Professional Documents

Culture Documents

Engine Performance Data at 1500 RPM: A1.4 1 Cummins Inc

Uploaded by

عماد صدقيOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Performance Data at 1500 RPM: A1.4 1 Cummins Inc

Uploaded by

عماد صدقيCopyright:

Available Formats

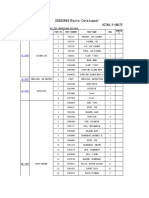

Basic Engine Model:

Curve Number:

3A1.4-G1

FR-35005

Engine Critical Parts List:

Date:

CPL: 3A1.4

17Aug05

Cummins Inc.

Columbus, Indiana 47201

Engine Data Sheet

Displacement : 1.45 litre (89 in 3 )

Bore : 84 mm (3.31 in.)

No. of Cylinders : 3

Aspiration : Naturally Aspirated

Engine Speed

Standby Power

G-DRIVE

A1.4

1

Stroke : 88 mm (3.46 in.)

Prime Power

Continuous Power

RPM

kWm

BHP

kWm

BHP

kWm

BHP

1500

12.2

16.4

11.1

14.9

N/A

N/A

1800

14.4

19.3

13.0

17.4

N/A

N/A

Emissions Certification (1800 RPM Only)

This engine complies with certain emissions requirements established by US EPA/CARB.

See Exhaust Emissions Data Sheet for conformance specifics.

Engine Performance Data @ 1500 RPM

OUTPUT POWER

%

kWm

Litre / hour

FUEL CONSUMPTION

kg/

kWmh

lb/

BHPh

litre/

hour

U.S. Gal/

hour

16.4

0.238

0.391

3.45

0.91

BHP

STANDBY POWER

100

12.2

3.5

100

11.1

14.9

0.231

0.380

3.05

0.81

75

8.3

11.2

0.238

0.391

2.36

0.62

50

5.5

7.5

0.260

0.427

1.72

0.45

2.0

1.5

1.0

0.5

25

2.8

3.7

0.350

0.575

1.18

0.31

0.0

N/A

N/A

N/A

N/A

PRIME POWER

CONTINUOUS POWER

100

N/A

N/A

1500 RPM

3.0

2.5

10 11 12 13

Gross Engine Output - kWm

Engine Performance Data @ 1800 RPM

OUTPUT POWER

%

kWm

BHP

U.S. Gallons / hour

FUEL CONSUMPTION

kg/

kWmh

lb/

BHPh

litre/

hour

U.S. Gal/

hour

14.4

1.0

1800 RPM

STANDBY POWER

100

1.2

0.8

19.3

0.238

0.391

4.07

1.08

0.6

PRIME POWER

100

13.0

17.4

0.241

0.397

3.66

0.97

75

9.5

12.8

0.246

0.404

2.80

0.74

50

6.4

8.6

0.270

0.444

2.05

0.54

25

3.2

4.3

0.350

0.575

1.33

0.35

N/A

N/A

N/A

N/A

0.4

0.2

0.0

0

CONTINUOUS POWER

100

N/A

N/A

CONVERSIONS:(litres = U.S. Gal x 3.785) (U.S.Gal = litres x 0.2642)

These guidelines have been formulated to ensure proper application of generator drive engines in A.C. generator set installations. STANDBY POWER RATING: Applicable for supplying emergency power for the duration of the utility power

outage. No overload capability is available for this rating. Under no condition is an engine allowed to operate in parallel

with the public utility at the Standby Power rating. This rating should be applied where reliable utility power is available. A

Standby rated engine should be sized for a maximum of an 80% average load factor and 200 hours of operation per year.

This includes less than 25 hours per year at the Standby Power rating. Standby ratings should never be applied except in

true emergency power outages. Negotiated power outages contracted with a utility company are not considered an emergency. PRIME POWER RATING: Applicable for supplying electric power in lieu of commercially purchased power. Prime

Power applications must be in the form of one of the following two categories:UNLIMITED TIME RUNNING PRIME POWER: Prime Power is available for an unlimited number of hours per year in a variable load application. Variable load should

not exceed a 70% average of the Prime Power rating during any operating period of 250 hours. The total operating time

at 100% Prime Power shall not exceed 500 hours per year. A 10% overload capability is available for a period of 1 hour

within a 12-hour period of operation. Total operating time at the 10% overload power shall not exceed 25 hours per year.

