Professional Documents

Culture Documents

Motor Constants

Uploaded by

oscalcOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor Constants

Uploaded by

oscalcCopyright:

Available Formats

DC Motor/Generator Technical Note A Practical Use Of The Motor Constant KM An Aid In The Selection Of DC Motors Or Generators In Power Limited

Or Efciency Sensitive Applications.

Introduction Frequently a dc motor or generator specication will include the value of the motor constant KM, which is the torque sensitivity divided by the square root of the winding resistance. Oftentimes even seasoned dc motor applications specialist will view this intrinsic motor property as a somewhat esoteric gure of merit useful only to the motor designer. The feeling is that motor constant KM has no real practical value in selecting and dc motors and generators in the real world. Nothing could be further from the truth! Utilizing this gure of merit properly will substantially reduce the iterative process in selecting a dc motor or generator since it is generally winding independent in a given case or frame size motor or generator from a given vendor. Even in ironless dc motors, where the KM may vary somewhat depending on winding due to variations in the copper ll factor, it remains a solid tool in the selection process. Particularly if there is a listing with Motor Constant in ascending or descending order, like there is in Appendix III at the end of this document. This methodology limits the winding hunt where one winding satises the current requirements but not the voltage requirements and vice versa. You cant get there from here if the motor does not have the intrinsic electromechanical ability to satisfy the application requirements. This is NOT a thermal issue, but the intrinsic ability of the motor to transform electrical power to mechanical power or the generator to transform mechanical power to electrical power. Since the KM of an electromechanical device does not address the losses in that device in all circumstances the minimum KM must be larger than calculated to address those losses. This method may not get you to exactly the correct house but it will put you on the correct street. This methodology is also a good sanity check since it forces the user to compute both the input and output power. This was an omission the author made more than a quarter century ago in attempting to address a requirement from a University PhDs need for a motorized prosthesis device that simply deed the Laws of Physics. It was also the rst and last time such an error was ever made!

Derivation The Motor Constant addresses the fundamental electromechanical nature of a motor or generator. The selection of a suitable winding is simple after an adequately powerful case or frame size is determined. The motor constant KM is dened as: 1. KM = KT/R Generators have torque constants too. In fact they are really nothing more than a motor driven backwards! In a dc motor application with limited power availability and a known torque needed at the motor shaft the minimum KM will be set. A derivation is in Appendix II at the end of this document. For a given motor application the minimum KM will be: 2. KM = T / (PIN- POUT)0.5 The power into the motor will be positive. For a generator application it would be negative since you are taking power out. PIN is simply the product of the current and voltage, assuming no phase shift between them. 3. PIN = V I The power out of the motor will be positive, since it is supplying mechanical power. For a generator application it would be negative since the generator is taking mechanical power. It is simply the product of the rotational speed and torque. 4. POUT = W T The nesse of performing these calculations in the metric system is that no burdensome conversion factors are needed. Example 1-Motor Application: A battery-powered device needs 300 rad/sec and 5 mNm of torque (2865 rpm and 0.708 oz-in). Power available is 12 Volts and 0.16 Amps. This example actually represents an efciency of 78.125%. Using equation 2, KM = T / (PIN - POUT)0.5 KM = 5 x 10-3 Nm / (12 Volts x 0.16 Amps 300 rad/sec x 5 x 10-3 Nm)0.5 KM = 5 x 10-3 Nm / (1.92 Watt 1.5 Watt)0.5 KM = 7.715 x 10-3 Nm/Watt Consulting the table in Appendix III we see that the rst MicroMo Coreless Motor that at nominal values has sufcient KM is the 2842 006C. It should be noted that the tolerances of the Torque Constant and the Winding Resistance should be accounted for. For example, if the Torque Constant and the Winding Resistance have 12% tolerances KM worst case will be: 5. KMWC = 0.88 KT/(R * 1.12) = 0.832 KM or almost 17% below nominal values with a cold winding. Taking worst case KMWC we nd that the rst motor that might work is the 3540 024C.

