pagesMH - 8 Test Report of Oil Purifieralin_popovici_12No ratings yet

- AFPX 407 Leaflet PDFDocument2 pagesAFPX 407 Leaflet PDFยุทธนา เทียมเมืองNo ratings yet

- SJ30FDocument2 pagesSJ30FRizky Dwi100% (1)

- SA 841 - 846 - Foundation DrawingDocument1 pageSA 841 - 846 - Foundation DrawingCentrifugal SeparatorNo ratings yet

- Future-Series - Operation Manual 1 - Fie-2000-01-Om1 - Scan3Document71 pagesFuture-Series - Operation Manual 1 - Fie-2000-01-Om1 - Scan3Centrifugal SeparatorNo ratings yet

- W-M-2421 - Otc 2Document2 pagesW-M-2421 - Otc 2Danny AriasNo ratings yet

- OSD Type Engl Separator WestfaliaDocument8 pagesOSD Type Engl Separator WestfaliaLTE002No ratings yet

- Alfa Laval PHE For REFDocument4 pagesAlfa Laval PHE For REFNiraj ReginaldNo ratings yet

- Fopx 610TFD-24 SPCDocument74 pagesFopx 610TFD-24 SPCFawllyn Guevara100% (1)

- Evaporator "Alfa Laval"Document22 pagesEvaporator "Alfa Laval"Jittipong HomchitNo ratings yet

- Documents - MX Alarms-55844b5bae365 PDFDocument38 pagesDocuments - MX Alarms-55844b5bae365 PDFCarlos MajanoNo ratings yet

- Alfa Laval Mab 103 24 Spare Parts Manual SPCDocument58 pagesAlfa Laval Mab 103 24 Spare Parts Manual SPCJonathan LisboaNo ratings yet

- Capacity WestfaliaDocument1 pageCapacity WestfaliaAlexanderNo ratings yet

- SA 831 - 836 - Foundation DrawingDocument1 pageSA 831 - 836 - Foundation DrawingCentrifugal SeparatorNo ratings yet

- 52 Filtrex BrochureDocument6 pages52 Filtrex BrochureCvitaCvitićNo ratings yet

- Automatic Separation Systems: ApplicationDocument4 pagesAutomatic Separation Systems: ApplicationJoao FernándezNo ratings yet

- SA - PA - Purifier System - Service Manual - 2006Document12 pagesSA - PA - Purifier System - Service Manual - 2006Centrifugal SeparatorNo ratings yet

- FWGDocument141 pagesFWGWajihNo ratings yet

- Alfa Laval Oil Separators, Purifier MAB 103B-24: Functions & UsesDocument13 pagesAlfa Laval Oil Separators, Purifier MAB 103B-24: Functions & UsesSyam NairNo ratings yet

- Separator Spares InternationalDocument8 pagesSeparator Spares InternationalAlexanderNo ratings yet

- Flex Separation Systems, S-Separators 921-987 - EMD00233ENDocument6 pagesFlex Separation Systems, S-Separators 921-987 - EMD00233ENRogerio Salvagni0% (1)

- Alfa Laval Emmie2 Heater 9016159 80 81 Rev8Document96 pagesAlfa Laval Emmie2 Heater 9016159 80 81 Rev8Amado RodriguezNo ratings yet

- PX 70 - 80 - (Non EX & EX) - Foundation DrawingDocument1 pagePX 70 - 80 - (Non EX & EX) - Foundation DrawingCentrifugal SeparatorNo ratings yet

- Alfa Laval MAB206 PDFDocument196 pagesAlfa Laval MAB206 PDFThái Mai ĐìnhNo ratings yet

- Gunclean Toftejorg T-73 Fixed IM-TE91A450-En3Document39 pagesGunclean Toftejorg T-73 Fixed IM-TE91A450-En3cengiz kutukcuNo ratings yet

- Emd00099en JWP26CDocument4 pagesEmd00099en JWP26CLupu Ane MarieNo ratings yet

- Future-Series - Operation Manual 2 - Fie-2000-01-Om2 - Scan3Document106 pagesFuture-Series - Operation Manual 2 - Fie-2000-01-Om2 - Scan3Centrifugal SeparatorNo ratings yet

- PB-05479 v00 PB300 Compact Flex OPDocument463 pagesPB-05479 v00 PB300 Compact Flex OPMichail AleksandrovNo ratings yet