LIMITED TIME RUNNING PRIME POWER: Limited Time Prime Power is available for a limited number of hours in a nonvariable load application. It is intended for use in situations where power outages are contracted, such as in utility power

curtailment. Engines may be operated in parallel to the public utility up to 750 hours per year at power levels never to exceed the Prime Power rating. The customer should be aware, however, that the life of any engine will be reduced by this

constant high load operation. Any operation exceeding 750 hours per year at the Prime Power rating should use the Continuous Power rating.CONTINUOUS POWER RATING : Applicable for supplying utility power at a constant 100% load for

an unlimited number of hours per year. No overload capability is available for this rating.

10

12

14

16

18

20

Gross Engine Output - BHP

Data Subject to Change Without Notice

Reference AEB 10.47 for determining Electrical Output.

Data shown above represent gross engine performance capabilities obtained and corrected in accordance with ISO3046 conditions of 100 kPa (29.53 in Hg) barometric pressure [110 m (361 ft) altitude], 25 C (77 F) air inlet temperature, and relative humidity of 30% with No. 2 diesel or a fuel corresponding to ASTM D2.

Derates shown are based on 15 in H2 0 air intake restriction and 2 in Hg exhaust back pressure.

The fuel consumption data is based on No. 2 diesel fuel weight at 0.85 kg/litre (7.1 lbs/U.S. gal). Power output curves are

based on the engine operating with fuel system, water pump and lubricating oil pump; not included are battery charging

alternator, fan, optional equipment and driven components.

Data Status: --Limited Production-Data Tolerance:

Chief Engineer:

G-DRIVE

1500 RPM Derate Curves

1800 RPM Derate Curves

A1.4

2

The engine may be operated at 1800 RPM and 1500 RPM up to 500 Ft. (150 m) and 77 F (25 C)

without power derate.

For sustained operation above these conditions, derate by 3% per 1,000 ft (300 m), and 1% per

10 F (2% per 11 C), and 1.5% per 10% relative humidity above 30%.

Cummins Inc.

G-DRIVE

A1.4

3

Engine Data Sheet

ENGINE MODEL :

3A1.4-G1

CONFIGURATION NUMBER : D951002GX03

INSTALLATION DIAGRAM

Fan to Flywheel

:

DATA SHEET : DS-35005

DATE : 17Aug05

PERFORMANCE CURVE : FR-35005

CPL NUMBER

Engine Critical Parts List

3A1.4

GENERAL ENGINE DATA

Type ...............................................................................................................................................................

Aspiration .......................................................................................................................................................

Bore x Stroke.............................................................................................................. in x in (mm x mm)

Displacement .............................................................................................................................. in3 (litre)

Compression Ratio........................................................................................................................................

Dry Weight

Fan to Flywheel Engine.......................................................................................................... lb (kg)

Wet Weight

Fan to Flywheel Engine.......................................................................................................... lb (kg)

Moment of Inertia of Rotating Components

with FW xxxx Flywheel ........................................................................................... lbm ft2 (kg m 2)

Center of Gravity from Rear Face of Flywheel Housing.......................................................... in (mm)

Center of Gravity Above Crankshaft Centerline ....................................................................... in (mm)

Maximum Static Loading at Rear Main Bearing .......................................................................... lb (kg)

4-Cycle; In-line; 3-Cylinder Diesel

Naturally Aspirated

3.31 x 3.64(84 x 88)

105 (1.7)

21.3: 1

TBD

(TBD)

414

(188)

5.7

7.72

3.82

TBD

(0.24)

(196)

(97)

TBD

929

(1260)

3

14.75

(76)

(20)

25

10

15

(635)

(254)

(381)

3.2

(3)

3

4

10

160-185

10

230 / 212

(35)

(28)

(3)

(71-85)

(69)

(110 / 100)

14

50

250

1.4

TBD

(98)

(350)

(121)

(5.4)

(TBD)

ENGINE MOUNTING

Maximum Bending Moment at Rear Face of Block......................................................... lb ft (N m)

EXHAUST SYSTEM

Maximum Back Pressure................................................................................................ in Hg (mm Hg)

Maximum Bending Moment to the Turbo Flange ............................................................. lb ft (N m)

AIR INDUCTION SYSTEM

Maximum Intake Air Restriction

with Dirty Filter Element ......................................................................................... in H2O (mm H2O)

with Normal Duty Air Cleaner and Clean Filter Element...................................... in H2O (mm H2O)

with Heavy Duty Air Cleaner and Clean Filter Element....................................... in H2O (mm H2O)

