Professional Documents

Culture Documents

Project On Knitted Fabric Parametre

Uploaded by

Mozzammal Hossain ShaownOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project On Knitted Fabric Parametre

Uploaded by

Mozzammal Hossain ShaownCopyright:

Available Formats

UNIVERSITY OF DHAKA COLLEGE OF TEXTILE ENGINEERING & TECHNOLOGY REPORT ON PROJECT WORK ANALYSIS OF SPECIFICATIONS OF BASIC SINGLE JERSEY

FABRIC. SUPERVISI NG TEACHER SHAH ALIMUZZAMAN Assistant professor, College of Textile Engineering & Technology Technolog Tejga on, Dhaka-1208 SUBMITTED BY: S/N 01. 02. 03. 04. 05. 06. 07. 08. 09. 10. 11. 12. 13. NAME FAISAL BIN ALAM MIR ABDUL NIME ROLL NO REG NO SESSION

TO THOSE WHO ARE INTERESTED TO LEARN

ACKNOWLEDGEMENT College of Textile Engineering & Technology has given us the opportunity to perf orm the project work. We are obliged to MD. SHAH ALIMUZZAMAN, Assistant professo r, supervising Teacher of the college for giving us the opportunity to accomplis h of the project work. We also take the opportunity to express our sincerest gratitude to Md. MASHUD AH MED, principle in-charge for his kind co-operation. Heartfelt thanks goes to Senior Textile Engineers of various industries (DBL, ME GHNA, ESQUIRE, S.M KNITTING INDUSTRY.) from whom we collect the sample. Above all, we would like to acknowledge our deep debt to all teachers of our col lege and especially of FMT department for their kind inspiration and help, which remain us the backdrop of all our efforts. Finally, we would like to convey our acknowledgement that we remain responsible for the inadequacies and errors, which doubtless remain.

ABSTRACT At first we collect some of knitted fabric samples along with required data whic h are needed to commence our project work with effective analysis. We also separ ate the fabrics according to their class so that we can establish an acceptable result which will be perfect for effective use and will help to carry out furthe r activities depending on the established form of work. During our industrial attachment we manage to watch carefully and effectively th e knitted fabric specification along with machine specification and the major fa ctors which are necessary to calculate different types of variation and variable on which the whole fabric construction depends. Our efforts were to develop a d ependable way so that we can easily visualize or can forecast the resulting fabr ic specification with required configuration. We have tried our best to emphasize on the adjustable points on which fabric G.S .M., stitch length, fabric width, & compactness directly or indirectly depends. The theoretical as well as the practical knowledge that we gathered from our cla sses and in the industry, help us to perform our project with credit and for thi s we specially convey thanks to our honorable teachers.

KEY WORD 1. G.S.M. 2. Yarn Count. 3. Stitch length. 4. Yarn Diameter. 5. Fabric Width. 6. Machine gauge. 7. Needle gauge. 8. Wales space. 9. Needle pitch.

CONTENTS Chapter no Chapter 1 Chapter 2 Chapter 3 Chapter 4 Chapter 5 Chapter 6 Chapter n ame General Introduction Literature review Terminology & definition Fabric speci fication Machine specification Result & discussion Bibliography Appendix Page no

CHAPTER 1 GENERAL INTRODUCTION

Fabric is a manufactured assembly of fibres and yarns that has substantial surfa ce area in relation to its thickness and sufficient cohesion to give the assembl y useful mechanical strength. Fabrics are most commonly woven or knitted but the term includes assemblies produced by felting, lace making, net making, non wove n processes and tufting. Our project basically is on knitted fabric specificatio n and machines which are related to knitted fabric production. A precise stateme nt of a set of requirement to be satisfied by a materials, product, and system o r service that indicates the procedures for determining whether each of the requ irements is satisfied. In the analysis of woven fabric specification we consider ends per inch, picks per inch, yarn count (warp & weft), and fabric width but i n case of knitted fabric specification GSM, stitch length are mainly considered. The title of our project work is Analysis of knitted fabric specification and o ther related machine specification. There are problem in our industries to produ ce knitted fabrics of required G.S.M. Other specification like fabric width, fab ric thickness is generally maintained in industries by previous data sheet. For this reason there are problem if any order comes which didnt produced in previous . Our target is to find out the easy process to get decision about yarn count se lection, loop length selection, machine Diameter selection & machine gauge selec tion. We strongly think that by this process we can get decision about yarn count, loo p length, machine gauge, and machine diameter for the single jersey, Rib and int erlock fabric. Aims of the project work are the following: Find out relation bet ween yarn count and GSM. Find out the logic of selection of stitch length select ion. Selection of machine diameter and machine gauge to get specific width of fa bric. Find out the fabric width.

CHAPTER 2 LITERATURE REVIEW

GSM: There are two formulas for calculating the GSM of a knitted fabric. i.e. Fi rst formula is GSM = Course per inch Stitch length 39.37 39.37 Tex 1000 1000 WPI CPI SL(mm) x 0.9155 Count(Ne) GSM = CALCULATION OF WALES PER INCH: We calculated the number of wales in 10 inch fabric unraveling the yarn. Then we divide the no of total wales by 10 inch to getting the wales per inch. CALCULATION OF COURSE PER INCH: We calculated the number of course in five inch with the help of counting glass and needle. Then we divide the total no of course by five inch to getting the co urse per inch. MEASUREMENT OF STITCH LENGTH: Stitch length is theoretically a single length of yarn which includes one needle loop and adjacent needle loops on either side of it. Loop exits in coarse in co urse length and it is that which influence fabric dimension and other properties including weight. In order to determine the stitch length, we count 100 no wale s or stitch and count its length by hanging the yarn on the stitch counter. The reading is found in mm unit. MEASUREMENT OF YARN COUNT: We have fallowed a different way to find out the count of the yarn. At first we unravel a considerable no yarn from the fabric. Then we measured the total lengt h of the yarn and measured the weight of that no of yarn. From these weights, we find out the count of the yarn. The equation we followed is as follow: Count = Where, n= number of yarn in bundle. L= length of yarn. Wt= weight of yarn. n l 453.6 wt 36 840

MEASUREMENT OF GSM: GSM is a very important parameter for specified a certain qu ality of knitted fabric. The production of knitted fabric is calculated in weigh t. The GSM cutter is very popular and easy usable GSM testing instrument used in most knitted factory. But the construction of this cutter is very simple. It is circular disk of 100 square cm area with sharp blade attached to its edge. So 1 00 square cm of fabric can easily cut by it and weighted at the electric balance to get GSM reading. Another formula is the following: GSM = Ks Tex Stitch length (mm) Where, Ks is a constant. Its value is different for different fabric structure a nd fabric type. Ks is calculated and estimated as below: GSM Stitch length Tex Ks = Fabric Type Color Value of Ks Single jersey Single lacoste Double lacoste Polo pique Plain interlock 11 Rib 11 R ib 21 Rib Flat back rib 3 Thread fleece Average Average Average Average Average Light Average Average 19.55 22.4 22.75 25 39.3 24.5 26.5 28.3 81 40.92

