Professional Documents

Culture Documents

Make or Buy

Uploaded by

Joju JohnyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Make or Buy

Uploaded by

Joju JohnyCopyright:

Available Formats

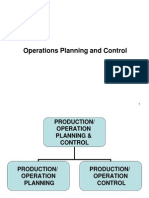

OBJECTIVES Make or Buy - rationale Scope Functional analysis Technological dimensions Factor analysis Quantitative techniques Introduction Production

uction of all parts and components of main equipment is uneconomical and infeasible. Production economy and competitive costing is possible by using modern technology and high volume capacity. Only critical parts / components may be produced in-house. Introduction (Continued) Plant capacity is limited to take care of captive requirements only In general it is economical to set up a production capacity based on horizontal integration. Manufacture concentrates on technology production and sales and procures the rest from sub-contractors. All units are engaged in make or buy decisions. Make OR Buy Decision Factors considered in Making a component Location, Layout, capacity, product and process technology, plant and machinery, facilities, production control, quality and maintenance aspects Factors considered in Buying a component What, How, How Much, When, Where and What price? Commonsense approach / in-depth analysis. Data must be available to analyse. Make OR Buy Decision - Techniques available Decision tree Break-even analysis When data is not fully available Statistical techniques forecasting, trend analysis, regression techniques. No analysis can substitute managerial capability and skill Scope : Covers all resources Materials and components Manufacturing capacity Infrastructure facilities Manpower skills Maintenance After-Sales service Functional analysis Make or Buy decisions have short and long term effects on all functions of the organization Financial Technological Marketing Purchasing

Strategic Intangible aspects Financial aspectsMake decision requires certain financial investments Fixed costs Variable costs Buy decision has only variable costs All benefits can be converted to financial terms and analyzed. Many techniques available Technological Aspects Technological dimensions a) Accessibility Latest technology IC circuits have to be bought. b) Exclusive Technology technology transfer agreements - manufacturer has to set up a plant. c) Non-exclusive technology - Manufacturer has an option d) Technological obsolescence - Manufacturers are reluctant to invest and set up a plant. It is prudent to buy design flexible for upgradation to new technology. e) Product Life cycle Product growth stage or at maturity set up capacity to manufacture critical components to reduce cost and improve competitiveness. At declining stage buy components. Marketing Aspects Make or Buy decision is dependent on a) Competition In case Severe competition cost and quality important. Make decision provides reliable supply and better quality however cost increases. Trade-off in decision b) Market share and potential In case of larger market share and future potential, make decision is preferred. c) End-User govt. departments, defense insist on quality and reliability. Manufacturers prefer to invest in plant and equipment. d) Profitability either cut costs or improve sales price and volume. Price in competitive market can be increased only by improved quality / additional features in product. An in-house set up is preferable. Purchasing Aspects Option to buy depends on Availability in right quantity at right time Acceptable quality and price levels Time and Quantity Delay in delivery causes production hold-ups. Early deliveries causes increased cost of carrying inventory. Concept of JIT Quality and Price Levels Quality and price are related in practice. The objective of Buy decision will not be realised unless we receive right quality at right price. Strategic aspects business Make or Buy decisions affect Long and Short term plans of

a) Maintaining the aim Objectives of business must be clearly defined and followed. Any diversion from plan will result in objective not being fulfilled. b) Economy of effort Unwise to distribute resources over wide area. Judicious selection of Make or Buy items is necessary.

c) Flexibility As future is uncertain a flexible strategy provides freedom to change the mix of make or buy components. d) Cooperation Between manufacturers and vendors is essential to the success of make-or-buy strategy with give and take on quantity, price, schedule etc. e) Offensive strategy steps taken to achieve market leadership. Surprise for competitors Security of ones own technology Introduce products of superior technology Produce in-house or buy from vendors having better technology / inhouse R and D to adopt and innovate superior technology. Security of technology Effective steps to deny information to competitors. Patent regimes. f) Self-reliance to protect self-interest and competitive position it is advisable to make critical components instead of buying. Intangible Aspects a) Reliability of vendors in case of Buy and of Plant and machinery / technology in case of Make b) Quality Applicable to both make or buy decisions. c) Technical assistance In case of make decisions technical assistance must be available from Equipment suppliers / collaborators / consultants d) Environmental Factors In case of make decision the products/processes must be compatible with existing manufacturing plant environment in terms of noise, vibration, dust, toxic emissions etc. e) Labour acceptance Union / Labour cooperation is vital in case of making of new items and outsourcing of existing items. f) Goodwill with vendors / suppliers / stakeholders influences Make or buy decisions. Factor Analysis Endogenous factors under control of organization Exogenous factors Company does not have full control They may be listed in favour of make or buy decisions and their impact evaluated as High , medium and low. These could be tabulated by the decision making committee. Factor Analysis - Endogenous factors Sr No 1 2 3 Factor Volume of Production Infrastructure Manpower Conditions Conditions favouring favouring Make Buy High Available Excess Low Not available Insufficient

4 5

Fixed cost Profitability

Low High

High Low

Factor Analysis - Exogenous factors

Sr No 1 2 3 4 5

Factor Collaboration agreement

Conditions Conditions favouring favouring Make Buy Exclusive Non exclusive Short term Reliable Yes Bad

Demand of item Long term Reliability of vendors Unreliable

Standard items No Labour relations Good

Quantitative Techniques These can help managers to evaluate the factors influencing the decisions. They have their own limitations. 1. Cost considerations - Break even analysis 2. Cost Volume analysis 3. Profit considerations Profit volume analysis 4. Use of equal cost chart. 5. Use of Probability 6. Use of decision Tree approach 7. Use of Discounted Cash Flow analysis 8. Use of Net present value method

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Life Insurance Asset ClassDocument6 pagesLife Insurance Asset Classhimita desai100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Excel Construction Budget TemplateDocument4 pagesExcel Construction Budget TemplateMohamedNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Finance Interview Prep: Key Accounting QuestionsDocument14 pagesFinance Interview Prep: Key Accounting Questionsmanish mishraNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Convertible Loan Term SheetDocument8 pagesConvertible Loan Term SheetMarius Angara0% (1)

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)zaki ansariNo ratings yet

- Vendor DevelopmentDocument13 pagesVendor DevelopmentJoju Johny100% (1)

- Business Process Re - Engineering: Product Development Case of KodakDocument8 pagesBusiness Process Re - Engineering: Product Development Case of KodakJoju JohnyNo ratings yet

- DA4139 Level II CFA Mock Exam 1 AnswersDocument84 pagesDA4139 Level II CFA Mock Exam 1 AnswersHelloWorldNowNo ratings yet

- GATPDocument14 pagesGATPJoju JohnyNo ratings yet

- Presentation - International Logistics & Supply Chain ManagementDocument25 pagesPresentation - International Logistics & Supply Chain ManagementJoju Johny100% (3)

- Foundations of Information Systems in BusinessDocument6 pagesFoundations of Information Systems in BusinessshellaNo ratings yet

- CENECO vs. Secretary of Labor and CURE - Employees' right to withdraw membershipDocument1 pageCENECO vs. Secretary of Labor and CURE - Employees' right to withdraw membershipเจียนคาร์โล การ์เซียNo ratings yet

- Materials Requirement PlanningDocument12 pagesMaterials Requirement PlanningJoju JohnyNo ratings yet

- EU: History, Institutions and PoliciesDocument2 pagesEU: History, Institutions and Policieszelenimarsovac100% (1)

- Technology Management 3Document6 pagesTechnology Management 3Joju JohnyNo ratings yet

- Theory of ConstraintsDocument3 pagesTheory of ConstraintsJoju JohnyNo ratings yet

- Technology Management 1Document4 pagesTechnology Management 1Joju JohnyNo ratings yet

- Business Ethics 2Document6 pagesBusiness Ethics 2Joju JohnyNo ratings yet

- Internal and External ConsistencyDocument35 pagesInternal and External ConsistencyAakriti ChNo ratings yet

- Joju Johny - Materials Requirement PlanningDocument20 pagesJoju Johny - Materials Requirement PlanningJoju JohnyNo ratings yet

- Quantitative Techniques - TheoryDocument2 pagesQuantitative Techniques - TheoryJoju JohnyNo ratings yet

- Joju - OPC - Materials Requirement PlanningDocument20 pagesJoju - OPC - Materials Requirement PlanningJoju JohnyNo ratings yet

- Sap 3Document29 pagesSap 3Joju JohnyNo ratings yet

- Joju - World Class Manufacturing (Learnings)Document8 pagesJoju - World Class Manufacturing (Learnings)Joju JohnyNo ratings yet

- Joju - OPC - Materials Requirement PlanningDocument15 pagesJoju - OPC - Materials Requirement PlanningJoju JohnyNo ratings yet

- Warehouse Management: Submitted To Prof. Sham Chaugule by Ajinkya J Bhavsar Roll No. 06Document11 pagesWarehouse Management: Submitted To Prof. Sham Chaugule by Ajinkya J Bhavsar Roll No. 06Joju JohnyNo ratings yet

- Joju - Logistics & Supply Chain ManagementDocument14 pagesJoju - Logistics & Supply Chain ManagementJoju JohnyNo ratings yet

- OPC - LectureDocument70 pagesOPC - LectureJoju JohnyNo ratings yet

- A Closer LookDocument49 pagesA Closer LookNasikhuddinNo ratings yet

- Joju - BPR 4Document12 pagesJoju - BPR 4Joju JohnyNo ratings yet

- Joju - BPR 5Document10 pagesJoju - BPR 5Joju JohnyNo ratings yet

- Operations Planning and ControlDocument11 pagesOperations Planning and ControlJoju Johny100% (1)

- Assembly Line BalancingDocument11 pagesAssembly Line BalancingOscar 'Mehsut' MudhuneNo ratings yet

- Joju - BPR 3Document7 pagesJoju - BPR 3Joju Johny100% (1)

- Joju - BPR 1Document4 pagesJoju - BPR 1Joju JohnyNo ratings yet

- Joju - ADSCM - DRP CaseDocument10 pagesJoju - ADSCM - DRP CasejojujohnyNo ratings yet

- Joju Johny - ADSCM - SPL Case StudyDocument15 pagesJoju Johny - ADSCM - SPL Case StudyJoju JohnyNo ratings yet

- Value AnalysisDocument32 pagesValue AnalysisJoju JohnyNo ratings yet

- Chapter 2 The Marketing Environment Social Responsibility and EthicsDocument32 pagesChapter 2 The Marketing Environment Social Responsibility and EthicsAnhQuocTranNo ratings yet

- Lesson 1 Analyzing Recording TransactionsDocument6 pagesLesson 1 Analyzing Recording TransactionsklipordNo ratings yet

- Customer Updation Form For Non IndividualDocument3 pagesCustomer Updation Form For Non IndividualThamilarasan PalaniNo ratings yet

- Kebede Kassa First Draft CommentedDocument73 pagesKebede Kassa First Draft CommentedBereketNo ratings yet

- Agricultural FinanceDocument22 pagesAgricultural Financeamit100% (3)

- Indian Tax ManagmentDocument242 pagesIndian Tax ManagmentSandeep SandyNo ratings yet

- DI Chapter 5 - CaseletsDocument4 pagesDI Chapter 5 - CaseletsDibyendu RoyNo ratings yet

- PatanjaliDocument52 pagesPatanjaliShilpi KumariNo ratings yet

- Distribution Channel in Wagh Bakri TeaDocument5 pagesDistribution Channel in Wagh Bakri TeaJuned RajaNo ratings yet

- Project Report On TCS Courier ServicesDocument8 pagesProject Report On TCS Courier ServicesMehwish ZahoorNo ratings yet

- Negotiation Mediation ADR Sample PlanDocument5 pagesNegotiation Mediation ADR Sample PlanAakash Raj ChauhanNo ratings yet

- Chapter 5 Review QuestionsDocument64 pagesChapter 5 Review QuestionsFlower T.No ratings yet

- Empire Jute CoDocument14 pagesEmpire Jute CoarmsarivuNo ratings yet

- Multi-Purpose Loan (MPL) Application Form: (E.g., JR., II) (For Married Women) (Check If Applicable Only)Document2 pagesMulti-Purpose Loan (MPL) Application Form: (E.g., JR., II) (For Married Women) (Check If Applicable Only)Lenaj EbronNo ratings yet

- Organogram 3-10-2018Document1 pageOrganogram 3-10-2018IqraNo ratings yet

- An Analysis of Recruitment & Selection Process at Uppcl: A Summer Training Report OnDocument92 pagesAn Analysis of Recruitment & Selection Process at Uppcl: A Summer Training Report OnManjeet SinghNo ratings yet

- Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument11 pagesDate Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceAryan JaiswalNo ratings yet

- Ba7022 Merchant Banking and Financial ServicesDocument214 pagesBa7022 Merchant Banking and Financial ServicesRitesh RamanNo ratings yet

- Design Sus NR Scheme PlanDocument23 pagesDesign Sus NR Scheme PlanFelekePhiliphosNo ratings yet

- Customer Satisfaction Towards Honda Two Wheeler: Presented By: Somil Modi (20152002) BBA-MBA 2015Document9 pagesCustomer Satisfaction Towards Honda Two Wheeler: Presented By: Somil Modi (20152002) BBA-MBA 2015Inayat BaktooNo ratings yet

- 6.1 Improper Accounting Procedures: Module 6: Avoiding Illegal AccountingDocument12 pages6.1 Improper Accounting Procedures: Module 6: Avoiding Illegal AccountingMartina MartinaNo ratings yet