Professional Documents

Culture Documents

CH 5 Piles

Uploaded by

qasu175Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH 5 Piles

Uploaded by

qasu175Copyright:

Available Formats

i

Chapter 5

PILES

CHAPTER 5

5.1 Piles

- For piles the length to width (diameter) ratio i.e. Lp/d > 4 , where Lp is the

pile length and d is pile diameter.

- The basic situation for a pile foundation is where soft soil exists near the

ground surface which underlain by rock formation e.g.

Figure 5-1 Pile foundation resting on hard stratum underlying a soft soil

layer

5.2 Uses of Piles

Piles are commonly used for the following purposes (Figure 5-2).

- To carry superstructure loads into or through a soil stratum. Both vertical

and lateral loads may be involved.

Building

Soft Soil

Piles

Firm Soil

2

- To resist uplift or overturning forces such as for basement mats below the

W.T. or to support the tower legs subjected to overturning from lateral loads

such as wind.

- To compact loose, cohesionless deposits through a combination of pile

volume displacement and driving vibration, thus increasing their bearing

capacity.

- To carry the foundation through the depth of scour to provide safety in the

event the soil is eroded away.

- To stiffen the soil beneath machine foundations to control both amplitudes

of vibration and the natural frequency of the system.

- In offshore construction to transmit the loads above the water surface

through the water and into the underlying soil. This case is one in which

partially embedded piling is subjected to vertical (and buckling) as well as

lateral loads.

Figure 5-2 (a) Tension pile to resist overturning movements in tall buildings (b) Shear pile to

resist horizontal forces or movements Friction pile (c) raking piles in harbor and river

(a)

(b)

(c)

tension

compression

Wind

3

5.3 Classification of Piles

5.3.1 Classification according to the mechanism of load transfer

End/Point Bearing Piles

If a bedrock or rocklike material is present at a site within a reasonable depth,

piles can be extended to the rock surface (figure 5-3(a)). In this case, the

ultimate bearing capacity of the pile depends entirely of the underlying

material; thus the piles are called end or point bearing piles. In most of these

cases the necessary length of the pile can be fairly well established.

Instead of bedrock, if a fairly compact and hard stratum of soil is encountered at

a reasonable depth, piles can be extended a few meters into the hard stratum.

Friction Piles (figure 5-3 b)

When no layer of rock or rocklike material is present at a reasonable depth at a

site, point/end bearing piles become very long and uneconomical. For this type

of subsoil condition, piles are driven through the softer material to specified

depth. These types of piles are called friction piles because the load on the pile

is resisted mainly by skin/friction resistance along the side of the pile (pile

shaft). Pure friction piles tend to be quite long, since the load-carrying capacity

is a function of the shaft area in contact with the soil.

In cohesionless soils, such as sands of medium to low density, friction piles are

often used to increase the density and thus the shear strength.

Friction cum end bearing piles

In the majority of cases, however, the load-carrying capacity is dependent on

both end-bearing and shaft friction (figure 5-3 c).

4

5.3.2 Classification of piles according to their method of

installation (figure 5-4)

Driven or displacement piles

They are usually preformed before being driven, jacked, screwed or hammered

into ground. This category consists of driven piles of steel or precast concrete

and piles formed by driving tubes or shells which are fitted with a driving shoe.

The tubes or shells which are filled with concrete after driving. Also included in

this category are piles formed by placing concrete as the driven piles are

withdrawn.

Bored or Replacement piles

They require a hole to be first bored into which the pile is then formed usually

of reinforced concrete. The shaft (bore) may be cased or uncased depending

upon type of soil.

Soft

ground

hard

Soft to

firm

Soft to

firm

Firm to

hard

Soft

Figure 5-3(a) End bearing pile (b) Friction pile (c) friction cum end bearing pile

(a) (b)

(c)

5

5.3.3 Classification of Piles according to Materials

Timber piles

- Timber piles are made of tree trunks driven with small end as a point

- Maximum length: 35 m; optimum length: 9 20m

- Max load for usual conditions: 450 kN; optimum load range = 80240

kN

- Disadvantages: difficult to splice, vulnerable to damage in hard driving,

vulnerable to decay unless treated with preservatives (If timber is below

permanent W.T. it will apparently last for ever), if subjected to alternate

(a) (b) (c)

(d)

(e) (f)

Figure 5-4 Principal types of pile: (a) precast RC pile (b) steel H pile (c) shell

pile (d) concrete pile cast as driven tube withdrawn (e) bored pile (cast in

situ), (f) under-reamed bored pile (cast in situ)

6

wetting & drying, the useful life will be short, partly embedded piles or

piles above W.T. are susceptible to damage from wood borers and other

insects unless treated.

- Advantages: comparatively low initial cost, permanently submerged piles

are resistant to decay, easy to handle, best suited for friction piles in

granular material.

Steel Piles

- Max length: practically unlimited,

- optimum length: 1250 m

- load for usual conditions = maximum allowable stress x-section area,

- Optimum load range = 3501050 kN

- The members are usually rolled HP shapes/pipe piles. Wide flange beams

& I beams proportioned to withstand the hard driving stress to which the

pile may be subjected, In HP pile the flange thickness= web thickness,

pipe piles are either welded or seamless steel pipes, which may be driven

either open ended or closed end. Closed end piles are usually filled with

concrete after driving. Open end piles may be filled but this is not often

necessary.

- Advantages: easy to splice, high capacity, small displacement, able to

penetrate through light obstructions, best suited for end bearing on rock,

reduce allowable capacity for corrosive locations or provide corrosion

protection.