COMMENT: It is very convenient to determine the stitch length against the requir ed GSM by using the value of Ks. We could not determine the value of Ks for othe r decorative fabric. It requires large time and industry. GSM DEPENDS ON: 1. TYPE OF YARN: The main material for knitting process is yarn. The quality of knitted yarn should be like as follows: 30/1 Cotton Combed Paramete rs Best Acceptable limit Uniformit y% Thin (50%) Thi ck (+50%) Neps (+200%) Hairiness 4.04.4 Tenacity (CN/tex) Elongatio n 21.822.6 6 .76.9 6.2-6.4 7.3-7.08 6.6-6.4 14.7-13.7 11.8-11.2 18.4-18.9 16.7-17.6 16.2-15.4 25.5-24 23.4-22.1 4.6-4.9 4.75-5.1 5.5-5.8 4-4.44 4.45-4.8 38-47 73-88 140-175 300-380 30-45 48-58 7-12 32-43 75-90 250-300 15-20 34-42 0 3-5 16-22 50-60 2-3 7 -10 9-9.5 9.7-10.2 11.5-12.1 Best Acceptable limit 12.8-13.5 9.5-9.8 Best Accept able limit 10.4-10.7 30/1 Cotton Carded 30/1 poly Cotton

2. YARN COUNT: The following counts of yarn that are widely used for knitting pr ocess are given: a) Cotton: 20/1, 24/1, 26/1, 28/1, 30/1, 34/1, 40/1 Ne. b) Tery lene cotton: 20/1, 24/1, 26/1, 28/1, 30/1 Ne. c) CVC: 26/1, 28/1, 30/1, 34/1 Ne. d) Melange: 20/1, 22/1, 26/1, 30/1 Ne. e) Spandex: 40D, 70D. f) Polyester: 75D, 150D. g) Sewing thread: 40/2, 150D etc. Other parameters are: Stitch length Fabric Structure. Finishing process. Depth o f shade. Stitch density. Machine gauge. RELATION BETWEEN YARN COUNT, FABRIC TYPE, STITCH LENGTH AND FINISH GSM: Fabric Type Yarn count Stitch length (mm) Color DG Finished diameter (inch) Finished GSM Plain S/j ,, ,, ,, ,, ,, ,, 18s/1 20s/1 24s/1 26s/1 28s/1 30s/1 34s/1 2.94 2.98 2.68 2.66 2.70 2.68 2.40 White White White White Avg Avg Avg 2624 3024 3024 3024 2624 3024 2624 30 33.5 32 31 25 30 24 220-230 200-210 175-185 160-170 150-160 130-140 125-135

,, Single lacost ,, ,, ,, 1 1 Rib ,, ,, ,, ,, ,, ,, ,, ,, 2 1 Rib ,, 1 1 lycra r ib ,, ,, ,, ,, ,, 2 2 rib ,, ,, ,, ,, 2 2 lycra rib ,, ,, s s 40s/1 18s/1 24s/1 26s/1 30s/1 26 /1 24s/1 26s/1 26s/1 26 /1 36 /1 24 /1 24s/1 28 s/1 34s/1 34s/1 20 /1 +40D 24s/1 +40D 26s/1 +40D 28s/1 +40D 30 /1 +70D 34 /1 +70 D 40 /1 28s/1 26s/1 24s/1 20s/1 20 /1 +40D 24s/1 +40D 30s/1 +70D s s s s s s s 2.44 3.00 Avg Avg 2424 3024 20 46 100-110 245-255 2.64 2.60 2.50 2.50 2.75 2.54 2.55 2.65 2.65 2.95 2.90 2.40 2.60 2.70 3.30 Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg 3024 3024 3024 40 36 33 41 210-215 200-210 180-190 240 235 245 235 230 170 220 225 232 190 185 320 3018 4018 4018 3218 3218 3418 4018 3024 4018 3218 3618 64 40 47 32 33 32 38 38.5 23 20 32 3.00 2.90 2.80 2.60 2.44 2.76 2.87 3.25 3.50 3.25 3.10 Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg Avg 3018 3018 3018 3220 3018 3020 3418 3418 3418 3420 3018 30 30 30 28 26 35T 32T 31T 31.5T 55OP 18T 280 260 250 260 240 160 260 205 285 260 390 2.90 2.90 Avg Avg 3018 18T 320 240

,, ,, Fleece 30s/1 +40D 30s/1 +40D 26s/1GM + 24 /1 c s 2.98 2.80 2.78 + 1.36 Avg Avg Avg 3018 3024 32T 240 220 220 ,, 26s/1GM + 26s/1 c 26s/1GM + 24 /1 c s 2.78 + 1.36 Avg 3024 32T 220 ,, 2.85 + 1.35 Avg 3024 32T 240 ,, 26s/1GM + 20s/1 c 28s/1GM + 28 /1 c s 2.90+ 1.35 Avg 3024 32T 220 ,, 2.8 + 1.35 Avg 3024

32T 235 ,, 30s/1GM + 26s/1 c 2.8 + 1.36 Avg 3024 32T 175 By the following three tables, we can summarize the above data: FOR SINGLE JERSE Y: Finished GSM 140 160 180 200 220 Count 30/1 26/1 24/1 20/1 18/1 Finished Diamete r Machine dia = Finished dia Machine dia +1 = Finished dia Machine dia + 2 = Fin ished dia Machine dia + 3 = Finished dia Machine dia + 4 = Finished dia N.B: If the fabric is to be Enzyme washed, the stitch length should be kept (10% ) less than the normal range. Because, enzyme wash reduces the total weight of t he fabric by removing the floating fibre and hairy fibre. For light color, the f inished GSM varies 1-2% from grey GSM. For average color, the finished GSM varies 2-4% If the GSM varies 25-30%, it is not only necessary to control the VDQ pulley dia but also yarn tension & take-up roller.

COMMENT (Reference 1): 1. It is very distinct from these tables that there is no proof that these values are true, as they are not actual or experimental and th ey have taken these values from the mill and factory. 2. They have determined th e value of count by beesleys balance. We never give the value of count in fracti on but by our method we find that the value of count is most of the time is frac tion. From our project work we manage to find the following equations for the selectio n of yarn count to get required G.S.M. equations vary for fabric types, fabric c onstruction. List of equations are tabulated below: Name of the fabrics Single jersey Pique Double lacoste 1 x 1 Rib Lycra 1 x 1 Rib Lycra 2 x 2 Rib Interlock Equations Yarn count = - 0.141 GSM + 50.22 Yarn count = - 0.146 GSM + 57.16 Yarn count = - 0.167 GSM + 64.36 Yarn count = - 0.123 GSM + 54.57 Yarn count = - 0.1 19 GSM + 59.12 Yarn count = - 0.108 GSM + 56.62 Yarn count = - 0.206 GSM + 80.56 EQUATIONS FOR GETTING REQUIRED GSM FROM THE SPECIFIC YARN COUNT: Fabric Single jersey Lycra single jersey Pique 1 1 Rib Lycra 1 1 Rib Lycra 2 2 R ib Interlock Equations GSM = -6.879yarn count + 350.4 GSM = -4.9716 yarn count + 354.56 GSM = -6.6737 y arn count + 386.44 GSM = -7.9731 yarn count + 437.66 GSM = -8.2839 yarn count + 494.08 GSM = -9.1216 yarn count + 519.05 GSM = -4.778 yarn count + 388.41

