Professional Documents

Culture Documents

Rail and Structural Mill

Uploaded by

Neeraj SoniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rail and Structural Mill

Uploaded by

Neeraj SoniCopyright:

Available Formats

Rail and Structural Mill

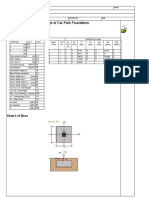

Rail and Structural Mill of Bhilai Steel Plant, SAL is the world's largest producer of rails with an

installed capacity to produce 500 000 tons of rails and 250 000 tons of structurals. Bhilai is also the

sole supplier of the country's longest rail tracks of 260 metres. The length of rails produced so far since

inception is sufficient to encircle the globe more than 8 times.

The major profiles produced in the mill are:

1. RALS 4. ANGLES

a. RS 52 Kg/m a. 200 * 200 * 20/16 mm

b. UC 60 b. 150 * 150 * 20/16 mm

c. Thick Web Asymmetric Rail Zu1-60

2. HEAVY BEAMS 5. CRANE RAILS

a. 600 * 210 * 12mm a. CR 120

b. 500 * 180 * 10.2 mm b. CR 100

c. 450 * 150 * 9.4 mm c. CR 80

d. 400 * 140 * 8.9 mm

e. 350 * 140 * 7.5 mm 6. CROSSING SLEEPERS

f. 250 * 125 * 6.9 mm

3. CHANNELS

a. 400 * 100 * 8.8 mm

b. 300 * 90 * 7.6 mm

c. 250 * 82 * 7.6 mm

The steel grades produced in these products are:

RaiIs:

W RS T-12/ 96 Grade 880 (90 UTS)

W Cu Mo corrosion resistant rails

W High Conductivity Metro Rails

W High YS/UTS Vanadium Micro-alloyed Rails

W Copper-Chromium alloyed High strength Rails

Heavy Structurals:

W S 2062 Grade A & B

W SALMA 300,350,410(with & without Hi)

) STEEL NPUTS OF RSM:

The Rail Steel making process at Bhilai Steel Plant is one of the most advanced. Rail steel is

made in BOF converters at SMS 2 and processed through RH degasser and ladle furnace etc.

The steel thus obtained is very clean and has hydrogen in liquid steel less than 1.6 ppm a world

benchmark. . t is continuously cast into blooms, which are flame cut to specified length &

weight, and sent to Rail and Structural Mill for rolling. Steel for structurals is made at SMS 1

in twin hearth furnaces and is cast into ingots, which are rolled into blooms at the blooming

mill.

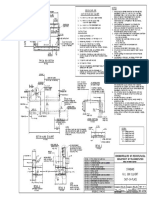

) PROCESS FLOW AT RAL AND STRUCTURAL MLL:

Reheating

furnaces

Roughing Stand

ntermediate

Stands

Finishing Stand

Hot Saws

Stamping

Machine

Cooling Bed &

Storage

Precambering &

walking beam

Cooling Bed

Rail Roller

Straightening

Rail Roller

Straightening

Structural Roller

Straightening

Non Destructive

Testing

nspection Non Destructive

Testing

End Cutting/ Milling Shipping End Cutting

nspection nspection

End straightening(if

reqd)

End straightening(if

reqd)

Dispatch Welding

SLrucLural flnlshlng llne

1. Reheating Furnaces

Blooms from BBM route and continuous casting route are supplied to charging roll table of

Reheating Furnaces, through 3 nos. of Bloom Feeders.

The blooms are the reheated in three reheating furnaces of 75 T / hr capacity each. These

furnaces are continuous pusher type, end-charging end-discharging type injection burner type

furnaces with three zones. These furnaces use a mixture of coke oven and blast furnace gas

of ~ 1900 Kcal/NM

3

as fuel. They use natural draft for air source and natural draft for flue gas

exit. The fuel gas is preheated in metallic recuperators and the combustion air is heated in

ceramic recuperators. The furnace instrumentation and control is automated with micro

processor based process controllers

The furnace is divided into three zones: the preheating zone, the heating zone and the soaking

zone. Bloom enters the preheating zone and in the process of passing through heating zone attains

desired temperature. n soaking zone (which has solid hearth) the temperature of bloom is equalized

throughout its length & cross section.

