Professional Documents

Culture Documents

100 Yer PM PPM 0121

Uploaded by

Crisanto CenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

100 Yer PM PPM 0121

Uploaded by

Crisanto CenaCopyright:

Available Formats

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

PREFACE This procedure is a revision or an overlay to a Saudi Aramco Engineering Requirement SAER, for the scope of the Yanbu Export Refinery Project, YERP, unless specifically defined as a New document. A YERP procedure consists of a revision or an overlay and the Saudi Aramco (SA) document with the same name. An overlay establishes any required changes to the SA document and specifically defines the changes. If the SA document is to be used without any changes the overlay will state there are no changes required. If the document is a new YERP document, with no reference to a SA procedure, the overlay will state it. The YERP Procedure Index identifies which YERP documents are new and the ones that relate to SA documents that are unchanged, changed, or deleted. All references to SA procedures, specifications and standards are to be defined as references to YERP procedures, specifications and standards unless specifically stated otherwise in the overlay. All references to SA organizations are to be defined as the YERP Management Team. Interpret the following as specified: Revise A specific revision to a SA or other Code paragraph or sentence as noted in this specification Add continuation of an SA or other Code paragraph with an overlay requirement Substitute replace the SA or other Code paragraph in entirety by the overlay requirement New New paragraph number in the overlay with no corresponding SA or other Code paragraph Delete SA or other Code paragraph is deleted by the overlay REVISION This is a new YERP document that replaces Saudi Aramco Engineering Report, SAER 1972, Saudi Aramco Materials Inspection and Testing, 31 January, 2005. ATTACHMENT None This is a stand alone document that replaces SAER-1972

General Business Confidential Page 2 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

TABLE OF CONTENTS 1.0 2.0 3.0 3.1 3.2 4.0 5.0 5.1 5.2 5.3 5.4 5.5 6.0 7.0 7.1 7.2 7.3 SCOPE.................................................................................................................. 4 REFERENCES...................................................................................................... 4 DEFINITIONS AND ABBREVIATIONS ................................................................ 4 Definitions............................................................................................................ 4 Abbreviations ...................................................................................................... 5 CONFLICTS AND DEVIATIONS .......................................................................... 5 INSTRUCTIONS FOR VENDOR ITPS ................................................................. 5 YERP-175 Forms In Purchase Order ................................................................. 5 Vendor Generated Inspection & Test Plan........................................................ 6 Packaged and Skid Mounted Equipment .......................................................... 6 Identification Codes ............................................................................................ 6 Absence of YERP-175 Forms ............................................................................. 6 INSPECTION LEVELS FOR CONTRACTOR SUPPLIED MATERIAL................ 7 RESPONSIBILITIES ............................................................................................. 7 Contractor ............................................................................................................ 7 Vendor .................................................................................................................. 8 Contract Package PMT ....................................................................................... 8

APPENDIX

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS....................................... 9

General Business Confidential Page 3 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

1.0

SCOPE This document provides instructions for the use of YERP Inspection and Testing Requirements, YERP-FORM-175, forms. This document also defines the minimum Contractor inspection activities that shall be assigned to materials and equipment.

2.0

REFERENCES YERP Engineering Procedures YERP-SAEP-302 YERP Project Procedures YERP-FORM-175 Inspection and Testing Requirements Instructions for Obtaining a Waiver of Mandatory YERP Engineering Requirements a

3.0 3.1

DEFINITIONS AND ABBREVIATIONS Definitions Company Representative PMT Contract Package Project Manager or designated individual who is duly authorized to act on behalf of YERP for a particular Contract Package. Contract Package A defined and designated portion of the Yanbu Export Refinery Project that is executed and managed as a unit. Contract Package PMT The personnel of the YERP Project Management Team assigned to manage a particular Contract Package. Contractor or Contractors Any Design, Construction or Service Contractor(s); Manufacturer(s); Vendor(s); Government Agencies; and other similar organization(s) having a contractual relationship or a prospective contractual relationship with the Yanbu Export Refinery Project. Inspection Level The quantity of inspection activities to be performed on a type of equipment or material. Inspection and Test Plan A plan for the inspections and tests to be performed on a particular type of equipment or material. Material Class A numeric code used to identify groups of similar equipment or material. Vendor The Company providing materials or equipment for the YERP project according to the provisions of a purchase order.

General Business Confidential Page 4 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

YERP-FORM-175 (forms) A set of Inspection and Test Plans that are provided to the Contractor to establish the minimum requirements for inspection and testing of equipment and materials purchased for the project by the Contractor. Yanbu Export Refinery Project (YERP) The Yanbu Export Refinery Project (YERP) as used in this procedure, shall also mean the Yanbu Export Refinery Company and its affiliated companies. It is also named as the COMPANY. YERP Project Management Team The group responsible for the management of the entire project and dedicated to the overall success, development and execution of the work and alignment across the numerous project interfaces. 3.2 Abbreviations ITP PMT YERP-175 4.0 Inspection and Test Plan Project Management Team YERP-FORM-175

CONFLICTS AND DEVIATIONS Any conflicts between this Procedure and other applicable YERP Engineering Procedures (YERP SAEP), YERP Engineering Standards (YERP-SAES), YERP Materials System Specifications (YERP-SAMSS), YERP Standard Drawings (YERPSASD), or industry standards, codes, and forms shall be resolved in writing by the PMT. Direct all requests to deviate from this Procedure in writing to the PMT, who shall follow internal company procedure YERP-SAEP-302, Instructions for Obtaining a Waiver of a Mandatory YERP Engineering Requirements, and forward such requests to the appropriate channel for review and approval No deviations will be necessary for the YERP-175 forms. Any clarifications / additions / deletions or waivers to the YERP-175 requirements will be reflected on the supplier generated ITP and acceptance will be through the normal project review and approval process

5.0 5.1

INSTRUCTIONS FOR VENDOR ITPS YERP-175 Forms In Purchase Order YERP-175 forms establish minimum inspection and testing requirements for procured, inspectable, material and equipment. YERP-175 forms are attached to purchase requisitions, requests for quotation and purchase orders.

General Business Confidential Page 5 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

YERP-175 forms are contractual requirements that the vendor shall comply with, in terms of notifying Contractors Inspector to witness specific inspection and test points, and/or providing quality certificates for review and evaluation. The YERP-175 forms, together with the purchase order and its technical attachments form an integral package that can be used to procure material or equipment. Vendor shall comply with all purchase order requirements. 5.2 Vendor Generated Inspection & Test Plan The YERP-175 forms will be used as a guideline to aid in the development of the vendor generated Inspection and Test Plan (ITP). The vendor generated ITP will become the document of record after project review and approval to support the inspection activities and quality requirements. The vendor generated ITP shall include all the requirements as detailed on the applicable YERP-175 forms. The vendor will include the inspections and testing identified on the YERP-175 forms and add to these any additional testing and inspections that are needed by the vendor and other tests and inspections identified in the purchase order. The vendor generated ITP shall include a column to allow the Contract Package PMT to indicate the YERP inspection activities. 5.3 Packaged and Skid Mounted Equipment The YERP-175 form concept provides sufficient flexibility to accommodate all types of equipment. However, one form is not normally designed to cover more than one kind of equipment. For packaged and skid mounted equipment, separate forms are required for each type of inspectable equipment in the package. In addition to the ITPs for individual components, an overall ITP to cover the inspection and testing of the assembled packaged or skid mounted equipment is to be created. Examples of overall ITPs are forms 175-341210 and 175-342810. 5.4 Identification Codes The 6-digit codes for YERP-175 forms identify different forms for inspectable material and equipment. The first two digits of the code refer to the class of material in the YERP Material System (i.e. 01 for pipes, 02 for fittings, 04 for valves, etc.). The remaining four digits are control numbers.

4

5.5

Absence of YERP-175 Forms If the Contractor finds that no appropriate YERP-175 Form is available, the Contractor will create a document defining the minimum inspection and testing requirements. This document is to be in the Contractors format with a Document Number appropriate to the Contract Package. The vendor generated ITP will incorporate the requirements of this document in the same way as if it had been a YERP-175 Form.

General Business Confidential Page 6 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

6.0 6.1

INSPECTION LEVELS FOR CONTRACTOR SUPPLIED MATERIAL Material Inspection Levels shall be assigned on Contractors supplied materials and equipment to specify the minimum amount of inspection coverage deemed necessary by YERP to ensure that a product or service conforms to specifications at a specific suppliers and/or sub-suppliers factory or fabrication site. The following system of coding Contractor inspections shall be used to define the inspection requirements. Level 0: Level 1: Level 2: Documentation requirements only; no vendor inspection required. Only final inspection is required prior to shipping. Includes, as a minimum, pre-inspection meetings, one or more unspecified in progress surveillance visit/s, all witness and hold points, final inspection, and release for shipment. Same as Level 2, except that in progress surveillance inspections shall be on a regular basis (daily, weekly, or bi-weekly). Resident inspector continually monitoring the work.

Level 3: Level 4: 6.2 6.3

Minimum Inspection Levels for Contractor supplied equipment and materials are indicated in Appendix 1. For materials not covered by this document, the Inspection Levels shall be assigned by the Contractor and agreed to by the Contract Package PMT. RESPONSIBILITIES Contractor The Contractor is responsible to: Include the text portion of YERP-FORM-175, 100-YER-PM-PPM-0756 in each purchase order. Include the applicable YERP-175 forms in each purchase order. Create a Contractor document giving minimum inspection requirements when no appropriate YERP-175 form is available. Review vendor ITPs and identify Contractor witness and hold points. Submit vendor ITPs to the Contract Package PMT for the appropriate YERP witness and hold points and for the required review and approval. Ensure that YERP inspection activities are incorporated into the vendor ITPs.

General Business Confidential Page 7 of 20

7.0 7.1

and

test

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

7.2

Vendor The vendor is responsible to: Generate the necessary draft ITPs. Submit the ITPs to the Contractor for review or approval. Incorporate the YERP and Contractor comments into the ITPs

7.3

Contract Package PMT The Contract Package PMT is responsible to: No review will be required for items of Inspection Level 0. Review and comment vendor ITPs for items with Inspection Levels of 1, 2, and 3. Review, comment, and approve vendor ITPs for items of Inspection Level 4.

General Business Confidential Page 8 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS

MATERIAL CLASS

01

FORM 175 CODE

010300

DESCRIPTION

PIPE: Plain End Electric Resistance or Electric Induction Welded Steel Pipe. 4 and Above in Nominal Diameter. PIPE: High Frequency Welded Line Pipe, Class C, NPS 4 and larger. PIPE: Carbon Steel; Seamless or Longitudinal Seam Submerged-Arc Welded; Purchased Small Quantities. PIPE: Beveled End, Seamless or Submerges Arc Welded, Straight or Spiral Seam, Carbon Steel Pipe 6. PIPE: Beveled End, Seamless, Carbon Steel Pipe < 6. PIPE & FITTINGS: Fiberglass; TRP (Glass-FiberReinforced Thermosetting Resin) & RPMP (Glass-Fiber-Reinforced Plastic-Mortar). CONCRETE MORTAR LINING FOR PIPE: For Internal Surfaces of Line Pipe and Fittings. CONCRETE WEIGHT COATING FOR PIPE: For Line Pipe Used Underwater. (a) PIPE: Fabrication of Spools; Carbon, Alloy, High Strength Special, Low and High Temperature Steels. PIPE BENDS: Shop Formed; Cold Bends, Furnace Hot Bends and Induction Bends.

INSPECTION LEVELS

2

REMARKS

010400 010600

3 1

010700

010701 012000

2 2

012500 012800 013100

2 4 3

(b)

014300

TUBES: For Condensers, Tubular HeatExchangers, and Similar Heat Transfer Apparatus, Seamless cold-drawn low-carbon steel; 1/8 to 3 outside diameter. TUBES: For Condensers and Heat Exchangers, Externally Helical, Integrally Finned Aluminumalloy Seamless with finned or un-finned ends, with continuous fins, or with un-finned sections; up to 2 in. outside diameter.-

014301

General Business Confidential Page 9 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

01

FORM 175 CODE

017800

DESCRIPTION

PIPE: Seamless 1 and Larger, and Straight Seam Submerged Arc Welded 16 and Larger, for Low Temperature Service. PIPE: Seamless or Welded; Carbon or Alloy Steel: A312; A335; A376; A430 or A524. PIPE: Electric Fusion Welded Austenitic Chromium Nickel Alloy Steel Pipe for High Temperature Service. PIPE: High Temperature, ASTM A-369; A-426; A-451; or A-660. PIPING: Auxiliary; for Mechanical Equipment Associated with Compressors, Pumps, Fans, Turbines and Gears. Also as part of packaged or skid mounted equipment.

INSPECTION LEVELS

2

REMARKS

018200 018400

2 2

019500 019800

2 3

02

022500 022501

FLANGES: Special Plates, Spacers & Blinds. FLANGES: Weld Neck, Forged Steel; for Temperature Ranges From -50C to +425C; Classes A105; A350 LF2, LF6CL1 & 2; A266 CL2 & 4; A707 L3CL1, 3 & 4, L5 CL3 & 4 and Approved Equivalents; Includes Welding Ends for Swivel Ring and Lapped Joint Flanges. PIPE COMPONENTS: Low Temperature Service, Wrought Carbon Steel and Alloy Steel; Seamless & Welded Construction; Includes elbows, tees, welding outlets, reducers, caps, bosses, couplings, unions, bushings, swaged nipples, pipe nipples, stub ends, blind flanges spectacle plates spacers 7 slip blinds. Sized JOINTS/SPOOLS: Insulating for Cathodic Protection. FITTINGS: Pipe, Butt Welding: Grade WPB Wrought Carbon Steel & High Strength Fitting; Seamless or Welded; Suitable for wet, sour service. Excludes cast fittings, corrosion resistant alloy fittings and pipe bends.

1 1

023400

023800 026100

2 1

General Business Confidential Page 10 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

02

FORM 175 CODE

026500 026800

DESCRIPTION

FITTINGS: Stainless Steel, Wrought Austenitic to ASTM A-403. TRAP, SCRAPER: Permanent Scraper Traps for Line Sizes 4 for Pressure Ratings of Class 150 to 1500. Applies to Water or Hydrocarbon Services.

INSPECTION LEVELS

1 3

REMARKS

04

043600

VALVES: Metallic and Non-Metallic; Includes gate, globe, angle, check, needle, ball, plug, piston, butterfly, choke, diaphragm, etc.; Excludes: Control, safety-relief, relief, surge relief, solenoid, pilot (& other valves classified under SAMSS Class 34), wellhead valves under SAMSS Class 45 and API 6A 10,000 PSI valves, chokes, and Low Severity Valves. VALVE: Low Severity, utility service in cast iron, brass material, and butterfly valves. Excluding high performance butterfly valves. VALVES & CHOKES API SPEC 6A 10,000 PSI 1 13/16; For use in Sour Wet Services Downstream of the Wellhead and Tree Assembly.

043601

045600

06

060100

GASKETS: Metal, Spiral-Wound or Jacketed.

08

080100 080101

HOSES: Marine Oil; Offshore Tanker Loading. HOSES: Oil Suction and Discharge Services; For Dock Tanker Loading.

