Professional Documents

Culture Documents

Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection System

Uploaded by

api-3752216Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection System

Uploaded by

api-3752216Copyright:

Available Formats

Banlaw FillSafeTM

Overview

Banlaw FillSafeTM does exactly what the name suggests: it ensures overfill protection during refuelling by allowing

fuel to be delivered with zero overfill, zero tank pressure and with zero spillage, and can readily accommodate

various flow rates and fluid types for example; diesel, oil or coolant.

Banlaw FillSafeTM removes the need for manual checking of tank levels, and eliminates any guesswork on whether

the tank if completely full. System healthy and filling required LED indication advises the operator that the tank

requires fuel.

Using the Banlaw FillSafeTM system there is also no risk of the fuel tank rupturing due to over pressurising of the

tank because the Banlaw FillSafeTM system ensures the fuel flow has ceased before the tank is overfilled. With the

bulk of mining equipment having fuel tanks in excess of 4,000 litres, reducing the risk of tank rupture has multiple

financial, environmental and safety benefits. Ensuring that the tank is completely full also increases the available

operation time for each machine.

Safety and the Environment

With 75% of environmental damage caused by mining and rail operators being fuel related, the refuelling process

represents the single largest cause of fuel loss for most mines and rail networks worldwide. Traditional refuelling

systems use tank overflow as the primary indicator for when the tank is full. At flow rates of up to 1000 litres per

minute (300 Gal/minute) even a two second delay by the operator in shutting off fuel flow can result in the loss of

over 30 litres.

Banlaw FillSafeTM eliminates fuel loss from overflow and spillage. Savings aside, the environmental consequences

of fuel spillage is greatly reduced as is the risk of fire.

When refuelling using traditional equipment, the operator has no way of knowing the tank is full until it overflows,

thereby creating a danger to themselves and nearby workers, and environmental problems through spillage. The

waste of a valuable resource is also costly. It’s also common in such refuelling systems for up to one eighth of a

tank to not being filled as a result of diesel foaming. Using Banlaw Dry Break Nozzles and Receivers and

FillSafeTM, there is no surging or foaming and the tank is filled to the pre-determined safe fill capacity at every

refuelling, while the operator remains at safe ground level during the process.

Efficiency and System Advantages

In the mining and heavy transport industries Banlaw FillSafeTM provides a time and cost effective solution.

In all instances the Banlaw FillSafeTM system:

o reduces the risk of fuel spillage or tank rupture during the refuelling process;

o increases efficiency through faster refuelling times;

o improves environmental outcomes;

o reduces maintenance costs as the zero tank pressure environment extends the working life of fuel

tanks;

o reduces the chance of Occupational Health & Safety related risks

Banlaw Pty. Limited FillSafeTM Copyright 2005 - 2006 Page 1 of 3

Hydrocarbon Management Specialists

Banlaw FillSafeTM main advantages over other similar systems on the market include:

o not restricted by flowrate.

o relatively unaffected by fluid cleanliness levels, unlike fuel piloted systems on the market.

o robust and simple operation – built to withstand harsh mining conditions.

o relatively unobtrusive to the existing quick-fill system, which remains as a back-up system in the

unlikely event of a fault with the Banlaw FillSafeTM system.

o the control valve remains closed except during refuelling, allowing an onboard automatic valve to

act as a fire-safe valve when installed directly onto the tank. This is especially relevant with large

excavators and shovels, providing a means of preventing fuel loss from the tank via the fill line in

the event of a hose rupture or similar event during a fire or other catastrophic event.

Mode of Operation

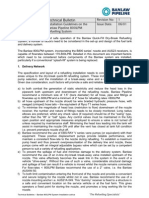

Banlaw FillSafeTM Electronic consists of up to 3 components:

o tank level switch (ZP3).

o Banlaw FillSafeTM electronics unit (ZP2).

o issue control device – e.g. automatic valve, or electronic ball valve.

Status LED’s and control buttons on the front panel of the ZP2 unit allow the operator to monitor the status of the

level switch and manually control the status of the control device.

