Professional Documents

Culture Documents

Design of T Beam Using SP16 Economic Depth and Check

Uploaded by

Riazahemad B JagadalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of T Beam Using SP16 Economic Depth and Check

Uploaded by

Riazahemad B JagadalCopyright:

Available Formats

Design of T Beam

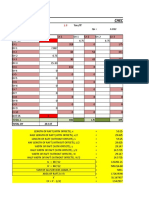

INPUT Span of Beam Lo FEM Thickness of Slab= Df Live Load= LL Floor thickness= thickness of Plaster= Beadth of WebBw Depth of Web Dw d 6.250 126.522 0.115 3.500 0.075 0.025 0.225 0.305 Mtrs KNM Mtrs Kn/sq.m Mtrs Mtrs Mtrs mtrs Bar Dia Clear Cover No Tyre Area of LL C/C of slab Hangr bar dia wall Height wall wdth 16 25 1 18 3.33 10 2.75 0.225

DESIGN Effective Depth= Dead Load Slab= Live Load= Floor Load= Plaster Total Load=

0.379 Mtrs dead load wall= 2.875 3.5 1.8 0.6 8.775 Kn/sq,m

a) Load per meter run of slab ,= Load on slab per unit area x centre to centre distance of beams 25.272 kn/m LL+DL+Wall wt=37.152 Effective width of flange Bf=Lo/6+ Bw+6Df 1.956667 Mtrs Minimum value of Flange width = 3.330 or 1.95667 C/c slab OR Bf calculated Bf= therefore Effective Width of Flange = 1.956666667 b) Dead Load of Beam 1.715625 Kn/m a) + b) 38.868 Kn/m WL^2 / 8 kNm

Total Load on Beam=

Factored maximum Bending Moment= 284.675 factored FEM on ends 189.783 KNM

Design Factored moment at centre =

94.8916626 KNM

mm mm Sq.m mtrs mm mtrs mtrs

11.880

tance of beams

Bf calculated

stress in comp steel

fy = 500 Fck 20 Roh Sc= 412 n/mm^2 Roh cc 0.446 Rsc n/mm^2

M= fMu bw= Bf= Df At= Asc= d= % p= 230

146 Knm 225 225 115 961.33 157.1 379 1.13%

Xm

=0.46*500 =0.46*fy

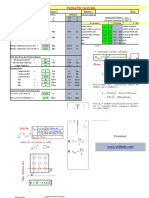

Df/d 0.303430079 greater than > 0.2 assume NA lies in Flange therefor Yt =0.15 x +0.65 Df 109.25 x= (0.87 Ry At -(Rsc Asc- 0.446 Fck *Asc)) / 0.36 * Fck Bf x= 219.045389 > Df cal culate x actual MR .87 Fy At (d-.42 x) MR 120.017 KNM

ie yt < Df

0.87* fy At = 0.36 Fck Bw X + 0.446 Fck (Bf-Bw) Yt + ( Rasc - Rasc ) calculated x = Yt = Df /x = 219.045389 x>depth of NA greater than 0.46*500 Xm =230 it is over reinforced section x < Xm under reinforced section 107.6068083 > Df < Df 0.525005345 < 0.43 over reinforced section > 0.43 under reinforced section

M resistance = 0.87* fy *At* Z a= Z= d- a MR = 82.76208247 296.2379175 123.8800016 KNM

Shear Check

%p= Vu = Tv = Tc= T d= 6 mm stirrups Asv = x= min steel 1.13% 158 1.852829 0.5 1.352829 kn n/mm^2 n/mm^2 n/mm^2

ref p no 165 ashok jain nominal shear stress

56.556 mm^2 = 0.87 * Fy Asv / ( Td *Bw) 80.8244 mm c/ c spacing 0.4 .b. x / fy 14.54839 mm^2 < Asv

ok

ref ; p no 129 of reinforced design by ashok jain for doubly reinforced beam stress steel concrete r = cost of steel / concrete r= sqrt ( r m 1..253 / (0.87*fy*Bw) ) 340.8177 mm 298300 per Cum 4800 per Cum 62.14583 steel 38/ kg

economical depth of T beam=

00 Xm =230 it is over reinforced section

ashok jain nominal shear stress

steel 38/ kg

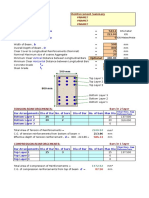

DESIGN OF T-BEAM ( NEAUTRAL AXIS IN THE FLANGE ) @ Centre

INPUT Fy= Fck= 500 20 optional INPUT BM FACTORED AT CENTRE 128 KNM NA < = Df

1)