- Disadvantages: Vulnerable to corrosion, HP section may be

damaged/deflected by major obstruction

Concrete Piles

- Concrete piles may be precast, prestressed, cast in place, or of composite

construction.

- Precast concrete piles may be made using ordinary reinforcement or they

may be prestressed.

7

- Pecast piles using ordinary reinforcement are designed to resist bending

stresses during picking up & transport to the site & bending moments

from lateral loads and to provide sufficient resistance to vertical loads

and any tension forces developed during driving.

- Prestressed piles are formed by tensioning high strength steel prestress

cables, and casting the concrete about the cable. When the concrete

hardens, the prestress cables are cut, with the tension force in the cables

now producing compressive stress in the concrete pile. It is common to

higher-strength concrete (35 to 55 MPa) in prestressed piles because of

the large initial compressive stresses from prestressing. Prestressing the

pile tends to counteract any tension stresses during either handling or

driving.

- Max length: 1015 m for precast, 2030 m for prestressed

- Optimum length: 1012 m for precast, 1825m prestressed

- Loads for usual conditions 900 for precast, 8500 kN for prestressed

- Optimum load range: 3503500 kN

- Disadvantages: difficult to handle unless prestressed, high initial cost,

considerable displacement, prestressed piles are difficult to splice.

- Advantages: high load capacities, corrosion resistance can be attained,

hard driving possible

- Remarks: cylinder piles in particular are suited for bending resistance.

- Cast in place concrete piles are formed by drilling a hole in the ground &

filling it with concrete. The hole may be drilled or formed by driving a

shell or casing into the ground.

- Disadvantages of Concrete piles: Concrete piles are considered

permanent, however, certain soil (usually organic) contain materials that

may form acids that can damage the concrete. Salt water may also

adversely react with the concrete unless special precautions are taken

when the mix proportions are designed. Additionally, concrete piles used

for marine structures may undergo abrasion from wave action and

floating debris in the water. Alternate freezing & thawing can cause

concrete damage in any exposed situation.

8

Composite piles

- In general, a composite pile is made up of two or more sections of

different materials or different pile types. The upper portion could be

cased cast-in-place concrete combined with a lower portion of timber,

steel H or concrete filled steel pipe pile. These piles have limited

application and are employed under special conditions.

5.4 Load Capacity of Piles

Three general methods are available to establish load capacity:

(1) Static Analysis (2) Dynamic Analysis (3) Load Testing (4) Correlation

with field tests (SPT, CPT etc)

Dynamic formulae are used for driven piles. Static formulae are used both for

bored and driven piles. Load testing is the most reliable method to determine

the load capacity of the pile in the field. They should be performed on all piling

projects. However, they are considerably more expensive than the other

methods used to determine pile capacity, and economic consideration

sometimes preclude their use on projects. Field tests like SPT, CPT are also

used to correlate to load carrying capacity particularly for cohesionless soils.

5.5 Driven Piles

5.5.1 Dynamic Pile Formulas

Piles are usually forced into the ground by a pile driver or pile hammer. In

medieval times piles were driven by men manually swinging hammer, which

consists of a weight raised by ropes or cables and allowed to drop freely

striking the top of the pile. After the drop hammer came the single acting

hammer, double acting hammer, differential acting hammer, diesel pile

hammer, vibratory driver.

Dynamic pile formulas are widely used to determine the static capacity of the

driven pile. These formulas are derived starting with the relation

Energy Input = Energy Used + Energy Lost

The Energy used equals the driving resistance (Pu) the pile movement (s).

9

Energy lost is due to friction, heat, hammer rebound, vibration and elastic

compression of the pile, the pacing assembly, and the soil.

Energy News Record (ENR) Formula:

This formula takes into account the energy lost due to temporary compression

(C) resulting from elastic compression of the pile. Thus

Energy Input = Energy Used + Energy Lost

Wr h = Pu s + Pu C

Pu = Wr h / (s + C)

Where Wr = weight of the ram, h= height of fall of the ram, s = penetration of

pile per hammer blow, Pu = average resistance of soil to penetration.

C= 25 mm (1 inch) for drop hammer, and

C= 2.5 mm (0.1 inch) for steam hammer (single acting/double acting)

Pa = Pu / SF where Pa = allowable load on pile, and SF(factor of safety) = 6

For single/double acting hammer, the term (Wr h) can be replaced by q

h

E

where q

h

=hammer efficiency (table-1) and E=rated energy of hammer. Thus

Pu = q

h

E / (s + C)

Table-1: Hammer efficiency q

h

Table 5-1 Hammer efficiency q

h

Hammer type Efficiency

q

h

Single and double acting

hammer

0.7-0.85

Diesel hammers 0.8-0.9

Drop hammers 0.7-0.9

10

Example: A precast concrete pile 12in 12 in in cross section is driven by a

steam hammer. The maximum rated hammer energy = 26 kips-ft, hammer

efficiency = 0.8 and the number of blows for the last 1 inch of penetration = 5.

Estimate the allowable pile capacity by using (a) ENR formula using SF=6.0

Solution:

ENR formula:

q

h

= 0.8, E=26 kip-ft, s=1/5 = 0.2 inch/blow. SF=6.0

SF C s

E

Pa

h

) ( +

=

q

= 0.8 26 12 / [ (0.2 + 0.1) 6 ] = 836 kips

5.5.2 PILE DRIVING EQUIPMENT

Piles are installed by a special pile driving device know as a pile hammer. The

hammer may be suspended from the boom of a crawler crane, supported on a

large frame called a pile driver or carried on a barge for construction in water.