The following illustration details the Banlaw FillSafeTM mode of operation.

Membrane

FillSafeTM

Stop Fill P/B ZP2 Control

Start Fill P/B Unit Level Sensor ZP3

& Filling Indication

On/Off Control

Tank

Fluid Inlet Solenoid or

i.e. Banlaw Fuel Electronic Ball

Receiver Valve

The connection between the ZP2 and ZP3 is failsafe designed. That is, a tank not full, is detected as a closed

circuit between the ZP2 and ZP3. If this circuit is therefore opened by either a ZP3 tank full detection or, a broken

or disconnected wire or, faulty component, the ZP2 will see this as tank full and close the Valve. A secondary

backup system within the ZP2 is a watchdog or fill safety timeout, which is used a backup to detect tank full or ZP3

failure. Once a “FILL” is initiated and in progress, the watchdog timer is started, if it times out then the ZP2 will

automatically close the valve. The watchdog time or fill safety timeout is link selectable to the filling times of 15, 30,

45 or 60 minutes.

Filling or closing of the Valve can also be manually stopped at any stage during the tank filling procedure by

pressing the “STOP” pushbutton on the front of the ZP2 unit.

Banlaw Pty. Limited FillSafeTM Copyright 2005 - 2006 Page 2 of 3

Hydrocarbon Management Specialists

Installations

Banlaw have installed Banlaw FillSafeTM Electronic systems onto a variety of mining and rail equipment including;

• diesel powered freight and passenger loco’s.

• Hitachi EX3600 excavator.

• Komatsu 830E haul trucks.

• Komatsu 930E haul trucks.

• Cat haul trucks.

• Komatsu PC5500 excavator.

• Komatsu/Demag H655 shovel.

During the installation, the refuelling system itself was typically upgraded to maximise the available flowrate during

refuelling and hence deliver often significant savings in downtime and plant operating efficiency. This is especially

relevant on large excavators, shovels and large truck fleets.

Contact Banlaw today for assistance in managing your Hydrocarbon systems.

17 Strathmore Road, Caves Beach NSW 2281, Australia

Telephone: +61 2 4972477

Fax: +61 2 49714910

Website: www.banlaw.com

Email: sales@banlaw.com.au

Banlaw Pty. Limited FillSafeTM Copyright 2005 - 2006 Page 3 of 3

Hydrocarbon Management Specialists

You might also like

- Flip-Flap Valve TypeDocument8 pagesFlip-Flap Valve TypehabibmusthafaNo ratings yet

- Spe 1241 GDocument8 pagesSpe 1241 GPaul MezaNo ratings yet

- PressureVacuum PV Valves For Chemical TankersDocument3 pagesPressureVacuum PV Valves For Chemical TankersSahil Biswas100% (1)

- Pump Control program -MANUAL PCP 1199-190Document19 pagesPump Control program -MANUAL PCP 1199-190moyali25176750No ratings yet

- Banlaw Fillsafe: Pressureless Overfill Protection Refuelling SolutionsDocument20 pagesBanlaw Fillsafe: Pressureless Overfill Protection Refuelling SolutionstagorNo ratings yet

- The Gamgram: No. 66 APR. 2015 Refueler Truck DesignDocument2 pagesThe Gamgram: No. 66 APR. 2015 Refueler Truck DesignJagadeesh KammaraNo ratings yet

- PV Valves Operation and Maintenance ProcedureDocument6 pagesPV Valves Operation and Maintenance ProcedureJeet SinghNo ratings yet

- Desalters 3Document2 pagesDesalters 3vishnumnair1No ratings yet

- Deck SealDocument7 pagesDeck SealAlamin Siddique100% (1)

- Duplex-Body Flow Meter Commissioning ProcedureDocument12 pagesDuplex-Body Flow Meter Commissioning ProcedureGeorge GuoNo ratings yet