Slde vlew of 8SM furnace

co/d b/oom from b/oom yord

not b/oom to kouqhinq stond chorqinq end

Soaking

ischorqinq end

Heating

Preheating

8

2. Roughing Stand

The blooms after re-heating are first rolled in the 950 mm roughing stand. This is a 2 high

reversing stand and the reduction to the bar is given in forward as well as backward

directions. The roll gap for each pass is

adjusted by top roll screw down and the blooms

guided into the passes by manipulators. The rolling

schemes for different profiles employ different

number of passes and different pass

gaps in these passes. The maximum reduction to

the bloom is given in this stand and the rough

shape of profile is made. The distance between

the pinions of top and bottom rolls is 950mm

and rolls have a barrel length of 2300mm. The

rolls are driven by a 4000 KW DC motor by

thyristor converters. The working rolls have

water cooled and lubricated textolite bearings. n rails primary descaling of bloom is done

prior to its rolling in roughing stand.

3. ntermediate Stands

The 800 mm intermediate mill is the only one of

its kind in ndia in that, that it is a 3 high non-

reversing mill. The mill has two 3 high stands

coupled together and driven by a single drive

motor. The scheme employs 3 passes in

each stand. Lifting tables lift the rolling bar up to

the upper passes for reversal of direction.

The distance between the pinions is 800 mm and

a barrel length of rolls is1900 mm.

The top rolls are hydraulically balanced

for reducing the mill spring and along with the high rigidity housings ensure high degree of

consistency in the dimensional accuracy of the rolled profile. The drive motor is a fully

compensated DC motor power supplied by thyristor converters. The 930V, 7100 kW 100 /

180 rpm motor is coupled to the rolls by a 3 high pinion roll set. n rails secondary descaling

is done in some passes and roll pass lubrication is employed for better surface finish and

increasing pass life.

ntermediate and finishing stand

Roughing stand

4. Finishing Stand

The 2 high finishing stand provides the final shape and dimensional accuracy to the rolled

profile. Rails are branded with month, year, profile, grade of steel and manufacturer's

name at the finishing stand. The working rolls are mounted on anti friction bearings and

have hydraulic roll balancing and a closed top housing to minimize mill spring and roll gap

variations. The distance between the pinions is 850 mm and a

barrel length of rolls is 1200 mm. The drive motor is

a fully compensated DC motor supplied by thyristor

converters. The 750V, 1800 kW, 90/180 rpm motor is

coupled to the rolls by a 2 high pinion roll set.

Long RaiI finishing compIex constitutes of the foIIowing areas:

1. Precambering and walking beam cooling bed

2. Rail straightening

3. Online NDT

4. End finishing/ straightening and inspection

5. Welding

6. Rail Handling

1. Precambering and walking beam cooling bed

@he process flow llne sLarLs wlLh Lhe lnsulaLed roll Lables Laklng Lhe

hoL ralls Lo Lhe coollng bed 8all has asymmeLrlcal shape

Maxlmum mass ls aL head and Lhe fooL ls Lhln When Lhe hoL rall

cools down Lhe fooL geLs cold very fasL and Lhe head cools very

slowly uurlng coollng Lhe head shrlnks and Lhe fooL geLs

elongaLed @herefore Lhe rall acqulres a parabollc camber afLer

coollng ln longer ralls Lhls camber ls very large So ralls are glven a

precamber ln opposlLe dlrecLlon whlle Lhey are hoL so LhaL Lhey

become almosL sLralghL afLer coollng down @he reverse camber ls

glven Lo ralls by a seL of poslLlon conLrolled carrlages @he

programmlng of Lhe carrlages produces precamberlng of Lhe ralls

@he ralls are clamped flrmly llfLed from roller Lable and

placed on Lo Lhe walklng beam coollng bed wlLh Lhe help of

hydraullc cyllnders @hese ralls move on Lhe coollng bed are also

Precambering of rails at Bhilai

cooled ln Lhe process

2. Rail Straightening

To meet straightness requirement, the rails are straightened

by roller straightening machine wherein the rails are passed

through series of rollers The cooled rails are passed

through most advanced straightening machine of the world

supplied by M/s SMS MEER, Germany. This bi-planar

straightening machine has 9 horizontal rollers and 8 vertical

rollers. These horizontal and vertical roller machines

collectively are capable of straightening in vertical as well

as horizontal plane. The machine with off-line straightening

model enables development of straightening parameters

and straightening models. The straightening machine also

communicates online with laser straightness machine such that timely corrective action for