Heating of the winding will further reduce KM since copper resistivity rises almost 0.4% per degree C. Just to exacerbate the problem the magnetic eld will attenuate with rising temperatures. Depending on the permanent magnet material utilized this could be as much as 20% for a 100C rise in temperature. The 20% attenuation for 100C magnet temperature rise would be for Ferrite Magnets. Neodymium-Boron-Iron has 11% or more, and Samarium Cobalt about 4%. Example 2-Generator Application: A brushless dc generator must develop 500 Watt at 24 Volts dc. This must be developed at a rotor speed of 30 rad/sec and 20.833 Nm of torque. To calculate the mechanical power delivered 6. PIN = W T Thus: PIN = - 30 rad/sec x 20.833 Nm = - 625 Watt To determine the efciency of the generator: 6. n = PIN / POUT= - 500 Watt /- 625 Watt = 80% We can utilize equation 2 or KM = T / (PIN- POUT)0.5 KM = 20.833 Nm / (- 625 Watt + 500 Watt)0.5 KM = 1.863 Nm / Watt = 1,863 mNm / Watt Just like in a motor application, this minimum KM must be at the windings steady state worst case operating temperature. Generators have heat losses just like motors do. This approach for a minimum KM is only the rst step in analysis. Tolerances in torque constant (or back emf constant) and winding resistance must also be accounted for, as well as any attenuation in the torque constant due to a rise in magnet temperature. A suitable winding must then be selected and a thermal analysis must be performed. Additionally, in the case of a generator it must be clear if the efciency is before or after losses in rectifying the ac voltage to a dc level. Interestingly, if for the same mechanical input power if a target of 88% efciency was desired then the minimum KM would skyrocket from 1.863 Nm/Watt to 2.406 Nm/Watt. That is equivalent to having the same Winding Resistance but needing the Torque Constant to increase more than 29%. The higher the efciency desired, the higher the KM required. Graph 1 illustrates the sensitivity of KM as efciency requirements. In Example 2 there is no standard MicroMo product that would satisfy this application at this time. Forthcoming products will be able to satisfy such applications in the near future. Choosing a Winding Although beyond the scope of this paper to go into detail on a rigorous winding selection and suitability check a hint is in order. If in the case of the motor application you know the maximum current available and the worstcase torque load. Compute the lowest torque constant that is acceptable. 7. KT =T/I Once you have found a motor family with sufcient KM select a winding that has a torque constant that is closes to your minimum but exceeds it. Then commence determining if the winding will, in all cases of tolerances and application constraints, perform satisfactorily.

Conclusion Clearly, choosing a motor or generator by rst determining the minimum KM in power sensitive motor and efciency challenging generator applications can speed the selection process. The next step will then be to select a suitable winding and insure that all application parameters and motor/generator limitations are acceptable, including consideration due to winding tolerances. Because of the manufacturing tolerances, thermal effects, and internal losses one should ALWAYS choose a KM somewhat larger than what the application requires. Indeed, a certain amount of latitude is needed since there are not an innite number of winding variations available from a practical point of view. The larger the KM, the more forgiving it is in satisfying a given applications requirements. Graph 1

Minimum Motor Constant vs. Efficiency 8.0 7.0 6.0 Km mNm/vWatt 5.0 4.0 3.0 2.0 1.0 0.0 40 45 50 55 60 65 70 75 80 85 90

2025 0245 1.23 oz 0.71 1331 012S 1336 006 0.81 oz 2036 024B 1.76 oz 1.77 oz 2230 015S 2233 006S 2.15 oz 6.35 oz 3540 024C

1 Watt Mechanical Output Power 2.5 mNm at 400 rad/sec (0.35 oz-in at 3820 rpm)

2.47 oz 2338 018S 3.5 oz 2444 S 024B

4.66 oz 2842 006C

2444 S 024B 3.5 oz

M otor W ei ght i Red n Fi rst M i croM o M otor to exceed necessary worst case KM i i cated i bl l s ndi n ue etters

% Efficiency Required

As Graph 1 illustrates, demanding higher efciency power generation or motor efciency will come at a price. The price will be larger motors and generators. That translates generally to more expensive motors and generators. In general, practical efciencies above 85 - 90% may be virtually unobtainable. Larger motors and generators have larger mechanical losses. This is due to bearing, windage, and electromechanical losses like hysteresis and eddy currents. Brush type motors also have losses from the mechanical commutation system. In the case of precious metal commutation, popular with coreless motors, these commutation losses can be extremely small, less than the bearing losses. Ironless dc motors and generators have virtually no hysteresis and eddy current looses in the brush variant of this design.

In the brushless versions these losses, although low, do exist. This is because the magnet is usually rotating relative to the back iron of the magnetic circuit. This induces eddy current and hysteresis losses. However, there are brushless dc versions that have the magnet and back iron moving in unison. In these cases losses are usually very low. Be it generating electrical power efciently or pumping out mechanical power with a misers attention to power consumption, brush and brushless dc ironless motors and generators are an excellent consideration in power sensitive or efciency craving applications.

July 22, 2002 George A. Beauchemin Corporate Product Manager MicroMo Electronics, Inc. http://www.micromo.com http://www.micro-drives.com email: George.Beauchemin@micromo.com Phone: (760) 451-2723 (Pacic Coast Time Zone) Fax: (727) 828-1598

Appendix I SYMBOLS AND UNITS Symbol I Denition Current to motor Or delivered from generator Back emf constant Motor Constant Motor Constant-Worst Case With tolerances considered Torque Sensitivity efciency of electrical to mechanical or mechanical to electrical conversion Input Power Unit(s) Amp

KER KM KMWC KT n

Volt-sec* Nm/Watt Nm/Watt

Nm/Amp** %

PIN

Watt Watt Ohm

POUT Output Power R Cold Winding Resistance specied by manufacturer Load Torque or Driving Torque Motor or Generator Rotational Speed Voltage Applied to Motor or Load Voltage of Generator