- MDLK YTVk NTUx MZK 4 MWNi ODQ0 Yj Q2 OTdk ZTY4 NGQ1 OWRl Yz Ri NGM3 YgDocument23 pagesMDLK YTVk NTUx MZK 4 MWNi ODQ0 Yj Q2 OTdk ZTY4 NGQ1 OWRl Yz Ri NGM3 Ygraihan alfathirNo ratings yet

- Hand Over NotesDocument6 pagesHand Over NotesDon100% (1)

- Marine Electro - Technology Palani Samy Muthu Selvam - 13el1813Document9 pagesMarine Electro - Technology Palani Samy Muthu Selvam - 13el1813muthu selvam palani samyNo ratings yet

- Operational and Maintenance Manual PDFDocument19 pagesOperational and Maintenance Manual PDFNano Villanueva100% (3)

- Outline EcochlorTrainingProgramv3Document4 pagesOutline EcochlorTrainingProgramv3vangeliskyriakos8998No ratings yet

- Improving Efficiency of Sealing Water SystemsDocument11 pagesImproving Efficiency of Sealing Water SystemsRudy WijayaNo ratings yet

- 0242 0001 4@1Document4 pages0242 0001 4@1Polaris BridgemanNo ratings yet

- 28.26.00006 07-JUL-2023 05-SEP-2023 Open A318, A319, A320, A321 28-00 UpdateDocument17 pages28.26.00006 07-JUL-2023 05-SEP-2023 Open A318, A319, A320, A321 28-00 UpdateYaser SahiboleNo ratings yet

- PetroTechManual 4Document32 pagesPetroTechManual 4jose luisNo ratings yet

- Wastegate - TSB Title - 122807 08 - 01 - 2011 Engine - Failsafe - Codes FC 3100 - FC 30FE - FC 30FF StoredDocument8 pagesWastegate - TSB Title - 122807 08 - 01 - 2011 Engine - Failsafe - Codes FC 3100 - FC 30FE - FC 30FF StoredBAO ANH LÊNo ratings yet

- 189 010 - en 15.710057 V3.0Document12 pages189 010 - en 15.710057 V3.0balzac191No ratings yet

- Trapped Key Interlock For ValvesDocument7 pagesTrapped Key Interlock For Valvesra9622No ratings yet

- Installation, Maintenance, & Repair Series 909 and LF909: Reduced Pressure Zone AssembliesDocument8 pagesInstallation, Maintenance, & Repair Series 909 and LF909: Reduced Pressure Zone AssembliesPrabath KNo ratings yet

- Pilot k25p Industrial Petrol ReciprocatingDocument14 pagesPilot k25p Industrial Petrol ReciprocatingPepeNo ratings yet

- B SafeunitDocument2 pagesB SafeunitvealealNo ratings yet

- Bilge Oil Water SeperaorDocument5 pagesBilge Oil Water SeperaorTanzilNo ratings yet

- T5 Fuel Tank RemovalDocument11 pagesT5 Fuel Tank RemovalDohc MasterNo ratings yet

- Kamstrup Valve DatasheetDocument12 pagesKamstrup Valve DatasheetLucaspasNo ratings yet

- Test A/C Compressors with CLT1 Hand UnitDocument11 pagesTest A/C Compressors with CLT1 Hand UnitBilal al zeitawiNo ratings yet

- Watson Marlow 505s Manual EngDocument13 pagesWatson Marlow 505s Manual EngThaVinciNo ratings yet

- Baxter Flo-Gard3 Infusion Pump - Service GuidelineDocument2 pagesBaxter Flo-Gard3 Infusion Pump - Service Guidelineamerico.villarrealNo ratings yet

- Aircraft Fuel SystemDocument63 pagesAircraft Fuel SystemsushantreshmaNo ratings yet

- All About Marine Enginnering OralsDocument76 pagesAll About Marine Enginnering OralsUdana Hettiarachchi100% (3)

- Choose the Right Piping Plan: 53A, 53B or 53CDocument3 pagesChoose the Right Piping Plan: 53A, 53B or 53CAmol PatkiNo ratings yet

