Professional Documents

Culture Documents

CT Faq

Uploaded by

Madhukar ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CT Faq

Uploaded by

Madhukar ParikhCopyright:

Available Formats

FAQBaldorRPMACTMCoolingTowerDirectDriveFANMOTOR& VS1CTDVariableSpeedControlSystem

Q. Whatisthistechnologyandhowdoesitdriveafandirectlywithoutspeedreducers?

A. BaldorRPMACTMCoolingTowerDirectDriveFanMotorisamarriageoftwoproven technologiesPermanentMagnet(PM)motorsforhightorque&compactsizeandVariable Frequencydrives(VFD)toprovideprecisespeedcontrol.ThestandardVFDincorporates speciallydesignedsoftwaredevelopedforthecoolingtowerfandriveindustry. Q. CanIreplacemycurrentgearbox&driveshaftwithaBaldorRPMACTMCoolingTower Motor?Whataboutmycurrentmotorstarter? A. Yesyoucandirectlyreplaceyourpresentgearbox&driveshaftwiththeBaldorRPM TM AC CoolingTowerMotor.Formostapplications,itwillsimplybolttoyourpresentgear mountwithoutmodification.Insomecasesanadapterplatewillberequiredwhichwillmatch theexistinggearboxboltholepatternandthatofthenewBaldormotorboltpattern.Your currentmotorstarterwillbereplacedbytheincludedVFDdrivewhichwilloftenmountclose toyourpresentstarterlocation. Q. Isitagoodideatooperateanelectricmotorinthehot,moistairstreamofacooling tower? A. Inthiscase,yes.ThemotorisTEAO(TotallyEnclosed,AirOver)essentiallysealedwitha capabilityofoperatingina40C(104F)ambienttemperatureandasealedClassHinsulation. Additionally,whenthemotoristurnedOFF,aDCtricklecurrentisappliedtokeeptheinterior warmandcondensationburnedoff,afeaturethateliminatestheneedforinternalspace heaters.Themotorcasingalsohasgenerouscoolingfinstodissipateheat.Inproshaftsealwith backupslingerhelpsprotectfromenvironmentingress.100%greasefilleliminatesvoidsand minimizescondensationdamageaswellasprovidesagreasedamassistinginsealingthe system. Q. Whatifthemotorneedsservicingorrewindingafterthewarrantyperiod?WheredoI takeit? A. AlthoughtheBaldorRPMACTMCoolingTowerMotordoesincorporatethelatest PermanentMagnettechnology,itcaneasilyberewoundatanyBaldorserviceshop.Thestator windingistypicalofastandardinductionmotor. Q.

Willwindmillingadverselyaffectthemotor?

A. No.TheautomaticDCtricklecurrentwhenthedriveisOFFwillalsosupplyabraking forcetothemotorpreventingwindmilling.Thisfeaturereplacesexistingmechanicalbrakes. However,ifDCtricklecurrentisnotappliedforsomereason,windmillingwillnotaffectthe motororVFDdrive. Q. Willwindmillingadverselyaffectthemotorunderhurricaneconditions?

A. Weassumethatunderhurricaneconditionswherepowerislost,thatagustofwind couldcauseafanspeedof125%ofbasespeed.Ifamotorisdesignedfor460VacRMSat100% speed,thenthisisanominalbusvoltageof650Vdc.TheBaldorCTdrivesaredesignedto withstandaround800Vdconthebus.WhenaBaldorRPMACTMCTmotoriswindmilling withoutanypowerappliedfromthedrive,thegeneratedvoltagebacktothedriveislessthan thatrequiredtooperateitfromthedrive.Forexample:a30HPmotoroperatinga12ftfanwill generatearound280Vacwhenrotatingatbasespeedof292RPM.Thuswhenrotatingat125% speed,thevoltagebeinggeneratedbacktothedriveisstillwithinthedesignlimits. Q. IfIonlyhaveasinglespeedmotornow,whywouldIneedaVFDdrive?

