Professional Documents

Culture Documents

Grinding

Uploaded by

Harshad PatelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grinding

Uploaded by

Harshad PatelCopyright:

Available Formats

ME477

Fall 2004

GRINDING AND OTHER ABRASIVE PROCESSES

1. Grinding 2. Related Abrasive Processes (Honing, Lapping, Super- finishing and Polishing & Buffing)

Abrasive Machining

Material removal by the action of hard, abrasive particles usually in a form of a bonded wheel. Grinding is the most important abrasive machining.

Similar to slab milling - Cutting occurs at either the periphery or the face of the grinding wheel. Different than milling - Cutting occurs by the abrasive grains that are much smaller, numerous and random,

Cutting speeds are higher, Higher negative rake angle, Self-sharpening as each abrasive falls off

Other abrasive processes: honing, lapping, superfinishing, polishing, and buffing. Can be used on all types of materials. Generally a finishing operation achieving the surface finish of up to 0.025m and extremely close tolerance.

1 2

Grinding wheel

Consists of abrasive material and bonding material, Abrasive particles accomplish cutting Bonding material holds particles in place and establishes shape and structure of wheel. Parameters Abrasive materials Grain size Bonding material Wheel grade Wheel structure

3

Abrasive Materials

Properties High hardness, Wear resistance, Toughness Friability - Capacity to fracture when cutting edge dulls, so a new sharp edge is exposed. Materials Al2O3 most common, for ferrous and high-strength alloys (Hknoop=2100) SiC harder but not as tough, for aluminum, brass, stainless steel, cast irons and certain ceramics (Hknoop=2500). cBN very hard, very expensive, ex.: Borazon by GE, for harden tool steels and aerospace alloys (Hknoop=5000) Diamond Harder and more expensive, natural and synthetic, for hard, abrasive materials such as ceramics, cemented carbides and glass (Hknoop=7000)

4

Grinding wheel

Grain size: Grit size between 8 (coarse for harder materials) and 250 (fine for softer materials) based on a screen mesh procedure. Small grit sizes produce better finishes Larger grit sizes permit larger material removal rates Harder work materials require smaller grain sizes to cut effectively Softer materials require larger grit sizes

Bonding materials

Requirements

Must withstand centrifugal forces and high temperatures Must resist shattering during shock loading of wheel Must hold abrasive grains rigidly

Type of Bonding Materials

Vitrified bond baked clay and ceramic materials Silicate bond sodium silicate (low temp.) Rubber bond Resinoid bond thermosetting resin materials Shellac bond strong but not rigid Metallic bond usually bronze

Kwon

ME477

Fall 2004

Wheel Structure & Grade

Proportion of abrasive grain, bond material and pores: Pg+Pb+Pp=1 Wheel Structure: measures on a scale that ranges between "open" and "dense:

the relative spacing of the abrasive grains Open structure: Pp >> Pg, for chips clearance. Dense structure: Pp << Pg for better surface finish and dimensional control

Grinding wheel Specification

Standard grinding wheel marking system used to designate abrasive type, grit size, grade, structure, and bond material

Example: A-46-H-6-V

XX V Manufacturers Private marking Bond Type: B, BF, E, R, RF, S and V Structure: Scale from 1 to 15 Grade: Scale from A (soft) to Z (hard) Grit Size Abrasive Type: A=Al2O3, C=SiC Manufacturers symbol for abrasive 30 A 46 H 6

7 8

Wheel Grade - Bond strength (amount of bonding material in wheel structure (Pb))

A scale ranging between soft and hard Soft wheels lose grains readily - for low material removal rates and hard work materials Hard wheels retain grains - for high material removal rates and soft work materials

Grinding wheel shapes

Analysis of Grinding Process

The peripheral speed: v = DN Infeed: Depth of cut, d Crossfeed: w t MRR = vw wd w Surface Finish Better finish than machining

Chip length

D

lc

A single chip

vw w

lc = Dd

(a) straight, (b) recessed two sides, (c) metal wheel frame with abrasive bonded to outside circumference, (d) abrasive cut- off wheel

9

The grain aspect w' rg = Ratio (10~20) t Number of chips Formed per time nc = vwC

C = grits per area

10

Analysis of Grinding Process

Force

Cutting force on a single grain:

r v d F = K1 g w vC D

' c 0.5 0.25

Surface Finish

Most grinding to achieve good surface finish Best surface finish is achieved by:

Small grain sizes Higher wheel speeds Denser wheel structure = more grits per wheel area

Specific Energy: U =

Fc v vw wd

Why Specific Energy in Grinding is High

Size effect - small chip size causes energy to remove each unit volume of material to be significantly higher - roughly 10 times higher Individual grains with extremely negative rake angles result in low shear plane angles & high shear strains Not all grits are engaged in actual cutting

11 12

U is greater than machining

The size effect Extremely negative rake angles Part of grits is engaged in cutting Cutting, plowing and rubbing

Kwon

ME477

Fall 2004

Three Types of Grain Action

Cutting - grit projects far enough into surface to form a chip - material is removed Plowing - grit projects into work, but not far enough to cut - instead, surface is deformed and energy is consumed, but no material is removed Rubbing - grit contacts surface but only rubbing friction occurs, thus consuming energy, but no material is removed

Analysis of Grinding Process

Temperature at the work surface

High temperature and friction Most of the energy remains on the surface (1) surface burn and cracks (2) softening of the work surface and (3) residual stress 0.5 r Cv Ts = K 2 d 0.75 g D 0.25 v w Dull and a hard grade wheel thermal problems Cutting fluids lower temperature by reducing friction and dissipating heat

Grinding oils and emulsified oils

13 14

Work Surface Temperatures

Grinding causes high temperatures and friction, and most energy remains in the ground surface (high work surface temperatures)

Surface burns and cracks Metallurgical damage immediately beneath the surface Softening of the work surface if heat treated Residual stresses in the work surface

Analysis of Grinding Process

Wheel wear

Grain fracture - a portion of the grain breaks off and the rest remains bonded in the wheel

Tendency to fracture - friability

Attrition wear dulling individual grains

Analogous to tool wear and similar mechanisms

To Reduce the work surface temperature

Decrease infeed (depth of cut) d, Reduce wheel speed v, Reduce number of active grits per square inch on the grinding wheel C Increasing work speed vw Use a cutting fluid

15

Bond fracture - the individual grains are pulled

(3) (1) (2)

(1) Grain fracture (2) Attrition wear (3) Grain become dull

16

Analysis of Grinding Process

Grinding ratio Surface finish

Grinding Applications

To optimize surface finish, smaller grit size and dense wheel, higher wheel speed and lower work speed, smaller depth of cut and large wheel diameter. To max. MRR, select large grit size, more open wheel structure and vitrified bond For steels and cast iron, alumina wheel For non-ferrous metals, SiC wheel For harden materials and aerospace alloys, CBN wheel For soft metal, large grit size and harder grade For harder metal, small grit size and softer grade To min. heat damage, smaller d, lower v and faster vw To avoid burn, softer grade and more open structure To avoid break down, harder grade & more dense structure

18

Grinding ratio

GR =

Vm Vg

where Vw = volume of work material removed; and Vg = corresponding volume of grinding wheel worn

Wheel speed

5 order of magnitude smaller than conventional machining

Dressing resharpening after the 3rd stage of wear

Breaks off dulled grits to expose new sharp grains Removes chips clogged in the wheel

Truing Not only sharpens wheel, but restore its cylindrical shape

17

Kwon

ME477

Fall 2004

Grinding operations

Cylindrical (a) External and (b) Internal (c) Centerless External and Internal

Creep Feed Grinding

Depths of cut 1000 to 10,000 times greater Feed rates reduced by about the same proportion Material removal rate and productivity are increased in creep feed grinding because the wheel is continuously cutting

(c)

19

20

Related Abrasive Processes

Process Usual Part

Flat, ext. Cylinder, holes Flat, ext. Cylinder, holes Round hole Near flat Flat, ext. cylinder Misc. Shape Misc. Shape

Honing

Abrasive process by a set of bonded abrasive sticks using a combination of rotational & oscillatory motions Commonly used to finish the bores of internal combustion engines Speed between 50 to 500 ft/min, Pressure of 150 to 450 lb/in2 and Grit sizes between 30 and 600 Surface finishes of 0.12 m (5 -in) or better Creates a characteristic cross-hatched surface that retains lubrication

Honing Lapping Superfinish Polishing

Grit sizes: 20 to 80, 90-120 and >120)

Surface Finish (m)

0.4-0.6

Grinding (Med. Grit)

Grinding (Fine Grit)

0.2-0.4

Honing Lapping Superfinishing Polishing Buffing

0.1-0.8 0.025-0.4 0.013-0.2 0.025-0.8 0.013-0.4

21

Buffing

Surface luster

22

Lapping

Surface finish of extreme accuracy and smoothness

Uses a fluid suspension of very small abrasive particles between workpiece and lap (tool) Lapping compound - fluid with abrasives, general appearance of a chalky paste Typical grit sizes between 300 to 600 Applications: optical lenses, metallic bearing surfaces, gages

Superfinishing

Similar to honing - uses bonded abrasive stick pressed against surface and reciprocating motion Differences with honing:

Shorter strokes Higher frequencies Lower pressures between tool and surface

Lower work speed Smaller grit sizes

23

24

Kwon

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ME364 Forming SheetDocument11 pagesME364 Forming SheetVed Prakash ChoudharyNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- MD TorqueDocument12 pagesMD TorqueHarshad PatelNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- HKP Gas Turbine Power PlantsDocument46 pagesHKP Gas Turbine Power PlantsHarshad PatelNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Evaluation SystemDocument2 pagesEvaluation SystemVignat VoraNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Metrology - Laser (EDocFind (1) .Com)Document1 pageMetrology - Laser (EDocFind (1) .Com)Harshad PatelNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Review of Electrical Sensors and ActuatorsDocument21 pagesReview of Electrical Sensors and ActuatorsManjula Udayanga HemapalaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- List of Govt HolidaysDocument4 pagesList of Govt HolidaysAlpesh PatelNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- List of Govt HolidaysDocument4 pagesList of Govt HolidaysAlpesh PatelNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Admi Schedule DetailDocument3 pagesAdmi Schedule DetailHarshad PatelNo ratings yet

- Gears CyrusDocument1 pageGears CyrusHarshad PatelNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

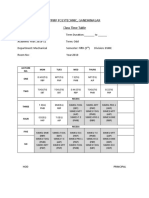

- VPMP Polytechnic, Gandhinagar Class Time Table: NO. MON Tues WED Thurs FRI SATDocument2 pagesVPMP Polytechnic, Gandhinagar Class Time Table: NO. MON Tues WED Thurs FRI SATHarshad PatelNo ratings yet

- EvaluationScheme From2010-11Document4 pagesEvaluationScheme From2010-11Amrat PatelNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- New Microsoft Office PowerPoint PresentationDocument1 pageNew Microsoft Office PowerPoint PresentationGbsReddyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Chapter-Cooling TowersDocument17 pagesChapter-Cooling TowersSAGIS ETIENNENo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- A Seminar Report ON Grinding: Submitted by Rajshree B. Tech (Mechanical Engineering) Third Year Roll No: 160180104039Document21 pagesA Seminar Report ON Grinding: Submitted by Rajshree B. Tech (Mechanical Engineering) Third Year Roll No: 160180104039Raj ShreeNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 936f H FramDocument60 pages936f H FramTASHKEELNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Thermal Spray Procedures For OHT Rear Spindles PDFDocument19 pagesThermal Spray Procedures For OHT Rear Spindles PDFalan gonzalez100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Honing and Superfinishing stones for the perfect finishDocument14 pagesHoning and Superfinishing stones for the perfect finishShiri ShaNo ratings yet

- Lecture03 - Chapter 25-GrindingDocument54 pagesLecture03 - Chapter 25-GrindingFarhad AliNo ratings yet

- Ch-10 Grinding and FinishingDocument83 pagesCh-10 Grinding and FinishingPrateek Bayal100% (1)

- CatálogoDocument2 pagesCatálogoJesus D. Gutierrez G.No ratings yet

- Abrasive Material Removal Processes: Chapter # 4Document42 pagesAbrasive Material Removal Processes: Chapter # 4Jeff HardyNo ratings yet

- Superfinishin G Processes: SMIT BHANDARI (1620002) EKTESH BARGODE (1620003) BHARAT BORATE (1620004)Document13 pagesSuperfinishin G Processes: SMIT BHANDARI (1620002) EKTESH BARGODE (1620003) BHARAT BORATE (1620004)Bharat BorateNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Krishna Engineering College Department of Mechanical EngineeringDocument4 pagesKrishna Engineering College Department of Mechanical EngineeringVivek BajpaiNo ratings yet

- Unit-5 - Non Conventional Machining ProcessesDocument72 pagesUnit-5 - Non Conventional Machining ProcessesMichael AugustineNo ratings yet

- Diamond and CBN English 07Document26 pagesDiamond and CBN English 07Vk PrabakranNo ratings yet

- The Art of Super FinishingDocument14 pagesThe Art of Super FinishingSarpreet GillNo ratings yet

- 47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11Document22 pages47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11dimitrisNo ratings yet

- MP Unit 4 GrindingDocument25 pagesMP Unit 4 GrindingJ S VAISHNAVNo ratings yet

- Norton Abrasive Solutions-Bearing IndustryDocument64 pagesNorton Abrasive Solutions-Bearing IndustryJItesh PAtilNo ratings yet

- Superfinishing Processes: HoningDocument5 pagesSuperfinishing Processes: HoningAyman HussienNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Abrasive Fine-Finishing TechnologyDocument24 pagesAbrasive Fine-Finishing TechnologyStanislav ArtemenkovNo ratings yet

- AMS 2452 Superfinishing of HVOF Applied Tungsten Carbide Coatings PDFDocument13 pagesAMS 2452 Superfinishing of HVOF Applied Tungsten Carbide Coatings PDFJose GasparNo ratings yet

- Report on Industrial Training at HAL Helicopter Division BengaluruDocument50 pagesReport on Industrial Training at HAL Helicopter Division BengaluruRavi ShankarNo ratings yet

- 3 Grinding ProcessDocument17 pages3 Grinding Processrabbi35_me10100% (2)

- 30 Super Finishing ProcessesDocument14 pages30 Super Finishing ProcessesPRASAD326100% (5)

- Manufacturing Process - Module5.0Document15 pagesManufacturing Process - Module5.0Fiza KamaNo ratings yet

- AMS 2452 Superfinishing of HVOF Applied Tungsten Carbide Coatings PDFDocument13 pagesAMS 2452 Superfinishing of HVOF Applied Tungsten Carbide Coatings PDFJose GasparNo ratings yet

- Surface Finishing ProcessesDocument32 pagesSurface Finishing ProcessesIqbal Singh SandhuNo ratings yet

- SR - NO. Chapter Name Page NoDocument61 pagesSR - NO. Chapter Name Page Nodeep bahirshetNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Super Finishing ProcessDocument14 pagesSuper Finishing ProcessKumarChirraNo ratings yet

- Super Finishing Operation for Ultra-Smooth SurfacesDocument8 pagesSuper Finishing Operation for Ultra-Smooth SurfacesUttara GargNo ratings yet

- PSI Superfinishing 2012 CatalogDocument52 pagesPSI Superfinishing 2012 CatalogjhscribdaccNo ratings yet

- 2.superfinishing ProcessDocument9 pages2.superfinishing ProcessVikrant Sharma100% (1)