3 3

09

091300 091400

COATING: Shop Applied, Internal or External COATING: Shop Applied for Drilling Tubulars.

2 3

General Business Confidential Page 11 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

09

FORM 175 CODE

091900

DESCRIPTION

COATING: Shop Applied, For Tanks, Piping, Pipelines (and Associated Appurtenances & Fittings), Structures, Process Equipment, Internal & External; Onshore, Offshore and/or Sub sea. COATING: Shop Applied; (Electrostatic Spray); Fusion Bonded Epoxy on Deformed and Plain Steel Reinforcing Bars. COATING: Shop Applied; Application of Composite Fluropolymer/Ceramic Coatings to Fasteners. COATING: Shop Applied; Extruded 3-Layer Polypropylene & 3-Layer P.E. Polyethylene External Coating for Line Pipe.

INSPECTION LEVELS

3

REMARKS

092000

092100

092200

10

100100

FASTNERS: Alloy or Stainless Steel Nuts & Bolting Materials; Bars, Bolts, Screws, Studs, Stud Blots, & Wire, for use in High Or Low Temperature Services.

12

120100

STEEL STRUCTURES: (Excludes Offshore Structures and Pre-Engineering Metal Buildings). BUILDING: Metal; One story, Preengineered. DOORS AND FRAMES: Steel; Fire rated or Blast Resistant TOWER: Communication. STRUCTURAL PLATES ROLLED SHAPES, TUBULARS: Carbon Steel or Carbon Manganese Steel, For Fixed Offshore Platforms FIBER REINFORCED PLASTICS (FRP): Grating and FRP Components BUILDING: Pre-Fabricated.

3 (One Shift) 4 (Two Shifts) 3 1 2 1

120200 120400 120500 121400

121600 121900

0 3

13

130300 130900 131000

GEAR UNITS: Special Purpose. COUPLING: Shaft, Special Purpose. GEAR UNITS: General Purpose, Limited to 3,000 HP

3 2 2

General Business Confidential Page 12 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

14

FORM 175 CODE

140200

DESCRIPTION

TRANSFORMER: Distribution; PadMounted, Compartmental-Type, SelfCooled, Three-Phase TRANSFORMERS: Power; 3 Phase, Dry Type, 501 KVA and Larger. TRANSFORMER: distribution; Overhead Type, Self-Cooled, Single-Phase and Three-Phase. TRANSFORMER: Power; Oil Filled, 60 HZ. WOOD: Utility Pole. WOOD: Cross Arm or Cross Braces.

INSPECTION LEVELS

2

REMARKS

140300 140400

2 1

140500 142100 142101

2 1 1

15

150100

SUBMARINE POWER CABLE 5 KV AND ABOVE: Designed to AEIC and ICEA Specifications. CABLE: Power, Insulated, 5KV through 35KV. HIGH VOLTAGE POWER CABLE: High Pressure Pipe Type, and Low and Medium Pressure Self-Contained Liquid Filled. HIGH VOLTAGE POWER CABLE: Solid Dielectric Insulated Cables

150200 150300

1 2

150400

16

160100

POWER CIRCUIT BREAKER SWITCHGEAR and DRAWOUT POWER CIRCUIT BREAKERS: Metal-Enclosed, Low Voltage INDOOR CONTROL GEAR: High Voltage, Built to Either IEC or NA, 50 or 60 HZ, 3

160300

Phase up to 4160 volts.

160400 160500 160600 CONTROL SWITCHBOARDS. SWITCHGEAR: Metal-Clad, Air Insulated, Indoor, 1 to 38 KV. METAL ENCLOSED BUS: Indoor and Outdoor; Self-Cooled, Non-segregatedphase, Rated up to and including 34.5 KV. SF6 GAS INSULATED CIRCUIT BREAKERS: Outdoor 34.5KV through 230KV 2 2 1

160700

General Business Confidential Page 13 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

16

FORM 175 CODE

162000

DESCRIPTION

INDOOR CONTROLGEAR: Low Voltage, Built to Either IEC or NA, 50 or 60 HZ, 3

INSPECTION LEVELS

2

REMARKS

Phase up to 480 volts, or Single Phase up to 277 volts.

162600 SWITCHGEAR: Load Interrupting, Manually Operated, Pad Mounted, Circuit Breakers & Fuses, 1 KV Through 15 KV. OUTDOOR SWITCHRACK: Low Voltage 2

162700

17

170200

MOTORS, ELECTRIC: Severe duty totally enclosed squirrel cage induction motors 250 HP or Below, 480 V or below. MOTORS: Form-Wound. Squirrel-cage Induction 250 HP and Larger, or Brushless Synchronous 500 HP and Larger. GENERATORS: Brushless, Synchronous, Continuous Duty, 3 Phases, 60 Hertz, 600 to 6500 KVA, Built to ANSI/NEMA MGI-22. DIESEL ENGINE GENERATOR SETS: Stationary or Potable, Rated From 35 KW up to and Including 2000 KW. RECTIFIERS: Constant Voltage, Tap Controlled, or Semiconductor Phase Controlled. GALVANIC ANODES: Aluminum, Magnesium, or Zinc, for Cathodic Protection. IMPRESSED CURRENT ANODES: Silicon Iron, Platinized, or mixed metal Oxide, for Cathodic Protection. CABLE: For Cathodic Protection. 600 Volts MAX BATTERY CHARGER: POWER SUPPLY, PHOTOVOLTAIC (PV): For Cathodic Protection. UNINTERUPTABLE POWER SUPPLY (UPS) SYSTEMS: Continuous-Duty, Solid State, 1 and 3 Phase, 60 or 50 Hertz, 110 KVA or Larger Rated Capacity.