COOLING SYSTEM

Coolant Capacity Engine Only................................................................................... US qtsl (litre)

Maximum Coolant Friction Head External to Engine

1800 rpm................................. psi (kPa)

1500 rpm................................. psi (kPa)

Maximum Static Head of Coolant Above Engine Crank Centerline............................................. ft (m)

Standard Thermostat (Modulating) Range................................................................................. F (C)

Minimum Pressure Cap ........................................................................................................... psi (kPa)

Maximum Top Tank Temperature for Standby / Prime Power................................................. F (C)

LUBRICATION SYSTEM

Oil Pressure @ Idle Speed.................................................................................................... psi (kPa)

@ Governed Speed ......................................................................................... psi (kPa)

Maximum Oil Temperature .......................................................................................................... F (C)

Oil Capacity with OP 35004 Oil Pan : High ....................................................................... US gal (litre)

Total System Capacity (Including Combo Filter) ............................................................... US gal (litre)

Angularity of OP 35004 Oil Pan Front Down .....................................................................................

Front Up..........................................................................................

Side to Side.....................................................................................

30

30

30

G-DRIVE

A1.4

4

FUEL SYSTEM

Type Injection System...................................................................................................................................................................... IDI Rotary

Maximum Restriction to Pump / with clean filter............................................................................................... in Hg (mm Hg)

2.95

with dirty filter..................................................................................................... in Hg (mm Hg)

0.89

Maximum Allowable Head on Injector Return Line (Consisting of Friction Head and Static Head)............. in Hg (mm Hg)

15

Maximum Fuel Flow to Injection Pump......................................................................................................... US gph (litre / hr)

6.35

Maximum Fuel Inlet Temperature

........................................................................................................................... F (C)

149

Maximum Fuel Drain Flow

.......................................................................................................... --- US gph (litre / hr)

4.23

(75)

(22.5)

(382)

(24)

(65)

(13)

ELECTRICAL SYSTEM

Cranking Motor (Heavy Duty, Positive Engagement)......................................................................................................... volt

Battery Charging System, Negative Ground................................................................................................................ ampere

Maximum Allowable Resistance of Cranking Circuit........................................................................................................ ohm

Minimum Recommended Battery Capacity [Cold Soak @ 10 F (-12 C) and Above]........................................... 0F CCA

12

45

0.001

500

COLD START CAPABILITY

Minimum Ambient Temperature for Aided (with Coolant Heater) Cold Start within 10 seconds................................ F (C)

Minimum Ambient Temperature for Unaided Cold Start............................................................................................... F (C)

Cranking Torque at minimum Unaided Cold Start Temperature......................................................................... lb ft (N m)

TBD

32

8

TBD

(0)

(12)

PERFORMANCE DATA

All data is based on:

Engine operating with fuel system, water pump, lubricating oil pump, air cleaner and exhaust

silencer; not included are battery charging alternator, fan, and optional driven components.

Engine operating with fuel corresponding to grade No. 2-D per ASTM D975.

ISO 3046, Part 1, Standard Reference Conditions of:

Barometric Pressure : 100 kPa (29.53 in Hg)

Air Temperature

: 25 C (77 F)

Altitude

: 110 m (361 ft)

Relative Humidity : 30%

Steady State Stability Band at Any Constant Load ............................................................................................................. %

STANDBY

60 hz

50 hz

Governed Engine Speed............................................................. rpm

Engine Idle Speed....................................................................... rpm

Gross Engine Power Output .......................................... BHP (kW m)

Brake Mean Effective Pressure .......................................... psi (kPa)

Piston Speed................................................................ ft / min (m / s)

Friction Horsepower.......................................................... HP (kWm)

Engine Water Flow at Stated Friction Head External to Engine:

4 psi Friction Head........................................... US gpm (litre / s)

Maximum Friction Head.................................. US gpm (litre / s)

1800

800-1300

19.3 (14.4)

95

(656)

1039

(5.3)

8.5

(6.3)

7.8 (0.495)

5.0 (0.317)

1500

800-1300

16.4 (12.2)

97

(667)

866

(4.4)

5.8

(4.3)

TBD

TBD

+/- 0.50

PRIME POWER

60 hz

50 hz

1800

800-1300

17.4

(13.0)

84

(580)

1039

(5.3)

8.5

(6.3)

(TBD)

(TBD)

7.8 (0.495)

5.0 (0.317)

34.9 (16.5)

756

(402)

90 (42.3)

23.5 : 1

56

(1.0)

655 (11.5)

516

(9.1)

44.5 (20.9)

730

(388)

85

(40.3)

25.6 : 1

59

(1.0)

683

(2.0)

538

(9.5)

1500

800-1300

14.9 (11.1)

88 (607)

866

(4.4)

5.8

(4.3)

TBD

TBD

(TBD)

(TBD)

Engine Data with Dry Type Exhaust Manifold

Intake Air Flow................................................................. cfm (litre / s)

Exhaust Gas Temperature..................................................... F (C)

Exhaust Gas Flow........................................................... cfm (litre / s)

Air to Fuel Ratio...................................................................... air : fuel

Radiated Heat to Ambient ..................................... BTU / min (kW m)

Heat Rejection to Coolant....................................... BTU / min (kW m)

Heat Rejection to Exhaust...................................... BTU / min (kW m)

44.3 (20.9)

791

(422)

90 (42.3)

23.5 : 1

67

(1.2)

773

(13.6

609

(10.7

35.0 (16.5)

702

(372)

85 (40.3)

25.6 : 1

50

(0.9)

579 (10.2)

456

(8.0)

N.A. - Data is Not Available

N/A - Not Applicable to this Engine

TBD - To Be Determined

Cummins Inc.

Columbus, Indiana 47202-3005

ENGINE MODEL :

DATA SHEET :

DATE :

CURVE NO. :

3A1.4

DS-35005

17Aug05

FR-35005

You might also like

- Spec C32 746kW@1800rpmDocument15 pagesSpec C32 746kW@1800rpmPhuc DcNo ratings yet

- FPT N Series Diesel Engine Data CatalogDocument14 pagesFPT N Series Diesel Engine Data CatalogMohamed Amine LimemNo ratings yet

- 4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"Document2 pages4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"NarcisaNo ratings yet

- Static Injector TimingDocument12 pagesStatic Injector TimingMohamed Mohamed100% (1)

- Dong-I Datos PDFDocument8 pagesDong-I Datos PDFraulNo ratings yet

- M25 Maintenance Schedule PDFDocument3 pagesM25 Maintenance Schedule PDFMYO WINNo ratings yet

- Workshop Manual Hyundai S250JDocument150 pagesWorkshop Manual Hyundai S250JwilmerNo ratings yet

- TP 6954Document160 pagesTP 6954Võ Văn ToànNo ratings yet

- Crank Shaft Calibration ReportDocument1 pageCrank Shaft Calibration Reportsarabjit mundaeNo ratings yet

- 6BT5.9-DM Non-Certified Ratings SSDocument2 pages6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- Lampiran 2 Lampiran Penawaran Harga: Pengadaan Filter Untuk Kebutuhan Motor Induk Dan Motor Bantu Kapal Perintis 2021Document10 pagesLampiran 2 Lampiran Penawaran Harga: Pengadaan Filter Untuk Kebutuhan Motor Induk Dan Motor Bantu Kapal Perintis 2021Deni prastiyoNo ratings yet

- Centamax: Assembly and Operating Instructions CM-2600 18000-SCA / - SCBDocument47 pagesCentamax: Assembly and Operating Instructions CM-2600 18000-SCA / - SCBgianni100% (1)

- TP6053 Catalago KohlerDocument70 pagesTP6053 Catalago KohlerOperaciones Max Diesel ProNo ratings yet

- Service BulletinDocument21 pagesService BulletinFalgon Islam100% (1)

- Perkins M215C and M185C 1006 SeriesDocument2 pagesPerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- Owners Handbook BUKH U125Document79 pagesOwners Handbook BUKH U125Alexandros KontosNo ratings yet

- Eliminator™ FilterDocument35 pagesEliminator™ FiltertstkupdhNo ratings yet

- Marine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIDocument3 pagesMarine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIOscar Eduardo Parra GuerreroNo ratings yet

- Gn65732u 404D-22Document179 pagesGn65732u 404D-22Nilupul WijeratneNo ratings yet

- S433 GENSET SPARE LISTDocument42 pagesS433 GENSET SPARE LISTvpsales2123No ratings yet

- Di13 SeriesDocument74 pagesDi13 Seriesramsey222No ratings yet

- Ship Resistance Estimation and Engine SelectionDocument20 pagesShip Resistance Estimation and Engine SelectionSean GyarinoNo ratings yet

- 6ey17w PDFDocument1 page6ey17w PDFfajee_faridNo ratings yet

- Scania Technical Data - Issue-13Document51 pagesScania Technical Data - Issue-13kman548No ratings yet

- Parts Catalog: EngineDocument84 pagesParts Catalog: EngineVivek AwasthiNo ratings yet

- Hydraulic Steering Systems for Marine EnginesDocument40 pagesHydraulic Steering Systems for Marine EnginesЯрослав БогдановNo ratings yet

- Manual DDFPDocument92 pagesManual DDFPCarlos VegaNo ratings yet

- Perkins 3008 Tag3Document1 pagePerkins 3008 Tag3ali s100% (1)

- Service Performance MEDocument2 pagesService Performance METhusitha DalpathaduNo ratings yet

- Yanmar 6HA2M WDT DatasheetDocument2 pagesYanmar 6HA2M WDT Datasheethungndo100% (1)

- Tailshaft Condition Monitoring TCM - Notation - Guide-July12Document2 pagesTailshaft Condition Monitoring TCM - Notation - Guide-July12Marlon Alejandro Arboleda TapiaNo ratings yet

- SO202843 (Parts Catalogue) : 6CTA8.3-GM175Document12 pagesSO202843 (Parts Catalogue) : 6CTA8.3-GM175Phyo Aung Kyaw0% (1)

- Service Performance ME-BDocument2 pagesService Performance ME-BValeriy DomashenkoNo ratings yet

- Mitsubishi 6D24 Diesel Engine Series 200-350 HpDocument2 pagesMitsubishi 6D24 Diesel Engine Series 200-350 Hpali4299100% (2)

- Service Performance ME-BDocument2 pagesService Performance ME-BThusitha DalpathaduNo ratings yet

- UMcrankshaftsDocument66 pagesUMcrankshaftsАндрей КулешовNo ratings yet

- Valvoline 6Document2 pagesValvoline 6munh100% (1)

- 4tne98-G1a (0CR10-G45800)Document30 pages4tne98-G1a (0CR10-G45800)Alaina Sousa100% (1)

- New Spares List SP HPCE 520 CPL 11-2012Document12 pagesNew Spares List SP HPCE 520 CPL 11-2012GMNo ratings yet

- KTA 19 Parts CatalogueDocument58 pagesKTA 19 Parts CatalogueMP Vasu Raju100% (1)

- 101402-9770 Parts ListDocument3 pages101402-9770 Parts ListMihai-Eugen Popa100% (1)

- Twin Disc PDFDocument6 pagesTwin Disc PDFLuis J. CastroNo ratings yet

- VESSEL ENGINE SERVICE DATADocument1 pageVESSEL ENGINE SERVICE DATAwalleyranNo ratings yet

- Cat 3408c Gen SetDocument4 pagesCat 3408c Gen Setshinichie100% (1)

- Cummins n855 Engine Specs PDF FreeDocument6 pagesCummins n855 Engine Specs PDF Freema.powersourceNo ratings yet

- 6-Cylinder Diesel Engine For Power Generation.: MAN NutzfahrzeugeDocument4 pages6-Cylinder Diesel Engine For Power Generation.: MAN NutzfahrzeugeMuhammad rizkiNo ratings yet

- Yd385D Engine Technical Data SheetDocument2 pagesYd385D Engine Technical Data SheetSerhan Aysan100% (1)

- M18 018 eDocument3 pagesM18 018 eFalgon IslamNo ratings yet

- Kta38-M0 900@1800 FR631Document2 pagesKta38-M0 900@1800 FR631Cak Soe Bujang Periang100% (1)

- MCOT Tank Operating ProcedureDocument18 pagesMCOT Tank Operating ProcedureLembang ApangNo ratings yet

- Report: Crankshaft Deflections: Plate 70815-40FDocument1 pageReport: Crankshaft Deflections: Plate 70815-40FwalleyranNo ratings yet

- 6btaa5 9G2Document3 pages6btaa5 9G2Budi Nais100% (2)

- 2011-04-11 193232 Om353 Valve Clearance PDFDocument6 pages2011-04-11 193232 Om353 Valve Clearance PDFazyoudNo ratings yet

- Data Sheet 4BT3.3G3Document4 pagesData Sheet 4BT3.3G3acere18100% (1)

- Cummins QST30-G5 Engine Specs and Performance DataDocument4 pagesCummins QST30-G5 Engine Specs and Performance DataMuhammed Ali NoureddeenNo ratings yet

- Datasheet QSX15G9Document3 pagesDatasheet QSX15G9walsystem22100% (2)

- 4BT3 9-G2Document4 pages4BT3 9-G2Николай Белый100% (1)

- Cummins Inc.: Engine Data SheetDocument4 pagesCummins Inc.: Engine Data SheetAnh Nguyen100% (1)

- QSK60G4Document4 pagesQSK60G4Mohamed Hamdallah100% (1)

- Engine Performance Data at 1500 RPM: QSB 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: QSB 1 Cummins IncMaged Beshara100% (3)

- Target Control TechniqueDocument7 pagesTarget Control Techniqueعماد صدقي100% (1)

- 4204 Portata Ultrasuoni ENGDocument2 pages4204 Portata Ultrasuoni ENGعماد صدقيNo ratings yet

- Technical Manual Profibus ACURO en PDFDocument75 pagesTechnical Manual Profibus ACURO en PDFprotesto06No ratings yet

- 26046Document11 pages26046عماد صدقيNo ratings yet

- 13 - Sharp and Broad-Crested Weirs - Sutherland TaylorDocument9 pages13 - Sharp and Broad-Crested Weirs - Sutherland Taylorনীল জোছনাNo ratings yet

- Datasheet AC58-Profibus enDocument11 pagesDatasheet AC58-Profibus enعماد صدقيNo ratings yet

- 4204 Portata Ultrasuoni ENGDocument2 pages4204 Portata Ultrasuoni ENGعماد صدقيNo ratings yet

- STAUFF and VOSWINKEL Catalogues 1-10Document1 pageSTAUFF and VOSWINKEL Catalogues 1-10عماد صدقيNo ratings yet

- Datasheet Ee776Document6 pagesDatasheet Ee776عماد صدقيNo ratings yet

- Company Profile JSTDocument6 pagesCompany Profile JSTعماد صدقيNo ratings yet

- CenterDocument8 pagesCenterعماد صدقيNo ratings yet

- Magflux A 1507 enDocument10 pagesMagflux A 1507 enعماد صدقيNo ratings yet

- Specs TX 3000Document4 pagesSpecs TX 3000عماد صدقيNo ratings yet

- Magflux M1 Datasheet 0810 enDocument3 pagesMagflux M1 Datasheet 0810 enعماد صدقيNo ratings yet

- GIS Application in Power DistributionDocument2 pagesGIS Application in Power Distributionعماد صدقيNo ratings yet

- NewLine CatalogueDocument2 pagesNewLine Catalogueعماد صدقيNo ratings yet

- Master of Body Language PDFDocument10 pagesMaster of Body Language PDFreversoNo ratings yet

- Calibrating and Testing Control Components On Your Heat Process.Document3 pagesCalibrating and Testing Control Components On Your Heat Process.Hayden LovettNo ratings yet

- Gis For Electric DistributionDocument4 pagesGis For Electric Distributionعماد صدقيNo ratings yet

- Phs Thesis2Document60 pagesPhs Thesis2Sachin KhandareNo ratings yet

- Ip Transmitter Calibration FormDocument1 pageIp Transmitter Calibration Formعماد صدقيNo ratings yet

- WP EDDL Calibration Trim FormDocument20 pagesWP EDDL Calibration Trim FormLaurian ŞtefanNo ratings yet

- GIS Application in Power DistributionDocument2 pagesGIS Application in Power Distributionعماد صدقيNo ratings yet

- White - Paper - Calibrating Calibrators PDFDocument3 pagesWhite - Paper - Calibrating Calibrators PDFعماد صدقي100% (1)

- The Expression of Uncertainty and Confidence in Measurement (Edition 3, November 2012)Document82 pagesThe Expression of Uncertainty and Confidence in Measurement (Edition 3, November 2012)JeransNo ratings yet

- Determining Accuracy Stability Digital Pressure GaugesDocument2 pagesDetermining Accuracy Stability Digital Pressure Gaugesعماد صدقيNo ratings yet

- Gas Custody Transfer Calibration BetaGauge 330Document8 pagesGas Custody Transfer Calibration BetaGauge 330عماد صدقيNo ratings yet

- Calibration Intervals, A Manufacturer'S PerspectiveDocument6 pagesCalibration Intervals, A Manufacturer'S Perspectiveعماد صدقيNo ratings yet

- Note DeviceCalibrationDocument8 pagesNote DeviceCalibrationعماد صدقيNo ratings yet

- 22 Kva Meer PDFDocument6 pages22 Kva Meer PDFDiary CompanyNo ratings yet

- FFDVFDocument1 pageFFDVFshamirNo ratings yet

- N47tu Top enDocument60 pagesN47tu Top enAdrian NegoiNo ratings yet

- Variable Valve Actuators - Inspect/Adjust: C11 and C13 Engines For Caterpillar Built MachinesDocument5 pagesVariable Valve Actuators - Inspect/Adjust: C11 and C13 Engines For Caterpillar Built MachinesIndiNo ratings yet

- Hy30-8200 UkDocument80 pagesHy30-8200 UklewisprotecNo ratings yet

- Concrete PumpDocument2 pagesConcrete Pumpajeet ranaNo ratings yet

- Mathematical Modelling and Simulation of An Electric CarDocument13 pagesMathematical Modelling and Simulation of An Electric CarAditya Gupta 2k18.ps.005No ratings yet

- The EA288 Diesel Engine Family: Self Study Program 820433Document76 pagesThe EA288 Diesel Engine Family: Self Study Program 820433Mishu MarcelNo ratings yet

- Cabinet 50 wiring diagramDocument52 pagesCabinet 50 wiring diagramAlanNo ratings yet

- CFD Simulation of Hydrogen CombustionDocument28 pagesCFD Simulation of Hydrogen CombustionLuis NunesNo ratings yet

- BMW E10Document83 pagesBMW E10mnbvqwert100% (2)

- Power Plant Engineering: - Portion of The Installed Reserved Kept inDocument8 pagesPower Plant Engineering: - Portion of The Installed Reserved Kept inStephen Lou Borja100% (1)

- Daihatsu Sirion Service Manual & Technical Information & Body Repair Manual & P.D.I ManualDocument2,764 pagesDaihatsu Sirion Service Manual & Technical Information & Body Repair Manual & P.D.I ManualMojiTTo100% (2)

- MAN Marine Propulsion SystemsDocument3 pagesMAN Marine Propulsion SystemsJereszNo ratings yet

- ON A/C 051-100: Zone/Access Zone DescriptionDocument7 pagesON A/C 051-100: Zone/Access Zone DescriptionEder LucianoNo ratings yet

- Engine2012 1Document52 pagesEngine2012 1Felipe Ramirez100% (1)

- Componentes de Tiempo y Marcas de AlineacionDocument2 pagesComponentes de Tiempo y Marcas de AlineacionsazamarNo ratings yet

- 4JH57 Marine Diesel Engine PerformanceDocument2 pages4JH57 Marine Diesel Engine PerformanceSandro MiqueletiNo ratings yet

- Unit 3 Main Course BookDocument34 pagesUnit 3 Main Course BookMohan0% (1)

- Catálogo Carrier v2203Document55 pagesCatálogo Carrier v2203Carlos CorreaNo ratings yet

- Azimuth Tunnel ThrustersDocument10 pagesAzimuth Tunnel ThrustersAnoop VANo ratings yet

- VT DIWA-NXT 23 BDI VT2543 enDocument6 pagesVT DIWA-NXT 23 BDI VT2543 enRonald MejiaNo ratings yet

- XAVS450Document2 pagesXAVS450wilmar tabordaNo ratings yet

- Ex 2.01 Human Error Chain in An AccidentDocument5 pagesEx 2.01 Human Error Chain in An AccidentAndrejSukoraNo ratings yet

- DC_AC_SERVOMOTORSDocument17 pagesDC_AC_SERVOMOTORSVi GaneshNo ratings yet

- Golf GTD Media LaunchDocument14 pagesGolf GTD Media LaunchMikeNo ratings yet

- Powerkit Engine 12M26 Series: General SpecificationsDocument3 pagesPowerkit Engine 12M26 Series: General SpecificationsstorkbNo ratings yet

- GARNER DENVER PZ-7 Manual de OperacionDocument40 pagesGARNER DENVER PZ-7 Manual de OperacionSam RugeNo ratings yet

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDocument36 pagesMobile Offshore Drilling Units 2008: Rules For Building and ClassingMarc FazioliNo ratings yet

- AUDI AG Product Communications 85045 Ingolstadt GermanyDocument23 pagesAUDI AG Product Communications 85045 Ingolstadt Germanyapi-25932955No ratings yet