- Sop Damper FanDocument6 pagesSop Damper FanferryNo ratings yet

- BEP 600-DCM V3.2 Contour Matrix DC Monitor: Installation AND Operating InstructionsDocument24 pagesBEP 600-DCM V3.2 Contour Matrix DC Monitor: Installation AND Operating InstructionsEmilcar FragueiroNo ratings yet

- Installation and Operating Instructions: Custom Watering Plan Waterproof Battery ControllerDocument6 pagesInstallation and Operating Instructions: Custom Watering Plan Waterproof Battery ControllerZlobcek LordNo ratings yet

- Boost Solenoid - TSB Title - 122807 08 - 01 - 2011 Engine - Failsafe - Codes FC 3100 - FC 30FE - FC 30FF StoredDocument8 pagesBoost Solenoid - TSB Title - 122807 08 - 01 - 2011 Engine - Failsafe - Codes FC 3100 - FC 30FE - FC 30FF StoredBAO ANH LÊNo ratings yet

- Cat MEUI DiagnosisDocument126 pagesCat MEUI DiagnosisJoe67% (3)

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (1)

- VCESDocument2 pagesVCES한기륜No ratings yet

- List of Turbine Interlock and Protection ItemDocument30 pagesList of Turbine Interlock and Protection ItemAsan Ibrahim100% (1)

- User'S Operation ManualDocument27 pagesUser'S Operation ManualDams MonsalveNo ratings yet

- AS FD Tab21 Charging refrigerant into systemDocument6 pagesAS FD Tab21 Charging refrigerant into systemjvicher61No ratings yet

- Air-Over-Oil Packing Lube System Operator's ManualDocument14 pagesAir-Over-Oil Packing Lube System Operator's Manualharshal patilNo ratings yet

- Adjustment of SPM-A Synchronizer To Lean-Burn, Spark-Ignited Gas EnginesDocument8 pagesAdjustment of SPM-A Synchronizer To Lean-Burn, Spark-Ignited Gas Engineslinkangjun0621No ratings yet

- AMM 15 ManualDocument16 pagesAMM 15 ManualJamirNo ratings yet

- Preparation of LNG Tanker For DischargeDocument5 pagesPreparation of LNG Tanker For DischargeMatteo ConciNo ratings yet

- Permco 997-01316 PDFDocument49 pagesPermco 997-01316 PDF4lk0nNo ratings yet

- AW 6 Speeds: Valve Body Diagnosis: From The SonnaxDocument7 pagesAW 6 Speeds: Valve Body Diagnosis: From The SonnaxtejonmxNo ratings yet

- RoMatik160-210-420_operating-instructions_INT_enDocument6 pagesRoMatik160-210-420_operating-instructions_INT_enPearceNo ratings yet

- EPF Glycol Pump Instruction Manual-GS2200 Series-2014Document19 pagesEPF Glycol Pump Instruction Manual-GS2200 Series-2014arasNo ratings yet

- Jim Cahill blog post on surge control considerationsDocument3 pagesJim Cahill blog post on surge control considerations586301No ratings yet

- FC 1013 FCIPumpPaperDocument4 pagesFC 1013 FCIPumpPaperkresimir.mikoc9765No ratings yet

- AMT 2202 Final Learning Module 1Document10 pagesAMT 2202 Final Learning Module 1Ian SolomonNo ratings yet

- Emotron DCM Product Brochure 01 4613 01 ENDocument8 pagesEmotron DCM Product Brochure 01 4613 01 ENerickzaoNo ratings yet

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Technical Bulletins TB - Quick-Fill Tank VentsDocument13 pagesTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216No ratings yet

- Technical Bulletins Hydrostatic Pressure & Flow Test Results Rev3Document1 pageTechnical Bulletins Hydrostatic Pressure & Flow Test Results Rev3api-3752216No ratings yet

- PhoneList (FirstName)Document35 pagesPhoneList (FirstName)api-3752216100% (3)

- Wiggins Vents Info Wiggins VentsDocument2 pagesWiggins Vents Info Wiggins Ventsapi-3752216No ratings yet

- Oil Sampling Valve Oil Sampling Valve0001Document1 pageOil Sampling Valve Oil Sampling Valve0001api-3752216No ratings yet

- Technical Bulletins TB - 800LPM Installation Advice 0601Document5 pagesTechnical Bulletins TB - 800LPM Installation Advice 0601api-3752216No ratings yet

- Technical Bulletins TB - Multi Compartment Tanks 0300Document4 pagesTechnical Bulletins TB - Multi Compartment Tanks 0300api-3752216No ratings yet

- Technical Bulletins TB - Quick-Fill Tank VentsDocument13 pagesTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216No ratings yet

- Technical Bulletins TB - Nozzle Shut-Off MechanismDocument4 pagesTechnical Bulletins TB - Nozzle Shut-Off Mechanismapi-3752216No ratings yet

- Technical Bulletins TB - 1000LPM Installation Advice 0601 - 1Document5 pagesTechnical Bulletins TB - 1000LPM Installation Advice 0601 - 1api-3752216No ratings yet

- Technical Bulletins TB - Dual Tanks 0300Document4 pagesTechnical Bulletins TB - Dual Tanks 0300api-3752216No ratings yet

- Installation Guidelines Installation Guidlines On The Installation of 800LPM Refueling SystemDocument1 pageInstallation Guidelines Installation Guidlines On The Installation of 800LPM Refueling Systemapi-3752216No ratings yet

- Technical Bulletins TB - Fluid Theory 0400Document8 pagesTechnical Bulletins TB - Fluid Theory 0400api-3752216No ratings yet

- Technical Bulletins TB - 800LPM Installation AdviceDocument4 pagesTechnical Bulletins TB - 800LPM Installation Adviceapi-3752216No ratings yet

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDocument11 pagesBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Bam 800 T001 - Air TestDocument2 pagesBam 800 T001 - Air Testapi-3752216No ratings yet

- Banlaw Sales Brochures Filtered VentDocument2 pagesBanlaw Sales Brochures Filtered Ventapi-3752216No ratings yet

- Fuel Trial Results Fuel TrialsDocument2 pagesFuel Trial Results Fuel Trialsapi-3752216No ratings yet

- Filtered Vents FilteredVentDocument2 pagesFiltered Vents FilteredVentapi-3752216No ratings yet

- Fill Safe General Operating Instructions 08-05Document1 pageFill Safe General Operating Instructions 08-05api-3752216No ratings yet

- Risk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3Document39 pagesRisk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3api-3752216100% (1)

- Installation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill VentsDocument1 pageInstallation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill Ventsapi-3752216No ratings yet

- Banlaw Sales Brochures FillSafeDocument2 pagesBanlaw Sales Brochures FillSafeapi-3752216No ratings yet

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemDocument3 pagesScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Fast Fill Couplers NEW FJ Broch PG 12Document1 pageFast Fill Couplers NEW FJ Broch PG 12api-3752216No ratings yet

- Fast Fill Couplers LubeCentralhfcouplingsDocument2 pagesFast Fill Couplers LubeCentralhfcouplingsapi-3752216No ratings yet

- Fast Fill Couplers LC Hi-Flow FlyerDocument3 pagesFast Fill Couplers LC Hi-Flow Flyerapi-3752216No ratings yet

- Fast Fill Couplers FF Coupling Price List-06Document1 pageFast Fill Couplers FF Coupling Price List-06api-3752216No ratings yet

- Fast Fill Couplers Flush Face Flyer - PDDocument2 pagesFast Fill Couplers Flush Face Flyer - PDapi-3752216No ratings yet

- Automatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFDocument29 pagesAutomatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFEi Po Po AungNo ratings yet

- CCIOM, Diagnostic Trouble CodesDocument6 pagesCCIOM, Diagnostic Trouble CodesHari Hara Suthan80% (5)

