Professional Documents

Culture Documents

New Text Document

Uploaded by

singh.amardeepOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Text Document

Uploaded by

singh.amardeepCopyright:

Available Formats

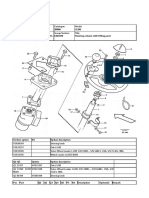

AIR BRAKE SYSTEM COMPONENTS OF AN AIR BRAKE SYSTEM: Air brake system consists of the following components: Compressor:

The compressor generates the compressed air for the whole system. Reservoir: The compressed air from the compressor is stored in the reservoir. Unloader Valve: This maintains pressure in the reservoir at 8bar.When the pressure goes above 8 bar it immediately releases the pressurized air to bring the system to 8-bar pre ssure. Air Dryer: This removes the moisture from the atmospheric air and prevents corrosion of the reservoir. System Protection Valve: This valve takes care of the whole system. Air from the compressor is given to v arious channels only through this valve. This valve operates only at 4-bar press ure and once the system pressure goes below 4-bar valve immediately becomes inac tive and applies the parking brake to ensure safety. Dual Brake Valve: When the driver applies brakes, depending upon the pedal force this valve releas es air from one side to another. Graduated Hand Control Valve: This valve takes care of the parking brakes. Brake Chamber: The air from the reservoir flows through various valves and finally reaches the brake chamber which activates the S-cam in the brake shoe to apply the brakes in the front Actuators: The air from the reservoir flows through various valves and finally reaches the brake chamber, which activates the S-cam in the brake shoe to apply the brakes i n the rear.

AIR BRAKE SYSTEM An air brake system uses compressed air to apply the brakes. Air under pressure can be conveniently stored and carried through lines or tubes. The Components of an Air Brake System. A basic air brake system capable of stopping a vehicle has the following compone nts: ? A compressor. ? A Reservoir. ? A Foot valve. ? Brake chambers and slack adjusters. ? Brake linings and drums. ? Reservoir

? Brake chamber ? Actuator ? Dual brake valve ? System protection valve ? Unloader valve ? Brake lining and drums ? Slack adjusters ? Foot valve ADVANTAGES ? Free resources so no refilling or changing required. ? Air pressure is quick to act and hence air brakes are immediate. ? The pressure of brake applied is directly proportional to the air pressure. ? A little feather touch would apply the same pressure. ? Air brakes can effectively stop loads of over 14 tons. LIMITATIONS ? Excessive use of brake results in overheating and leads to brake fade. Brake f ade results from excessive heat causing chemical changes in the brake lining tha t reduces friction and causes expansion of the brake drums. ? To reduce pressure loss problems : Reservoirs can be charged independently of the brake pipe, this being accomplished via a check valve to prevent back feedin g into the pipe. This arrangement helps to reduce the pressure loss problems, an d also reduces the time required for the brakes to release. ? Air brake systems are not applicable to the pressure less than 60psi. ? Excessive Oil and Water Present in the Air Brake System causes the Reservoirs to corrode if not drained often enough. APPLICATIONS ? Air brakes are used on heavy trucks. ? Agricultural tractor and trailer. ? Forestry vehicles. ? City Works vehicles. ? Tractors with self propelled power engines. CONCLUSION The air brake system is quick to act and the pressure applied on the brake is di rectly proportional to the air brake system. The efficiency of air brake system is relatively high when compared to the other types of brakes. Reference: http://www.seminarprojects.com/Thread-air-brake-system#ixzz1cd0GdGAb

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Takeuchi Tl12 (P-tl12-Ad) Crawler Loader Parts ManualDocument353 pagesTakeuchi Tl12 (P-tl12-Ad) Crawler Loader Parts ManualWilliam Roark0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Alarm and Safety SystemsDocument44 pagesAlarm and Safety SystemsagvassNo ratings yet

- Process Automation Examples From Various Plant Stations in A Beet Sugar FactoryDocument36 pagesProcess Automation Examples From Various Plant Stations in A Beet Sugar FactoryRiadh2012No ratings yet

- Biotech: VenairDocument38 pagesBiotech: VenairSalvador CorralNo ratings yet

- Filter Selection Guide-EDocument78 pagesFilter Selection Guide-ENuñez JesusNo ratings yet

- Lista de Partes 2009Document106 pagesLista de Partes 2009camilogueeeeeNo ratings yet

- Asoma Model 682t HPDocument2 pagesAsoma Model 682t HPJairo SotomayorNo ratings yet

- BS En-671-1-2012Document13 pagesBS En-671-1-2012chorn pholinNo ratings yet

- Manual RF Baghouse CollectorDocument24 pagesManual RF Baghouse Collectorheroj83100% (1)

- Control Loops PDFDocument48 pagesControl Loops PDFAnonymous PTHwJyinsNo ratings yet

- Manual Partes PowerlinkDocument34 pagesManual Partes PowerlinkMiguel Henriquez TizkaNo ratings yet

- Camfil Brochure - Explosion - Protection - SolutionsDocument3 pagesCamfil Brochure - Explosion - Protection - Solutionsgvargas0485No ratings yet

- Lab Pneumatic 2aDocument4 pagesLab Pneumatic 2aSam100% (1)

- Bermad - LisDocument66 pagesBermad - LisRamesh Kumar100% (1)

- MM Pressure Regulator Catalogue - E (1) 015-PCV-588Document32 pagesMM Pressure Regulator Catalogue - E (1) 015-PCV-588Do PhanNo ratings yet

- Zetkama Fig. 215 SpecsDocument11 pagesZetkama Fig. 215 SpecsAntonio VelardeNo ratings yet

- E Series ATEX Handbook V7Document16 pagesE Series ATEX Handbook V7jithukshajiNo ratings yet

- Sanitary Material Prices in Addis AbabaDocument3 pagesSanitary Material Prices in Addis Ababanasru haji100% (2)

- Alfa Laval Gunclean Toftejorg I40 D: Dual-Nozzle Tank Cleaning MachineDocument4 pagesAlfa Laval Gunclean Toftejorg I40 D: Dual-Nozzle Tank Cleaning MachineSamo SpontanostNo ratings yet

- Valve Maintenance GuideDocument301 pagesValve Maintenance GuideDyandra Ihsan Hafidza Farisya100% (3)

- Aircraft Engine Starting and Ignition Systems Solomon BezunehDocument118 pagesAircraft Engine Starting and Ignition Systems Solomon Bezunehsbezuneh1716100% (4)

- Newsletter16 4 PDFDocument31 pagesNewsletter16 4 PDFasimbuyukNo ratings yet

- 06 Steering PDFDocument33 pages06 Steering PDFDaniel NavasNo ratings yet

- Valvula Borboleta Lug z614 ADocument6 pagesValvula Borboleta Lug z614 AWellington S. FrançaNo ratings yet

- Pompe GrundfosDocument14 pagesPompe Grundfos_keoNo ratings yet

- APCO Silent Check PDFDocument8 pagesAPCO Silent Check PDFtanvir04169No ratings yet

- OSE 10-0196-. - 10 - Parts ListDocument51 pagesOSE 10-0196-. - 10 - Parts ListCentrifugal Separator100% (1)

- Vent Silencer Spec SheetDocument2 pagesVent Silencer Spec SheetAqeel Bisma100% (1)

- Great Plains Parts Manual 705 and 1005Document144 pagesGreat Plains Parts Manual 705 and 1005a04205No ratings yet

- A760E F H VBL InteractiveDocument1 pageA760E F H VBL InteractivehaddadiNo ratings yet