EQUATION FOR DETERMINING FABRIC WIDTH: Fabric width = No. of wales X Wales space . =No. of needle X Wales space. = dg X Wales space Where, d = Cylinder diameter. g = Gauge. FOR CALCULATING YARN DIAMETER: d Tex d= Tex mm For Cotton 26.7 d d= 1 Ne 0.91 Ne Rel tion mong GSM, stitch length nd y rn count c n be derived from the followi ng equ tion: GSM 1 Y rn count Stitch length (When Y rn count nd Stitch length both re v ri ble) Y rn count Loop length G.S.M. = K Where K is Const nt. K which c n be derived

s follows:

CONSTANT AT A GLANCE: F bric Sinlgle jersey pl in Double L coste 1 X 1 Rib 2 X 1 Rib Interlock Const n t 12068.509 14855.2 16431.497 19005.333 24013.8 W les sp ce = 4d; [where d is the y rn di meter] Minimum stitch length = 14d

FABRIC THICKNESS: In the fully rel xed st te the f bric thickness for double jer sey, t= 4d For single jersey, t = 2d COMMENT (Reference 2): 1. It is underst nd ble th t g uge is n import nt f ctor for f bric width but ctu lly the width of f bric is dependent upon the number of needle present in the m chine. Often the number of needle present in the m ch ine is not equ l to dg . So the equ tion should only be like following: COMMENT (Reference 3): Different properties were found in Different knit structures cco rding to stitch length, stitch density th t me ns w les per inch, course per inc h. Shortly they told loose structure th t me ns higher loop length gives less GS M on f bric & comp ct structure th t me ns shorter loop length gives high GSM on f bric. In their project n lysis, they observed th t single jersey pl in struc ture & 11 pl in rib structure v ri tion of c lcul ted GSM with respect to ctu l GSM is too sm ll. But in single l coste & polo-pique structure v ri tion of c lc ul ted GSM with respect to ctu l GSM is high. Bec use single l coste & polo-piq ue structure re m de by combin tion of knit & tuck loops. They lso n lyzed th t one knit loop consumes 30% more y rn th n tuck loop. So c lcul ted GSM is hig her in single l coste & polo-pique structure th n single jersey pl in structure & 11 pl in rib structure. In gener l, the ngle of spir lity v lues decre ses whe n the tightness f ctor v lues gets higher th t is decre se of loop length in ll knitted s mples. In sl ck knitted f bric structures, the loop c n e sily find n re to rot te & spir lity incre ses. The spir lity ngle of the f brics knitt ed with ring y rns re very high comp ring with the f brics knitted with open en d y rns. This shows the effect of the spir lity on twist liveliness. F bric shri nk ge depends on different f bric structure i.e.; single jersey, rib, interlock & their deriv tives, y rn composition i.e.; 100% cotton, cotton & polyester & sy nthetic y rn.

CHA TER 3 TERMINOLOGY & DEFINITION

TERMINOLOGY AND DEFINITION OF DIFFERENT KEYWORDS ARE DISCUSSED BELOW: WALES ER INCH: W les per inch me ns how m ny numbers of w les re present in one inch, it is very import nt for c lcul tion of knitted f bric GSM nd f bric properties. COURSES ER INCH: Courses per inch me n how m ny numb ers of courses re present in one inch. It is lso very import nt for c lcul tio n of knitted f bric GSM. STITCH LENGTH: Stitch length is theoretic lly is sing le length of y rn which include one needle loop nd h lf the length of Y rn (h lf of sinker loop) between th t needle loo p nd the dj cent needle loops on either side of it. Loop exists in course in c ourse length nd it is th t which influence f bric dimension nd other propertie s including weight. YARN COUNT: Y rn count is numeric l expression of fineness or co rseness of y rn. Y rn count is c lcul ted in two systems: . Direct syste m b. Indirect system They re described below: Direct system: In this system the count lf y rn express the no. wt. units in one length unit. In direct system hig her the count, co rser the y rn This system is used for thrown silk, rtifici l s ilk, jute etc nd count c lcul tion formul is the following: Count = Here, W l w L W = weight of s mple. L = length of s mple. w = unit weight in system. l = unit length in system.

Indirect system: In this system the count of y rn express the no of unit length per unit weight. In this system higher the y rn count finer the y rn. It is gene r lly used for cotton, worsted, woolen, linen etc nd the y rn count c lcul tion formul is the following: Count = Here, Lw W l W = weight of s mple. L = length of s mple. w = unit weight in system. l = unit length in system. GSM: GSM me ns the weight in gr m per squ re meter of f bric. F bric re densit y: F bric re density c n be c lcul ted by the following formul , Are density = Here, T = Tex, S = Stitch density, l = Stitch length. F bric width: F bric wid th c n be c lcul ted by the following formul : F bric width = = course length Stitch length Kw S l T gm/m2 100 d G Stitch length Kw Where, Stitch length is in cm D = Machine diameter, G = Machine Gauge and Kw = 3 8 (for dry relaxed state) = 41 (for wet relaxed state) = 42.2 (for finished rela xed stat

CHAPTER 4 FABRIC SPECIFICATION

Elements of S ecification: 1. GSM. 2. Loo length. 3. Yarn count. 4. Fabric width. 1. G.S.M: The weight of fabric in gm

FACTORS CONSIDERED FOR REQUIRED G.S.M: Yarn Count (English count): Through our roject work we manage to find out the following relation between yarn count and G.S.M: i.e. GSM GSM 1 Y rn count (When Stitch length is s me ) .(1) 1 Loop length (When Y rn count is s me) .(2) From the equ tion (1) & (2) we get, GSM 1 Y rn count Stitch length (When Y rn count nd Stitch length both re v ri ble) Y rn count Loop length G.S.M. = K

Where K = Const nt. K v ries for the single jersey with different gsm, count, n d loop length.

er square meter is called G.S.M.

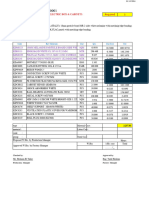

CONSTANT FOR SINGLE JERSEY FROM COLLECTED FABRIC (Ref-Appendix): S/N GSM SL COUNT EQUATION AVERAGE STD DVE CV 1. 2. 3. 4. 5. 6. 7. 8. 9. 122.488 127.038 135.77 141.36 144.5 148 153 155.22 163.715 2.664324 37.777 2.965405 31.6278 2.319347 32.92 3.046935 31.8744 2.698962 30.87 2.610811 28.8 2.701087 30 2.881429 27.12405 2.880883 26.97 12328.44 11914.8 10366.43 13728.77 12039.3 11128.32 12397.99 12131.38 12720.23 12083.96 946.3509 7.831462 ACTUAL RACTICING OF CONSTANT VALUE IN THE INDUSTRY: Type Ne M x GS M 220 Min GS M 200 GS M 220 210 200 190 180 170 160 170 160 150 155 150 140 150 140 130 S/L (mm) 2.85 3.00 3.10 2.70 2.85 3.00 3.15 2.75 2.90 3.00 2.70 2.80 2.95 2.65 2.80 3.00 Const nt K Avg Std CV% Singl 20 e jerse y 24 190 160 26 170 150 28 155 140 30 150 130 12540 12600 12400 12312 12312 12240 12096 12155 12047.625 12064 11700 11718 1176 0 11564 11925 11676 11700 334.9383774 2.780119546 Deflection = 12083.96 12047.625 100 12047.625 = 0.3%

