Professional Documents

Culture Documents

Cedar Strip Canoe Part 1

Uploaded by

galenswright0 ratings0% found this document useful (0 votes)

405 views9 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

405 views9 pagesCedar Strip Canoe Part 1

Uploaded by

galenswrightCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

The Family Handyman

woopDWOR K S

eT homey

The beauty of wood and the strength of fiber-

Pe Mesa Lice MORAL cet NC

NTN

Our photo-packed three-part series

PASO EE Mona aR De

Pear asai

Ed eco ard

PART ONE:

Assembling the

wooden form on

which your canoe

will be built.

that you're thinking:

none, aual I'd ove: ki

but this isos! fon bisa

Lor ane.”

Well, we think you're in for a

sani surprise. ‘Truc ths i

rae. projec

. But it

house — fots of tng

-work, but not all hs

like most fornis of hoatbuilting, a

cance is very forgiving in

emisiniciion. A frsttin cane

builder with modest tol sk

build an excellent erat

To ensure your success, we've

tn this wlory Alen

lotos andl plenty of dray-

sauiee you through every

stop, We're spreading it oul over

this and the nest two issues, but if

ied up ta ster, go right

aad); don'¢wait forall three install

Our canoe is 18 tt long,

sigued as a general-purpo iy

uring craft for canpin anet fet.

water paddling le, mo

‘es plenty of weight,

, and is easy to portage

we buill for this

weighed in at 54 ths, though your

canoe may end up a pound er bw

‘ferent.

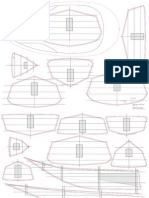

attach the molds, which are

curved plywood pieces that the hull

will built on, ‘The pla

tthe stronghav

‘molds look

WHAT 15 4 CEDAR-STRIP

ANCE, ANYWAY?

idea behind a cedar strip

hull of narrow

tripe, each one glued to the

ext with ordinary carpenter

and then cover the hull with 4

tremely strong, lightweight ani

Mey 199 THEFAMRY HANDIMAN 81

Cedar-Sinp CANOE

‘xalorproot, No ribsare needed, no

| canvas covering, and no caulking.

‘This “sandwich” construction, with

the Mberglass as bread and wood as the

filing, isalyo why this type of canoe is

very iorgiving toa noviee builder — Ue

‘wooden strips don’t have toe bite

exactly, because the ibereass

ers all the gaps,

Whar ff TAKES TO BUILD

You don' need the Sills (or the fuss

ness) of an expert woodworker o make

cedar strip canoe, Ii you can operate

table sow or radial arm saw, you ean

doit, You de uved patieace and persis:

thin piace of poster board.

‘CUT POSTER BOARD TEMPLATES from

each tracing poper pattern,

egain teping the tracing paper

down for accuracy.

82. war00) THe AMY HANDIAAN

TRANSFER MOLD SHAPES fram our drewing

toa piece of plywood using brads and o

;/w e0obpWORK S

lence, however, There are a lot of wood

‘én sips w pul bu, aiid here's plenty of

surface area to san. You should count

on it taking about 150-175 hours to

finish the canoe. Inadcition, the materi.

als will ost around 3485.

Aggarage’s the best place for build

ing, because you need 12-16 ft of

clearance infront! and bend your

avs for eutting the longestrins. Furor

more, sanding the glued-up hull pro-

duces clouds ofsavdus, and applying

the fherlass produces hoxious {ues

You could workin hasement shop, but

‘bu sure youcan get the finished canoe

uf, and install « powerful fa to exaust

dustand fumes. The tools vou will need

are listed on p. 88.

Ityou're ready, take-a deep breath,

‘and lets get started.

CUT STRONGEACK

PIECES To SizE

Begin by cutting all the plrword pieces

A= the dimensions svenin the

Cutting List. ‘Then eut the leg supports

(QM) to their Anished shapes,

Cut he pincpivses N - Uto the’

finishe! dimensions, necutthe

tapered ends af the top pieces (12).

THE GRID LAYOUT SCARD

‘Ths grid layout board is used for draw-

ing all the mold shapes to their ful size.

‘The shapes ure thon tansferred to

poster board templales, and then (o the

TRACE the shape of each mold to 2 seperate

sheet of racing paper, taping it securely to the

plywood layout board for accuracy.

ALIGN the

poster

board tem-

plates to tho

‘enter lines

‘on the ply-

weed mold

pieces.

Mark the

mold

shapes

on the

plywood.

Lian wir

‘CENTER LINE.

HARDWARE LEGEND

1 txernexteas

BOLT OTH WASIIER

‘AND MU fe ReaD,

2. axa uexnean

Bott with WASHER

‘AND MU REGD,)

3. yaxeuz"Hexiean

BOLT WITH WASHER

ANE NUT (2oREGD

~ Botrwin wasten

ANDNUT 2 ReGD)

Be taxa tag aout

ira wes

apnea)

©. go x20 ORYWALL

SCREW (38 REO,

7. ex cue peywalt

SoHE (ia ReaD,

on

E MOLDS 3 AND 1:

F MOLDS AND 40,

cACHSO

neleas

Hawoine

G-HoLDs 5 awa,

5 FAND 8

END

Jenoun7,

apo -

=e

oe a

I nowsurons

te}

INSIONS TO.

|= OUTSIDE OF Matos

Ss

e

STRONGBACK Detail

CENTER LINE OF MOLD

rae

aevet cunven cOGE

OFEND MOLDS

=

‘STRONGBACK ASSEMBLY

‘mar 299

1G SUPPORT

TWEFAMAY HANOYMAN B89

woopWORK §

plywood pieces B-J. Thismay seem

like a cumbersome process, but the

payoff is that your eanoe will be sym:

‘meiriea and siaotl,

Draw the don the: grid layout

hoard (A), To eliminate any confusion,

transfer on sel ofmold shapes ala

time, Start with molds 1 and 13, Tra

fer the intersecting points irom our grid

to yours, Draw the curvesioiring the

intersecting points and complete the

mold halfs shape (Photo 2)

shapes, and the 1/2in. hole locations,

MAKE POSTER BOARD TEMPLATES

‘Trace the individual mold shapes to

separate sheels of heavy (nieing paper,

Don't forget the hole locations (Phole

2), Cutthe shopes oat abeut 1/2.

‘outside of the drayar lines,

Tape the tracing paper shy

pieces of poster hor, but den't cover

the peaeillines with tape. Use a center

punch to transfer the hole locations to

the poster board then carefully cut aut

the shapes. ‘then check the accuracy

ofthese (eimpates agains! the grid

Pattern.

Note that you cin huy printed tem.

plates from us, rendy to cut out, See

p89.

ur our THE MoLDS

Draw couter ines dividing the width ow

beth sdes ofall the plywood mol

pieces (J. ‘Trace the poster board

shapes to one piece of each pair of

plywuod mold picces and to the center

mold 7 (Photo 4)

CUT THE MOLDS out with @ sober sew. staying

outside the lines, Since the canoe

cal, you con cut two molds at once.

Gras

Baca rrs

symmatri

SNAP A

CHAU LINE

down the

center of

the strong:

back. This

Une will bo

used to

‘Stack the pairs of alywood mold

Heces and strew Uiem togecier widh

Hin, serews, Cul anil sund them asa

nit 30 the shapes of the two moldsare

exacily the sime (Photo 5), Drill the

1/2, oles, then separate the:

screwedstogether pieces,

ASSEMBLE THE STRONGBACK

Sere tho pine slrungberk pieces N= Q

together (Photo 6).

Screw the stronghack top (U) to the

strougbeck, Assctuible die lavs Q,R,

{NO and then bol the lees to the streno-

ack,

mount THe Moin suPPonTs

Use a chalk ine to saapa centerline

cov the length of tae strongback top

Photo 7). Mark die locations ofthe

ASSEMBLE

THE STRONG:

Eis

BOLT THE MOLD SUPPORTS to the strong:

back se the center lines match. The over-

size holes leave you plenty of room for

adjustment,

ojign the

mold sup-

ports and

molds.

Pad

BA aay ort Te eanuyHanoYMAN

WANTED

—eeccre Dus mea

“tt 5 minutes pe itend'S20 to fol, was

aberaan

BoP Hareyman.

fort 0

I PROC Oy

DOS avis ele VE Ube

BUILD THIS QUILTRACK

Bula thishand-me-down quit rack

Inelurlos stop-by-step plans. To

crdor cord $6 95 plus 50 or post

‘ge and handing 10 THE FAMILY

HANDYMAN PLAN SERVICE PO,

Box 885, Stilweter, MN 58063,

Please alow 4 weeks for delivery,

fue

Waite iaieru)

eli}

caer

Cer

EINa aw alely i aac}

Colic onmtiarsy

Hino

mipwest Aint

ELECTRONICS INC. trea

INFORVATIONTOFOERS

1-800

648-3030

sti)

DWORKS

molds oa the strongback too, The

spas between the nigids are equal

except for howe between molds 6 and 7

and molds Rand 2, which are 1/4 in,

Jess than the rest

Draw canter ines dividing the leagth

on all sides of the mold supports 6, T)

Drill the bol: holes in the mold supports

and end mold supports (KL). Drill the

holes in the ends of the stronglack for

the end mold supporis (1. then tll

them inplace, Boltthe mold supports

lo the suungback hoi 8).

ere

Etaiety

Et eit

BOLT END MOLD SUPPORTS to the

‘end molds through the front hole,

thon slide tho end molds inte the

strongback and bolt them down.

ALIGN THE END MOLDS. Long,

atraigh’ piecor of woed clamped to

the end molds will allow you to de it

accurately by eye.

86 Mavro9)

ALIGN THE (CHECK THE

‘MOLDS, mows

wing a with 6

cedar strip,

cand shift

them if

needed, to

be sure

that all the

holding the ‘strips will

molds to the flat

supports, against

each mold.

HEARTLAND PRODUCTS, INC.

P.O Dox 77 m Yaly Ci, tO 8072

‘Avalatieatporcpaing K-MARTS.

For Grae nous you or mare pogtct

inloonabon col TOLL FREE 12004974760

S120 pert, 10% micimim oxder

Shipping and Handing eluded

Mayioor ue RAMULY HaMDYHAN 87

Woo bD WORK §

MOUNT AND ALIGN THE MOLDS

Holtthe end mold su»ports (0) tothe

fend molds, and then to the strenghack

(Photo 3).

Align the end melds 0 theyre paral

Jel p each other and ina straight line

(Photo 10), Place poster board shims

under de end mold supports to adust

the end molds

‘olethe molds w the mold supports

(Phote 11).

Screw a serew to the top edge af each

end mld and ile a sung beeen the

screws, Align the center Ines of the

melds to the string (Photo 12). Pe fussy

about this step, because the canoe won't

‘paddle straight ifall lie snolds aren't in

astraight ine.

yay

yee |

INVENT IT.

Oe

Pinot tatemaeencrt:

Corea cece

Srey ea

CUE Oro ne

Cunlotscn cu

Steals

Ceci

And Better wthos

Touencmeryei

Gites cei

CE EN ae €

pees eRe

tigger) :

seas Museen ec

eMEex THE FAIRNESS

OF THE MOLDS:

‘Fais” iva boatbuilding term that

describes a curve that is smooth, with:

‘ut bumps or hollows. To ensure that

your canoe hullis fair, you must care

‘lly align Ube mds

et by cutting the cedar trips (V)

that willbe used to build the hull

(Photo 13), and choose one of tne

strips asa faring suip. First ly it

across the lest connie of melds and the

end mold, Bevel the edges of the end

mold al bool a degree angle with a

rasp 30 the strip lies fal on il.

Lay the fairing batten across the

molds ai dificreat positions and look

along ito see ifs Matagalust the

moalde (Phoio 14), Chere ane urea on

‘one side and then the simearea on the

other side, ‘The batten should Le simi-

larly on both sides, Cheek all the

mols in niany places and make any

necessary adjustments by shifting the

molds siggy cx Lhe strongback oF by

‘eimming or shimmings.

‘When it looks like the cesar strips

illic smouthly on the molds, youre

seady Wostart Part 2.

Power tools: alle caw ol av

igen ent dil altaanday, era corde

fra out

Hard toale: wiarcoes chalk in, tr 2

Spring clomos fours clara, wo say

turk, Surpimie, rane Alara, wo 7 ro

in pain lire are tes trays, to pant

Ssorenera, copig su, combrton snare

‘Mistellenaoet.thatehkey ean opaner ot

Sal act pul, 29 Salespns. cali: ynn

ropa, satay gogale, dist masta and

ruber gives

COMING UP NEXT MONTH

1m our next issue, the fun starts —

actually building the cance. We'll

‘ue cedar strips together on top of

the melds to form the woaden hull,

and put fiberglass on it,

BORER CRESS Coe

ELT AY Ta

TEM ‘QUANTITY

25 2 postr board 3 sheets

1 ha raeng paper Sarecte

(2 xB nti fr plywood | 2 sheets

Phin ane 7

Praeee pine 2

ates bor oad botewin [2

ie" ahr ued bots win |

Mutt and wasters,

18" 2 1" Hox ewe ts wy | 26

lt anawamere

41 2°lonneadbolts with | 2

Tule anducenare

i$" 19" lg bs 2

sexo azuyval sores (50

orads y sn

Tea ae Kae W Aywnod OI

layout Fea)

B"y 12" 1802 fr sywoad

(end metic

2 | ESTs vee pyvoos

2 [uz ianb'y sect,

Diyrood mots 2 ure,

e fazicrasa's a0 fe pao

(tse ane 11}

2 [umes 2m i vmod

[tals dane 10}

‘les Sane 9}

{melds 6 re 0)

5 [area ee a" yuo

mold?)

4 | EKS 2" 7" hr ptywoos

(ed mel spa

UBS S23 12" Ir phyweod

(ect mal anne

2 | zea to's 20h pywoed (ag

casa

2 [taster iz pie |

Tetonpinct slo

2 [itary carat? pine

isnytack ands)

6 [tsat ene eat pin

[atongack centr ar foe)

2 pepo te

(stiorgback leas)

Suppors).

2 [Ese seca pnotmen |

suppor)

2 antes ne pnw

‘gtongaack ip}

iy | area re cea

dor KEN COUR

Ar Dinton «IE SATH,GORDY WLKNSON

Tec rt = EUGINE NOMSON.

Hote okra Bll ZUM

teed P= PE av

ouster 08 MOH

TEMPLATE OFFER

‘We've printed © sc! of seven templates for the molds of this

cance. They're fullsize, readl to cut out, will save you

several hours of work and help ensure accuracy. The set

costs $10, and can be ordered from Canoe Templates, The

Family Handyman, 7900 International Drive, Minneapolis,

MN 55425. Offer good while supplies lost. TEM

&) Macy fais ae broine Cpnines rom nls, wh more ation

pencing How wil YOU ge nd bags Crpings nthe 90

«# THIS MOWER LEAVES NO CLIPPINGS; us and ec hem no ine pat

Gh love them don in ps vots No more agit

‘© Clippings become FREE Fertilizer every ime you mow. Automatically recycles

Pepe neh Clippings it 100% natural nga fd

Onin blade ad deck design Other salle “ulcer” ae smo

xd ve wis hie che ce ot

# Billo TROY-WILT danfarés, with Bigs & Seaonengins,¢mdels up o SP,

22" ca Piet et ver aged ei ajsinent, be ara} Le Dae

1-800-453-6100 Bias

! Send Taday for FREE information!

| Sic ntl coupon oe TOLL-FREE at wel ws on

| fesnlomatnn ao he none wu me acme

| Ree CT eps an rg

|!

|

| C1 YES! Please send me the whole sory of the |

t

ime and (rouble to | amezing TROY-BILT Mulching Mower!

bap orrake Clipping hen yte

feet ofthe) ew ee 0% | nan

ach eter ny?

1 Action:

‘Troy Maautactaring Co

2nd St, de 9th Ave, Troy, NY 2180

cw

You might also like

- Redwood Canoe PDFDocument6 pagesRedwood Canoe PDFpaulo_enpjNo ratings yet

- Canoe and Kayak Building the Light and Easy Way: How to Build Tough, Super-Safe Boats in Kevlar, Carbon, or FiberglassFrom EverandCanoe and Kayak Building the Light and Easy Way: How to Build Tough, Super-Safe Boats in Kevlar, Carbon, or FiberglassNo ratings yet

- Wooden Canoe FDocument12 pagesWooden Canoe Fxtmxepav25% (4)

- 095-067 - Build A Bent-Plywood KayakDocument5 pages095-067 - Build A Bent-Plywood Kayakkkd108100% (3)

- Quick Canoe Made From PlywoodDocument43 pagesQuick Canoe Made From PlywoodKades100% (1)

- Building A Cedar Strip CanoeDocument8 pagesBuilding A Cedar Strip CanoecagedraptorNo ratings yet

- Stripbuilding Notes For Canoes & Row Boats: The Newfound Woodworks, IncDocument25 pagesStripbuilding Notes For Canoes & Row Boats: The Newfound Woodworks, IncBOREBGKNo ratings yet

- The Boatbuilder's Apprentice: The Ins and Outs of Building Lapstrake, Carvel, Stitch-and-Glue, Strip-Planked, and Other Wooden BoaFrom EverandThe Boatbuilder's Apprentice: The Ins and Outs of Building Lapstrake, Carvel, Stitch-and-Glue, Strip-Planked, and Other Wooden BoaRating: 4 out of 5 stars4/5 (2)

- Guillemot Kayaks Custom Boat Catalog 2011Document32 pagesGuillemot Kayaks Custom Boat Catalog 2011Guillemot Kayaks50% (4)

- Wooden Boats: The Art of Loving and Caring for Wooden BoatsFrom EverandWooden Boats: The Art of Loving and Caring for Wooden BoatsRating: 2.5 out of 5 stars2.5/5 (1)

- Stiletto BoatDocument7 pagesStiletto BoatJim100% (5)

- Pete Culler on Wooden Boats: The Master Craftsman's Collected Teachings on Boat Design, Building, Repair, and UseFrom EverandPete Culler on Wooden Boats: The Master Craftsman's Collected Teachings on Boat Design, Building, Repair, and UseNo ratings yet

- How To Build An Easy Home Built Sea Kayak PDFDocument26 pagesHow To Build An Easy Home Built Sea Kayak PDFBritt Fulghum0% (1)

- Strip Building NotesDocument26 pagesStrip Building Notesknujdlo100% (2)

- A Classic Guide to Building Punts and Canoes - Including Construction Your Own Canvas Canoes and Building a Sailing BoatFrom EverandA Classic Guide to Building Punts and Canoes - Including Construction Your Own Canvas Canoes and Building a Sailing BoatRating: 1 out of 5 stars1/5 (1)

- Rolling Home by John WintersDocument3 pagesRolling Home by John WintersSwift Canoe And Kayak100% (1)

- Simple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardFrom EverandSimple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardNo ratings yet

- FAO Building Small Wooden Boats in Myanmar PDFDocument47 pagesFAO Building Small Wooden Boats in Myanmar PDFfridomero100% (5)

- Small-Boat Sailing - An Explanation of the Management of Small Yachts, Half-Decked and Open Sailing-Boats of Various Rigs, Sailing on Sea and on River; Cruising, Etc.From EverandSmall-Boat Sailing - An Explanation of the Management of Small Yachts, Half-Decked and Open Sailing-Boats of Various Rigs, Sailing on Sea and on River; Cruising, Etc.No ratings yet

- CanoePlansPart1 PDFDocument20 pagesCanoePlansPart1 PDFcockybundoo80% (5)

- Boat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsFrom EverandBoat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsRating: 1 out of 5 stars1/5 (1)

- Mason 33 Practical ReviewDocument5 pagesMason 33 Practical ReviewManuelPérez-Sola100% (1)

- Jon Boat PlansDocument3 pagesJon Boat Planslm13700100% (2)

- Practical Boat Building for Amateurs: Full Instructions for Designing and Building Punts, Skiffs, Canoes, Sailing Boats, Etc.From EverandPractical Boat Building for Amateurs: Full Instructions for Designing and Building Punts, Skiffs, Canoes, Sailing Boats, Etc.No ratings yet

- Sea HawkDocument19 pagesSea HawkAlphamatrix01100% (1)

- Canoe and Boat Building 1000738069Document172 pagesCanoe and Boat Building 1000738069adiseif100% (4)

- Plywood Touring Canoe PlansDocument14 pagesPlywood Touring Canoe PlansRush Wingate100% (1)

- The Dory BookDocument283 pagesThe Dory BookplutocowNo ratings yet

- TeslinDocument9 pagesTeslinJim100% (2)

- Pirogue PlansDocument6 pagesPirogue Plansnative11247250% (2)

- Build It Yourself The Glen-L WayDocument38 pagesBuild It Yourself The Glen-L WayAlphamatrix01100% (2)

- Epoxy Works 10Document24 pagesEpoxy Works 10leather_nunNo ratings yet

- Brockwayfull PDFDocument38 pagesBrockwayfull PDFjacquesmayolNo ratings yet

- Duck SkiffDocument61 pagesDuck SkiffKay Pratt100% (2)