170300

170301

170400

170700

171300

171400

171500 172500 173100 173400

0 2 1 2

General Business Confidential Page 14 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

17

FORM 175 CODE

173700

DESCRIPTION

AUXILIARY ELECTRICAL SYSTEMS: As provided on custom-engineered, factoryassembled and pre-wired equipment skids. STATIONARY BATTERIES:

INSPECTION LEVELS

3

REMARKS

173800

22

220200 220300

FLOAT: For Submarine Oil Hose, 12 to 24 Diameter. CHAIN, ANCHOR CHAIN, SHACKLES or SWIVELS:

2 0

23

230100

DISTRIBUTED CONTROL SYSTEM (DCS): Equipment and Associated Software; Excludes Advanced Control Systems, Field Instrumentation, Auxiliary Systems, Remote Terminal Units, and Management Information Systems. SUPERVISORY CONTROL and DATA ACQUISITION (SCADA) System.

FAT to be witnessed by Instrument Engineer

230200

27

270300

DIRECT EXPANSION AIR CONDITIOING SYSTEMS: For Offshore Facilities, 10-Ton Cooling Capacity and Over.

30

300100

DIESEL ENGINES: Reciprocating, Compression-Ignition.

31

310300 310400 310500 310600 310900

PUMPS: Positive Displacement Rotary. PUMPS: Positive Displacement Reciprocating. PUMPS: Centrifugal, Horizontal, End Suction Single Stage, or Vertical In-line. PUMP: API, Centrifugal.. PUMPS: Submersible, Bowl Type, Including Electric Motors.

1 1 2 3 3 Inspection at both pump and motor shops

General Business Confidential Page 15 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

31

FORM 175 CODE

311500

DESCRIPTION

PUMPS: Positive Displacement, Controlled Volume, Diaphragm & Packed Plunger Types. (Excluded: Diaphragm Pumps using Mechanical Actuation) COMPRESSOR: Centrifugal AIR COMPRESSOR: Centrifugal, Constant Speed, Packaged, Integrally Geared, Including Accessories COMPRESSOR: Integrally Geared, Centrifugal. COMPRESSOR: Reciprocating, In Plant and Instrument air Service. This Does Not Apply to Compressors for Services Requiring Less Than 140 SCFM. COMPRESSOR: Rotary, for General Refinery Services. HOISTS OR OVERHEAD CRANES: Lifting Capacity Over 500 Kg. CENTRIFUGAL FLUOROCARBON REFRIGERATION UNITS: For Industrial/Process Applications.. CENTRIFUGAL FLUOROCARBON REFRIGERATION UNITS: For Utility Service and HVAC.

INSPECTION LEVELS

1

REMARKS

311900 311901

4 3

312000

312200

312400 313100 313800

3 1 3

313800

32

320200

TURBINES-STEAM OR GAS: Steam, General Purpose Or Special Purpose; or Heavy Duty and Aero Derivative Gas Turbines. POSITIVE MATERIAL IDENTIFICATION (PMI): For ASME B31.3, B31.4, and B31.8 Piping Components, Including Welds, and other Piping or Equipment where Specified in the SAMSS or Purchase Order. BOILER: Power, Water Tube. BURNERS PRESSURE VESSEL HEAT EXCHANGERS: Shell and Tubes.

See also 325517

320300

321300 321500 321900 323100

3 2 3 3

General Business Confidential Page 16 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

32

FORM 175 CODE

323300 323400 323500 323600 323700

DESCRIPTION

HEAT EXCHANGERS: Plate and Frame. HEAT EXCHANGERS: Electrical, Immersion-Type FLOATING HEADS, or TUBE BUNDLES: Separately Ordered. HEAT EXCHANGERS: Unclad Air-Cooled HEATER OR FURNACE: Direct Fired

INSPECTION LEVELS

2 3 2 2 3

REMARKS

324300

COOLING TOWERS: Induced Draft Used for Domestic and Industrial Applications.

324900

TANKS: Atmospheric, Steel, within the Scope of API-650. Except for Tanks According to Appendices F and J of the Same Standard.

324901

TANKS: Low Pressure, Steel, within the Scope of API-620. Except for Tanks According to Appendix Q of the Same Standard.