In all cases, the hammer is guided between two parallel steel members called

leads. The leads may be adjusted at various angles for driving vertical and

batter piles.

Several types of hammers are in use and each of which are different sizes. The

hammer types are:

Drop hammer

The drop hammer consists of a heavy ram in between the leads. The ram is

lifted up to a certain height and released to drop on the pile. This type is slow

and therefore not in common use. It is used in the cases where only a small

number of piles are driven.

Single-acting hammer

In single acting hammer a heavy ram is lifted up by steam or compressed air but

dropped by its own weight. The energy of a single acting hammer is equal to

the weight of the ram times the height of fall.

Double-acting hammer

The double-acting hammer employs steam or air for lifting the ram and for

accelerating the downward stroke. The energy of a double-acting hammer is

11

equal to the (weight of the ram + mean effective pressure x the effective area of

ram) x times the height of fall.

Diesel hammer

The diesel hammer is a small, light weight and highly mobile. They use

gasoline for fuel. To start the operation, the ram is raised, and the fuel is

injected. As the ram is released, the ram falls and compresses air and fuel. The

air and fuel becomes hot because of the compression and the air-fuel mixture is

ignited. The resulting explosion (1) advances the pile and (2) lifts the ram. If the

pile advance is very great as in soft soils, the ram is not lifted by the explosion

sufficiently to ignite the air-fuel mixture on the next cycle, requiring that the

ram be again manually lifted.

Vibratory hammer

The principle of the vibratory driver is two counter-rotating eccentric weights.

The driving unit vibrates at high frequency and provides two vertical impulses-

one up and one down. The downward pulse acts with the pile weight to increase

the apparent gravity force. These hammers have reduced driving vibrations,

reduced noise, and great speed of penetration.

5.5.3 HAMMER SELECTION

Generally the size of hammer is more important factor than type of hammer.

A heavy pile should be driven by a heavy hammer delivering large energy.

Preferably the weight of the hammer should be at least on-half the total weight

of the pile, and the deriving energy should be at least one foot-pound for each

pound of pile weight.

Each type of hammer has its use under suitable conditions. The advantages and

disadvantages of each type are summarized below:

Single-acting hammer

They are advantageous when driving heavy piles in compact or hard soils; the

heavy ram striking at low velocity produces least damage due to impact. The

disadvantages are low driving speed and large headroom requirement.

Double-acting hammer

12

They are generally used to drive piles of light or moderate weight in soils of

average resistance against driving. This type of hammer can drive piles at fast

speed, requires less headroom and can be used to extract piles by turning them

[i.e. the double-acting hammer] upside down.

Diesel hammer

They are similar in application as double-acting hammers, but driving may

become difficult in extremely soft ground.

Vibratory hammer

They have fairly good results in silty and clayey deposits. They are used in

heavy clays or soils with appreciable numbers of boulders. These hammers

have reduced driving vibrations, reduced noise, and great speed of penetration.

5.6 STATIC PILE FORMULAS

The ultimate load which can be carried by a pile is equal to the sum of the base

resistance and the shaft resistance (figure 5-5).

P

u

+ W

p

= A

b

q

b(gross)

+ A

s

q

s

P

u

is the ultimate load that can be carried at top of pile, q

b

ultimate (gross)

bearing capacity at base level, A

b

= base area of pile, q

s

=ultimate shearing/skin

resistance per unit area, A

s

= perimeter area of pile, and Wp = weight of the pile.

Subtracting Ws from both sides of the equation. Where Ws is effective soil

weight replaced/displaced due to pile volume. Ws = 'LA

b

where ' is the

effective weight of soil, and L is pile length.

P

u

+ (W

p

Ws)= A

b

q

b(gross)

+ A

s

q

s

-Ws

P

u

+ (W

p

Ws) = A

b

q

b(gross)

+ A

s

q

s

- 'LA

b

P

u

+ (W

p

Ws) = (q

b(gross)

- 'L)A

b

+ A

s

q

s

P

u

+ (W

p

Ws) = (q

b(gross)

- oo')A

b

+ A

s

q

s

Where oo'='L is effective vertical stress at pile base

P

u

+(W

p

Ws) = A

b

q

b

+ A

s

q

s

13

P

u

= A

b

q

b

+ A

s

q

s

(W

p

Ws)

P

u

= A

b

q

b

+ A

s

q

s

W

P

u

is the ultimate load that can be carried at top of pile, q

b

ultimate (net) bearing

capacity at base level, A

b

= base area of pile, q

s

=ultimate shearing/skin

resistance per unit area, A

s

= perimeter area of pile, W= Wp Ws = weight of

the pile effective weight of soil replaced. In most cases Wp~ Ws and hence

W~0.

P

u

= A

b

q

b

+ A

s

q

s

However in the case of under-reamed piles (figure 5-4 f) the reduction in

pressure on the soil at base level due to the removal of soil is greater than the

subsequent increase in pressure due to the weight of the pile and hence use

equation-1 (i.e. do not assume that W

p

~ W

s

)

5.6.1 COHESIONLESS SOILS

End bearing Resistance (q

b

)

q

s

q

b

W

P

Figure 5-5 Free body diagram of a pile

P

u

14

The ultimate B.C. and settlement of a pile depends mainly on the relative

density of sand. However, if a pile is driven into sand the relative density

adjoining the pile is increased by compaction due to soil displacement (except

in dense sands, which may be loosened). The soil characteristics governing

ultimate bearing capacity and settlement, therefore, are different from the

original characteristics prior to driving. This fact, in addition to the

heterogeneous nature of sand deposits, makes the prediction of pile behavior by

analytical methods extremely difficult.

The ultimate (net) B.C. at base level can be expressed as

q

b

= cN

c

+ o

o

' N

q

+ B N

-o

o

' [o

o

' is subtracted to get net value of q

b

]

Where o

o

' is the effective overburden pressure at base level of pile.

q

b

= cN

c

+ o

o

'(N

q

-1) + B N

c=0 for sand and 1/2BN

term can be neglected because the B (width/diameter

of pile) is small compared to the length of pile. so

q

b

= o

o

' (N

q

-1) ~ o

o

'N

q

(N

q

-1) ~ N

q

[because reduction of N

q

by 1 is a

substantial refinement not justified by estimated soil parameters]. N

q

is a B.C.

factor (figure 5-6)

15

Figure 5-6: Values of Nq for pile formulae (After Berezantsev et al. 1961)

16

Friction/Shaft Resistance (qs):

The average value of skin resistance (q

s

) over the length of pile embedded in

sand can be expressed as

o o tan ' ' + = c q

s

Where

'

'

o s

K o o = and c=0

o o tan

'

o s s

K q =

K

s

a coefficient of earth pressure dependent largely on the relative density of

the soil, ' o = average effective pressure in the layer perpendicular to q

s

(i.e.

horizontal).

'

o

o = average effective vertical overburden pressure in the layer, and

o=angle of friction between the pile and the soil.

Table 5-2 K

s

and o values

Pile Type o

K

s

Loose Sand Dense Sand

Concrete 3/4 | 1.0 2.0

Steel 20 0.5 2.0

Wood 2/3 | 1.5 4.0

Variation of q

b

and q

s

with depth

The above equations for q

b

and q

s

indicate a linear increase with depth of q

b

and

q

s

. However, tests on full scale and model piles have shown that these equations

are valid up to certain depth called critical depth (z

c

). Below this depth z

c

(=15d

to 20d, conservatively take z

c

= 15 d), base (q

b

) and shaft/skin (q

s

) resistances

do not develop linearly [i.e. become constant]. This is because the vertical

effective stress adjacent to the pile is not necessarily equal to the effective

overburden pressure (away from the effect of pile) but reaches a limiting value

at critical depth z

c

(figure 5-7).

17

q

b

and q

s

from SPT Test

Ultimate base resistance q

b

Due to the critical depth limitation and to the difficulty of obtaining values of

the required parameters, the above equations are difficult to apply in practice. It

is preferable to use empirical correlations

The following empirical correlations have been proposed by Meyerhof for

driven piles in sand.

q

b

= (40N

55

)L

b

/B s 400N

55

(kN/m

2

)

N= is the value of standard penetration resistance in the vicinity of the pile base.

Use any applicable SPT N corrections discussed in earlier chapter-3.

B = width or diameter of pile point

L

b

= the length of pile embedded in sand

Skin friction resistance

W.T.

d

o

oc

'

d

o

oc

'

z

c

=15 d

z

c

=15d

Figure 5-7 Effective vertical stress distribution diagram adjacent to pile

18

Skin friction resistance is N q

s

2 = [kN/m

2

]

Where N is the average value of standard penetration resistance over the

embedded length of the pile within the sand stratum.

The values of q

s

should be halved in the case of small displacement piles such

as steel H piles. For bored piles the values of q

b

and q

s

are approximately 1/3

and 1/2, respectively, of the corresponding values for driven piles.

5.7 COHESIVE SOILS

5.7.1 Driven Piles

In the case of driven piles, the clay adjacent to the pile is displaced both

laterally and vertically. Upward displacement of the clay results in heaving of

the ground surface around the pile and can cause a reduction in the bearing

capacity of adjacent piles already installed. The clay in the disturbed zone

around the pile is completely remoulded during driving. The excess porewater

pressure set up by the driving stresses dissipates within a few months as the

disturbed zone is relatively narrow (of the order B): in general, dissipation is

virtually complete before significant structural load is applied to the pile.

Dissipation is accompanied by an increase in skin friction. Thus the skin

friction at the end of dissipation is normally appropriate in design.

5.7.2 Bored Piles

In the case of bored piles, a thin layer of clay (of the order of 25 mm)

immediately adjoining the shaft will be remoulded during boring. In addition, a

gradual softening of the clay will take place adjacent to the shaft due to stress

release, pore water seeping from the surrounding clay towards the shaft. Water

can also be absorbed from wet concrete when it comes in contact with the clay.

Softening is accompanied by a reduction in shear strength and a reduction in

skin friction. Construction of a bored pile, therefore, should be completed as

quickly as possible. Limited reconsolidation of the remoulded and softened clay

takes place after installation of the pile.

Base Resistance

19

The relavent shear strength for the determination of the base resistance of a pile

in clay is the undrained strength at base level. The ultimate bearing capacity is

expressed as

q

b

= c

u

N

c

+ o

o

' N

q

+ B N

-o

o

' [o

o

' is subtracted to get net value of q

b

]

1/2BN

term can be neglected because the B (width/diameter of pile) is small

compared to the length of pile and for |u=0, Nq=1, we get

q

b

= c

u

N

c

where N

c

= 9, and cu is undrained shear strength at pile base

Skin Resistance

Total Stress (Undrained Conditions |

u

=0)

) tan(

u a s

c q | o + = [where c

a

is average adhesion]

0 ) tan( =

u

| o as |

u

=0

Hence

u a s

c c q = = o is a coefficient depending on type of clay, the method of

installation, and the pile material. The appropriate value of o is obtained from

load tests. Values of o range from 0.3 to 1.

u

c is the average undrained shear

strength. One difficulty with this approach is that there is usually a considerable

scatter in the plot of undrained shear strength against depth and it may be

difficult to define the value of

u

c . See figure 5-8 for different values of o.

Effective Stress (drained conditions)

An alternative approach is to express skin friction in terms of effective stress.

The zone of soil disturbance around the pile is relatively thin, therefore

dissipation of the positive or negative excess pore water pressure set up during

installation should virtually be complete by the time the structural load is

applied. In principle, therefore, an effective stress approach has more

justification than one based on total stress. In terms of effective stress the skin

friction can be expressed as

) ' tan( '

'

| o

o s s

K c q + =

) ' tan(

'

| o

o s s

K q = [c=0 for saturated clay under drained conditions]

20

Where K

s

is the average coefficient of earth pressure and

'

o

o is the average

effective overburden pressure adjacent to the pile shaft. Failure is assumed to

take place in the remoulded soil close to the pile shaft, therefore the angle of

friction between the pile and the soil is represented by the angle of shearing

resistance in terms of effective stress (|) for the remoulded clay: the cohesion

intercept for remoulded clay will be zero. The above equation can also be

written as

'

o s

q o | = [where ) ' tan(| |

s

K = ]

Approximate value of | can be deduced by making assumptions regarding the

value of K

s

, especially in the case of normally consolidated clays. However, the

coefficient is generally obtained empirically from the results of load test carried

out a few months after installation. Correlations with loading tests have shown

that for soft clays | falls within a narrow range of values (0.25 to 0.4),

irrespective of the clay type.

21

Figure 5-8 Relationship between the adhesion factor o and undrained

shear strength s

u

(c

u

).

5.8 FACTOR OF SAFETY

The base resistance requires a larger deformation for full mobilization than the

shaft resistance, therefore different values of load factor may be appropriate for

the two components, the higher factor being applied to the base resistance.

In the case of large-diameter bored piles, including underreamed piles, the shaft

resistance may be fully mobilized at working load and it is advisable to ensure a

22

load factor of 3 for base resistance, with a factor of 1 for shaft resistance, in

addition to the specified over all load factor (generally 2) for the pile.

5.9 NEGATIVE SKIN FRICTION

When piles are driven through a layer of fill material which slowly compacts or

consolidates due to its own weight, or if the layers underlying the fill

consolidate under the weight of the fill, a downward drag is imposed in the pile

shaft (figure 5-9).

The skin friction between the pile and soil therefore acts in a downward

direction. The force due to this downward or negative skin friction is thus

carried by the pile instead of helping to support the external load on the pile.

Negative skin friction increases gradually as consolidation of the clay layer

proceeds, the effective overburden pressure gradually increasing as the excess

pore water pressure dissipates.

P

u

+ q

sN

As = q

b

A

b

+ q

s

A

s

where q

sN

is negative skin friction

(downward), A

sN

is the corresponding surface area of pile, q

s

is the skin friction

q

sN

q

b

q

sN

q

s

Fill: consolidating

under own weight

Soft clay: consolidating

under weight of fill

Firm or Hard bearing

layer

Figure 5-9 Negative skin friction

P

u

23

(upward) and A

s

is the corresponding surface areas of pile, A

b

is the end bearing

area of pile.

To calculate negative skin friction equation

'

o N s

q o | = can be used. In normally

consolidated clays, a value of |=0.25 represents a reasonable upper limit to

negative skin friction for preliminary design purposes.

It should be noted that there will be a reduction in effective overburden pressure

adjacent to the pile in the bearing stratum due to the transfer of part of the

overlying soil weight to the pile: if the bearing stratum is sand, this will result in

a reduction in bearing capacity above the critical depth.

5.10 PILE GROUP

Rarely is the foundation likely to consist of a single pile. Generally, there will

be a minimum of two of three piles under a foundation element or footing to

allow for misalignments and other inadvertent eccentricities.

The group of piles is installed fairly close together (typically 2B-4B where B is

the width or diameter of a single pile) and joined by a slab, known as the Pile

Cap, cast on top of the piles.

The cap is usually in contact with the soil in which case part of the structural

load is carried directly on the soil immediately below the surface. The group of

piles in this case is called piled foundation. If the cap is clear of the ground

surface, the piles in the group are referred to as free-standing (figure 5-10).

24

5.10.1 Load Distribution in Pile Group

It is generally assumed that the load distribution between the piles in an axially

loaded group is uniform.

However experimental evidence indicates that for a group in sand the piles at

the center of the group carry greater loads than those on the perimeter.

In clay, on the other hand, the piles on the perimeter of the group carry greater

loads than on those at the center.

5.10.2 Efficiency of Pile Group

In general the ultimate load which can be supported by a group of N piles is not

equal to N times the ultimate load of a single isolated pile of the same

dimensions in the same soil. Where N is the number of piles in a group. So

[in general] Ultimate load of Pile Group = N Ultimate load of a single pile

The ratio of the average load per pile in a group at failure to the ultimate load

for a single pile is defined as the efficiency of the group ().

Average load per pile in a group at failure = Ultimate group load / N

= ( Ultimate group load ] / ( N Ultimate Individual load )

Pile Cap

Pile Cap

(a) (b)

Figure 5-10 (a) A group of free-standing piles (b) A group of piled foundation

25

5.10.3 Pile Group in Cohesionless Soils

Driven Piles

The driving of a group of piles into loose sand or medium-dense sand causes

compaction of the sand between the piles, provided that the spacing is less than

about 8B: consequently the efficiency of the group is greater than unity. The

maximum efficiency is reached at a spacing of 2 to 3 diameters and generally

ranges between 1.3 to 2. It is recommended that in this case the design value

of =1 be taken.

In the case of piles driven into dense sand, the group efficiency is less than

unity due to loosening of the sand and the overlapping of zones of shear (figure

5-11).

Bored Piles

However, for a group of bored piles the efficiency may be as low as 2/3 because

the sand between the piles is not compacted during installation but the zones of

shear of adjacent piles will overlap.

26

Figure 5-11 Stress surrounding a friction pile and the summing effects of a

pile group

5.10.4 Pile Group in Cohesive Soils

A closely spaced group of piles (spacing = 2B to 3B) in clay may fail as a

unit, with shear failure taking place around the perimeter of the group and

Four piles contributing

to this stress zone

Three piles contributing to

this stress zone

Two piles contributing to

this stress zone

27

below the area covered by the piles and the enclosed soil. This is referred to as

Block Failure. (figure 5-12)

The ultimate load in the case of a pile group which fails as a block is given by

u sg b bg ug

c A q A P + =

A

bg

= base are of the group = Bg Lg; A

sg

= perimeter area of the group =

2D(B

g

+ L

g

); c

u

= undrained shear strength at depth D

u

c = average undrained shear strength between 0 and D below the ground.

qb=cuNc where N

c

=5.14 (1+0.2B

g

/L

g

) [ 1 + \(0.053D/B

g

) ] s 9

) ( 2

g g u g g u c ug

L B D c L B c N P + + =

Design Ultimate Load

Piled Foundation

The ultimate load should be taken as the lesser of the

Block Failure value (2) The sum of the individual pile values

Free Standing Group of Piles

The ultimate load should be taken as the lesser of the

(1) Block Failure value (2) 2/3 of the sum of the individual pile values

5.11 Settlement of Pile Group

The settlement of pile group is always greater than the settlement of a

corresponding single pile, as a result of the overlapping of the individual zones

of influence of the piles in the group. The bulbs of pressure of a single pile and

a pile group (with piles of the same length as the single pile) are of the form

illustrated in figure 5-13.

In order to estimate settlement for a pile group, it is assumed that the total load

is carried by an Equivalent raft located at a depth of 2L/3 where L is the

length of piles (figure 5-14). It may be assumed as shown in figure 5-14 that the

load is spread from the perimeter of the pile group at a slope of 1 horizontal to 4

vertical to allow for that part of the load transferred to the soil by skin friction.

The vertical stress increment at any depth below the equivalent raft may be

28

estimated by assuming in turn that the total load is spread to the underlying soil

at a slope of 1 horizontal to 2 vertical.

29

Pile Cap

Pile Cap

(a) A group of free-standing piles

(b) A group of piled foundation

L

g

B

g

D

D

L

g

B

g

D

Figure 5-12Block failure of pile group in clay

(c ) Dimensions of Failure block

30

Figure 5-13 Bulbs of pressure for a single and a pile group

31

Figure 5-14 Equivalent raft concept

5.12 Pile Load Test

The loading of a test pile enables the ultimate load to be determined directly

and provides a means of assessing the accuracy of predicted values.

Tests may also be carried out in which loading is stopped when the proposed

working load has been exceeded by a specified percentage.

Figure 5-15 shows a schematic diagram of the pile load test arrangement for

testing in axial compression in the field. The load is applied to the pile by a

hydraulic jack. The load is applied in suitable increments, allowing sufficient

time between increments for settlement to be substantially complete. According

to ASTM D1143, the test pile is loaded in eight equal increments up to a

maximum load, usually twice the predetermined working (allowable) load.

Unloading stages are normally included in the test program. This testing

procedure is Maintained load test (or Controlled load test).

In constant rate of penetration (CRP) test the pile is jacked into the soil at a

constant speed, the load applied in order to maintain the penetration being

continuously measured. Suitable rates of penetration for tests in sands and clays

are 1.5 mm/min and 0.75 mm/min respectively.

Another type of pile load test is cyclic loading, in which an increment load is

repeatedly applied and removed.

Driven piles in clays should not be tested for at least a month after installation

to allow most of the increase in skin friction (a result of dissipation of the

excess pore water pressure due to the driving stresses) to take place. Load tests

on piles in sand can be carried out immediately after the piles are driven.

5.12.1 Ultimate Load

Figure 5-15 shows load settlement diagram obtained from fried loading and

unloading. For any load Q, the pile settlement can be calculated as follows.

When Q=Q1,

net settlement, s

net(1)

= s

t(1)

s

e(1)

32

When Q=Q2

net settlement, s

net(2)

= s

t(2)

s

e(2)

and so on.

Where s

net

= net settlement

s

e

= elastic settlement of the pile itself

s

t

= total settlement

These values of Q can be plotted in a graph against the corresponding net

settlement, s

net

as shown in figure 5-15 (c). The ultimate load of the pile can be

determined from this graph. Pile settlement may increase with load to a certain

point, beyond which the load settlement curve becomes vertical. The load

corresponding to the point where Q-snet becomes vertical is the ultimate load,

Qu, for the pile. It is shown by curve 1 of the figure 5-15 (c ).

In many cases, the latter stage of the load-settlement curve is almost linear,

showing large degree of settlement for a small increment of load; it is shown by

curve 2 in figure 5-15 ( c). The ultimate load for such cases is determined from

the point of the curve where this steep linear portion starts.

5.12.2 Disadvantages

The performance of single pile does not correspond to actual conditions of

performance underneath the structure within the entire group of piles. (2) The

loading test must be performed at the actual construction site and under real

conditions of the blueprint conditions which are often difficult to fulfill and to

execute. (3) This method of test requires specially heavy, sturdy equipment and

platforms, precise settlement measuring devices, large quantities of dead load,

or powerful hydraulic jacks. (4) The aforementioned conditions and factors

make this kind of pile bearing capacity test very expensive.

33

34

Figure 5-15 (a) Schematic diagram of pile load test arrangement; (b) plot

of load against total settlement (c) plot of load against net settlement

35

Figure 5-16 Schematic setup for applying vertical load to the test pile using

a hydraulic jack acting against an anchored reaction frame

36

Problem 5-1Single Pile in Sand

A 12m long, 305mm square section pile is to be embedded in sand. Water table

is encountered at 3m depth below the ground surface. Sand has the following

properties: =16.8 kN/m

3

above WT, sat=18 kN/m

3

, |'=35. Angle of friction

between soil and pile is taken to be o=0.6|', lateral earth pressure coefficient

Ks=1.4. Calculate the ultimate compressive load.

Solution:

End-bearing resistance:

q

b

= o

o

'Nq from figure 5-6, L/B=12/0.305=40, and |'=35, Nq=42

q

b

= 54.742=2297.4 kPa

Friction resistance:

o o tan

'

o s s

K q =

First find average vertical effective stress along the pile length, it is

equal to the area under vertical effective stress distribution diagram

divided by the length of pile.

2 '

kN/m 46 = 4.575) - (12 54.7 + 2) - (4.575 54.7)/2 + (33.6 + 2)/2 (33.6 12 / 1 =

o

o

kPa k K q

o s s

7 . 24 ) 35 6 . 0 tan( 46 4 . 1 tan

'

= = = o o

L=12m

zc=150.305

=4.575 m

16.82=33.6 kPa

(18-9.81)(4.575-2)+33.6

=54.7 kPa

o

o

'=54.7 kPa

2m

37

Ultimate compressive load (Pu)

Pu = A

b

q

b

+ A

s

q

s

A

b

=0.305

2

= 0.093 m

2

, A

s

= 40.30512= 14.64 m

2

Pu= 0.0932297.4 + 14.6424.7 = 213.6 + 361.6 = 575.2 kN

Example 5-2 Single Pile Capacity in Sand using SPT

A precast concrete pile 450 mm square in section and 9 m long is to be driven

into a river bed which consists of a depth of sand. The standard penetration

resistance (N) at the pile base is 24, and the average value of N along the pile

length is 13. Calculate the ultimate compressive and tensile load carrying

capacity of the pile.

Solution

N = 24

13 = N

L

b

= 9.0 m

Ultimate compressive load capacity = A

b

q

b

+ A

s

q

s

Ultimate tensile load capacity = A

s

q

s

q

b

= (40N)Lb/B s 400N (kN/m

2

)

qb = 40 24 9/ 0.45 =

N q

s

2 = [kN/m

2

]

=2 13 = 26 kN/m

2

Problem 5-3, Single Pile in Clay

L=12

38

A 400mm, square section concrete pile is driven to an embedded depth of 12m

in a cohesive soil, which has the following properties, |u=0, =20 kN/m

3

both

above & below W.T., cu at 12m depth is 85.4 kPa. The water table is at a depth

of 3m. Assume |=0.4. Calculate safe load capacity for the pile adopting a FOS

of 3 for the base shear and factor of safety of 2.5 for skin resistance.

Solution

End bearing resistance

kPa cN q

c b

6 . 768 4 . 85 9 9c = = = =

Skin/friction resistance:

'

=

o s

q o |

Let us find average effective overburden pressure

kPa

o

9 . 86 )] 3 12 ( 2 / ) 60 7 . 151 ( 2 / ) 60 3 [( 12 / 1 = + + =

'

o

kPa q

o s

7 . 34 9 . 86 4 . 0 = =

'

= o |

Ultimate & Allowable Compressive loads:

s s b b u

q A q A P + =

kN P

u

792 2 . 666 8 . 125 7 . 34 12 ) 4 . 0 4 ( 6 . 786 ) 4 . 0 4 . 0 ( = + = + =

L=12m

203=60 kPa

(20-9.81)(12-3)+60=151.7 kPa

3m

39

kN P

a

308

5 . 2

2 . 666

3

8 . 125

= + =

Problem 5-4Pile Group in Clay

Determine the safe load capacity for a square group of 9 piles in cohesive soil.

Safety factor 2.5 against block failure. =20 kN/m

3

, cu at the base 85.4 kPa,

average undrained shear strength =60.2 kPa, |u=0. Pu for single pile is equal to

819 kN.

Given Data

No of piles = n = 9, =20 kN/m3, cu (base) = 85.4 kN/m2, cu (avg.) = 60.2 kPa

P

u

(single pile) = 819 kN

Required

Safe Load Capacity of pile group = Pug

Solution

s s b b gp u

q A q A P + =

) (

2

/ 2 . 60 m kN c q

u s

= =

c u b

N c q =

Find N

c

by using the relation:-

9 053 . 0 1 2 . 0 1 14 . 5 s

(

(

+

(

(

+ =

g g

g

c

B

D

L

B

N

9

25 . 2

12

053 . 0 1

25 . 2

25 . 2

2 . 0 1 14 . 5 s

(

+

(

+ =

c

N

9 45 . 9 > =

c

N

So take 9 =

c

N

kPa N c q

c u b

6 . 768 9 4 . 85 = = =

40

2

0625 . 5 25 . 2 25 . 2 m A

b

= =

depth Parameter A

s

=

2

108 12 ) 25 . 2 25 . 2 ( 2 m A

s

= + =

kN P

gp u

10392 2 . 60 108 6 . 768 0625 . 5

) (

= + =

Ultimate load for piled foundation (Pile cap resting over group).

(a) Base Failure Value=10392 kN

(b) Such as of induced pile cap=8199=7371 kN

Minimum of (a) & (b) is selected for Pu(group)= 7371 kN

kN

FOS

P

P

u

allowable

4 . 2948

5 . 2

7371

= = =

12 m

2.25 m

2.25 m

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Catalog Robot Zyj800bDocument74 pagesCatalog Robot Zyj800b96phamminhNo ratings yet

- Types of Foundation LectureDocument79 pagesTypes of Foundation LectureVannah Elyssa AustriaNo ratings yet

- Modul 6 Analisa Data ProduktivitasDocument18 pagesModul 6 Analisa Data Produktivitaseacsy IndustryNo ratings yet

- PDA Testing Assess Pile CapacityDocument2 pagesPDA Testing Assess Pile Capacityphongmel50% (2)

- Pile Hammer SizingDocument3 pagesPile Hammer SizingIsabelle WongNo ratings yet

- Installation Specification For Driven PilesDocument39 pagesInstallation Specification For Driven PilessiswoutNo ratings yet

- APE Pile Driving Course: Understanding Pile Driving LeadsDocument104 pagesAPE Pile Driving Course: Understanding Pile Driving LeadsAifam RawNo ratings yet

- Construction Safety NotesDocument201 pagesConstruction Safety NotesAmitkumar Singh67% (6)

- Pile Driving Equipments PDFDocument151 pagesPile Driving Equipments PDFPn Ekanayaka100% (1)

- Chief/senior Construction InspectorDocument3 pagesChief/senior Construction Inspectorapi-76922386No ratings yet

- Pile Driving Effects on Nearby BuildingsDocument5 pagesPile Driving Effects on Nearby BuildingsRanga KalharaNo ratings yet

- Hydraulic Diagram For Liebherr 544Document12 pagesHydraulic Diagram For Liebherr 544Liebherr100% (1)

- Method For Dynamic & PITDocument10 pagesMethod For Dynamic & PITsumankanthnelluri7No ratings yet

- Bridge Construction Plan and Cost EstimateDocument67 pagesBridge Construction Plan and Cost Estimatesanusi69No ratings yet

- MKT Vibratory Hammer Selection and Soils TrainingDocument24 pagesMKT Vibratory Hammer Selection and Soils Traininggustavo caicedoNo ratings yet

- Pile Driving System GuideDocument91 pagesPile Driving System GuidedannyzuanNo ratings yet

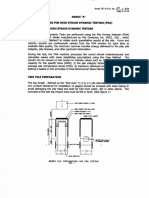

- Annex "A" Test Procedures For High Strain Dynamic Testing (Pda) Principles of High Strain Dynamic TestingDocument11 pagesAnnex "A" Test Procedures For High Strain Dynamic Testing (Pda) Principles of High Strain Dynamic TestingMacneoNo ratings yet

- 012 MS - Driven Piling Works-Concrete Spun Pile (P123C)Document7 pages012 MS - Driven Piling Works-Concrete Spun Pile (P123C)Muhamad Amirul SallehuddinNo ratings yet

- Catalog 2013 (Eng)Document20 pagesCatalog 2013 (Eng)Maldwin MenorcaNo ratings yet

- PWD Civil Rates 2014 (Civil Works)Document71 pagesPWD Civil Rates 2014 (Civil Works)Pioneer Design and Development LimitedNo ratings yet

- TPPN 1088Document5 pagesTPPN 1088sshapiro3622No ratings yet

- Driving U SheetpileDocument14 pagesDriving U SheetpilealexNo ratings yet

- Machines & Plant Rates Block 89 Khatima SOR 2021-22Document3 pagesMachines & Plant Rates Block 89 Khatima SOR 2021-22Girish lohaniNo ratings yet

- Pile Foundation Design A Student GuideDocument79 pagesPile Foundation Design A Student GuideAref MalkawiNo ratings yet

- Sample Method Statement For Pile DrivingDocument2 pagesSample Method Statement For Pile Drivingaimkcl90No ratings yet

- WMS-wharf Beacon Works - SatoDocument14 pagesWMS-wharf Beacon Works - SatoArchie Joseph LlanaNo ratings yet

- LAPORAN METKON - UnderpassDocument27 pagesLAPORAN METKON - UnderpassNadia WijanarkoNo ratings yet

- 2020 Experimental Identification of The (GDP)Document12 pages2020 Experimental Identification of The (GDP)叶晓平No ratings yet

- Impact vs Vibratory HammersDocument21 pagesImpact vs Vibratory HammersDilhara WickramaarachchiNo ratings yet

- Ce601 A.C.Document2 pagesCe601 A.C.Tarang ShethNo ratings yet