Let Us Assume Neutral Axis In the Flange 1950 128

Bf= at centre F BM = i.e, X= F BM=

d=

0.379

x=0.87x fy At / ( 0.36 x Fck x Bf ) 0.00003 At

Force of Tension x Z ,= 0.87 * Fy * At * ( d-0.42 x) 128000000 164865 0.00566 C= bX aX^2 A= A= 29124347 776.4135

2 C= X= bX

1 , - aX^2 2 -1

Which ever is Less At= 776.4135 mm^2 and X= 0.0240555 mm Slab Thickness = So X = 0.02 115

0.02406 Less than Slab Thickness Design OK

3.86 4.00 16 mm dia bars beam in 16 mm dia bars beam in 10 mm dia bars beam in say 804.2477 mm^2 603.1858 173.3156 776.5014 mm^2

Therefore NA Lies In Flange Therefore Use bar dia USE OR USE USE 4.00 Nos 3.00 Nos 2.207 Nos 16 mm

2) minimum area of tension steel=

Ao = 0.85*Bw * d / ( Fy) Ao = 144.9675 mm^2 At = 804.24772 Greater than minimum area of Steel required

Design OK

3) maximum area of tension steel= At= 0.04 Bw D At = 3780 mm^2 At = 804.25 mm^2

Less than Maximum tension steel Design OK

DESIGN OF T BEAM ( NEAUTRAL AXIS IN THE FLANGE) @ end

INPUT Fy= Fck= Let Us Assume Neutral Axis In the Flange 2.19 146 x=0.87x fy At / ( 0.36 x Fck x Bf ) X= F BM= Force of Tension x Z ,= 0.87 * Fy * At * ( d-0.42 x) 164865 5.04024 aX^2 2 C= X= 0.02759 At 500 20

optional INPUT FEM FACTORED AT END

1)

NA < = Df

Bf= at ENDS F BM = i.e,

d=

0.379

1.46E+08 C= bX A= A= Which ever is Less At= and X= Slab Thickness = So X = Therefore NA Lies In Flange Therefore Use bar dia Therefore Use bar dia USE 2) minimum area of tension steel=

31798.8116 910.9420986

910.9420986 mm^2

25.13063248 mm 25.13 115

25.13 Less than

10 mm 16 mm 4.00 Nos

2.00 3.41 16 mm dia bars in

Ao = 0.85*Bw * d / ( Fy) Ao = 144.97 At = 961.33

Greater than

3) maximum area of tension steel= At= 0.04 Bw D At = 3780.00 At = 961.33

Less than

HE FLANGE) @ end

optional INPUT FEM FACTORED AT END 146 KNM

1 bX 2 -1 , - aX^2

Slab Thickness

Design OK

Nos hanger bars 3.00 say beam

mm dia bars in

mm^2 minimum area of Steel required

Design OK

mm^2 mm^2 Maximum tension steel

Design OK

DESIGN OF T BEAM ( NEAUTRAL AXIS IN THE web) @ end

INPUT Fy= Fck= Let Us Assume Neutral Axis In the Flange 225 146 x=0.87x fy At / ( 0.36 x Fck x Bf ) X= F BM= Force of Tension x Z ,= 0.87 * Fy * At * ( d-0.42 x) 164865 49.05833 aX^2 #NUM! #NUM! 2 C= X= 0.26852 At 500 20

optional INPUT FEM FACTORE

1)

NA > = Df

Bw= at ENDS F BM = i.e,

d=

379

1.46E+08 C= bX A= A= Which ever is Less At= and X=

#NUM!

mm^2 mm #NUM! 115

#NUM! Slab Thickness = So X = #NUM!