T W V

Nm rad/sec Volt

* **

Volts-sec is equivalent to Volt/(rad/sec) Nm/Amp is Newton-meters/Amp

Appendix II Determination of Minimum Motor Constant KM. The dynamic equation of a dc motor is: A. V = I R + K w The Motor constant KM is dened as: B. KM = KT/R

In the MKS system KT = KER = K Therefore: C. KM = K/R

If we solve Equation C for R we have, after squaring both sides: D. R = K2 / KM2

We further know that the torque generated is: E. T=IK

Or, solving for I: F. I = T /K

If we then subtract (K x w) from both sides in Equation A, and substitute values of R in Equation D and I in Equation F: V K x w = I x R = (T/K) K2 / KM2 = T K / KM2 Solving for KM: G. KM2= T K /(V - K x w)

If we solve Equation E for K we have: H. K = T/I

Continuing to solve Equation G for KM by substituting K of Equation H. I. KM2= T (T/I)/(V (T/I) x W) = T2/(V I-T w)

Taking the square root we have: J. KM= T/(V I-T W)0.5

Note that the mechanical power is dened as the product of speed and torque or: K. POUT = T W

The electrical power is the product of Voltage and Current or: L. PIN = V I

Therefore, putting Equations K and L into J we have: M. KM = T / (PIN- POUT)0.5

Just remember that in a generator application PIN and POUT will have negative values.

Appendix III Motor Constant of MicroMo DC Motor Products Descending by Nominal Motor Constant Data from Spread Sheet Supplied By Clyde Hancock Some Data May Have Minor Revisions Since The Spread Sheet Was Created Part Number GNM 70130 80V GNM 70130 24V 1.5K GNM 70130 180V 3K GNM 70130 24V 3K GNM 70130 180V 1.5K GNM 8070/4 GNM 7085 180V 1.5K GNM 7085 24V 1.5K GNM 7085 180V 3K GNM 7085 80V GNM 7085 24V 3K GNM 62100 180V 1.5K GNM 62100 24V 1.5K GNM 8035/4 GNM 62100 180V 3K GNM 62100 80V GNM 62100 24V 3K GNM 7045 24V 1.5K GNM 7045 180V 3K GNM 5480 180V 3K GNM 7045 24V 3K GNM 5480 180V 1.5K GNM 7045 180V 1.5K GNM 5480 24V 3K GNM 5480 34V GNM 5480 24V 1.5K GNM 5480 42V GNM 7045 80V GNM 5440 180V 3K GNM 5440 24V 1.5K GNM 5440 42V GNM 4175 24V 1.5K GNM 4175 42V GNM 4175 180V 1.5K GNM 4175 180V 3K GNM 5440 34V GNM 5440 180V 1.5K GNM 4175 34V GNM 5440 24V 3K GNM 4175 24V 3K GNM 4150 24V 1.5K GNM 4150 42V GNM 4150 180V 3K GNM 4150 34V GNM 4150 180V 1.5K GNM 4150 24V 3K GNM 3175 3K GNM 3175 4K GNM 4125 24V 3K GNM 4125 24V 2K Motor Constant-Nominal 464.8 mNm/Watt 448.1 mNm/Watt 444.2 mNm/Watt 424.3 mNm/Watt 422.9 mNm/Watt 386.8 mNm/Watt 365.1 mNm/Watt 354.6 mNm/Watt 352.8 mNm/Watt 336.4 mNm/Watt 319.2 mNm/Watt 295.9 mNm/Watt 286.2 mNm/Watt 272.2 mNm/Watt 270.0 mNm/Watt 237.4 mNm/Watt 236.7 mNm/Watt 230.7 mNm/Watt 226.0 mNm/Watt 221.9 mNm/Watt 219.9 mNm/Watt 219.9 mNm/Watt 216.1 mNm/Watt 214.0 mNm/Watt 213.5 mNm/Watt 208.9 mNm/Watt 208.9 mNm/Watt 205.7 mNm/Watt 136.3 mNm/Watt 136.3 mNm/Watt 136.3 mNm/Watt 136.2 mNm/Watt 136.2 mNm/Watt 135.7 mNm/Watt 133.8 mNm/Watt 132.5 mNm/Watt 131.2 mNm/Watt 125.7 mNm/Watt 124.4 mNm/Watt 115.5 mNm/Watt 111.9 mNm/Watt 111.9 mNm/Watt 111.4 mNm/Watt 109.5 mNm/Watt 108.3 mNm/Watt 107.2 mNm/Watt 80.7 mNm/Watt 80.3 mNm/Watt 69.4 mNm/Watt 69.3 mNm/Watt Motor Constant-Worst Case 386.5 mNm/Watt 372.6 mNm/Watt 369.3 mNm/Watt 352.8 mNm/Watt 351.6 mNm/Watt 321.7 mNm/Watt 303.6 mNm/Watt 294.8 mNm/Watt 293.4 mNm/Watt 279.7 mNm/Watt 265.4 mNm/Watt 246.1 mNm/Watt 238.0 mNm/Watt 226.3 mNm/Watt 224.5 mNm/Watt 197.4 mNm/Watt 196.9 mNm/Watt 191.8 mNm/Watt 187.9 mNm/Watt 184.5 mNm/Watt 182.8 mNm/Watt 182.8 mNm/Watt 179.7 mNm/Watt 178.0 mNm/Watt 177.5 mNm/Watt 173.7 mNm/Watt 173.7 mNm/Watt 171.0 mNm/Watt 113.4 mNm/Watt 113.3 mNm/Watt 113.3 mNm/Watt 113.2 mNm/Watt 113.2 mNm/Watt 112.8 mNm/Watt 111.2 mNm/Watt 110.2 mNm/Watt 109.1 mNm/Watt 104.5 mNm/Watt 103.5 mNm/Watt 96.1 mNm/Watt 93.1 mNm/Watt 93.1 mNm/Watt 92.6 mNm/Watt 91.0 mNm/Watt 90.1 mNm/Watt 89.1 mNm/Watt 67.1 mNm/Watt 66.8 mNm/Watt 57.7 mNm/Watt 57.6 mNm/Watt