325000 325100 325200 325300

COLUMN TRAYS AND PACKING TANKS: Steel; Aboveground or Underground to API-12F, API-650 TANK: Fiberglass; Underground; UL-1316 or ASTM D-4021, Single or Double Wall; TANK: Aboveground, Fiberglass to AWWA D120, ASTM D3299, API-12P

2 3 2 1

General Business Confidential Page 17 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS FORM 175 CODE

325500 32

DESCRIPTION

INLET AIR FILTRATION SYSTEMS : (a) Combustion Gas Turbines (b) Centrifugal Air Compressors Systems are Limited to the Automatic Pulse-Jet Self-Cleaning Type. COMBUSTION GAS TURBINE PACKAGE: Industrial and Aero - Derivative LUBRICATION SHAFT SEALING AND CONTROL OIL SYSTEMS: For Special Purpose Applications. This Form is not Applicable to Combustion Gas Turbine Lubrication Systems. FLARE SYSTEMS: Including Flare Stacks, Flare Tips, Dry Gas Seals, and Knockout & Liquid-Seal Drums. MIXERS: Side Entry REFRACTORIES: Hydraulic-Setting, Castable Systems; to be used on Pressure Vessels, Boilers, Process Heaters; HEXs, Piping, and Flare Tips. REFRACTORIES: Ceramic Fiber System (RCF) for Boilers and Process Heaters.

INSPECTION LEVELS

3

REMARKS

325517 326100

4 3

See also 320200

326700

327300 328110

2 4

328120

34

340100

VALVES: Control, Steel, General Service, Pneumatic Operated, Up To and Including Class 600 Ratings. INSTRUMENTATION FOR PACKAGED UNITS: ACTUATORS, VALVE: (a) Pneumatic Actuator ON-OFF Service. (b) Electric Motor Operated Valve Actuators. ACTUATOR VALVE HYDRAULIC: With Integral or Remote Power Unit for Rising AUTOMATIC TANK GAUGING EQUIPMENT:

340200 341000

2 1

341001 341600

1 0

General Business Confidential Page 18 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

34

FORM 175 CODE

341900 342000 342800

DESCRIPTION

VALVE: Safety Relief Flanged Conventional and Balanced Type. VALVE: Safety Relief, Pilot Operated Types. MECHANICAL METER PROVERS: BiDirectional Displacement-Type; for use in Royalty and Custody Transfer Applications (Covers Complete Packaged and Skid-Mounted Unit, Including Pipe-Prover Valves, Locally Installed Instruments and Auxiliary Equipment for Meter). METER: Flow, Turbine. METERS: Positive Displacement, Liquid and Gas. INSTRUMENT CONTROL PANELS: 1. INDOOR: For Panels, Cabinets, Consoles, and Marshalling Cabinets in electrically Unclassified Air-Conditioned Buildings. 2. OUTDOOR: For Panels and Cabinets for Locations in Electrically Classified or Unclassified Outdoor Areas. CHROMATOGRAPHS: Process Gas. ANNUCIATORS: FIRE DETECTION AND ALARM SYSTEMS: Includes but not Limited to: Fire Alarm Control Panels, Associated Detectors, Manual Alarm Box Stations, Visual & Audible Devices (Sirens, Bells, Horns, etc.). UV Detection Systems, External Terminal Strips, Power Supplies. PROGRAMMABLE LOGIC CONTROLLER: ESD LOGIC SYSTEM: RELAY EMERGENCY SHUTDOWN SYSTEMS:

INSPECTION LEVELS

2 2 3

REMARKS

342900 343000 343100

1 1 2

343200 343300 343500

1 1 1

344000 344200 344300

2 2 2

General Business Confidential Page 19 of 20

Yanbu Export Refinery Project

PROJECT PROCEDURE MANUAL (PPM) YERP-SAER-1972, YERP Materials Inspection and Testing Document No.: 100-YER-PM-PPM-0121 Revision No.: 4 Issue Date: 26 February 2010

APPENDIX 1: MINIMUM CONTRACTOR INSPECTION LEVELS (Continued)

MATERIAL CLASS

34

FORM 175 CODE

344400

DESCRIPTION

PROGRAMMABLE CONTROLLERS BASED ESD SYSTEMS: MONITORS: Combustible Gas or Hydrogen Sulfide, Stationary MONITORING SYSTEMS: Vibration, Axial Position, and Bearing Temperature. DENSITY METERS:

INSPECTION LEVELS

2

REMARKS

344900

345100

345100

345300

345400

ANALYZER: Oxygen Covers Flue Gas, Trace, Dissolved On-Line or Portable Analyzers. FLAME MONITORING SYSTEMS: For Igniters and Burners Used in Fired Equipment. ANALYZER: Moisture Covers Both InLine (or in-situ) and Extractive. AUTOMATIC SAMPLERS: For Petroleum and Petroleum Products. INSTRUMENTATION AND THERMOCOUPLE EXTENSION CABLE: For Signaling and Control Purposes (Excluding Data Highway Cable). FIBER OPTIC CABLE:

345600

347400 347500

0 2

347600

LATER

MULTIPLE

MULTIPLE

PACKAGED EQUIPMENT AND SKID MOUNTED EQUIPMENT:

Make an overall ITP that invokes individual ITPs

General Business Confidential Page 20 of 20

You might also like

- 100 Yer PM PPM 0775Document793 pages100 Yer PM PPM 0775Janakiraman Malliga100% (1)

- Saep 1150Document50 pagesSaep 1150ishaq_khanNo ratings yet

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiNo ratings yet

- Saep 50Document33 pagesSaep 50Demac SaudNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- 076551C 000D Sow 9000 001 - R0Document37 pages076551C 000D Sow 9000 001 - R0ikenn100% (1)

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument11 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualMohamedNo ratings yet

- Method Statement Pipe Re-Routing Saudi BinladinDocument11 pagesMethod Statement Pipe Re-Routing Saudi BinladinShyju MelepurathNo ratings yet

- Age 10802Document162 pagesAge 10802vinoratheeshNo ratings yet

- Schedule B - Job SepcificationsDocument129 pagesSchedule B - Job SepcificationsKalpana SrinivasNo ratings yet

- Quality Control ManualDocument77 pagesQuality Control ManualsbmmlaNo ratings yet

- On - Plot HydrotestingDocument14 pagesOn - Plot HydrotestingarunmirandaNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Materials System SpecificationDocument14 pagesMaterials System SpecificationSyed Zain Ali100% (1)

- Inspection and Test Plan FOR External Drainage SystemDocument6 pagesInspection and Test Plan FOR External Drainage SystemAnonymous NR3qZ30No ratings yet

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocument4 pagesGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshNo ratings yet

- SP1246 Part-5 PDFDocument23 pagesSP1246 Part-5 PDFMohammad Aamir Perwaiz100% (1)

- AramcoDocument9 pagesAramcoTamsila AmjadNo ratings yet

- Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)Document27 pagesControl Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)Muhammad SalmanNo ratings yet

- Instrumentation Control Cables, Cable Trays, Conduits, Junction Boxes and Cable GlandsDocument35 pagesInstrumentation Control Cables, Cable Trays, Conduits, Junction Boxes and Cable Glandsmasoud132No ratings yet

- MIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)Document14 pagesMIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)AmeerHamzaWarraichNo ratings yet

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Document15 pagesSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- 04-SAMSS-048 Valve Inspection and Testing RequirementsDocument8 pages04-SAMSS-048 Valve Inspection and Testing RequirementsHAYKEL79100% (1)

- 00250621DVSH00011 Exde02 34Document34 pages00250621DVSH00011 Exde02 34manish318No ratings yet

- Saes G 115Document9 pagesSaes G 115junaidNo ratings yet

- Erection Contractor's ScopeDocument4 pagesErection Contractor's ScopeasifaliabidNo ratings yet

- ESD Project Documentation RequirementsDocument56 pagesESD Project Documentation Requirementsmasimerise100% (2)

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- A00 Za e 0009635 - BBG - BDocument30 pagesA00 Za e 0009635 - BBG - Bjustin vivek0% (1)

- Other NDT TechniquesDocument12 pagesOther NDT TechniquesabyNo ratings yet

- Engineering Encyclopedia: Fabrication, Inspection, and Testing of Pressure VesselsDocument70 pagesEngineering Encyclopedia: Fabrication, Inspection, and Testing of Pressure VesselsAfzaalUmairNo ratings yet

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Visual Inspection Test Procedure B-QAC-PRO-210-39162Document14 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Visual Inspection Test Procedure B-QAC-PRO-210-39162ZaidiNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- 27951.ico - Avv.sds 00Document211 pages27951.ico - Avv.sds 00Raji OlawaleNo ratings yet

- Engineering ProcedureDocument50 pagesEngineering Procedure MohammedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- RE-286329 - ITP Rev ADocument3 pagesRE-286329 - ITP Rev AJohn Philip Buntales100% (1)

- Saudi Aramco Inspectable ItemsDocument9,400 pagesSaudi Aramco Inspectable ItemsAzeem Chaudhry50% (2)

- MC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1Document18 pagesMC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- 000-Za-E-M09402 - C Method Statement For Brown Green Field InstallationDocument21 pages000-Za-E-M09402 - C Method Statement For Brown Green Field Installationsyam prasadNo ratings yet

- 0002 710 Mechanical Completion Performance Acceptance of Facilities PDFDocument33 pages0002 710 Mechanical Completion Performance Acceptance of Facilities PDFjusstv1No ratings yet

- AE-036411-001 INDEX For Drawing and EquipmentDocument1 pageAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216No ratings yet

- Schedule B - Attachment III SCOPE OF WORKDocument6 pagesSchedule B - Attachment III SCOPE OF WORKxue jun xiangNo ratings yet

- BO-0475 - Const - Work - Pro - For Gasket Install (Rev 0) - 20150605Document35 pagesBO-0475 - Const - Work - Pro - For Gasket Install (Rev 0) - 20150605Rijwan MohammadNo ratings yet

- 00 Saip 80Document75 pages00 Saip 80heidarNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- 00 Saip 80 PDFDocument90 pages00 Saip 80 PDFsaghir hassanNo ratings yet

- Saes A 004Document18 pagesSaes A 004emmanuilmoulos6339100% (1)

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDocument7 pagesSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNo ratings yet

- Schedule B - Attachment IV Project Facilities RequirementsDocument52 pagesSchedule B - Attachment IV Project Facilities Requirementsxue jun xiangNo ratings yet

- Saudi-Arabian-Engineering-Standardssaes-J-001 PDFDocument11 pagesSaudi-Arabian-Engineering-Standardssaes-J-001 PDFsalasineNo ratings yet

- NSH KBR Skop e 007 - Junction Boxes InstallationDocument6 pagesNSH KBR Skop e 007 - Junction Boxes InstallationFrancisco Severino Gatoc Jr.No ratings yet

- Inspection ProcedureDocument10 pagesInspection ProcedureMoustafa BayoumiNo ratings yet

- Jurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover SheetDocument35 pagesJurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover Sheettomj9104No ratings yet

- 002-PDS-CON-010 Method Statement For Site Preparation WorksDocument15 pages002-PDS-CON-010 Method Statement For Site Preparation WorksMalik ZamanNo ratings yet

- Yanbu-Project Procedure Manual PDFDocument793 pagesYanbu-Project Procedure Manual PDFumesh100% (3)

- 100 Yer PM PPM 0006Document53 pages100 Yer PM PPM 0006Janakiraman MalligaNo ratings yet

- 131 - 100-Yer-Pm-Ppm-0031 - Interface Management Coordination ProcedureDocument14 pages131 - 100-Yer-Pm-Ppm-0031 - Interface Management Coordination ProcedureIonut LefterNo ratings yet

- Report On Marketing of ArecanutDocument22 pagesReport On Marketing of ArecanutsivakkmNo ratings yet

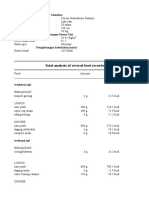

- Contoh Perhitungan DDD Excell - IRNADocument8 pagesContoh Perhitungan DDD Excell - IRNAMaya DamanikNo ratings yet

- Adult Survivors Act Summons Against Mayor Eric AdamsDocument3 pagesAdult Survivors Act Summons Against Mayor Eric AdamsCity & State New York100% (1)

- Screenshot 2019-10-30 at 12.44.00Document25 pagesScreenshot 2019-10-30 at 12.44.00Miền VũNo ratings yet

- Surgical Management in LeprosyDocument33 pagesSurgical Management in Leprosynsv.epicNo ratings yet

- Accomplishment Report Rle Oct.Document7 pagesAccomplishment Report Rle Oct.krull243No ratings yet

- Molecular MechanicsDocument26 pagesMolecular MechanicsKarthi ShanmugamNo ratings yet

- Cardiovascular Pharmacology: DR Muhamad Ali Sheikh Abdul Kader MD (Usm) MRCP (Uk) Cardiologist, Penang HospitalDocument63 pagesCardiovascular Pharmacology: DR Muhamad Ali Sheikh Abdul Kader MD (Usm) MRCP (Uk) Cardiologist, Penang HospitalCvt RasulNo ratings yet

- TestDocument233 pagesTestye rightNo ratings yet

- Hijama Cupping A Review of The EvidenceDocument5 pagesHijama Cupping A Review of The EvidenceDharma Yoga Ayurveda MassageNo ratings yet

- GASESDocument55 pagesGASESja_QuinineNo ratings yet

- Topic: Going To and Coming From Place of WorkDocument2 pagesTopic: Going To and Coming From Place of WorkSherry Jane GaspayNo ratings yet

- Assignment 2 ME 326Document10 pagesAssignment 2 ME 326divided.symphonyNo ratings yet

- Campus DrinkingDocument2 pagesCampus DrinkingLiHertzi DesignNo ratings yet

- Diablo LED Wall LightDocument2 pagesDiablo LED Wall LightSohit SachdevaNo ratings yet

- Tugas Gizi Caesar Nurhadiono RDocument2 pagesTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoNo ratings yet

- Sathyamangalam Chennai MR Sivakumar N: Rolsun TravelsDocument2 pagesSathyamangalam Chennai MR Sivakumar N: Rolsun TravelsGayu carita catoNo ratings yet

- Aronson AffidavitDocument18 pagesAronson AffidavitNorthDecoder2No ratings yet

- Achievement Test Science 4 Regular ClassDocument9 pagesAchievement Test Science 4 Regular ClassJassim MagallanesNo ratings yet

- A Walk in The Physical - Christian SundbergDocument282 pagesA Walk in The Physical - Christian SundbergKatie MhNo ratings yet

- Writing Workshop G7 PDFDocument12 pagesWriting Workshop G7 PDFJobell AguvidaNo ratings yet

- WEEK 3 LAB EXERCISE - Cell Structures and Functions - UY-OCODocument4 pagesWEEK 3 LAB EXERCISE - Cell Structures and Functions - UY-OCOBianca LouiseNo ratings yet

- Aircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management EngineerDocument46 pagesAircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management Engineerchouchou chamaNo ratings yet

- LNG Simulation PDFDocument28 pagesLNG Simulation PDFRobert WatersNo ratings yet

- Application of Knowledge QuestionsDocument16 pagesApplication of Knowledge QuestionsElllie TattersNo ratings yet

- ProjectxDocument8 pagesProjectxAvinash KumarNo ratings yet

- El MeligyDocument7 pagesEl Meligysystematic reviewNo ratings yet

- Aphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMCDocument2 pagesAphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMC2aliciast7No ratings yet

- Umali v. Estanislao (1992, 209 SCRA 446)Document12 pagesUmali v. Estanislao (1992, 209 SCRA 446)KTNo ratings yet