straightness can be taken up

3. Online NDT

Non-destructive test carried out for

long rail comprise of Ultrasonic,

Eddy Current and Laser Geometry

test. Ultrasonic test is carried out to

detect any sub-surface anomalies.

Eddy Current test is used to detect

surface defects. An integrated paint

marking station indicates the

position of the defect found.

The Laser Geometry test measures

the straightness and top flatness of the rail. Laser Geometry Station is used to measure the

body straightness and top flatness. This system comprises of a laser beam incident on the

railhead and a CCD as a receiver capable of highly accurate displacement measurement, and

generation of the test results. The top flatness of the rail is measured using thrubeam laser

sensor.

4. End Cutting/ Straightening & nspection

Straightening machine

Laser Straightness measurement

8alls are cuL Lo lengLh by carblde saws from M/s Llnslnger AusLrla @hese saws cuL downwards from

head glve a good flnlsh wlLhouL lnduclng any ouL of square defecL @hey are auLomaLed Lo cuL ralls ln

any lengLh

@hese ralls are Lhen vlsually lnspecLed and LesLed for dlmenslons wlLh gauges aL Lwo onllne vlsual

sLaLlons equlpped wlLh mlrror lnspecLlon

f required the rails are sent to hydraulic presses to ensure 100 percent straightness of the rail

ends in all directions.

5. Welding

8alls of m are welded Lo or m @he

weldlng machlne supplled by LSA8 Sweden ls

has lnLegral sLrlpplng sysLem ls fully

auLomaLed wlLh dedlcaLed mlcroconLroller

for Lhe weld process conLrol and LC for

sequenclng of operaLlons @he anLl LwlsL

clamps and auLomaLlc allgnmenL ensure

perfecL proflle maLchlng of rall ends whlle

weldlng @he dlsLrlbuLed clamplng ensures

hlghly rlgld and sllppage free clamplng of ralls

whlle weldlng @he profllegrlndlng machlne

grlnds boLh Lhe runnlng faces and Lop of Lhe rall wlLh a very hlgh preclslon and flnlsh ulLrasonlc

LesLlng ensures flawless [olnLs

6. Rail Handling

Pandllng and loadlng of ralls upLo quarLer a kllomeLer

requlres speclallzed equlpmenL @he ralls are handled by

an auLomaLlc compuLer conLrolled Lelphers @he ralls are

loaded ln speclal rakes of flaL boLLom wagons called

Lu8's(Lnd unloadlng rakes)

Welding of Rails

You might also like

- 3 D Modelling and Finite Element Analysis of Eot CraneDocument4 pages3 D Modelling and Finite Element Analysis of Eot CraneKenneth ShumNo ratings yet

- BIM Model Management PDFDocument6 pagesBIM Model Management PDFpyaephyozawNo ratings yet

- Plant Simulation ManufacturingDocument3 pagesPlant Simulation ManufacturingCarlos MolinaNo ratings yet

- QB400Document2 pagesQB400Éverton KafskiNo ratings yet

- Components Design of Hoisting Mechanism of 5 Tonne Eot CraneDocument6 pagesComponents Design of Hoisting Mechanism of 5 Tonne Eot CraneRahman Listanto100% (1)

- Structural Design (Type B) : GeneralDocument4 pagesStructural Design (Type B) : GeneralRakesh ShresthaNo ratings yet

- Building Element As Per Submitted Design Remarks: GeneralDocument6 pagesBuilding Element As Per Submitted Design Remarks: GeneralRabi DhakalNo ratings yet

- R C C Design ServicesDocument12 pagesR C C Design ServicesPrayas SubediNo ratings yet

- Final Project - Analyze and Design A Multi-Storied BuildingDocument40 pagesFinal Project - Analyze and Design A Multi-Storied Buildingyash vermaNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument13 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Footing AnslysisDocument197 pagesFooting AnslysisjayNo ratings yet

- Deionized For Cooling Tower PDFDocument8 pagesDeionized For Cooling Tower PDFThipsuree KornboonraksaNo ratings yet

- For StudentsDocument35 pagesFor StudentspranabNo ratings yet

- Duct WT CalDocument13 pagesDuct WT CalAMMAR MAWNo ratings yet

- Sheet Metal Thickness Schedule As Per Smacna: Thinckness in Inches Weight Thickness in MillimetersDocument1 pageSheet Metal Thickness Schedule As Per Smacna: Thinckness in Inches Weight Thickness in MillimetersMuhammedShafiNo ratings yet

- 2business Center-Section-2 Sanitary & Plumbing PPDocument43 pages2business Center-Section-2 Sanitary & Plumbing PPSourov SamadderNo ratings yet

- Department of Civil Engineering: Analysis and Design of A G+15 Storey Residential BuildingDocument35 pagesDepartment of Civil Engineering: Analysis and Design of A G+15 Storey Residential Buildingpatil sanikaNo ratings yet

- Single Line Flow Diagram of Fly Ash Pressure Conveying SysDocument7 pagesSingle Line Flow Diagram of Fly Ash Pressure Conveying SysHari PrasadNo ratings yet

- Unit Weight of Metal Sheet & Metal Plate.Document3 pagesUnit Weight of Metal Sheet & Metal Plate.subodh kumar shahNo ratings yet

- Isolated Footing Design (ACI 318-08)Document91 pagesIsolated Footing Design (ACI 318-08)Mario Sajulga Dela CuadraNo ratings yet

- 3-d Modelling and Finite Element Analysis of Eot CraneDocument4 pages3-d Modelling and Finite Element Analysis of Eot CraneGogyNo ratings yet

- Speed Control of Steel Rolling Mill Using Neural Network: January 2006Document6 pagesSpeed Control of Steel Rolling Mill Using Neural Network: January 2006Pranati MishraNo ratings yet

- Bokaro Steel PlantDocument3 pagesBokaro Steel PlantSayan ChatterjeeNo ratings yet

- Micro PelletisationDocument32 pagesMicro PelletisationArup SarkarNo ratings yet

- STAAD Pro LABDocument22 pagesSTAAD Pro LABPT shamhoonNo ratings yet

- Footing Calculation Rev1Document17 pagesFooting Calculation Rev1RobbyTeresaNo ratings yet

- Designing Concrete BeamsDocument31 pagesDesigning Concrete BeamsMariappan .PNo ratings yet

- Stacker Reclaimers: Equipment Division of The HALL GroupDocument2 pagesStacker Reclaimers: Equipment Division of The HALL GroupJavier TorresNo ratings yet

- Concrete Frame Multi Storey Cost EstimateDocument2 pagesConcrete Frame Multi Storey Cost Estimateaddrien danielNo ratings yet

- Estimation and Evaluation of G+3 Residential BuildingDocument4 pagesEstimation and Evaluation of G+3 Residential BuildingVIVA-TECH IJRINo ratings yet

- DRI Charging in EAFDocument3 pagesDRI Charging in EAFMuhammad NbNo ratings yet

- Design of Stair Waist Slab: Concrete Slab Deflection CheckDocument2 pagesDesign of Stair Waist Slab: Concrete Slab Deflection CheckRathinavel VenkateshwaranNo ratings yet

- Detail Study of Working in Blast Furnace Area (Vizag Steel Plant)Document42 pagesDetail Study of Working in Blast Furnace Area (Vizag Steel Plant)kselvan_1No ratings yet

- Design of RCC Post-Tensioned Flat SlabsDocument6 pagesDesign of RCC Post-Tensioned Flat SlabsjayadushNo ratings yet

- Steel Beam Marked B6Document27 pagesSteel Beam Marked B6Babu SundararamanNo ratings yet

- Autodesk Revit: Presented By: Eng. Heba Adel - Structural Engineer-Alexandria UniversityDocument71 pagesAutodesk Revit: Presented By: Eng. Heba Adel - Structural Engineer-Alexandria UniversityMustafizur SaounNo ratings yet

- Rotating TrolleyDocument12 pagesRotating TrolleyInderdeep TatlaNo ratings yet

- Process Plant Simulation, Oxford University Press, 2004: DownloadDocument30 pagesProcess Plant Simulation, Oxford University Press, 2004: Downloadsurabhi singhNo ratings yet

- Thumb RuleDocument6 pagesThumb RuleShafique AhmedNo ratings yet

- Sponge IronDocument11 pagesSponge IronVenkatadurgarao VendraNo ratings yet

- Basement Shear Wall PDFDocument3 pagesBasement Shear Wall PDFYogen SthaNo ratings yet

- Footing DesignDocument7 pagesFooting Designmsiddiq1No ratings yet

- TMT BarsDocument26 pagesTMT BarsPardeep KushwahaNo ratings yet

- Earthing BOQ For Kanoria Rev-0Document8 pagesEarthing BOQ For Kanoria Rev-0aps0% (1)

- 4 Numerical Example On Design of 3 or More Span Cont. BeamDocument21 pages4 Numerical Example On Design of 3 or More Span Cont. BeamAshok Kumar RajanavarNo ratings yet

- STAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters SuchDocument6 pagesSTAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters Suchsivasan10006098No ratings yet

- Calculation Sheet of RCC Frame BuildingDocument77 pagesCalculation Sheet of RCC Frame BuildingShubham PuriNo ratings yet

- MAGDY Final - BASEMENTDocument4 pagesMAGDY Final - BASEMENTtahaelnourNo ratings yet

- Design For Isolated Footing 1Document11 pagesDesign For Isolated Footing 1Edilberto ContrerasNo ratings yet

- Design of Column at C (Intermediate Column)Document4 pagesDesign of Column at C (Intermediate Column)সন্দীপ চন্দ্রNo ratings yet

- Free Vibration Analysis ofDocument77 pagesFree Vibration Analysis ofvinaycamNo ratings yet

- Industrial Report On Production Process of Steel Mills LTD: A Study On Ratanpur Steel Re-Rolling MillsDocument21 pagesIndustrial Report On Production Process of Steel Mills LTD: A Study On Ratanpur Steel Re-Rolling MillsAbid HasanNo ratings yet

- Class B (Residential RCC With Is Code) Structural ChecklistDocument6 pagesClass B (Residential RCC With Is Code) Structural Checklistdwarika2006No ratings yet

- BD632MDocument13 pagesBD632MPRAKASHNo ratings yet

- Industrial Building: by Tausif Kauswala Adit College V.V. Nagar, Anand, Gujarat, IndiaDocument59 pagesIndustrial Building: by Tausif Kauswala Adit College V.V. Nagar, Anand, Gujarat, IndiaPhuong ThaoNo ratings yet

- Elevated Service ReservoirDocument3 pagesElevated Service ReservoirSureshNo ratings yet

- SOM All Chapters With TimingsDocument376 pagesSOM All Chapters With TimingsSUMIT SUMANNo ratings yet

- Combined FootingDocument4 pagesCombined FootingSita G ShresthaNo ratings yet

- Wire Rod MillDocument13 pagesWire Rod Milldaravathdeepu34No ratings yet

- Spiral Pipe Mill Project ReportDocument24 pagesSpiral Pipe Mill Project ReportVikalp Shri Bachchan50% (2)

- Department of Public Works and Highways - On-The-Job TrainingDocument6 pagesDepartment of Public Works and Highways - On-The-Job TrainingJovan BucolNo ratings yet

- Crew AgreementDocument6 pagesCrew AgreementMuhammad AliNo ratings yet

- Ship Models: LNG / LPG Carriers Tankers Bulk CarriersDocument4 pagesShip Models: LNG / LPG Carriers Tankers Bulk CarriersRAMSINGH CHAUHANNo ratings yet

- The Story of Village Palampur: Flow Chart Economic Ch-1Document1 pageThe Story of Village Palampur: Flow Chart Economic Ch-1GggNo ratings yet

- Expression of InterestDocument4 pagesExpression of InterestSyed ZamanNo ratings yet

- A 814 - A 814M - 03 Qtgxnc9bode0tqDocument6 pagesA 814 - A 814M - 03 Qtgxnc9bode0tqsachinguptachdNo ratings yet

- Case 5 Ford MotorDocument8 pagesCase 5 Ford MotorVani ChellAm100% (1)

- D4259 ssrf9249Document2 pagesD4259 ssrf9249Raymond TahanNo ratings yet

- Chapter 3 Programming Challenges CodeDocument5 pagesChapter 3 Programming Challenges CodeCameron MarottoNo ratings yet

- Seminar On Rocket EngineDocument17 pagesSeminar On Rocket EngineSam Samrat100% (2)

- ACS128 Steel SleepersDocument7 pagesACS128 Steel SleepersRam NiwasNo ratings yet

- Travelling EssaysDocument9 pagesTravelling Essayslarisa_elena_1No ratings yet

- WDC Sop - 3Document29 pagesWDC Sop - 3bkwsubantingNo ratings yet

- Iso 20crmo4Document2 pagesIso 20crmo4Kumar SanthanamNo ratings yet

- Technological Challenges in Manufacturing of Heavy Reactors Using New Generation 2.25Cr-1Mo-0.25V SteelDocument10 pagesTechnological Challenges in Manufacturing of Heavy Reactors Using New Generation 2.25Cr-1Mo-0.25V Steelgovimano100% (1)

- Presentation: Meti - JetroDocument26 pagesPresentation: Meti - JetroSejal_chirag0% (1)

- Siddhachal Elite BrochureDocument27 pagesSiddhachal Elite BrochureLokesh BangaloreNo ratings yet

- PIL Crash BarriersDocument4 pagesPIL Crash Barriersmedic009No ratings yet

- DO - 036 - s2017 - Item 1049 Jet GroutingDocument8 pagesDO - 036 - s2017 - Item 1049 Jet GroutingRay RamiloNo ratings yet

- The Sintering Process of Iron Ore FinesDocument5 pagesThe Sintering Process of Iron Ore FinesRanggaa RamandanaNo ratings yet

- Trail Tender Rule in NCL For Casting ItemDocument43 pagesTrail Tender Rule in NCL For Casting ItemvijaybaidNo ratings yet

- Pal ExpressDocument3 pagesPal ExpressCharmaine MagdangalNo ratings yet

- Unit 4 Agricultural and Rural Land Use: VocabularyDocument2 pagesUnit 4 Agricultural and Rural Land Use: VocabularyIsabella O ReillyNo ratings yet

- Sankar Ganguly - Pharma ManagerDocument2 pagesSankar Ganguly - Pharma Managersurojitsaha15094No ratings yet

- Indian Auto Industry . The Way: Presentation By-Sunil Kakkar General Manager (Supplychain) Maruti Suzuki India LTDDocument35 pagesIndian Auto Industry . The Way: Presentation By-Sunil Kakkar General Manager (Supplychain) Maruti Suzuki India LTDViral JainNo ratings yet

- IPSCM - Week 4Document14 pagesIPSCM - Week 4Redhwan85No ratings yet

- Aerospace Directory 09 11aDocument58 pagesAerospace Directory 09 11aAnanta RanaNo ratings yet

- Food Industry: Adding Citations To Reliable SourcesDocument3 pagesFood Industry: Adding Citations To Reliable SourcesRajesh ShahNo ratings yet

- Stone Cladding Fixation 1Document3 pagesStone Cladding Fixation 1wadyspring100% (2)

- Tender Specification Klaus Multiparking Multibase 2072I Eb / Multibase 2072I DBDocument6 pagesTender Specification Klaus Multiparking Multibase 2072I Eb / Multibase 2072I DBama29No ratings yet