#NUM!

#NUM!

Therefore Use bar dia Therefore Use bar dia USE #NUM! Nos

10 mm 16 mm

2.00 #NUM! 16 mm dia bars in

2) minimum area of tension steel=

Ao = 0.85*Bw * d / ( Fy) Ao = 144.97 At = #NUM!

#NUM!

3) maximum area of tension steel= At= 0.04 Bw D At = 3780.00 At = #NUM!

#NUM!

THE web) @ end

ptional INPUT FEM FACTORED AT END 146 KNM

1 bX 2 -1 , - aX^2

Slab Thickness

#NUM!

Nos hanger bars #NUM! say beam

m dia bars in

mm^2 minimum area of Steel required

#NUM!

mm^2 mm^2 Maximum tension steel

#NUM!

You might also like

- Cantilever SlabDocument16 pagesCantilever SlabMukhlish AkhatarNo ratings yet

- A. For Column C: Design of Combined Footing (CF) : 1. Design DataDocument12 pagesA. For Column C: Design of Combined Footing (CF) : 1. Design Datap_ignatiusNo ratings yet

- 1106.ductile Intermediate Beam Design As Per ACI 318MDocument4 pages1106.ductile Intermediate Beam Design As Per ACI 318MNapoleon CarinoNo ratings yet

- 2a - Design of Spread Footing-Usd MethodDocument27 pages2a - Design of Spread Footing-Usd MethodLouise LuyNo ratings yet

- Wcr= (h-x) 3 a ϵ 1+2 (a C) : Crack Width Calculation for ColumnDocument3 pagesWcr= (h-x) 3 a ϵ 1+2 (a C) : Crack Width Calculation for ColumnAnil kumar RNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- Reinforced Concrete Retaining Wall Design To BS 8110Document10 pagesReinforced Concrete Retaining Wall Design To BS 8110thabisoNo ratings yet

- On RCC DetailingDocument22 pagesOn RCC DetailingjadeaachiNo ratings yet

- Design of Reinforced Concrete Shear WallDocument8 pagesDesign of Reinforced Concrete Shear WallklynchelleNo ratings yet

- Combine Footing FinallDocument227 pagesCombine Footing FinallKhalid BanafaNo ratings yet

- Slab Design ExcelDocument5 pagesSlab Design ExcelVinod RevankarNo ratings yet

- Raft DesignDocument27 pagesRaft DesignZain SaeedNo ratings yet

- Pile Cap Design Calculations With CSI SAFEDocument6 pagesPile Cap Design Calculations With CSI SAFEroshanNo ratings yet

- L Footing Design ProgramDocument5 pagesL Footing Design ProgramTariku DessuNo ratings yet

- Lecture 4 Shear EC2Document13 pagesLecture 4 Shear EC2BasmiNo ratings yet

- Design of Isolated FootingDocument28 pagesDesign of Isolated FootingmeenuNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Design of Reinforced Concrete Shear WallDocument15 pagesDesign of Reinforced Concrete Shear WallAnonymous nwByj9L0% (1)

- Design of Shear Wall: Reference DataDocument8 pagesDesign of Shear Wall: Reference DataKiranNo ratings yet

- T Beam DesignDocument6 pagesT Beam Designkalpanaadhi0% (1)

- Design of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250Document5 pagesDesign of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250kiran raghukiranNo ratings yet

- Coupling BeamDocument2 pagesCoupling Beamwilliam6703100% (1)

- International Codes-Is456 - Beam Design in STAAD Pro - V8iDocument5 pagesInternational Codes-Is456 - Beam Design in STAAD Pro - V8iUmesh ChikhlikarNo ratings yet

- Composite Floor GirderDocument3 pagesComposite Floor GirderlucianduNo ratings yet

- Basement Wall DesignDocument2 pagesBasement Wall DesignArindam RoyNo ratings yet

- RCC Beams: Doubly Reinforced BeamDocument2 pagesRCC Beams: Doubly Reinforced BeamSandeep ChavanNo ratings yet

- Given Data: Given Data:: Design of Raft Foundation Design of Raft FoundationDocument8 pagesGiven Data: Given Data:: Design of Raft Foundation Design of Raft FoundationBikram BhusalNo ratings yet

- Eccentric-Footing 2Document5 pagesEccentric-Footing 2Yash GoyalNo ratings yet

- RCC51 Column Load Take-Down & DesignDocument8 pagesRCC51 Column Load Take-Down & DesignirrezaNo ratings yet

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNo ratings yet

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDocument6 pagesSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraNo ratings yet

- Design of Isolated MatDocument5 pagesDesign of Isolated MatYAROFENo ratings yet

- 3 Analysis and Design of Deck SlabDocument14 pages3 Analysis and Design of Deck SlabAshish BhoiNo ratings yet

- Design of Two-Way Restrained Slab (IS456:2000)Document3 pagesDesign of Two-Way Restrained Slab (IS456:2000)BasandharaAdhikariNo ratings yet

- RCC FormulaDocument7 pagesRCC FormulaIqbal HasanNo ratings yet

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignZayyan RomjonNo ratings yet

- Isolated Trapezoidal Footing DesignDocument6 pagesIsolated Trapezoidal Footing Designhemantkle2uNo ratings yet

- Lintel DesignDocument5 pagesLintel DesignZayyan Romjon100% (1)

- Single Footing Design - SI UnitsDocument2 pagesSingle Footing Design - SI UnitsA.K.M Shafiq MondolNo ratings yet

- Design Detail For RCC One Way SlabDocument18 pagesDesign Detail For RCC One Way SlabWanda BeasleyNo ratings yet

- Single Isolated Rectangular FootingsDocument13 pagesSingle Isolated Rectangular FootingsAamirShabbirNo ratings yet

- IAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanDocument29 pagesIAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanSrikanth ReddyNo ratings yet

- RCC Rect Col-Dsn Kns 176Document7 pagesRCC Rect Col-Dsn Kns 176nvnrevNo ratings yet

- R.C.C Designs As Per Is 456-2000Document188 pagesR.C.C Designs As Per Is 456-2000Umesh ChamaraNo ratings yet

- Check For Crack Width As Per Is 456-2000: 250 MM 350 MMDocument2 pagesCheck For Crack Width As Per Is 456-2000: 250 MM 350 MMgmhameedaliNo ratings yet

- Design of Cantilever Slab (Balconey)Document11 pagesDesign of Cantilever Slab (Balconey)Engineeri TadiyosNo ratings yet

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDocument10 pagesVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanNo ratings yet

- RCD Course Work PDFDocument60 pagesRCD Course Work PDFSaciid LaafaNo ratings yet

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Unit SS Design Calculations For PrecastDocument13 pagesUnit SS Design Calculations For PrecastKumar SureshNo ratings yet

- PDF Wind Load Calculations As Per Is 875 Part 3xls CompressDocument85 pagesPDF Wind Load Calculations As Per Is 875 Part 3xls CompressNews Side Effects.No ratings yet

- Two Way Slab Design Excel SheetDocument11 pagesTwo Way Slab Design Excel SheetZevanyaRolandTualakaNo ratings yet

- ACI Beam DesignDocument1 pageACI Beam DesigndantevariasNo ratings yet

- Section Properties: Column Design As Per IS:456-2000 Column No. 3Document4 pagesSection Properties: Column Design As Per IS:456-2000 Column No. 3Eknath TaleleNo ratings yet

- Detail Design of Primary BeamDocument6 pagesDetail Design of Primary BeamAmit TharuNo ratings yet

- Aci BeamDocument6 pagesAci BeamkumsbamaNo ratings yet

- F1Document16 pagesF1engineerkranthi4055No ratings yet

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Bracket - 4 DesignDocument1 pageBracket - 4 Designbjreddy100% (2)

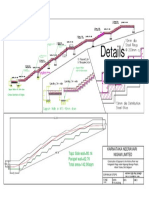

- Prayer Ghat For Hindus/sopanum Plan Final-SectionDocument1 pagePrayer Ghat For Hindus/sopanum Plan Final-SectionRiazahemad B JagadalNo ratings yet

- Sopanum Photos PDFDocument6 pagesSopanum Photos PDFRiazahemad B JagadalNo ratings yet

- Sopanum Plan Final-StepsDocument1 pageSopanum Plan Final-StepsRiazahemad B JagadalNo ratings yet

- Sopanum Plan Final-PlanDocument1 pageSopanum Plan Final-PlanRiazahemad B JagadalNo ratings yet

- Multi Level Pool Irrigation SystemDocument63 pagesMulti Level Pool Irrigation SystemRiazahemad B Jagadal100% (1)

- Schedule of Rates 2012-13 WRD KarnatakaDocument173 pagesSchedule of Rates 2012-13 WRD KarnatakaRiazahemad B Jagadal100% (1)

- Gantt Chart, CPM/Pert ChartDocument2 pagesGantt Chart, CPM/Pert ChartRiazahemad B JagadalNo ratings yet

- Schedule of Rates 2012-13 WRD KarnatakaDocument173 pagesSchedule of Rates 2012-13 WRD KarnatakaRiazahemad B Jagadal100% (1)

- RCC SLAB 11-12 Rate AnalysisDocument2 pagesRCC SLAB 11-12 Rate AnalysisRiazahemad B Jagadal0% (1)

- Gantt Chart Building Ground FloorDocument1 pageGantt Chart Building Ground FloorRiazahemad B JagadalNo ratings yet

- PWD SR 11-12 KarnatakaDocument470 pagesPWD SR 11-12 KarnatakaRiazahemad B Jagadal87% (30)

- Road Bridge Drawing by Autocad Parametric MethodDocument1 pageRoad Bridge Drawing by Autocad Parametric MethodRiazahemad B JagadalNo ratings yet

- Applications of Electronic Science in Sugar IndustriesDocument30 pagesApplications of Electronic Science in Sugar IndustriesRiazahemad B Jagadal100% (1)

- CONT 3S Ofre OcantiDocument2 pagesCONT 3S Ofre OcantiRiazahemad B Jagadal100% (1)

- PRTL FRM Swy 3spn+3mdfyDocument9 pagesPRTL FRM Swy 3spn+3mdfyRiazahemad B JagadalNo ratings yet

- Propped End SS BEAM Program in C++Document1 pagePropped End SS BEAM Program in C++Riazahemad B JagadalNo ratings yet

- Schedule of Rates 2011-12Document149 pagesSchedule of Rates 2011-12Riazahemad B JagadalNo ratings yet

- Data Rates 07-08 CanalDocument156 pagesData Rates 07-08 CanalRiazahemad B JagadalNo ratings yet

- Handbook For Developing Watershed PlansDocument400 pagesHandbook For Developing Watershed Planseuthan100% (6)

- WRD, Karnataka, India, Schedule of Rate 2007-8Document106 pagesWRD, Karnataka, India, Schedule of Rate 2007-8Riazahemad B Jagadal100% (1)

- Hydrostatic Pressure Test Safety ChecklistDocument3 pagesHydrostatic Pressure Test Safety ChecklistJerry Faria60% (5)

- VTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFDocument176 pagesVTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFIbrahim AwadNo ratings yet

- 6.T24 Common Variables-R14Document29 pages6.T24 Common Variables-R14Med Mehdi LaazizNo ratings yet

- LSM - Neutral Axis Depth CalculationDocument2 pagesLSM - Neutral Axis Depth CalculationHimal KafleNo ratings yet

- Ibps Po Mains Model Question Paper PDF Set 2Document92 pagesIbps Po Mains Model Question Paper PDF Set 2DHIRAJNo ratings yet

- Lesson 1 - Basic Concept of DesignDocument32 pagesLesson 1 - Basic Concept of DesignSithara BandaraNo ratings yet

- ET275 Unit 2 - Lesson Plan - SlidesDocument27 pagesET275 Unit 2 - Lesson Plan - SlidesDonald LeedyNo ratings yet

- OOPS Module 1Document26 pagesOOPS Module 1robinptNo ratings yet

- 13 DocumentsDocument38 pages13 DocumentsPoorClaresBostonNo ratings yet

- Paper 1 - 2017 EETDocument10 pagesPaper 1 - 2017 EETRayNo ratings yet

- 1-10 Clariant - Prasant KumarDocument10 pages1-10 Clariant - Prasant Kumarmsh43No ratings yet

- PosdmDocument29 pagesPosdmChandraBhushan67% (3)

- For Visual Studio User'S Manual: Motoplus SDKDocument85 pagesFor Visual Studio User'S Manual: Motoplus SDKMihail AvramovNo ratings yet

- Dell Online - Case AnalysisDocument5 pagesDell Online - Case AnalysisMohit Agarwal0% (1)

- TEMI880&850 Manual (Eng)Document122 pagesTEMI880&850 Manual (Eng)Mihir PrajapatiNo ratings yet

- Fuel Supply Agreement - First DraftDocument104 pagesFuel Supply Agreement - First DraftMuhammad Asif ShabbirNo ratings yet

- Landini Tractor 7000 Special Parts Catalog 1820423m1Document22 pagesLandini Tractor 7000 Special Parts Catalog 1820423m1katrinaflowers160489rde100% (122)

- Rachel Mitchell Task 1Document1,003 pagesRachel Mitchell Task 1nazmul HasanNo ratings yet

- 5th Year PES Mrs - Hamdoud Research Methodology 2Document3 pages5th Year PES Mrs - Hamdoud Research Methodology 2Rami DouakNo ratings yet

- Sustainable Project Management. The GPM Reference Guide: March 2018Document26 pagesSustainable Project Management. The GPM Reference Guide: March 2018Carlos Andres PinzonNo ratings yet

- Reflection of The Movie Informant - RevisedDocument3 pagesReflection of The Movie Informant - RevisedBhavika BhatiaNo ratings yet

- Dilip - SFDC CPQ Architect14 GCDocument5 pagesDilip - SFDC CPQ Architect14 GCmariareddy17100% (1)

- Mechanical FPD P.sanchezDocument9 pagesMechanical FPD P.sanchezHailley DensonNo ratings yet

- Case Study On DominoDocument7 pagesCase Study On Dominodisha_pandey_4No ratings yet

- 1000.01 Good Documentation PracticesDocument13 pages1000.01 Good Documentation PracticescipopacinoNo ratings yet

- WFP Situation Report On Fire in The Rohingya Refugee Camp (23.03.2021)Document2 pagesWFP Situation Report On Fire in The Rohingya Refugee Camp (23.03.2021)Wahyu RamdhanNo ratings yet

- Pipenet: A Wireless Sensor Network For Pipeline MonitoringDocument11 pagesPipenet: A Wireless Sensor Network For Pipeline MonitoringMykola YarynovskyiNo ratings yet

- NV 2Document2 pagesNV 2Joshua ApongolNo ratings yet

- Which Among The Following Statement Is INCORRECTDocument7 pagesWhich Among The Following Statement Is INCORRECTJyoti SinghNo ratings yet

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDocument6 pages29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (4)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionFrom EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionRating: 3.5 out of 5 stars3.5/5 (129)

- ChatGPT: The Future of Intelligent ConversationFrom EverandChatGPT: The Future of Intelligent ConversationRating: 3.5 out of 5 stars3.5/5 (8)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSFrom EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSNo ratings yet

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildFrom EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildRating: 5 out of 5 stars5/5 (5)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsFrom EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsRating: 5 out of 5 stars5/5 (3)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- Building with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksFrom EverandBuilding with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksNo ratings yet

- Practical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)From EverandPractical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)No ratings yet

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Artificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesFrom EverandArtificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesRating: 5 out of 5 stars5/5 (2)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 3.5 out of 5 stars3.5/5 (22)

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet