Professional Documents

Culture Documents

Iscor Rails

Uploaded by

mgeorgiadis7Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iscor Rails

Uploaded by

mgeorgiadis7Copyright:

Available Formats

PRICE LIST REFERENCE: 240

FILE REFERENCE H1.1

DATA SHEET : AVAILABILITY AND PROPERTIES

RAILS

HOT ROLLED STEEL SECTIONS FOR RAILWAY MATERIAL GENERAL DESCRIPTION

Rails for use in mines are supplied against ISCORs own specification as Mines and Sidings rails in 15 kg/m, 22 kg/m and 30 kg/m sizes. This data sheet contains only the standard manufactured specifications. Other steel specifications, surface specifications, rolling tolerances, sizes and lengths may be considered on an enquiry basis.

STEEL MAKING

Steel used for the manufacture of rails is made in a basic oxygen furnace and then continuously cast into blooms before rolling.

QUALITY ASSURANCE

Quality assurance systems based on the requirements of ISO 9002 are in operation.

STEEL SPECIFICATION

Specification Mines and Sidings:Grade 700 Mines and Sidings:Grade 700 Mines and Sidings:Grade 700 Code 512 300 512 300 512 550 Rail size 15 kg/m 22 kg/m 30 kg/m % Carbon Equivalent1 0,63/0,74 0,63/0,74 0,67/0,82

1 % Carbon equivalent = % C + % Mn + (%Cr+%Mo+%V) + (%Ni+%Cu) 4 5 15

MECHANICAL PROPERTIES

Modern testing and analysis facilities are used to ensure compliance with the rail specifications. Specification Mines and Sidings Grade 700

1

Tensile strenght (min) MPa 680

Elongation (min) % 10

Yield1) strength (min)MPa 400

Typical values, not guaranteed.

2002-04-01

Cancels and supersedes issue dated

2001-03-01

PRICE LIST REFERENCE: 240

FILE REFERENCE H1.1

DESIGN DATA

Data Nominal mass (kg/m) -3 2 Cross sectional areas (x10 m ) Head Web Base Total -6 4 Second moment of area: (Ixx)(10 m ) -6 3 Min. section modulus: (Zxxmin)(10 m ) -6 3 Max. section modulus: (Zxxmin)(10 m ) 15 14,905 0,916 0,303 0,677 1,896 1,49 38,84 39,2 Sizes in kg/ m 22 22,542 1,381 0,519 0,983 2,883 3,48 72,8 73,1 30 30,250 1,738 0,726 1,387 3,851 6,27 111,0 118,0

WELDING

Rails produced by ISCOR can be welded by "flash-butt" or "thermit" techniques. For practical details it is recommended that an authority should be consulted. The following table gives an indication of the minimum cooling time recommended for the heat-affected zone. Specification Mines and Sidings : Grade 700 1 Austenitising temperature Minimum cooling time from 800C to 500C in seconds 1000C1) 850C1) 35 26

TYPICAL DIMENSIONS

Designated mass (kg/ m) 30 22 15 Nominal calculated mass (kg/ m) 30,15 22,37 14,87 Standard lengths (m) 5 - 18 5 - 18 5 - 18 Number 4 4 4 Standard holes Diameter Distance between (mm) hole centres (mm) 20 101,6 20 101,6 20 88,9 : 101,6

Note: All holes in 15, 22 and 30 kg/m Mines and Siding rails are punched. See the cross sectional drawings for other dimensions. For Mines and Sidings rails, starting distances are as follows: 30, 22 & 15 kg/m : half the distance between the hole centres given above, less 3,2mm.

TOLERANCES to SPE 240

15, 22 and 30 kg/ m rails

2002-04-01 Cancels and supersedes issue dated 2001-03-01

PRICE LIST REFERENCE: 240

FILE REFERENCE H1.1

Overall height Width of the head Width of the base Thickness of the web Corner radius Length Hole diameter 2 Hole position Delivery tolerance: 40 < 100 tons 100 tons

1 2 15 to 30 kg/m rails are hot sawn Horizontal and vertical

+1,0 -0,5 mm 1,0 mm 2,0 mm +1,0 -0,5 mm 1,0 mm 20 mm 2,0 mm 2,0 mm

1

10 % 5%

SUPPLY CONDITIONS

Railway rails are supplied in accordance with ISCOR's General Conditions of Sale and Price List on Rails Number 240.

FOR FURTHER INFORMATION, CONTACT:

ENQUIRY MANAGER ISCOR LONG STEEL PRODUCTS P.O BOX 2 (PP 49) NEWCASTLE 2940 TEL: FAX: E-mail: (034) 314 7310 or 314 7315 (034) 314 7235 enquiries@new.iscorltd.co.za

Care has been taken to ensure that information in this data sheet is accurate. ISCOR Ltd. does not however, assume responsibility for any inaccuracies or misinterpretations of this data. We are continuously engaged in product development and revised data sheets will be issued from time to time. Please ensure that you have the most recent issue.

3 x SKETCHES

2002-04-01

Cancels and supersedes issue dated

2001-03-01

You might also like

- List of BS CodeDocument8 pagesList of BS CodeCC OoiNo ratings yet

- SVE14A Series: Sony ConfidentialDocument22 pagesSVE14A Series: Sony ConfidentialALEXNo ratings yet

- SVS151SERIESDocument24 pagesSVS151SERIESALEXNo ratings yet

- European Standard Norme Européenne Europäische Norm: Eurocode 5: Design of Timber Structures - Part 2: BridgesDocument29 pagesEuropean Standard Norme Européenne Europäische Norm: Eurocode 5: Design of Timber Structures - Part 2: Bridges2013No ratings yet

- Sony VAIO VGN-AR Series Service ManualDocument33 pagesSony VAIO VGN-AR Series Service Manualme262No ratings yet

- PD 06682-8-2004Document18 pagesPD 06682-8-2004Jorge Salasën100% (1)

- 007JTG D40-2011-EnDocument80 pages007JTG D40-2011-Enziming li100% (1)

- Russian Metro Standard (SNIP)Document295 pagesRussian Metro Standard (SNIP)Gogo GogovNo ratings yet

- Light Rail Technical Manual for ADA ComplianceDocument47 pagesLight Rail Technical Manual for ADA ComplianceGhazala FarooqNo ratings yet

- Book - Advanced Steel Structures, Fire and Fatigue Design - by W LuDocument118 pagesBook - Advanced Steel Structures, Fire and Fatigue Design - by W LuAbbes ChakchoukNo ratings yet

- E-4-2 Traffic Appraisal Manual, Chapter 13Document26 pagesE-4-2 Traffic Appraisal Manual, Chapter 13sareenpriya100% (1)

- Steel Track Spikes: Standard Specification ForDocument4 pagesSteel Track Spikes: Standard Specification Forvikramadithan renugopalNo ratings yet

- Network Management System: Submitted by Guru Vashist 0830531011 E.C. Vii SemDocument46 pagesNetwork Management System: Submitted by Guru Vashist 0830531011 E.C. Vii SemGuru VashistNo ratings yet

- Global RFP Document For Modern FasteningDocument32 pagesGlobal RFP Document For Modern FasteningSarthak DiwanNo ratings yet

- CP N-05 Vol.2 Sec.6 Ib Ts 200Document452 pagesCP N-05 Vol.2 Sec.6 Ib Ts 200Nadine PascualNo ratings yet

- Ut b-01-04Document62 pagesUt b-01-04Veeraiah AnbuNo ratings yet

- By THE The Private of South: ISBN 0-828.081 80.8Document10 pagesBy THE The Private of South: ISBN 0-828.081 80.8EtNo ratings yet

- Monitoring Fouling BallastDocument58 pagesMonitoring Fouling BallastSuciu Florin100% (1)

- The Conditions For Water Reticulation PlansDocument1 pageThe Conditions For Water Reticulation PlansedwinhlcNo ratings yet

- All New Works Future: WPC-DRG-TBB-GSG-3-05-ALB-0014 Signals AlbionDocument1 pageAll New Works Future: WPC-DRG-TBB-GSG-3-05-ALB-0014 Signals AlbionShauna MooreNo ratings yet

- Chapter I: Data of Design I.General Data: P8 1.concreteDocument25 pagesChapter I: Data of Design I.General Data: P8 1.concreteDuong NguyenNo ratings yet

- Ottawa Light Rail Transit Public Inquiry City's Response and Action PlanDocument36 pagesOttawa Light Rail Transit Public Inquiry City's Response and Action PlanCTV OttawaNo ratings yet

- Needs Report 2021-2022 FinalDocument353 pagesNeeds Report 2021-2022 FinalMoshiur RahmanNo ratings yet

- On The Fundamentals of Track Lateral Resistance: © 2011 AREMA ®Document45 pagesOn The Fundamentals of Track Lateral Resistance: © 2011 AREMA ®pippo50@No ratings yet

- New TSI Ammendment CELEX 32019R0776 enDocument204 pagesNew TSI Ammendment CELEX 32019R0776 enNazli SubasiNo ratings yet

- Highway Manual - Part 0 Section 2 Quality AssuranceDocument56 pagesHighway Manual - Part 0 Section 2 Quality Assurancecris5001No ratings yet

- Road Administration and Protection GuideDocument76 pagesRoad Administration and Protection GuideAnonymous GmbdAQGhNo ratings yet

- Tdot 2015 Spec Book Final PDFDocument1,104 pagesTdot 2015 Spec Book Final PDFRAIMUNDO SUHERDINNo ratings yet

- BS en 1991 PART 1-5-2003 Actions On Structures - General Actions - Thermal ActionsDocument52 pagesBS en 1991 PART 1-5-2003 Actions On Structures - General Actions - Thermal Actions陈辕No ratings yet

- Polished Stone Value Test Method RC 374.01Document1 pagePolished Stone Value Test Method RC 374.01m_k_tripathyNo ratings yet

- 1-6 Concrete Sleepers PDFDocument16 pages1-6 Concrete Sleepers PDFAndita Tri BudiantoNo ratings yet

- RUB Drainage System 1657785624136-RUB-Subways Drainage RDSO Report 2020Document56 pagesRUB Drainage System 1657785624136-RUB-Subways Drainage RDSO Report 2020Kartik OmNo ratings yet

- Railway Board Orders on Minutes of 80th Meeting of Track Standards CommitteeDocument109 pagesRailway Board Orders on Minutes of 80th Meeting of Track Standards CommitteecdmNo ratings yet

- Uic Code 435-2: Standard of Quality For A European Flat Wood Pallet, With Four Entries and Measuring 800 MM X 1 200 MMDocument56 pagesUic Code 435-2: Standard of Quality For A European Flat Wood Pallet, With Four Entries and Measuring 800 MM X 1 200 MMIlya PuchkovNo ratings yet

- Loading Guidelines Volume2Document243 pagesLoading Guidelines Volume2AndreiCabaNo ratings yet

- BD 212Document75 pagesBD 212Zayyan RomjonNo ratings yet

- Asean Standards (Brunei) - ElectricalDocument5 pagesAsean Standards (Brunei) - ElectricalsulaimanNo ratings yet

- Railway Track Cross SectionDocument10 pagesRailway Track Cross SectionayeshakynaNo ratings yet

- Uganda National Roads Authority Shortlist (4th Batch Final)Document71 pagesUganda National Roads Authority Shortlist (4th Batch Final)The Campus Times50% (2)

- Finally Revised Paper On 'Modern Turnout For High Speed' For IPWE SeminarDocument12 pagesFinally Revised Paper On 'Modern Turnout For High Speed' For IPWE SeminarShipra MishraNo ratings yet

- Minutes - 10th Extraordinary TSCDocument43 pagesMinutes - 10th Extraordinary TSCcdmNo ratings yet

- ESPEC. Pandrol FastclipDocument4 pagesESPEC. Pandrol FastclipFilipe Souza de JesusNo ratings yet

- