Professional Documents

Culture Documents

OM - I National Cranberry Cooperation

Uploaded by

amritjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OM - I National Cranberry Cooperation

Uploaded by

amritjCopyright:

Available Formats

INDIAN INSTITUTE OF MANAGEMENT, INDORE

Operations Management - I Assignment 1 National Cranberry Cooperative

Course Instructor: Prof. A H Kalro

Date of Submission: 16th August, 2009 Submitted by Group 11, Section C Jigar Jain Manish Verma Parul Gupta Angad Kikla Hara Prasad Pradhan

ASSUMPTIONS: 1) There is a cost associated with trucks waiting to be unloaded and it is $5 per hour. 2) When required, for overtime we have considered full-year employees working.

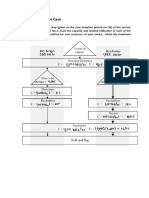

Case A: 10000 bbls of Berries

Average Daily Arrival = 10000 Wet Berries ( @ 70% ) = 7000 Dry Berries = 3000 Dryer Speed = 3*200 = 600 per hour Wet Berries: Arrival Rate of wet berries per hour = 7000/11 = 636.36 bbls/hr Rate of accumulation of wet berries = 636 - 600 = 36 bbls

3200

Inventory

396

11 11.67

Time

Dry Berries: Entering Rate = 3000/11 = 272.72 bbls/hr If wet berries are consumed at rate of 600 bbls/hr then (1200-600)bbls/hr of capacity in miller is free Hence there is no Requirement of any additional Capacity. ANALYSIS ON DRYERS TO BE PROCURED Time taken for manufacturing wet berries = 600/hour Total time taken to manufacture wet berries = 7000/600 = 11.67 hrs 4 DRYERS (Speed = 4*200 = 800 bbls/hr) Total time for dryers = 7,000/800 = 8.75 hrs Milling: total time = 10,000/1200 = 8.33 hrs Assuming that workers are paid = 1.5 * 6.5 $/hr = 9.75 $/hr Reduction of 2.92 hrs/day, results in = 28.47 $/day Payback time = 40,000/ (28.47 * 30) = 46.83 months 5 DRYERS (Speed = 5*200 = 1000 bbls/hr) Total time for dryers = 7,000/1,000 = 7

Milling: total time = 8.33 hours Reduction of 3.34 hrs/day, results in = 32.56 $/day Payback time = 80,000/ (32.56 * 30) = 81.98 months Therefore, the optimum strategy will be to procure one new dryer. NUMBER DRYERS 3 4 5 OF DRYING TIME 11.67 8.75 7 MILLING TIME 8.33 8.33 8.33 REDUCTION FROM 3 DRYERS 0 2.92 3.34 PAY BACK MONTHS 46.8 81.9 IN

SAVING OF TRUCK WAITING TIME (with 1 extra dryer): Truck waiting time for 3 dryers: 0 hr Truck waiting time for 4 dryers: 0 hr BIN CONVERSION REQUIREMENT: No dry bins need to be converted to dry/wet bins SCHEDULING OF WORKFORCE AND ANOTHER SHIFT: Here the overtime is so minimal, that addition of another shift is not required.

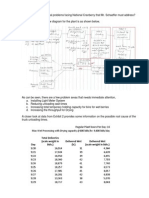

Case B: 15000 bbls of Berries

Average Daily Arrival = 15000 Wet Berries ( @ 70% )= 10500 Dry Berries = 4500 Dryer Speed = 3*200 = 600 per hour Wet Berries: Arrival rate per hour = 10500/11 = 955 bbls/hr Therefore, rate of accumulation = 955-600 = 355 bbls/hr

Inventory

3900 3200

9.03

11

12.67

17.5

Time

Dry berries are entering at rate = 4500/11 = 409bbls/hr Since 600 bbls/hr of mining is free, there is no accumulation of dry berries in holding tanks. ANALYSIS ON DRYERS TO BE PROCURED Time taken for manufacturing wet berries = 600/hour Total time taken to manufacture wet berries = 10500/600 = 17.5 hrs 4 DRYERS (Speed = 4*200 = 800 bbls/hr) Total time for dryers = 10500/800 = 13.125 hrs Milling: total time = 15000/1200 = 12.5 hrs Assuming that workers are paid = 1.5 * 6.5 $/hr = 9.75 $/hr Reduction of 4.375 hrs/day, results in = 42.66 $/day Payback time = 40,000/ (42.66 * 30) = 31.25 months 5 DRYERS (Speed = 5*200 = 1000 bbls/hr) Total time for dryers = 10500/1000 = 10.5 Milling: total time = 12.5 hours Reduction of 5 hrs/day, results in = 48.75 $/day Payback time = 80,000/ (48.75 * 30) = 54.7 months

Therefore, the optimum strategy will be to procure one new dryer. NUMBER DRYERS 3 4 5 OF DRYING TIME 17.5 13.125 10.5 MILLING TIME 12.5 12.5 12.5 REDUCTION FROM 3 DRYERS 0 4.375 5 PAYBACK MONTHS 31.25 54.7 IN

SAVING OF TRUCK WAITING TIME (with 1 extra dryer): Truck waiting time for 3 dryers: 17.08 hr Truck waiting time for 4 dryers: 0 hr BIN CONVERSION REQUIREMENT: No dry bins need to be converted to dry/wet bins SCHEDULING OF WORKFORCE AND ANOTHER SHIFT: Here the overtime is very high (5.125 hrs), we should calculate the overhead in both case (overtime and extra shift). In case of overtime, per worker spending = 5.125 * 6.5 * 1.5 = $49.97 (per worker per day) In case of more shift, per worker spending = 8 * 6.5 = $52 (per worker per day) So it would be better to have overtime instead of adding one extra shift.

Case C: 20000 bbls of Berries

Average Daily Arrival = 20000 Wet Berries ( @ 70% )= 14000 Dry Berries = 6000 Dryer Speed = 3*200 = 600 per hour Wet Berries: Incoming rate of Wet berries = 14000/11 = 1272 bbls/hr Accumulation rate = 1272-600 = 672 bbls/hr

7400

Inventory

3200

4.76

11

Time

18

23.3

Dry berries are entering at rate = 6000/11 = 545.45 bbls/hr Since 600 bbls/hr of mining is free, there is no accumulation of dry berries in holding tanks. ANALYSIS ON DRYERS TO BE PROCURED Time taken for manufacturing wet berries = 600/hour Total time taken to manufacture wet berries = 14000/600 = 23.33 hrs 4 DRYERS (Speed = 4*200 = 800 bbls/hr) Total time for dryers = 14000/800 = 17.5 hrs Milling: total time = 20000/1200 = 16.66 hrs Assuming that workers are paid = 1.5 * 6.5 $/hr = 9.75 $/hr Reduction of 5.83 hrs/day, results in = 56.84 $/day Payback time = 40,000/ (56.84 * 30) = 23.5 months 5 DRYERS (Speed = 5*200 = 1000 bbls/hr) Total time for dryers = 14000/1000 = 14 Milling: total time = 16.66 hours Reduction of 6.67 hrs/day, results in = 65.03 $/day Payback time = 80,000/ (65.03 * 30) = 41.25 months

Therefore, the optimum strategy will be to procure one new dryer. NUMBER DRYERS 3 4 5 OF DRYING TIME 22.3 17.5 14 MILLING TIME 16.7 16.67 16.67 REDUCTION FROM 3 DRYERS 0 5.8 6.63 PAYBACK MONTHS 23.5 41.25 IN

SAVING OF TRUCK WAITING TIME (with 1 extra dryer): Truck waiting time for 3 dryers: 370.72 hr Truck waiting time for 4 dryers: 89.24 hr BIN CONVERSION REQUIREMENT: Some dry bins need to be converted to dry/wet bins Cost of truck waiting: = waiting hour * hourly rate * total number of daye = 89.24 * 5 * 90 = $40158 By converting 1 bin, waiting time = 68.17 hr Cost of truck waiting = $30677 Saving = (40158 - 30677) - 7500 (Cost of conversion) = $1981 Similarly, by converting 2 bins, Saving = $640 Addition of 3rd bin is not cost effective. So we should go with converting 2 dry bins to dry/wet bins. SCHEDULING OF WORKFORCE AND ANOTHER SHIFT: Here the overtime is very high (9.5 hrs), so it will be nice idea to add another shift of 8 hours, and the rest 1.5 hrs should be allowed for overtime.

You might also like

- National Cranberry Part IDocument3 pagesNational Cranberry Part IPrateekRaj167% (3)

- IDS 532 - National Cranberry Case Study - AnswersDocument4 pagesIDS 532 - National Cranberry Case Study - AnswersVikas Mani TripathiNo ratings yet

- NationalCranberryCooperative CaseAnalysisDocument10 pagesNationalCranberryCooperative CaseAnalysisJishnu RoychaudhuriNo ratings yet

- National Cranberry Cooperative Case AnalysisDocument9 pagesNational Cranberry Cooperative Case AnalysisAudrey Tay100% (3)

- 11BM60008 Sec B National Cranberry CooperativeDocument9 pages11BM60008 Sec B National Cranberry CooperativeKunal Verma100% (3)

- Case 1 - National Cranberry CooperativeDocument7 pagesCase 1 - National Cranberry Cooperativewhitney100% (1)

- National Cranberry Cooperative SolutionsDocument2 pagesNational Cranberry Cooperative Solutionsjr_gimp83% (6)

- NCC Awasthi 11BM60071Document8 pagesNCC Awasthi 11BM60071Abhishek AwasthiNo ratings yet

- National Cranberry Cooperative CaseDocument7 pagesNational Cranberry Cooperative CaseMano Ranjani83% (12)

- National Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsDocument11 pagesNational Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsFabiola SE100% (2)

- National Cranberries CaseDocument7 pagesNational Cranberries CaseHyper Green MindNo ratings yet

- National Cranberry HBS Case SolutionDocument9 pagesNational Cranberry HBS Case SolutionSandhya Patil100% (1)

- National Cranberry Case Report Operations ManagementDocument7 pagesNational Cranberry Case Report Operations ManagementKarthik TirupatiNo ratings yet

- CranberryDocument4 pagesCranberryharshkhambraNo ratings yet

- Critical Problems and Recommendations for National CranberryDocument5 pagesCritical Problems and Recommendations for National Cranberrymaverick_659No ratings yet

- NCC - Case StudyDocument3 pagesNCC - Case StudyDeepika GuptaNo ratings yet

- Essay ReviewDocument11 pagesEssay ReviewMilagros AzparrentNo ratings yet

- National Cranberry Cooperative 1996-1 PDFDocument10 pagesNational Cranberry Cooperative 1996-1 PDFnephielive.cnNo ratings yet

- OM WordDocument3 pagesOM WordpulakitNo ratings yet

- Answers NCCDocument2 pagesAnswers NCCAmara Khan0% (1)

- OM-I Assignment - Group 1 - Section A - National Cranberry CooperativeDocument8 pagesOM-I Assignment - Group 1 - Section A - National Cranberry Cooperativeaglakshmanan50% (2)

- Assignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?Document9 pagesAssignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?TerryNo ratings yet

- National Cranberry CaseDocument10 pagesNational Cranberry CaseanshumanNo ratings yet

- National Cranberry CooperativeDocument15 pagesNational Cranberry CooperativeSaswata Banerjee100% (4)

- National Cranberry Case SolutionDocument4 pagesNational Cranberry Case SolutionAli Umer MughalNo ratings yet

- National Cranberry Case ReportDocument10 pagesNational Cranberry Case ReportCharles Van Hoorebeke75% (4)

- National Cranberry Cooperative: Operations Management-SCH-MGMT-670Document8 pagesNational Cranberry Cooperative: Operations Management-SCH-MGMT-670Shreyas SatardekarNo ratings yet

- National Cranberry CaseDocument20 pagesNational Cranberry CaseRicardo David Pareja Baquerizo100% (2)

- OPTIMIZED OPERATIONSDocument10 pagesOPTIMIZED OPERATIONSSahil sangwanNo ratings yet

- National Cranberry Cooperative - 11BM60070Document3 pagesNational Cranberry Cooperative - 11BM60070Neelesh KhattarNo ratings yet

- National Cranberry CooperativeDocument5 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- National Cranberry CooperativeDocument3 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- Operations Management National Cranberry CaseDocument12 pagesOperations Management National Cranberry CaseKarthik TirupatiNo ratings yet

- National Cranberry Case Report Operations Management - IDocument9 pagesNational Cranberry Case Report Operations Management - IVikash KumarNo ratings yet

- National Cranberry CooperativeDocument14 pagesNational Cranberry CooperativeDenisa A86% (7)

- National Cranberry Cooperative Case AnalysisDocument6 pagesNational Cranberry Cooperative Case AnalysisTeja RaoNo ratings yet

- National Cranberry Cooperations 1996Document15 pagesNational Cranberry Cooperations 1996Mithilesh Singh67% (3)

- The National Cranberry CooperativeDocument5 pagesThe National Cranberry CooperativeHussein BayramNo ratings yet

- National Cranberry Cooperative 1981Document10 pagesNational Cranberry Cooperative 1981Nicole Dorado0% (1)

- National Cranberry Case Analysis BottleneckDocument3 pagesNational Cranberry Case Analysis BottleneckHardik SemlaniNo ratings yet

- Answers To Old Midterm QsDocument11 pagesAnswers To Old Midterm QsdarshangoshNo ratings yet

- Group 1 Donner Company CaseDocument7 pagesGroup 1 Donner Company CaseAjay Kumar100% (1)

- OM Group 5, National Cranberry CooperativeDocument10 pagesOM Group 5, National Cranberry Cooperativesudip2003No ratings yet

- Valley Forge Problem SoutionDocument5 pagesValley Forge Problem SoutionSashi Velnati0% (1)

- Donner CompanyDocument11 pagesDonner Companymathilde_144100% (2)

- Donner Company Process Flow ChartDocument1 pageDonner Company Process Flow ChartzindalonerNo ratings yet

- Bergerac Systems: The Challenge of Backward IntegrationDocument3 pagesBergerac Systems: The Challenge of Backward IntegrationPulkit Aggarwal100% (1)

- Littlefield Simulation Preparation - S08Document5 pagesLittlefield Simulation Preparation - S08Prerana Rai BhandariNo ratings yet

- Logistic & Distribution Management: Lotus Thread Company LTDDocument6 pagesLogistic & Distribution Management: Lotus Thread Company LTDSanchit GuptaNo ratings yet

- MGMT611 Managing Littlefield TechDocument4 pagesMGMT611 Managing Littlefield Techqiyang84No ratings yet

- National Cranberry Cooperative Reduces Truck Wait TimesDocument16 pagesNational Cranberry Cooperative Reduces Truck Wait TimesNitish Raj SubarnoNo ratings yet

- National Cranberry Cooperative Case Answer 1Document6 pagesNational Cranberry Cooperative Case Answer 1PRITEENo ratings yet

- NCCDocument5 pagesNCCDeepika GuptaNo ratings yet

- Kasus 1 - Koperasi Cranberry NasionalDocument7 pagesKasus 1 - Koperasi Cranberry NasionalScribdTranslationsNo ratings yet

- Xuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpDocument8 pagesXuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpJason zhuNo ratings yet

- Assignment 3: Name IDDocument4 pagesAssignment 3: Name IDAsifI.KhanNo ratings yet

- Executive Shirt CompanyDocument20 pagesExecutive Shirt CompanySauravRikunNo ratings yet

- Chapter 3 Assignment Group D: Ziyang Zhang Hao Weng Zixuan Wei Ganjian Ye 3.3 AnswerDocument4 pagesChapter 3 Assignment Group D: Ziyang Zhang Hao Weng Zixuan Wei Ganjian Ye 3.3 Answerzixuan weiNo ratings yet

- Optimize Orange Juice Production Line OutputDocument22 pagesOptimize Orange Juice Production Line OutputHarshit Bhattaram100% (2)

- National Cranberry - Section 4 Group 16Document8 pagesNational Cranberry - Section 4 Group 16milwandaNo ratings yet

- The Nature and Purpose of Accounting: Mcgraw-Hill/IrwinDocument36 pagesThe Nature and Purpose of Accounting: Mcgraw-Hill/IrwinAshutosh KumarNo ratings yet

- Section F, Group 2 - Retail Industry in IndiaDocument35 pagesSection F, Group 2 - Retail Industry in IndiaamritjNo ratings yet

- Group Assignment 1 - 38Document8 pagesGroup Assignment 1 - 38amritjNo ratings yet

- Faces: B.E. ProjectDocument56 pagesFaces: B.E. ProjectamritjNo ratings yet

- Towards An Efficient Distributed Object Recognition SystemDocument15 pagesTowards An Efficient Distributed Object Recognition SystemamritjNo ratings yet

- MQP For MBA I Semester Students of SPPUDocument2 pagesMQP For MBA I Semester Students of SPPUfxn fndNo ratings yet

- Doing Research in Business ManagementDocument20 pagesDoing Research in Business Managementravi_nyseNo ratings yet

- An Examination of Audit Delay Further Evidence From New ZealandDocument13 pagesAn Examination of Audit Delay Further Evidence From New ZealandAmelia afidaNo ratings yet

- Amrit Notes - PDF Version 1 PDFDocument49 pagesAmrit Notes - PDF Version 1 PDFAmrit GaireNo ratings yet

- Chapter-I: Customer Service and Loan Activities of Nepal Bank LimitedDocument48 pagesChapter-I: Customer Service and Loan Activities of Nepal Bank Limitedram binod yadavNo ratings yet

- Purchase Order: Pt. Prastiwahyu Tunas EngineeringDocument1 pagePurchase Order: Pt. Prastiwahyu Tunas EngineeringBowoNo ratings yet

- A NATIONAL STUDY of Human Resource Practices, Turnover, and Customer Service in The Restaurant Industry.Document32 pagesA NATIONAL STUDY of Human Resource Practices, Turnover, and Customer Service in The Restaurant Industry.ROCUnitedNo ratings yet

- CH 09Document35 pagesCH 09ReneeNo ratings yet

- Organization Development and Change: Chapter Twenty: Organization TransformationDocument16 pagesOrganization Development and Change: Chapter Twenty: Organization TransformationGiovanna SuralimNo ratings yet

- Three Eras of Survey ResearchDocument11 pagesThree Eras of Survey ResearchGabriela IrrazabalNo ratings yet

- Global Mobile Money Services ReportDocument128 pagesGlobal Mobile Money Services ReportlazagasyNo ratings yet

- Ril JioDocument6 pagesRil JioBizvin OpsNo ratings yet

- RAM Guide 080305Document266 pagesRAM Guide 080305Ned H. CriscimagnaNo ratings yet

- New Kyc FormDocument3 pagesNew Kyc Formvikas9saraswatNo ratings yet

- How Organizations Change Over TimeDocument36 pagesHow Organizations Change Over TimeTareq Abu Shreehah100% (1)

- My Dream Company: Why Join ITC Limited (Under 40 charsDocument9 pagesMy Dream Company: Why Join ITC Limited (Under 40 charsamandeep152No ratings yet

- Isaca Cisa CoursewareDocument223 pagesIsaca Cisa Coursewareer_bhargeshNo ratings yet

- 05 - E. Articles 1828 To 1842Document14 pages05 - E. Articles 1828 To 1842Noemi MejiaNo ratings yet

- Kwality WallsDocument18 pagesKwality WallsKanak Gehlot0% (2)

- PFR Volume IDocument327 pagesPFR Volume IMaria WebbNo ratings yet

- North America Equity ResearchDocument8 pagesNorth America Equity ResearchshamashmNo ratings yet

- Dhurjoti Bhattacharjee's ResumeDocument6 pagesDhurjoti Bhattacharjee's ResumeSai Anil KumarNo ratings yet

- Powerpoint Presentation To Accompany Heizer and Render Operations Management, 10E Principles of Operations Management, 8EDocument45 pagesPowerpoint Presentation To Accompany Heizer and Render Operations Management, 10E Principles of Operations Management, 8EAnum SaleemNo ratings yet

- Basel III Capital Regulations and Liquidity StandardsDocument40 pagesBasel III Capital Regulations and Liquidity Standardsrodney101No ratings yet

- Supply Chain ChecklistDocument2 pagesSupply Chain ChecklistAli Aliakbari100% (4)

- GROUP 4 FinalDocument33 pagesGROUP 4 FinalHuong MleNo ratings yet

- Ihc Insight Aug 2015Document21 pagesIhc Insight Aug 2015Advan ZuidplasNo ratings yet

- CH 02 Project Life Cycle and Organization: A Guide To The Project Management Body of Knowledge Third EditionDocument15 pagesCH 02 Project Life Cycle and Organization: A Guide To The Project Management Body of Knowledge Third Editionapi-3699912No ratings yet

- Find the perfect candidate for Wakil Kepala Klinik Utama GR Setra CMIDocument2 pagesFind the perfect candidate for Wakil Kepala Klinik Utama GR Setra CMIRscmi Dan LaboratoriumNo ratings yet

- Daftar Kantor Akuntan PublikDocument16 pagesDaftar Kantor Akuntan PublikLeni JanarkoNo ratings yet