A. TheVFDdriveisrequiredtooperatethenewCTPMmotorbutitcanbeeasily programmedtosimplyramptofulldesignspeedeachtimeitstarts.Theadvantageofthe slowstartcapabilityinherentinaVFDdriveincludeenergysavingbynothavingthenormal inrushcurrenttypicalduringnormalmotorstartups.Thisslowstartrampwillalsoprovideless mechanicalstressontheoverallsystemandinsomecasesremovetheneedfortorquetubes. AlsodriveshavethecapabilitytocommunicatewithcommonHVACinterfacessuchasBACnet, JohnsonControlsMetasysN2,LonWorksandMODBUSRTUwhichcanadjustfanspeedbased onrequiredsystemload.Thiscapabilitycanhaveamajorimpactonenergysavingsandtotal systemefficiency. Q. Whataboutmoisturegettingintothebearings?

A. TheverylatestInproVBXXsealsandashaftslingerareincorporatedintothedriveend shafttominimizecontaminationingress.Thebearingcavitiesarelubricantpacked100%to eliminatevoidsandminimizecondensationcontamination.Thereisonlyoneentrypointfor contaminateswiththisdesign,nottwoasisstandardforgearboxes.Thetopendbrackethas beendesignedwithacastdraftanglewhichwillfunnelstandingwateroffofthemotorinthe staticcondition.Intheoperatingconditiontheflingercentrifugalforcewilldrivecontamination awayfromtheonlyingresspoint. Q. CanIuseageneralpurposeACDrivetocontrolthismotor?

A. TheBaldorCTDDriveutilizesaunique,customfirmwareforoptimalcontrolofthe CoolingTowerMotorandispowermatchedforthePermanentMagnetTechnology. Q. Whatkindofwarrantyisoffered?

A. Afull5yearwarrantyappliestoboththemotorandVFDdrivepackagefrom manufacturingdefectsandperformance.Fanbalancemaintenanceandrelubricationofmotor bearingsarestillrequired.(Refmotorrelubricationfrequencyrecommendationsbelow) Q. A. Q. Whataboutmotorlubricationfrequency? Astandard12monthrelubricationcycleisrequiredonbothbearings. IsthereadangeroftheVFDoverdrivingmyfanstospeedshigherthanrated?

A. No.TheVFDdrivesaretorquelimitedthuspreventingoverspeedbutadditional measuresalsopreventthissinceexcessivefanspeedswouldalsorequireexcessivedrive current.EachVFDdrivehasbuiltinelectronicmotoroverloaddetectionwhichwill immediatelyshutdowntheunitintheeventofoveramperage. Q. Arethebearingsprotectedfrommotorshaftcurrentdamage?

A. AlloftheBaldorCTmotorbearingsareprotectedfromshaftcurrentdamage.Smaller Hpunitshaveceramiccoatedbearingouterrings.AndthelargerHpunitshavetheend bracketswithaceramicsleevetopreventthepassageofshaftcurrentsthruthebearings. Q. CanIusemycurrentBMSsoftwarewiththisnewmotor?

A. Yes.TheBaldorVS1CTDCoolingTowerdrivesarefullycompatiblewithallpopular communicationprotocols. Q. Whatkindofvibrationmonitoringoptionssuppliedwithmotor?

Eachmotorissuppliedwithavibrationpadwhichisusedtoattachavibrationswitch. A. Thiswouldbethesameaswhatisusedonthepresentdaygearboxsolutions.Ifvibration accelerometersarerequiredthenrequiredmountingholesotherthenstandardwouldneedto beknown. Q. Doesthissolutionhavesoftstartcapabilities?

A. Yesthepackagehassoftstartcapabilitieswhichrampupthespeedslowlyfromstopto fullspeed/load.Thisfeatureminimizesimpactstressestothetowerstructureandmechanical components.

Q.

IfIhaveabankof4towerscanIuseonedrivetorunallfourtowers?

A. TheBaldorCoolingTowerDirectDriveMotorsolutionrequiresonedriveforeach motor. Q. WhatisthemotorPowerFactor(PF)?

A. TheBaldorCTmotorPFisintherangeof88whichisapproximately5%higherthana typicalACmotorPF.AnotheradvantagetotheBaldorCTmotorPFisthatitonlyreduces slightlyastheloaddecreases.Unlikeastandardmotorwhichreducesatahigherrateasthe loaddecreases.OneofthemainreasonsisthenoslipadvantageoftheBaldordesign. Q. WhatisthemotorbearingratedL10life?

A. AlltheBaldorCTmotorbearingsareratedforanABMAL10lifeofgreaterthan100,000 hours.Thesmallerhpmotorsutilizeballbearingsandthelargerhpunitshavetaperedroller bearings. Q. IpresentlyhaveaheaterwithinmygearboxwillIalsoneedaheaterwithintheBaldor CTmotor? A. NotheBaldorCTmotor&drivepackagewillsenseoncethemotor/fanhasstoppedfor 5minutesatwhichtimethedrivewillsendatricklecurrenttothemotorcreatinganinternal heatsource.Thishasanumberofbenefits.Itminimizesthepossibilityofcondensationwithin themotorduringperiodsofidleconditions.Italsowarmsthegreasewithinthebearingsto minimizestartingfrictionafterlongperiodsofdowntimeinwintermonths. Q. NoiseisbecomingagreaterconcernhowdoestheBaldorsolutioncomparetoexisting solutions? A. TestingaccordingtoCTIStdATC128hasshownuptoa5dBAreductionatthefandeck withtheBaldorsolution. Q. WhatkindofairflowisrequiredovertheBaldorCTmotor?

A. TheBaldorCTmotorisdesignedbasedoncatalogedhpratingstorequireanairflowof 750fpmoverthemotor.Ifagreaterthan750fpmairflowoverthemotorispossiblethenthe hpcapabilitiesofthemotoraregreatlyincrease. Revdate7222009

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Solar Energy Fundamentals (Citizenre Training)Document69 pagesSolar Energy Fundamentals (Citizenre Training)Earth Phone90% (20)

- A Homebuilt Threshing Machine For Small HoldersDocument62 pagesA Homebuilt Threshing Machine For Small HoldersJaremy Scott Golightly100% (1)

- Evaluation of A Bio CurtainsDocument7 pagesEvaluation of A Bio CurtainsrenicolaiNo ratings yet

- User'S Manual: Mitsubishi Heavy Industries Ltd. Packaged Air ConditionerDocument12 pagesUser'S Manual: Mitsubishi Heavy Industries Ltd. Packaged Air ConditionerPaing Phyo Ko50% (2)

- 2014-4968-1L-1002 - Rev. D HVAC Specification For LQ ModuleDocument60 pages2014-4968-1L-1002 - Rev. D HVAC Specification For LQ ModuleArshavin Watashi Wa100% (1)

- Rotary Club Admiration ManualDocument25 pagesRotary Club Admiration ManualMadhukar ParikhNo ratings yet

- CTV049Document47 pagesCTV049Madhukar ParikhNo ratings yet

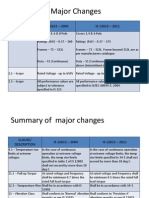

- Summary of Major Changes Is 12615 2011Document8 pagesSummary of Major Changes Is 12615 2011Madhukar ParikhNo ratings yet

- CHP Thermally Activated Lithium BromideDocument50 pagesCHP Thermally Activated Lithium BromideMadhukar ParikhNo ratings yet

- Pima N-Power Solutions MJP2Document24 pagesPima N-Power Solutions MJP2Madhukar ParikhNo ratings yet

- JNNSM FinalDocument104 pagesJNNSM FinalMadhukar ParikhNo ratings yet

- Intelligent Mcc-White PaperDocument5 pagesIntelligent Mcc-White PaperMadhukar ParikhNo ratings yet

- Give Your Motor A Health Check With The E3: Electronic Motor Protection Relays E3 and E3 PlusDocument28 pagesGive Your Motor A Health Check With The E3: Electronic Motor Protection Relays E3 and E3 PlusMadhukar ParikhNo ratings yet

- School Project Who Am IDocument37 pagesSchool Project Who Am IMadhukar ParikhNo ratings yet

- Cooling TowersDocument57 pagesCooling TowerspreanandNo ratings yet

- Oil Refinery Industry: Assignment 1Document19 pagesOil Refinery Industry: Assignment 1Azni ZulkifliNo ratings yet

- Finalvalue Usb FanDocument9 pagesFinalvalue Usb FanDianne De FranciaNo ratings yet

- Heater System Article TextDocument5 pagesHeater System Article TextCopyShop SuceavaNo ratings yet

- TCB CatalogDocument32 pagesTCB Catalogm1n1bl4ckNo ratings yet

- Rules For Building and Classing Mobile Offshore Drilling Units - 2015Document177 pagesRules For Building and Classing Mobile Offshore Drilling Units - 2015Adriano CostaNo ratings yet

- Klima ProduktiDocument78 pagesKlima ProduktiPavle PerovicNo ratings yet

- Interview Q and Ans FOR THARMAL POWER PLANTDocument15 pagesInterview Q and Ans FOR THARMAL POWER PLANTRajkumar Prasad100% (2)

- Case PDFDocument87 pagesCase PDFTeresa Marina PeraltaNo ratings yet

- Generator Sizing CalculatorDocument4 pagesGenerator Sizing CalculatorNedunuri.Madhav Murthy100% (1)

- Accesorii Estap PDFDocument41 pagesAccesorii Estap PDFmaluxroNo ratings yet

- AHU Instalation Manual YorkDocument36 pagesAHU Instalation Manual YorkBangto Yibsip50% (2)

- ME 439 Refrigeration and Air ConditioningDocument3 pagesME 439 Refrigeration and Air ConditioningMuhammad AliNo ratings yet

- NT 3036 - Handout 1 - Introduction To Air ConditioningDocument23 pagesNT 3036 - Handout 1 - Introduction To Air ConditioningAnonymous 1Z5K9QXNo ratings yet

- APOGEE Unit Conditioner Controller - Electronic Output Owner S Manual - A6V10308415 - Us en PDFDocument44 pagesAPOGEE Unit Conditioner Controller - Electronic Output Owner S Manual - A6V10308415 - Us en PDFhuy1983No ratings yet

- 09 Se CatalogDocument80 pages09 Se CatalogOtto AcnNo ratings yet

- MHI VRF Indoor Unit SpecsDocument36 pagesMHI VRF Indoor Unit SpecsPH LimNo ratings yet

- ThesisDocument124 pagesThesisRonel PagcaliwaganNo ratings yet

- Tender Specifications EC-Mitteldruck-Axialventilator 1120-1600 enDocument2 pagesTender Specifications EC-Mitteldruck-Axialventilator 1120-1600 enspscribd1No ratings yet

- Fisaire DFRC ManualDocument23 pagesFisaire DFRC ManualLjiljana GlisicNo ratings yet

- Trane FWDDocument12 pagesTrane FWDFrinaru CiprianNo ratings yet

- REHS0883 - Installation and Maintenance of The Fumes Disposal Filter PDFDocument18 pagesREHS0883 - Installation and Maintenance of The Fumes Disposal Filter PDFvoivod6No ratings yet

- WKH ManualDocument60 pagesWKH ManualantmangNo ratings yet

- TVDC SWGRDocument108 pagesTVDC SWGRDeepak JayNo ratings yet

- Kks CodeDocument11 pagesKks CodeJason GarrettNo ratings yet

- NVHDocument30 pagesNVHAjay YadavNo ratings yet