GNM 4125 42V GNM 4125 180V 3K GNM 4125 180V 2K GNM 4125 34V GNM 3150 3K GNM 3150 4K 4490 H 036 B 4490 H 024 B 4490 H 048 B GNM 2670A 4K GNM 2670A 3K 3863 048C 3863 024C 3863 012C GNM 3125 4K GNM 3125 3K GNM 2636A 4K GNM 2636A 3K 3557 048CR 3557 012CR 3557 024CR 1331 006S 3564 012B 3557 012CS 3557 009CS 3564 024B 3564 048B 3564 036B 3557 048CS 3557 024CS 3557 020CS 3042 036C 3042 012C 3557 020C 3042 018C 3557 006C 3042 024C 3557 012C 3557 032C 3557 009C 3557 024C 3042 006C GNM 2145 24V GNM 2145 12V 3056 048B 3056 024B 3056 036B 3056 012B 2342 024 CR 2842 024C 3540 015C 2342 012 CR 2342 006 CR 2842 028C GNM 2130 12V GNM 2130 24V 3540 006C 2842 012C 2842 036C 3540 012C

69.3 mNm/Watt 67.9 mNm/Watt 65.3 mNm/Watt 65.3 mNm/Watt 62.5 mNm/Watt 61.8 mNm/Watt 49.0 mNm/Watt 48.9 mNm/Watt 48.8 mNm/Watt 48.0 mNm/Watt 46.6 mNm/Watt 42.6 mNm/Watt 42.5 mNm/Watt 41.8 mNm/Watt 38.4 mNm/Watt 37.2 mNm/Watt 34.1 mNm/Watt 32.9 mNm/Watt 30.7 mNm/Watt 30.4 mNm/Watt 30.3 mNm/Watt 27.3 mNm/Watt 18.8 mNm/Watt 18.1 mNm/Watt 17.8 mNm/Watt 17.6 mNm/Watt 17.6 mNm/Watt 17.6 mNm/Watt 17.6 mNm/Watt 17.5 mNm/Watt 17.1 mNm/Watt 16.5 mNm/Watt 16.0 mNm/Watt 15.9 mNm/Watt 15.5 mNm/Watt 15.5 mNm/Watt 15.2 mNm/Watt 15.1 mNm/Watt 15.0 mNm/Watt 14.8 mNm/Watt 14.4 mNm/Watt 14.2 mNm/Watt 12.2 mNm/Watt 11.9 mNm/Watt 10.4 mNm/Watt 10.3 mNm/Watt 10.3 mNm/Watt 10.1 mNm/Watt 10.0 mNm/Watt 9.8 mNm/Watt 9.7 mNm/Watt 9.6 mNm/Watt 9.6 mNm/Watt 9.6 mNm/Watt 9.6 mNm/Watt 9.6 mNm/Watt 9.6 mNm/Watt 9.5 mNm/Watt 9.5 mNm/Watt 9.5 mNm/Watt

57.6 mNm/Watt 56.4 mNm/Watt 54.3 mNm/Watt 54.3 mNm/Watt 52.0 mNm/Watt 51.4 mNm/Watt 40.7 mNm/Watt 40.6 mNm/Watt 40.5 mNm/Watt 39.9 mNm/Watt 38.8 mNm/Watt 35.4 mNm/Watt 35.3 mNm/Watt 34.8 mNm/Watt 31.9 mNm/Watt 30.9 mNm/Watt 28.3 mNm/Watt 27.4 mNm/Watt 25.5 mNm/Watt 25.2 mNm/Watt 25.2 mNm/Watt 22.7 mNm/Watt 15.6 mNm/Watt 15.0 mNm/Watt 14.8 mNm/Watt 14.7 mNm/Watt 14.7 mNm/Watt 14.7 mNm/Watt 14.6 mNm/Watt 14.6 mNm/Watt 14.2 mNm/Watt 13.7 mNm/Watt 13.3 mNm/Watt 13.2 mNm/Watt 12.9 mNm/Watt 12.9 mNm/Watt 12.6 mNm/Watt 12.6 mNm/Watt 12.5 mNm/Watt 12.3 mNm/Watt 12.0 mNm/Watt 11.8 mNm/Watt 10.1 mNm/Watt 9.9 mNm/Watt 8.6 mNm/Watt 8.6 mNm/Watt 8.5 mNm/Watt 8.4 mNm/Watt 8.3 mNm/Watt 8.1 mNm/Watt 8.1 mNm/Watt 8.0 mNm/Watt 8.0 mNm/Watt 8.0 mNm/Watt 8.0 mNm/Watt 8.0 mNm/Watt 7.9 mNm/Watt 7.9 mNm/Watt 7.9 mNm/Watt 7.9 mNm/Watt

3540 024C 2842 006C 2444 048B 2444 S 048 B 2444 024B 2444 S 024 B 2224 006S R 2224 012S R 2338 4.5S 2224 024S R 2338 006S 2230 040S 2338 024S 2233 04.5S 2338 009S 2338 018S 2338 012S 2233 012S 2233 006S 2233 018S 2230 003S 1727 006C 2230 015S 2230 012S 1727 012C 2230 024S 1724 012S 1724 006S 2230 006S 1724 024S 1724 018S 2036 012B 2233 024S 1724 003S 2036 036B 2036 024B 2036 048B 1727 024C 2225 003S 2225 006S 1336 012C 1336 024C 2233 030S 1336 006 2025 003S 1331 012S 1331 024S 1331 4.5S 1331 015S 2225 009S 1524 006S R 2225 012S 1524 012S R 1524 024S R 2025 006S 2025 012S 2225 024S 2025 009S 2025 024S 1624 009S

9.4 mNm/Watt 8.7 mNm/Watt 7.0 mNm/Watt 7.0 mNm/Watt 6.8 mNm/Watt 6.8 mNm/Watt 5.0 mNm/Watt 5.0 mNm/Watt 4.9 mNm/Watt 4.8 mNm/Watt 4.8 mNm/Watt 4.8 mNm/Watt 4.7 mNm/Watt 4.7 mNm/Watt 4.7 mNm/Watt 4.6 mNm/Watt 4.5 mNm/Watt 4.3 mNm/Watt 4.2 mNm/Watt 3.9 mNm/Watt 3.8 mNm/Watt 3.7 mNm/Watt 3.7 mNm/Watt 3.6 mNm/Watt 3.6 mNm/Watt 3.6 mNm/Watt 3.5 mNm/Watt 3.5 mNm/Watt 3.5 mNm/Watt 3.5 mNm/Watt 3.4 mNm/Watt 3.4 mNm/Watt 3.4 mNm/Watt 3.4 mNm/Watt 3.3 mNm/Watt 3.3 mNm/Watt 3.2 mNm/Watt 3.1 mNm/Watt 3.1 mNm/Watt 3.0 mNm/Watt 3.0 mNm/Watt 3.0 mNm/Watt 3.0 mNm/Watt 3.0 mNm/Watt 2.9 mNm/Watt 2.7 mNm/Watt 2.7 mNm/Watt 2.6 mNm/Watt 2.6 mNm/Watt 2.6 mNm/Watt 2.6 mNm/Watt 2.6 mNm/Watt 2.5 mNm/Watt 2.5 mNm/Watt 2.5 mNm/Watt 2.4 mNm/Watt 2.3 mNm/Watt 2.3 mNm/Watt 1.9 mNm/Watt 1.9 mNm/Watt

7.8 mNm/Watt 7.2 mNm/Watt 5.8 mNm/Watt 5.8 mNm/Watt 5.6 mNm/Watt 5.6 mNm/Watt 4.2 mNm/Watt 4.1 mNm/Watt 4.1 mNm/Watt 4.0 mNm/Watt 4.0 mNm/Watt 4.0 mNm/Watt 3.9 mNm/Watt 3.9 mNm/Watt 3.9 mNm/Watt 3.8 mNm/Watt 3.7 mNm/Watt 3.6 mNm/Watt 3.5 mNm/Watt 3.3 mNm/Watt 3.2 mNm/Watt 3.1 mNm/Watt 3.1 mNm/Watt 3.0 mNm/Watt 3.0 mNm/Watt 3.0 mNm/Watt 2.9 mNm/Watt 2.9 mNm/Watt 2.9 mNm/Watt 2.9 mNm/Watt 2.9 mNm/Watt 2.9 mNm/Watt 2.8 mNm/Watt 2.8 mNm/Watt 2.8 mNm/Watt 2.8 mNm/Watt 2.7 mNm/Watt 2.6 mNm/Watt 2.6 mNm/Watt 2.5 mNm/Watt 2.5 mNm/Watt 2.5 mNm/Watt 2.5 mNm/Watt 2.5 mNm/Watt 2.4 mNm/Watt 2.3 mNm/Watt 2.2 mNm/Watt 2.2 mNm/Watt 2.2 mNm/Watt 2.2 mNm/Watt 2.1 mNm/Watt 2.1 mNm/Watt 2.1 mNm/Watt 2.1 mNm/Watt 2.1 mNm/Watt 2.0 mNm/Watt 2.0 mNm/Watt 1.9 mNm/Watt 1.6 mNm/Watt 1.6 mNm/Watt

1717 012S 1628 024B 1624 018S 1717 006S 1628 012B 1624 003S 1624 024S 1624 006S 1624 012S 1717 003S 1319 015 1524 018S 1319 003 1319 006 1319 012 1319 024 1524 012S 1524 009S 2017 1.5S 1524 006S 1516 009SR 1516 012R 1516 006SR 2017 006S 2017 012S 1219 4.5G 2017 009S 1219 012G 1219 006G 2017 003S 1616 003S 1616 004S 1516 1.5S 1016 012G 1016 006G 1219 015G 1616 006S 1616 018S 1616 012S 1016 003G 1516 4.5S 1516 002S 1516 012S 1516 006S 0816 003S 0816 006S 0816 008S 1212 2.7G 1212 1.8G 1212 004G 1212 006G 0206 H

1.9 mNm/Watt 1.9 mNm/Watt 1.9 mNm/Watt 1.9 mNm/Watt 1.9 mNm/Watt 1.9 mNm/Watt 1.8 mNm/Watt 1.8 mNm/Watt 1.8 mNm/Watt 1.7 mNm/Watt 1.5 mNm/Watt 1.4 mNm/Watt 1.4 mNm/Watt 1.4 mNm/Watt 1.4 mNm/Watt 1.3 mNm/Watt 1.3 mNm/Watt 1.3 mNm/Watt 1.3 mNm/Watt 1.3 mNm/Watt 1.1 mNm/Watt 1.1 mNm/Watt 1.1 mNm/Watt 1.0 mNm/Watt 0.9 mNm/Watt 0.9 mNm/Watt 0.9 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.8 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.5 mNm/Watt 0.5 mNm/Watt 0.4 mNm/Watt 0.4 mNm/Watt 0.4 mNm/Watt 0.4 mNm/Watt 0.3 mNm/Watt 0.0 mNm/Watt

1.6 mNm/Watt 1.6 mNm/Watt 1.6 mNm/Watt 1.6 mNm/Watt 1.5 mNm/Watt 1.5 mNm/Watt 1.5 mNm/Watt 1.5 mNm/Watt 1.5 mNm/Watt 1.4 mNm/Watt 1.2 mNm/Watt 1.2 mNm/Watt 1.2 mNm/Watt 1.2 mNm/Watt 1.2 mNm/Watt 1.1 mNm/Watt 1.1 mNm/Watt 1.1 mNm/Watt 1.1 mNm/Watt 1.0 mNm/Watt 0.9 mNm/Watt 0.9 mNm/Watt 0.9 mNm/Watt 0.9 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.7 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.6 mNm/Watt 0.5 mNm/Watt 0.5 mNm/Watt 0.5 mNm/Watt 0.4 mNm/Watt 0.4 mNm/Watt 0.4 mNm/Watt 0.3 mNm/Watt 0.3 mNm/Watt 0.3 mNm/Watt 0.3 mNm/Watt 0.0 mNm/Watt

Copyright 2002 George A. Beauchemin, MicroMo Electronics All Rights Reserved

You might also like

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- DC Motor Selection For Dynamic Motion Control ApplicationsDocument3 pagesDC Motor Selection For Dynamic Motion Control ApplicationsMohamed SayedNo ratings yet

- AC DC kilns compared for cement applicationsDocument10 pagesAC DC kilns compared for cement applicationsPrateek SinghNo ratings yet

- Applying PMDC Motors: Product FocusDocument4 pagesApplying PMDC Motors: Product FocusAniesh MahajanNo ratings yet

- MCC & ContactorsDocument9 pagesMCC & ContactorsbimboawotikuNo ratings yet

- AC DC Kilns (Drives, Cement Plant)Document10 pagesAC DC Kilns (Drives, Cement Plant)RajuNo ratings yet

- Open-phase Protection for MotorsDocument5 pagesOpen-phase Protection for MotorsAnamarialuzNo ratings yet

- CTAN 291 Dynamic BrakingDocument10 pagesCTAN 291 Dynamic BrakingpieroquirozNo ratings yet

- Using Baldor Motors as Micro-Hydro GeneratorsDocument4 pagesUsing Baldor Motors as Micro-Hydro GeneratorsAdrián Gael Nina EscobarNo ratings yet

- How To Calculate New DC Motor Parameters of A Modified WindingDocument7 pagesHow To Calculate New DC Motor Parameters of A Modified WindingIqbal BaigNo ratings yet

- Design and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsDocument12 pagesDesign and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsNicholas ValdezNo ratings yet

- Data Bulletin: Benefits of Thermal Magnetic Circuit BreakersDocument9 pagesData Bulletin: Benefits of Thermal Magnetic Circuit Breakersamitbharadwaj7No ratings yet

- Ecce2012 2 RaleighDocument8 pagesEcce2012 2 RaleighGeorge CălinNo ratings yet

- A Alternator DesignDocument6 pagesA Alternator DesignKathir RkpNo ratings yet

- How To Select A DC MotorDocument4 pagesHow To Select A DC MotorMehdi RabbaniNo ratings yet

- Choosing The Right Permanent Magnet Motor For Your ApplicationDocument6 pagesChoosing The Right Permanent Magnet Motor For Your ApplicationGenGtNo ratings yet

- PX7203 SpecialElectricalMachinesDocument11 pagesPX7203 SpecialElectricalMachines1balamanianNo ratings yet

- Traction Motor DesignDocument11 pagesTraction Motor DesignS.m. FerdousNo ratings yet

- Motor Run Capacitors PDFDocument6 pagesMotor Run Capacitors PDFLili SugengNo ratings yet

- Differences Between Shunt and Series DC Motors On Drilling RigsDocument8 pagesDifferences Between Shunt and Series DC Motors On Drilling RigsSohail ANo ratings yet

- Micro Mo Comparing MiniDocument5 pagesMicro Mo Comparing MiniVlad DonoseNo ratings yet

- Sri Shakthi Institute of Engg and Technology: Two Marks Questions and AnswersDocument12 pagesSri Shakthi Institute of Engg and Technology: Two Marks Questions and AnswersdhivyadevinNo ratings yet

- PM BLDC Motors: Structure, Operation and ApplicationsDocument25 pagesPM BLDC Motors: Structure, Operation and ApplicationsDEEPANo ratings yet

- Wind PowerDocument6 pagesWind Powerوليد ابو شاكرNo ratings yet

- 57Document4 pages57SidhuSid100% (1)

- Motor Rating and Protection ConsiderationsDocument21 pagesMotor Rating and Protection Considerationsjosenit1787No ratings yet

- Motor Circuit Analysis For Energy, Reliability and Production Cost ImprovementsDocument4 pagesMotor Circuit Analysis For Energy, Reliability and Production Cost ImprovementsAmin Mustangin As-SalafyNo ratings yet

- Induction Motor Protection GuideDocument28 pagesInduction Motor Protection GuideJaleesNo ratings yet

- Module 3 - 2&16marksDocument25 pagesModule 3 - 2&16markskesavantNo ratings yet

- MCCB Selection ConsiderDocument4 pagesMCCB Selection ConsiderPham Khac LuNo ratings yet

- CCCCCCCCCCCCCCCCCC CCCC CCCCCCCCCCCCC CCCCCCCDocument37 pagesCCCCCCCCCCCCCCCCCC CCCC CCCCCCCCCCCCC CCCCCCCRamani NalajalaNo ratings yet

- Electric Motor For Centrifugal CompressorDocument10 pagesElectric Motor For Centrifugal Compressoralex696100% (1)

- Chapter 3.10: Energy Efficient Technologies in Electrical SystemsDocument8 pagesChapter 3.10: Energy Efficient Technologies in Electrical SystemsdineshvhavalNo ratings yet

- Captive Motor-Transformer PDFDocument11 pagesCaptive Motor-Transformer PDFAmorn Thumrat100% (1)

- Control and Protection of HV MotorsDocument28 pagesControl and Protection of HV Motorstkdrt2166No ratings yet

- Ansi MV Techtopics20 enDocument4 pagesAnsi MV Techtopics20 enmohamad5357No ratings yet

- Protection of Industrial SystemsDocument13 pagesProtection of Industrial SystemsJorge A. Perez YebraNo ratings yet

- Energy Savings of Variable Frequency DrivesDocument31 pagesEnergy Savings of Variable Frequency DrivesAnand AgrawalNo ratings yet

- Permanent Magnet DC MotorsDocument25 pagesPermanent Magnet DC MotorsShreyansh Vishwakarma100% (1)

- Motor Driver Selection For CompressorsDocument13 pagesMotor Driver Selection For CompressorsMuhammad ImranNo ratings yet

- Application Characteristics of Permanent Magnet Synchronous Motors (Case Study)Document6 pagesApplication Characteristics of Permanent Magnet Synchronous Motors (Case Study)RakeshconclaveNo ratings yet

- White Paper - Do DC Generators Offer Fuel Economy Advantages - Lexe0339-01Document9 pagesWhite Paper - Do DC Generators Offer Fuel Economy Advantages - Lexe0339-01sdiamanNo ratings yet

- Energy Efficient Motors Full Seminar Report, Abstract and Presentation DownloadDocument7 pagesEnergy Efficient Motors Full Seminar Report, Abstract and Presentation DownloadJIN KHATRI33% (3)

- Switched Reluctance Drives For Electric Vehicle ApplicationsDocument7 pagesSwitched Reluctance Drives For Electric Vehicle ApplicationsHuynh Thanh AnhNo ratings yet

- Integrated Starter GeneratorDocument9 pagesIntegrated Starter GeneratorThanh NgaNo ratings yet

- Energy Conservation Measures in Industrial Drives Through Selection, Operation and MaintenanceDocument10 pagesEnergy Conservation Measures in Industrial Drives Through Selection, Operation and Maintenancemorshad61No ratings yet

- E GEA M1019Document8 pagesE GEA M1019matealoredana8015100% (1)

- Electric Motors: Syllabus Electric Motors: Types, Losses in Induction Motors, Motor Efficiency, Factors AffectingDocument12 pagesElectric Motors: Syllabus Electric Motors: Types, Losses in Induction Motors, Motor Efficiency, Factors AffectingAjay kunwar singhNo ratings yet

- MoappDocument5 pagesMoappluanleNo ratings yet

- Types of MotorsDocument12 pagesTypes of MotorsMatin Inamdar100% (1)

- Motor IqDocument4 pagesMotor IqPaul HkloNo ratings yet

- Induction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion PerformanceDocument9 pagesInduction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion Performancemlkz_01No ratings yet

- PX7203-Special Electrical Machines PDFDocument11 pagesPX7203-Special Electrical Machines PDFvaishnavisriNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Ricoh 301 PARTS CATALOGDocument68 pagesRicoh 301 PARTS CATALOGbefremdenNo ratings yet

- ATS1801 - Interface PC - ImpDocument8 pagesATS1801 - Interface PC - ImpluismantonioNo ratings yet

- Nuclear Radioactivity WorksheetDocument3 pagesNuclear Radioactivity Worksheet14569874No ratings yet

- Green Aviation SeminarDocument19 pagesGreen Aviation SeminarAromalSPillaiNo ratings yet

- Verilog Interview Questions & AnswersDocument6 pagesVerilog Interview Questions & AnswersKrishna Saroja SankaNo ratings yet

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocument1 pageChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimNo ratings yet

- Indian Standards As On 17.01.2004 LatestDocument19 pagesIndian Standards As On 17.01.2004 LatestSaravana KumarNo ratings yet

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsDocument6 pagesStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009No ratings yet

- KB Rebar BrochureDocument4 pagesKB Rebar BrochureJun Xian Wai100% (1)

- Manual Huawei Hg655bDocument36 pagesManual Huawei Hg655bAnonymous nJm0Ff8z0sNo ratings yet

- Study of Buffer Overflows and Keyloggers in The Linux Operating SystemDocument8 pagesStudy of Buffer Overflows and Keyloggers in The Linux Operating Systemrobyrulz100% (1)

- Capacitor Banks - Schedules FILLEDDocument11 pagesCapacitor Banks - Schedules FILLEDyahyaNo ratings yet

- A ProcessDocument41 pagesA ProcessjulioNo ratings yet

- Jeepney Demand and Supply in Baguio CityDocument19 pagesJeepney Demand and Supply in Baguio CityJanna CrowNo ratings yet

- Properties of LPGDocument33 pagesProperties of LPGmukund madhav100% (2)

- RPVP Puerto PrincesaDocument8 pagesRPVP Puerto PrincesaRanny LomibaoNo ratings yet

- Purushothaman.V Head-Technical 9500118390: Kind Attn: Ln. RDocument9 pagesPurushothaman.V Head-Technical 9500118390: Kind Attn: Ln. RsramkmNo ratings yet

- Maxxi Report FinalDocument7 pagesMaxxi Report FinalDepanshu Gola100% (1)

- Peanut Brittle LabDocument2 pagesPeanut Brittle LabMary Bacon HillebrandNo ratings yet

- Under Water WeldingDocument23 pagesUnder Water WeldingNishanth GowdaNo ratings yet

- Hoarding Guide 2020Document46 pagesHoarding Guide 2020Mohammed HafizNo ratings yet

- Software TestingDocument3 pagesSoftware TestingDr. P. N. Renjith Associate Professor - CSENo ratings yet

- CRSP ManualDocument140 pagesCRSP ManualCarlos Andrés Buenahora BallesterosNo ratings yet

- Lab Report Experiment 5Document4 pagesLab Report Experiment 5Czarina mantuano100% (2)

- MMMDocument1 pageMMMkhan22imranNo ratings yet

- Fisher Poistioner CatalogueDocument12 pagesFisher Poistioner CatalogueUsama IqbalNo ratings yet

- Hybrid or Standard?: Why The Urge To "Go Green"Document20 pagesHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonNo ratings yet

- FTS ScaleoEUserManualEN 10 1082177Document2,044 pagesFTS ScaleoEUserManualEN 10 1082177JNo ratings yet

- Aviation Week & Space Technology - September 22, 2014 USADocument60 pagesAviation Week & Space Technology - September 22, 2014 USAJohn David Hoyos MarmolejoNo ratings yet

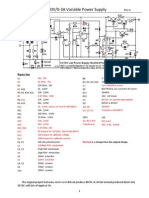

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Document2 pagesModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraNo ratings yet