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDocument2 pagesPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhNo ratings yet

- Method Statement of Foundation Concrete CoatingDocument17 pagesMethod Statement of Foundation Concrete CoatingGerry Dwi PutraNo ratings yet

- Sabah TL 1Document1 pageSabah TL 1MT HazrieNo ratings yet

- Parts Crane Hitachi FK600 - PRDocument2 pagesParts Crane Hitachi FK600 - PRDefly Gusti100% (1)

- Strength Improvement of Loose Sandy Soils Through Cement GroutingDocument56 pagesStrength Improvement of Loose Sandy Soils Through Cement Groutinganilsmg09No ratings yet

- Solar Project REPORTDocument15 pagesSolar Project REPORTismailNo ratings yet

- Feed Mill InfoDocument33 pagesFeed Mill InfoSapelNo ratings yet

- Introduction To Batteries - BatteryDocument17 pagesIntroduction To Batteries - BatteryJ dixojoNo ratings yet

- Laundry Engineering and Planning HandbookDocument343 pagesLaundry Engineering and Planning HandbookKhanh mai quocNo ratings yet

- ασκήσεις υδραυλικων λαδιουDocument160 pagesασκήσεις υδραυλικων λαδιουchristodoulos charalambousNo ratings yet

- Surge TankDocument2 pagesSurge TankBilel MarkosNo ratings yet

- Method of Statement-RTDocument7 pagesMethod of Statement-RTbuddhikasat50% (2)

- Datasheet GT CT8900Document2 pagesDatasheet GT CT8900Muhammad ImranNo ratings yet

- Tk09 Report Assignment 4Document112 pagesTk09 Report Assignment 4Bella Novia BerlianaNo ratings yet

- Copy of Vehicle-Maintenance-Record Work BacklogsDocument41 pagesCopy of Vehicle-Maintenance-Record Work BacklogsHughoNo ratings yet

- Lzdzmobmvrtpctpfnstcm 0616 eDocument2 pagesLzdzmobmvrtpctpfnstcm 0616 eMomo1010No ratings yet

- The Breaker Failure Protection BFP Schemes in UtilitiesDocument9 pagesThe Breaker Failure Protection BFP Schemes in UtilitiesTrigras Bangun PerkasaNo ratings yet

- Air & Flue Gas Path CFBCDocument2 pagesAir & Flue Gas Path CFBCJAY PARIKHNo ratings yet

- Engineer's and Contractor's Sticker DetailsDocument4 pagesEngineer's and Contractor's Sticker DetailssartajNo ratings yet

- 3-day CertificateDocument25 pages3-day Certificateganesh kondikire100% (8)

- Inter-Row Spacing Calculator by SeanwhiteDocument22 pagesInter-Row Spacing Calculator by SeanwhiteAMIRNo ratings yet

- Advances in Graphene Based Semiconductor Photocatalysts For Solar Energy ConversionDocument27 pagesAdvances in Graphene Based Semiconductor Photocatalysts For Solar Energy ConversiondevNo ratings yet

- NERC Reactive Support and Control WhitepaperDocument307 pagesNERC Reactive Support and Control WhitepapersulemankhalidNo ratings yet

- Boq - Sewer Pump Station Example: Project Name, Town Tender NoDocument8 pagesBoq - Sewer Pump Station Example: Project Name, Town Tender Nodelovan cheikhoNo ratings yet

- Hydrostatic Testing Procedure 02250-1Document2 pagesHydrostatic Testing Procedure 02250-1RanielNo ratings yet

- MSBTETE Thermal Engineering Model Answer KeyDocument15 pagesMSBTETE Thermal Engineering Model Answer KeyMohit D MoreNo ratings yet

- Totse Knowledge Thread 4Document14 pagesTotse Knowledge Thread 4negzNo ratings yet

- Pocket Mechanic Manual (Petrol Version)Document177 pagesPocket Mechanic Manual (Petrol Version)Bill jonesNo ratings yet