ACTUAL DETERMINATION OF FABRIC GSM AND YARN COUNT FROM THE COLLECTED FABRIC: S/N 01. 02. 03. 04. 05. 06. 07. 08. 09. 10. 11. 12. 13. 14. COUNT 36.74 32.13 30.87 37.77 31.63 28.8 27.12 35.29 29.99 26.97 32.13 32.92 25. 57 22.71 G.S.M 116 134.33 172.33 121.33 139.33 142.63 176.67 154.33 165.33 168.33 134.33 139.33 181.67 138.33

GRAPH SHOWN THE RELATION BETWEEN THE COUNT AND THE GSM: By taking two oints from the straight line, we can find the following equation: Yarn Count (y) (116,36.74) (181.67,25.57) x = GSM , y = Count x 116 y 36.74 = 116 181.67 36.74 25.54 x 116 y 36.74 = 65.67 11.17 ( y 36.74)( 65.67) x= + 116 11.17 x = 5.88 + 116 x = 332 5.88 y From (i) ( x 116)11.17 y= + 36.74 65.67 = ( x 116)( 0.17) + 36.74 = ( 0.17 x) + 19. 72 + 36.74 y = 56 0.17 x Exam le : Count , y = 30 GSM = 332 5.88 30 = 155.6

The above conce ts clarify that Fabric width closely de ends on total no. of nee dle not directly related to machine diameter or machine gauge. WALES SPACE: The s ace covered by a wale is called wale s ace for that wale. Wal es s ace de ends on: a. Yarn diameter. b. Loo length. They are described below: 1. YARN DIAMETER: For English count 1.4 1.2 yarn diameter 1 0.8 yarn dia 0.6 0.4 0.2 0 0 20 40 60 80 yarn count From the ex eriment it is seen that yarn diameter decreases with the increases o f yarn count. The count which are generally used in circular knitting machine in Bangladesh

2. FABRIC Along the d for the = No. of

WIDTH: fabric width there resents the wales. The total no. of needle is fixe same cylinder having the equal gauge as well as diameter. Fabric width wales X Wales s ace. =Total no of needle in the machine X Wales s ace.

(20 to 40) the rate of decrease is generally slow than that of below 20 count in which the rate of increase of yarn count is higher or it increase ra idly. When the loo length is minimum, the leg of loo comes in close contact with each ot her and there is no free s ace among left, middle and right zone of interlo ing area. Left Zone Middle Zone x y Right Zone z Interlo ing Area Fig.: Im act of yarn diameter on free s ace in interloo ing area Under the circu mstance the wales s ace will be less than four times of yarn diameter. dd dd Wales s ace = d+d+d+d = 4d When loo length is minm COMMENT: In case of minimum loo ea. length there is no s ace left in interlo ing ar

i.e. stretched due to tension the wales s ace become less than 4d (d is the yarn diameter) When loo length is increased the s ace into the interlo ing area i.e . the zone a, b & c are increased as a result wales s ace becomes wider. It may be u to 5.2d (de ending on the collected data)

ACTUAL VALUE OF RATIO OF WALES SPACE AND DIA OF YARN: Count 18 18 18 18 18 18 24 24 24 24 24 24 24 24 24 24 30 30 30 30 30 30 Wales s ace(mm) 0.808917197 0.808917197 0.889808917 0.808917197 0.889808917 0.80 8917197 0.73027247 0.73537927 0.73537927 0.723663669 0.723663669 0.702185067 0.7 23663669 0.696567587 0.674097665 0.73027247 0.692121666 0.692121666 0.692121666 0.674097665 0.674097665 0.674097665 Yarn dia(inch) 0.008417938 0.008417938 0.008417938 0.008417938 0.008417938 0.008 417938 0.007290148 0.007290148 0.007290148 0.007290148 0.007290148 0.007290148 0 .007290148 0.007290148 0.007290148 0.007290148 0.006520507 0.006520507 0.0065205 07 0.006520507 0.006520507 0.006520507 Yarn dia(mm) 0.213815622 0.213815622 0.213815622 0.213815622 0.213815622 0.21381 5622 0.18516976 0.18516976 0.18516976 0.18516976 0.18516976 0.18516976 0.1851697 6 0.18516976 0.18516976 0.18516976 0.165620869 0.165620869 0.165620869 0.1656208 69 0.165620869 0.165620869 Ratio 3.78324647 3.78324647 4.161571119 3.78324647 4.161571119 3.78324647 3.9437 99834 3.971378851 3.971378851 3.908109336 3.908109336 3.792115223 3.908109336 3. 761778304 3.640430618 3.943799834 4.178952036 4.178952036 4.178952036 4.07012516 5 4.070125165 4.070125165 Average 3.97625 COMMENT: Its clear from the chart that, the ratio of yarn dia to wales s ace is very near of 4. So we can say that one wales occu y 4d s ace, where d is the yarn diameter . So, from the above chart, we found the relation between the yarn count and the W PI as follow, WPI = 28 Ne 4

TABLE SHOWS THE ACTUAL WPI IN ACCORDANCE TO THE COUNT: Count Wales s ace(mm) 18 0.808917197 18 0.808917197 18 0.889808917 18 0.80891719 7 18 0.889808917 18 0.808917197 24 0.73027247 24 0.73537927 24 0.73537927 24 0.7 23663669 24 0.723663669 24 0.702185067 24 0.723663669 24 0.696567587 24 0.674097 665 24 0.73027247 30 0.692121666 30 0.692121666 30 0.692121666 30 0.674097665 30 0.674097665 30 0.674097665 Wales s ace(inch) 0.031847134 0.031847134 0.035031847 0.031847134 0.035031847 0. 031847134 0.028750885 0.02895194 0.02895194 0.028490696 0.028490696 0.027645081 0.028490696 0.027423921 0.026539278 0.028750885 0.027248884 0.027248884 0.027248 884 0.026539278 0.026539278 0.026539278 WPI Avg Std Cv% 31.4 31.4 28.54545 30.44848 1.474081 4.841229 31.4 28.54545 31.4 34.78154 34.54 34.54 35.09918 35.09918 35.42579 1.024035 2.890649 36.1728 35.09918 36.46452 37. 68 34.78154 36.69875 36.69875 36.69875 37.18937 0.537453 1.445178 37.68 37.68 37 .68 COMMENT: From the above chart, we came to the decision that WPI the equation as follows: WPI = 28 Ne 4

CHAPTER 5 MACHINE SPECIFICATION

MACHINE SPECIFICATION: 1. Machine gauge. 2. Machine Diameter. 3. Needle gauge. T hey are described below: 1. MACHINE GAUGE: No. of needles er inch resent in a needle bed of a knitting machine is called machine gauge for that knitting machine. A term giving a notat ional indication of the no. of needles er unit length along a needle bed or nee dle bar of a knitting machine in current ractice, a common unit length of one E nglish inch (25.4mm) is used for all ty es of war and weft knitting machine. Se lection of machine gauge de ends u on yarn diameter. Yarn diameter de ends u on the following: 1. Yarn count 2. Fibre ty e 3. Yarn twist 4. Yarn finished Genera l ractice of yarn count and machine gauge in different industries in Bangladesh given below: TYPICAL SELECTION OF M/C GAUGE FOR DIFFERENT COUNT YARN: M/C Gauge 18 20 22 24 26 28 30 32 Ne 14.0/1 23.5/1 18.0/1 26.0/1 21.5/1 29.5/1 23.5/1 35. 5/1 26.0/1 41.5/1 29.5/1 47.5/1 35.5/1 59.0/1 41.5/1 70.0/1