- How To Build A Wood Paddle BoardDocument8 pagesHow To Build A Wood Paddle BoardJavi JaviNo ratings yet

- Traditional BoatsDocument124 pagesTraditional BoatsKatja G0% (1)

- Building The Wood Duck KayakDocument72 pagesBuilding The Wood Duck Kayaktallerbioarq100% (1)

- The 23.5ft Light Schooner Full PlansDocument7 pagesThe 23.5ft Light Schooner Full PlansAlphamatrix01100% (1)

- Igdlorssuit 36x48Document2 pagesIgdlorssuit 36x48ski96467% (3)

- Thoreau Canoeing in The Wilderness 1916Document226 pagesThoreau Canoeing in The Wilderness 1916backwardsmessagesNo ratings yet

- The 10.5ft Pointy Skiff Full PlansDocument7 pagesThe 10.5ft Pointy Skiff Full PlansMaria Vasile100% (2)

- Kastri 12: Study PlansDocument19 pagesKastri 12: Study PlansGEORGE KARYDIS0% (1)

- FreeCanoePlansB03 10 PDFDocument32 pagesFreeCanoePlansB03 10 PDFtdfsks100% (1)

- Adirondack Beach Chair W 2 Positions PDFDocument15 pagesAdirondack Beach Chair W 2 Positions PDFNana Obiri Yeboa Darko100% (1)

- 0071477926Document242 pages0071477926DELA DAVID100% (1)

- Illustrated Guide To Building A Spira International Ply-On-Frame BoatDocument50 pagesIllustrated Guide To Building A Spira International Ply-On-Frame Boatlcortezbr100% (2)

- Design and Build Dinghy Manual 2020Document78 pagesDesign and Build Dinghy Manual 2020Joao Calinho100% (2)

- Boat Building 1931Document218 pagesBoat Building 1931orlsalomao77% (13)

- Julie SkiffDocument4 pagesJulie SkiffDan100% (1)

- Construction Folding Boats From Polypropylene SheeDocument9 pagesConstruction Folding Boats From Polypropylene Sheemarius_danila8736No ratings yet

- 20 FT Trimaran PlansDocument9 pages20 FT Trimaran PlanstesermetNo ratings yet

- Trixie 7 Dinghy - Study PlansDocument16 pagesTrixie 7 Dinghy - Study Planssaiga30894170% (1)

- Birch Bark Canoe BuilderDocument5 pagesBirch Bark Canoe Builderjcoppala4476No ratings yet

- Armor BasicsDocument18 pagesArmor BasicsJustin Kelly100% (10)

- China's Evolving StrikeDocument131 pagesChina's Evolving StrikegalenswrightNo ratings yet

- SHORADDocument31 pagesSHORADgalenswright100% (3)

- Iranian Military Capability 2011 - Ground Forces - March 15th 2011Document142 pagesIranian Military Capability 2011 - Ground Forces - March 15th 2011galenswright100% (4)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersFrom EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersRating: 5 out of 5 stars5/5 (13)

- The Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadFrom EverandThe Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadRating: 4 out of 5 stars4/5 (10)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerFrom EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerRating: 4 out of 5 stars4/5 (5)

- Hockey: Hockey Made Easy: Beginner and Expert Strategies For Becoming A Better Hockey PlayerFrom EverandHockey: Hockey Made Easy: Beginner and Expert Strategies For Becoming A Better Hockey PlayerNo ratings yet

- The Darkest White: A Mountain Legend and the Avalanche That Took HimFrom EverandThe Darkest White: A Mountain Legend and the Avalanche That Took HimRating: 4 out of 5 stars4/5 (1)

- Strong is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerFrom EverandStrong is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerRating: 4 out of 5 stars4/5 (22)

- Climb to Conquer: The Untold Story of WWII's 10th Mountain Division Ski TroopsFrom EverandClimb to Conquer: The Untold Story of WWII's 10th Mountain Division Ski TroopsRating: 5 out of 5 stars5/5 (1)

- Higher Love: Climbing and Skiing the Seven SummitsFrom EverandHigher Love: Climbing and Skiing the Seven SummitsRating: 5 out of 5 stars5/5 (5)

- Winterdance: The Fine Madness of Running the IditarodFrom EverandWinterdance: The Fine Madness of Running the IditarodRating: 4.5 out of 5 stars4.5/5 (279)