- Instruction BookDocument186 pagesInstruction Bookjc1ceronNo ratings yet

- TPXData SheetDocument4 pagesTPXData Sheetrameshkarthik810No ratings yet

- MOPXDocument4 pagesMOPXMansoor AhmadNo ratings yet

- Alfa Laval PurifiersDocument4 pagesAlfa Laval PurifiersNasim AbbasNo ratings yet

- PurifierDocument4 pagesPurifierRizal Falevy100% (1)

- FCMDocument4 pagesFCMMansoor Ahmad100% (1)

- Lec 2 - Tall Building Criteria and Loading-2003Document30 pagesLec 2 - Tall Building Criteria and Loading-2003JibonGhoshPritomNo ratings yet

- After12th FinalDocument114 pagesAfter12th FinaltransendenceNo ratings yet

- Fastcap 22 630v PDFDocument1 pageFastcap 22 630v PDFDarrenNo ratings yet

- Plasma TV SMPS TroubleshoutingDocument5 pagesPlasma TV SMPS TroubleshoutingmindjokerNo ratings yet

- Wike Tec 530 Assignment 1Document11 pagesWike Tec 530 Assignment 1heatherpianistNo ratings yet

- Hydraulic Vehicle Lift ST List of Parts and Appendices Stertil B.V BDocument24 pagesHydraulic Vehicle Lift ST List of Parts and Appendices Stertil B.V BOvidiu PopaNo ratings yet

- CBSE Class 12 Political Science WorksheetDocument2 pagesCBSE Class 12 Political Science WorksheetKamal BhardwajNo ratings yet

- ASH ReportDocument3 pagesASH ReportChandra SekharNo ratings yet

- Grade 2 SasmoDocument8 pagesGrade 2 SasmoThích Toán HọcNo ratings yet

- Serie: Guía RápidaDocument12 pagesSerie: Guía RápidalumapueNo ratings yet

- Indicsoft ProfileDocument13 pagesIndicsoft ProfileMahmood AkhtarNo ratings yet

- 3M Scotchkote - Custom Coating GuideDocument16 pages3M Scotchkote - Custom Coating GuideUgoRibeiroNo ratings yet

- 4 Ataxle PDFDocument22 pages4 Ataxle PDFAnonymous XTkln6H100% (1)

- HTTP StreamsDocument8 pagesHTTP StreamsMarcelo Castro MartinoNo ratings yet

- Addressing Corrosion Under Pipe Supports (CUPS) (PRS200a)Document2 pagesAddressing Corrosion Under Pipe Supports (CUPS) (PRS200a)Trajko GorgievskiNo ratings yet

- Linear ProgrammingDocument6 pagesLinear ProgrammingabeerNo ratings yet

- Resume Executive Summary ExampleDocument5 pagesResume Executive Summary ExampleSathish GunasekarNo ratings yet

- Oscilloscope Lab Manual11Document16 pagesOscilloscope Lab Manual11DM RafiunNo ratings yet

- Japan Servo CatalogDocument39 pagesJapan Servo CatalogKofaKing100% (1)

- 46 50Document1 page46 50isturmanNo ratings yet

- Performance of Gesture Controlled DroneDocument11 pagesPerformance of Gesture Controlled DroneKrishna SivaNo ratings yet

- Specification For Foamed Concrete: by K C Brady, G R A Watts and Ivi R JonesDocument20 pagesSpecification For Foamed Concrete: by K C Brady, G R A Watts and Ivi R JonesMaria Aiza Maniwang Calumba100% (1)

- Ebara Pump Brochure DML-DMLFDocument15 pagesEbara Pump Brochure DML-DMLFkutecoolNo ratings yet

- SIRTOS A Simple Real Time Operating SystemDocument6 pagesSIRTOS A Simple Real Time Operating Systemmiguel angelNo ratings yet

- Ingrid Olderock La Mujer de Los Perros by Nancy GuzmnDocument14 pagesIngrid Olderock La Mujer de Los Perros by Nancy GuzmnYuki Hotaru0% (3)

- Electric Fan RepairDocument12 pagesElectric Fan RepairYsabelle Tagaruma33% (3)

- Binary Code PowerPoint TemplateDocument36 pagesBinary Code PowerPoint TemplateAbhinand AdhiNo ratings yet

- Identify Challenges in Relationship Development Final AhahhaDocument2 pagesIdentify Challenges in Relationship Development Final AhahhaKylaNo ratings yet

- VLSI Design FlowDocument20 pagesVLSI Design FlowPranav DarganNo ratings yet

- Tank Specification - Fiberglass Tanks 0408Document13 pagesTank Specification - Fiberglass Tanks 0408shankarkl100% (2)