2. MACHINE DIAMETER: Machine diameter is mainly diameter of cylinder. It is im o rtant for fabric width. Only diameter does not determine the fabric width. It ne ed hel s machine gauge and wales s ace which is de end u on yarn count and loo length. MACHINE DIAMETER SELECTION: S/N Count (Ne) 18 18 20 20 22 22 22 24 24 24 26 26 2 6 28 28 28 30 30 30 32 32 32 34 34 34 36 36 36 Gauge WPI Fabric found from 1 inc h machine erimeter 0.64516129 0.774193548 0.634920635 0.761904762 0.606060606 0 .727272727 0.848484848 0.571428571 0.685714286 0.8 0.555555556 0.666666667 0.777 777778 0.540540541 0.648648649 0.756756757 0.526315789 0.631578947 0.736842105 0 .5 0.6 0.7 0.487804878 0.585365854 0.682926829 0.476190476 0.571428571 0.6666666 67 Percentage of fabric found X% 64.51612903 77.41935484 63.49206349 76.19047619 60.60606061 72.72727273 84.84848485 57.14285714 68.57142857 80 55.55555556 66.6 6666667 77.77777778 54.05405405 64.86486486 75.67567568 52.63157895 63.15789474 73.68421053 50 60 70 48.7804878 58.53658537 68.29268293 47.61904762 57.14285714 66.66666667 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 20 24 20 24 20 24 28 20 24 28 20 24 28 20 24 28 20 24 28 20 24 28 20 24 28 20 24 28 31 31 31.5 31.5 33 33 33 35 35 35 36 36 36 37 37 37 38 38 38 40 40 40 41 41 41 4 2 42 42

29 30 31 32 33 34 38 38 38 40 40 40 20 24 28 20 24 28 43 43 43 44 44 44 0.465116279 0.558139535 0.651162791 0.454545455 0.545454545 0.636363636 Fabric dia X 100 X% 46.51162791 55.81395349 65.11627907 45.45454545 54.54545455 63.63636364 So, the machine dia for articular fabric dia is = X = ercentage of fabric found in relation to The m/c erimeter. So, the relatio n between the machine dia and the machine dia is = 7 x Again, the relation can b e inversely shown that, Fabric dia (Tubular) = Machine dia M/C Gauge 7 Ne Fabric dia Ne M/C Gauge For exam le, if the machine dia is 32, yarn count 24Ne, and the machine gauge is 24 then the fabric dia will be = 32 24 = 22.4 inch. 7 24 GRAPH SHOWN THE RELATION BETWEEN THE COUNT AND THE WPI: 50 45 40 35 30 25 20 15 10 5 0 0 10 20 30 40 50 WPI WPI COUNT FIG: Relation between the yarn count and the w i.

3. NEEDLE GAUGE: Thickness of needle ex ress by the needle gauge. It is im ortan t for selection of machine gauge. Needle gauge is different for the different ga uge and different Brand. Some needle gauge found in industries is given below: Machine gauge Needle thickness in (mm) 24 28 0.52 0.41

CHAPTER 6 RESULT & DICUSSION

From our roject work we manage to find the following equations for the selectio n of yarn count to get required G.S.M. equations vary for fabric ty es, fabric c onstruction. List of equations are tabulated below: The constant for the lain single jersey is as follow: K (Yarn count X stitch le ngth X GSM) = 12083.96 Relation between the fabric GSM and the yarn count: if th e GSM of the fabric is x and the count of yarn is y, then the equation for determini ng GSM and the Yarn count is as follows: GSM, x = 332 5.88y & Yarn count(Ne), y = 56 0.17x Machine diameter selection: The relation between the Fabric dia and t he Machine dia is = 7 x Fabric dia Ne M/C Gauge Again, the relation can be inversely shown that, Fabric dia (Tubular) = Machine dia M/C Gauge 7 Ne

Bibliogra hy 1. Knitting technology By Devid J. S encer 2. Handbook of Technical Textile By Horrocks & Anand 3. Textile Terms & Definitions By J E Mclintyre 4. Circular knitting 5. Knitting calculation 6. Reference 1(Project On Analysis of knitted fabric s ecification and related machine s ecification) 7. Reference 2 (Project On Analysis of knitted fabric s ecification and

related machine s ecification) 8. Reference 3 (Project On analysis of weft knitted fabric s ecifications and o erties)

APPENDIX

CPI S/ L N O LENGT H OF FABRIC NO. OF COURS E LENGT H OF FABRIC WPI NO. OF WALE S LENGT H OF YARN STITCH LENGTH NO OF WALE S LENGT H OF EACH YARN NO OF YAR N COUNT TOTAL LENGT H TOTAL WEIGH T AVG COUN T GSM DEFELECTION % OF ACTUAL GSM FROM CAL GSM SAMPL E NO CPI AVG CPI WPI AVG WPI S.L AVG S.L COUN T GS M AVG GSM CACULATE D GSM UNIT 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 2 1 INCH UNIT 53 54 52 54 UNI T 53 54 52 54 53 53 54 52 53 53 52 50 50 51 51 52 51 50 52 50 UNI T INCH UNIT 289 289 289 289 UNI T 34 34 34 34 34 34 34 34 34 34 37 38 37 37 37 37 37 37 37 37 UNI T MM 775 785 785 775 775 UNIT 289 289 289 289 289 289 289 289 289 289 372 376 373 372 373 372 372 373 372 372 1 53 53 54 52 53 53 52 50 50 51 53.1

9 289 289 289 289 289 289 372 376 373 372 34 775 785 785 775 785 988 1010 991 988 991 37 991 996 991 993 991 1 51 52 51 50 52 50 50.9 10 373 372 372 373 372 372 MM 2.68 2 2.71 6 2.71 6 2.68 2 2.68 2 2.68 2 2.71 6 2.71 6 2.68 2 2.71 6 2.65 6 2.68 6 2.65 7 2.65 6 2.65 7 2.66 4 2.67 7 2.65 7 2.66 9 2.66 4 MM INCH UNI T INCH GM NE NE GM GM GM % 170 27 10 270 0.14 28.93 2.69 9 30.87 175 172.3 3 144.5 19.23% 35 10

350 0.16 32.81 172 120 2.66 4 34 20 680 0.27 37.78 37.78 127 121.3 3 122.5 ( )0.945% 117

CPI S/ L N O LENGT H OF FABRIC INCH NO. OF COURS E UNIT LENGT H OF FABRIC INCH WPI NO. OF WALE S UNIT LENGT H OF YARN MM STITCH LENGTH NO OF WALE S UNIT LENGT H OF EACH YARN INCH NO OF YAR N UNIT COUNT TOTAL LENGT H INCH TOTAL WEIGH T GM AVG COUN T NE GSM DEFELECTION% OF ACTUAL GSM FROM CAL GSM % SAMPL E NO UNIT CPI UNI T AVG CPI UNI T WPI UNI T AVG WPI UNI T S.L MM AVG S.L MM COUN T NE GS M GM AVG GSM GM CACULATE D GSM GM 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 4 1 3 1 43 40 40 40 39 40 40 39 40 39 48 49 49 49 48 47 48 49 47 48 43 40 40 40 39 40 40 39 40 39 48 49 49 49 48 47 48 49 47 48 48. 2 5 40 10 370 370 370 370 370 370 370 370 370 370 185 185 185 185 185 185 185 185 185 185 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 1100 1105 1100 1095 1097 1095 1095 1093 1097 1095 483 485 485 486 485 484 480 48 0 480 482 370 370 370 370 370 370 370 370 370 370 185 185 185 185 185 185 185 185 185 185 2.97 3 2.98 6 2.97 3 2.95 9 2.96 5 2.95 9 2.95 9 2.95 4 2.96 5 2.95 9 2.61 1 2.6 2 2 2.62 2 2.62 7 2.62 2 2.61 6 2.59 5 2.59 5 2.59 5 2.60 5 139 24 18 432 0.2 32.4 2.96 5 31.63 140 139.3 3

127 9.68% 24 18 432 0.21 30.86 139 144 12 16 192 0.1 28.8 2.61 1 28.8 142 142.6 7 148 ( )4.05% 12 16 192 0.1 28.8 142

CPI WPI STITCH LENGTH LEN GTH OF EAC H YAR N INC H COUNT GSM s/ L no SAMP LE NO UNIT LENG TH OF FABR IC INCH NO. OF COUR SE UNIT CPI UN IT AV G CPI UNI T LENG TH OF FABR IC INCH NO. OF WAL ES UNIT WP I UN IT AV G WP I UN IT LENG TH OF YAR N MM NO OF WAL ES UNIT S.L MM AVG S.L MM NO OF YA RN UNI T TOTA L LENG TH INCH TOTA L WEIG HT GM COU NT NE AVG COU NT NE GSM GM AVG GSM GM CACULAT ED GSM GM DEFELECTI ON% OF ACTUAL GSM FROM CAL GSM % 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 4 1 3 1 43 40 40 40 39 40 40 39 40 39 48 49 49 49 48 47 48 49 47 48

43 40 40 40 39 40 40 39 40 39 48 49 49 49 48 47 48 49 47 48 48. 2 5 40 10 370 370 370 370 370 370 370 370 370 370 185 185 185 185 185 185 185 185 185 185 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 1100 1105 1100 1095 1097 1095 1095 1093 1097 1095 483 485 485 486 485 484 480 48 0 480 482 370 370 370 370 370 370 370 370 370 370 185 185 185 185 185 185 185 185 185 185 2.973 2.986 2.973 2.959 2.965 2.959 2.959 2.954 2.965 2.959 2.611 2.622 2.622 2. 627 2.622 2.616 2.595 2.595 2.595 2.605 12 16 192 0.1 28.8 142 2.61 1 28.8 142 1 42.6 7 148 ( )4.05% 12 16 192 0.1 28.8 144 24 18 432 0.21 30.86 139 2.96 5 31.6 3 140 139.3 3 127 9.68% 24 18 432 0.2 32.4 139

CPI WPI STITCH LENGTH COUNT GSM S/ L N O SAMPL E NO LENGT H OF FABRIC NO. OF COURS E CPI UNI T AVG CPI UNI T LENGT H OF FABRIC NO. OF WALE S WPI UNI T AVG WPI UNI T LENGT H OF YARN NO OF WALE S S.L AVG S.L LENGT H OF EACH YARN NO OF YAR N TOTAL LENGT H TOTAL WEIGH T COUN T AVG COUN T GS M AVG GSM CACULATE D GSM DEFELECTION % OF ACTUAL GSM FROM CAL GSM UNIT

INCH UNIT INCH UNIT MM UNIT MM MM INCH UNIT INCH GM NE NE GM GM GM % 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 6 7 8 9 10 1 5 1 42 44 43 43 42 42 43 43 42 42 46 45 48 44 46 45 46 45 45 46 42 44 43 43 42 42 43 43 42 42 46 45 48 44 46 45 46 45 45 46 45. 6 10 42. 6 180 180 180 180 5 180 180 180 180 180 180 350 350 350 350 350 350 350 350 350 35 0 36 36 36 36 36 36 36 36 36 36 35 35 35 35 35 35 35 35 35 35 35 36 375 375 365 390 380 375 380 375 380 380 1012 1010 1008 1008 1008 1000 1006 1010 1015 1008 180 180 180 180 180 180 180 180 180 180 350 350 350 350 350 350 350 350 350 350 2.08 3 2.08 3 2.02 8 2.16 7 2.11 1 2.08 3 2.11 1 2.08 3 2.11 1 2.11 1 2.89 1 2.8 8 6 2.88 2.88 2.88 2.85 7 2.87 4 2.88 6 2.9 2.88 113 12 10 120 0.05 36 2.09 7 36.75

115 116 80.13 44.77% 15 10 150 0.06 37.5 120 176 29 19 551 0.32 25.83 2.88 1 27.12 176 176.6 7 155.2 13.82% 36 20 720 0.38 28.42 177

CPI WPI NO. OF WALE S UNIT STITCH LENGTH NO OF WALE S UNIT LENGT H OF EACH YARN INCH NO OF YAR N UNIT COUNT GSM DEFELECTIO N% OF ACTUAL GSM FROM CAL GSM % S/L NO SAMPL E NO UNIT LENGT H OF FABRIC INCH NO. OF COURS E UNIT CPI UNIT AVG CPI UNIT LENGT H OF FABRIC INCH WPI UNIT AVG WPI UNI T LENGT H OF YARN MM S.L MM AVG S.L MM TOTAL LENGT H INCH TOTAL WEIGH T GM COUN T NE AVG COUN T NE GSM GM AVG GSM GM CACULAT ED GSM GM 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 8 1 7 1 47 47 46 47 48 47 48 47 47 47 51 51 51 51 51 51 51 51 51 51 47 47 46 47 48 47 48 47 47 47 51 51 51 51 51 51 51 51 51 51 51 10 47.1 10 367 367 367 367 367 367 367 367 367 367 368 368 368 368 368 368 368 368 368 368 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 37 1110 1110 1110 1110 1110 1110 1110 1110 1110 1110 995 994 995 995 992 993 994 99 5 994 993

367 367 367 367 367 367 367 367 367 367 368 368 368 368 368 368 368 368 368 368 3.02 5 3.02 5 3.02 5 3.02 5 3.02 5 3.02 5 3.02 5 3.02 5 3.02 5 3.02 5 2.70 4 2.7 0 1 2.70 4 2.70 4 2.69 6 2.69 8 2.70 1 2.70 4 2.70 1 2.69 8 153 3.02 5 40 20 800 0.34 35.29 35.29 155 154.3 3 135.6 13.80% 155 166 2.70 1 36 20 720 0.36 30 30 165 165.3 3 153 8% 165

CPI LENGT H OF FABRI C INCH LENGT H OF FABRI C INCH WPI NO. OF WALE S UNIT STITCH LENGTH NO OF WALE S UNIT LENGT H OF EACH YARN INCH COUNT GSM DEFELECTION% OF ACTUAL GSM FROM CAL GSM % S/L NO SAM PLE NO UNIT NO. OF COURS E UNIT CPI UNIT AVG CPI UNI T WPI UNI T AVG WPI UNI T LENGT H OF YARN MM S.L MM AVG S.L MM NO OF YARN UNIT TOTAL LENGT H INCH TOTAL WEIGH T GM COUN T NE AVG COUN T NE GSM GM AVG GSM GM CACULAT ED GSM GM 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 10 1 9 1 79 80 78 81 82 79 80 83 80 81 46 47 47 46 47 46 46 47 46 46 79 80 78 81 82 79 80 83 80 81 46 47 47 46 47 46 46 47 46 46 46. 4 5 80. 3 10 290 289 289 292 291 289 290 289 289 290 182 180 183 182 181 179 178 179 180 180 29 29 29 29 29 29 29 29 29 29 36 36 37 36 36 36 36 36 36 36 36 29 780 777 777 786 783 777 780 777 777 777 523 518 525 524 520 520 515 516 518 518 290 289 289 292 291 289 290 289 289 290 182 180 183 182 181 179 178 179 180 180

2.69 2.68 9 2.68 9 2.69 2 2.69 1 2.68 9 2.69 2.68 9 2.68 9 2.67 9 2.87 4 2.87 8 2.86 9 2.87 9 2.87 3 2.90 5 2.89 3 2.88 3 2.87 8 2.87 8 217 27 12 326 0.19 25.77 2.68 8 25.18 216 216.6 7 227.7 ( )4.85% 28 13 361 0.22 24.6 217 168 40 12 480 0.27 26.67 2.88 1 26.97 169 168.3 3 163.7 2.82% 40 10 400 0.22 27.27 168

CPI S/ L N O LENGT H OF FABRIC INCH NO. OF COURS E UNIT LENGT H OF FABRIC INCH WPI NO. OF WALE S UNIT LENGT H OF YARN MM STITCH LENGTH NO OF WALE S UNIT LENGT H OF EACH YARN INCH NO OF YAR N UNIT COUNT TOTAL LENGT H INCH TOTAL WEIGH T GM AVG COUN T NE GSM DEFELECTION% OF ACTUAL GSM FROM CAL GSM % SAMPL E NO UNIT CPI UNI T AVG CPI UNI T WPI UNI T AVG WPI UNI T S.L MM AVG S.L MM COUN T NE GS M GM AVG GSM GM CACULATE D GSM GM 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 12 1 11 1 43 42 43 44 43 42 43 42 43 42 51 53 53 52 53 53 52 53 52 53 43 42 43 44 43 42 43 42 43 42 51 53 53 52 53 53 52 53 52 53 52. 5 10 42. 7 10 383 379 384 379 383 380 380 383 379 384 398 398 398 398 398 398 398 398 398 398 38 38 38 38 38 38 38 38 38 38 40 40 40 40 40 40 40 40 40 40 40 38 1166 1155 1170 1155 1167 1158 1158 1167 1155 1170 927 927 915 915 915 921 935 92 1 915 940 383 379 384 379 383 380 380 383 379 384 398 398 398 398 398 398 398 398 398 398 3.04 4 3.04 7 3.04 7 3.04 7 3.04 7 3.04 7 3.04 7 3.04 7 3.04 7 3.04 7 2.32 9 2.3 2 9 2.29 9 2.29 9 2.29 9 2.31 4 2.34 9 2.31 4 2.29 9 2.36 2 135 20 16 324 0.15 32.4 3.04 7 32.14 133 134.3 3

141.4 ( )4.97% 43 10 425 0.2 31.87 135 140 35 10 345 0.16 32.34 2.31 9 32.92 140 139.3 3 135.8 2.62% 34 10 335 0.15 33.5 138

You might also like

- Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionDocument4 pagesEfficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionElias KhalilNo ratings yet

- 18.estimating Thread ConsumptionDocument4 pages18.estimating Thread ConsumptionSugar Lipss0% (1)

- Knitting CalculationsDocument11 pagesKnitting CalculationsArul Deepak50% (2)

- Thread ConsumptionDocument4 pagesThread ConsumptionMd Mamun Hosain100% (1)

- What Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsDocument1 pageWhat Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsMoktar Hossain0% (1)

- Formula For Fabric Weight CalcualtionDocument2 pagesFormula For Fabric Weight Calcualtionmichahkg100% (1)

- What Is Difference Between Lacoste Fabric and Pique Fabric?Document1 pageWhat Is Difference Between Lacoste Fabric and Pique Fabric?Sayed Hossain Ahmed (Shawon)100% (1)

- Circular Knitted FabricsDocument16 pagesCircular Knitted Fabricsrdsekar7633% (3)

- Apparel Costing Unit - II NDocument49 pagesApparel Costing Unit - II NAnonymous BstqCP5aNo ratings yet

- Yarn Count Used According To Grey GSM - Textile CalculationDocument3 pagesYarn Count Used According To Grey GSM - Textile CalculationSZNo ratings yet

- Textil Testing Manual-Gihan RanganaDocument16 pagesTextil Testing Manual-Gihan RanganaGihan RanganaNo ratings yet

- Assignment On Different Kinds of Knitting Faults Causes and Their RemediesDocument4 pagesAssignment On Different Kinds of Knitting Faults Causes and Their RemediesRaihan Moner Manush0% (2)

- Thread Consumption FormulaDocument4 pagesThread Consumption Formulayuganshu_soni100% (1)

- Fabric Bow-Skew - Gihan RanganaDocument2 pagesFabric Bow-Skew - Gihan RanganaGihan Rangana100% (3)

- How Do You Calculate The Fabric Consumption For Knit GarmentsDocument3 pagesHow Do You Calculate The Fabric Consumption For Knit GarmentsimmmranNo ratings yet

- Chapter-7 - Knitting DerivativesDocument39 pagesChapter-7 - Knitting DerivativesMD Shakil Khan0% (1)

- Woven Shirt Garments CostingDocument6 pagesWoven Shirt Garments CostingMd. Al-Amin AhmedNo ratings yet

- Assignment On An Overview of Quality and Quality Control in Textile IndustryDocument9 pagesAssignment On An Overview of Quality and Quality Control in Textile IndustryZAyedNo ratings yet

- Fabric Consumption For Knit Garments Knit Fabric Consumptio CalculationDocument2 pagesFabric Consumption For Knit Garments Knit Fabric Consumptio CalculationFaisal Ibn Haque100% (3)

- How To Find Yarn Count From GSM - Textile Learner PDFDocument1 pageHow To Find Yarn Count From GSM - Textile Learner PDFKM NAZRUL IslamNo ratings yet

- Fabric Design Lecture 20 Cover FactorDocument2 pagesFabric Design Lecture 20 Cover FactorAtul NaikNo ratings yet

- Weaving Commission CalculationsDocument1 pageWeaving Commission Calculationsraj_85No ratings yet

- SpiralityDocument9 pagesSpiralitySenthil KumarNo ratings yet

- Faults in The Knitted FabricsDocument11 pagesFaults in The Knitted FabricsShwetaLoonkarPitliya100% (2)

- Naisargi SCAP End TermDocument11 pagesNaisargi SCAP End TermNaisargiNo ratings yet

- 4.knit Fabric Specification Consumption Yarn Consumption PDFDocument56 pages4.knit Fabric Specification Consumption Yarn Consumption PDFRifatNo ratings yet

- Presentation ShrinkageDocument27 pagesPresentation Shrinkagemhrscribd014No ratings yet

- Wet Processing 1Document47 pagesWet Processing 1Rahul ThomasNo ratings yet

- How Do Calculate The Fabric & Yarn Consumption of A Yarn Dyed T-Shirt?Document9 pagesHow Do Calculate The Fabric & Yarn Consumption of A Yarn Dyed T-Shirt?light lightNo ratings yet

- Textile FinishingDocument21 pagesTextile FinishinganowartexNo ratings yet

- Construcction of Woven FabricDocument8 pagesConstrucction of Woven FabricAdii ChatthaNo ratings yet

- Consumption Costing 2Document10 pagesConsumption Costing 2Al Arafat RummanNo ratings yet

- Process Flow Chart of Knitting: A. Stitch LengthDocument9 pagesProcess Flow Chart of Knitting: A. Stitch LengthAushru HasanNo ratings yet

- Operation BullatinDocument4 pagesOperation BullatinraiyanduNo ratings yet

- Factors Affecting Yarn StrengthDocument11 pagesFactors Affecting Yarn StrengthAbhishek ThakurNo ratings yet

- Stitch 140503091259 Phpapp01Document35 pagesStitch 140503091259 Phpapp01Steve ShamNo ratings yet

- Knit Asia Operation ProcessDocument12 pagesKnit Asia Operation ProcessParvezMridhaNo ratings yet

- Parameters For Fabric CostingDocument34 pagesParameters For Fabric CostingAbhinav VermaNo ratings yet

- MSC Presentation Apparel Consumption & CostingDocument44 pagesMSC Presentation Apparel Consumption & Costingsaaqib100% (1)

- On Textile TestingDocument17 pagesOn Textile TestingGourav Arora100% (2)

- Knitting CalculationDocument2 pagesKnitting Calculationmontasirahmed100% (1)

- Classification & Yarn NumberingDocument21 pagesClassification & Yarn NumberingMewar FashionsNo ratings yet

- Fabric CostingDocument5 pagesFabric CostingAsif NewtonNo ratings yet

- KnittingDocument15 pagesKnittingReyad Billah100% (1)

- Fabric Consumption Calculation For Woven BottomDocument4 pagesFabric Consumption Calculation For Woven Bottomajay kalangiNo ratings yet

- Presentation of Shrinkage of KnitsDocument21 pagesPresentation of Shrinkage of KnitsRajesh KasettyNo ratings yet

- Knit Fabric DefectsDocument14 pagesKnit Fabric DefectsArjun YadavNo ratings yet

- Study On Sizing Practices in Bangladeshi Weaving MillsDocument41 pagesStudy On Sizing Practices in Bangladeshi Weaving MillsSubrata Majumder50% (2)

- Fully FashionDocument30 pagesFully FashiondewNo ratings yet

- Controlling and Check Points in Spinning ProcessDocument10 pagesControlling and Check Points in Spinning ProcessBithy Paul100% (1)

- Analysis of Garment W.R.T To Stitches and SeamsDocument10 pagesAnalysis of Garment W.R.T To Stitches and SeamsRehan Saeedi0% (1)

- Fabric Manufacturing StepsDocument15 pagesFabric Manufacturing StepsFazlul AzimNo ratings yet

- NSQF - Knitting Machine Operator - Circular KnittingDocument23 pagesNSQF - Knitting Machine Operator - Circular KnittingSakibMDShafiuddinNo ratings yet

- Point System For Evaluating Quality in TextilesDocument115 pagesPoint System For Evaluating Quality in TextilesBenjamin OchoaNo ratings yet

- Knitting ScienceDocument24 pagesKnitting ScienceKathirrveluSubramainanNo ratings yet

- Fabric Check ProcedureDocument7 pagesFabric Check ProcedureEleni LanaraNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Visual Reasoning - Practice SheetDocument21 pagesVisual Reasoning - Practice SheetSahilNo ratings yet

- A0000710 Picar XDocument2 pagesA0000710 Picar XSatriyo SatriyoNo ratings yet

- CP KK 2016Document17 pagesCP KK 2016David Susilo NugrohoNo ratings yet

- Artist HandoutDocument10 pagesArtist Handoutapi-384538988100% (1)

- Machine Knitting OperatorDocument50 pagesMachine Knitting OperatorDyah FanniNo ratings yet

- D 0000 1330 015 - 1 - 00001Document1 pageD 0000 1330 015 - 1 - 00001Mary DenizeNo ratings yet

- (E) Vermotion - 3D Models, Textures, Tutorials, Architecture, 3D Graphic, VraDocument12 pages(E) Vermotion - 3D Models, Textures, Tutorials, Architecture, 3D Graphic, VraGonzalo Ramis NivinNo ratings yet

- Musicology From - The - Erotic - To - The - Demonic PDFDocument267 pagesMusicology From - The - Erotic - To - The - Demonic PDFHans Kastorp100% (2)

- Comics911 Cooper AtkinsonDocument18 pagesComics911 Cooper AtkinsonLeo AlsabieNo ratings yet

- (123doc) - Word-Forms-Part-6-Exercises-With-KeysDocument4 pages(123doc) - Word-Forms-Part-6-Exercises-With-KeysHoàng HuyềnNo ratings yet

- Shaw/Mount Vernon West Historic District - National Register of Historic Places Registration Form (1999)Document56 pagesShaw/Mount Vernon West Historic District - National Register of Historic Places Registration Form (1999)eastshawdc100% (1)

- Mrichchakatika - A Chronicle of Its MilieuDocument8 pagesMrichchakatika - A Chronicle of Its MilieuSehajdeep kaurNo ratings yet

- Sched ClassesDocument106 pagesSched ClassesckaddingtonNo ratings yet

- 1st Semester B Arch: Architectural Communication Skills-IDocument4 pages1st Semester B Arch: Architectural Communication Skills-ISidhu0017No ratings yet

- Film StudioDocument3 pagesFilm StudioDudez RañolaNo ratings yet

- S P S A D: Introduction To LandscapeDocument1 pageS P S A D: Introduction To LandscapePankaj SehrawatNo ratings yet

- Created Ruby & Diamond Stackable Ring in Sterling Silver 9T69000 BevillesDocument1 pageCreated Ruby & Diamond Stackable Ring in Sterling Silver 9T69000 Bevillesnick leeNo ratings yet

- Islands Magazine 19th Photo ContestDocument5 pagesIslands Magazine 19th Photo Contestjjaguirr6434No ratings yet

- Gost 3916-96Document7 pagesGost 3916-96Jing VeeNo ratings yet

- Đề KTHK I -TA 10 -ma de 303 doneDocument3 pagesĐề KTHK I -TA 10 -ma de 303 doneDương VũNo ratings yet

- Raymond Pettibon Exhibition PosterDocument2 pagesRaymond Pettibon Exhibition PosterThe Renaissance SocietyNo ratings yet

- What Is A Definition of Short Story?Document8 pagesWhat Is A Definition of Short Story?Nimra Khalid100% (1)

- Sources and Kin-WPS OfficeDocument4 pagesSources and Kin-WPS Officeangelica joyce caballesNo ratings yet

- The Coffee Series EP 3Document19 pagesThe Coffee Series EP 3magojuank100% (1)

- SinkDocument2 pagesSinkYuan RoselNo ratings yet

- Under Stairs Electric Box and CabinetsDocument213 pagesUnder Stairs Electric Box and Cabinetsshamshad.pudhuveetilNo ratings yet

- Femme Fatales v01n03Document68 pagesFemme Fatales v01n03marceloNo ratings yet

- Cat in The Hat Clocks PDFDocument13 pagesCat in The Hat Clocks PDFJóse Manuel Urra CruzNo ratings yet

- Karaoke ListDocument30 pagesKaraoke Listinef111No ratings yet

- The Big Book of Watercolor (1985) - 11Document3 pagesThe Big Book of Watercolor (1985) - 11PbNo ratings yet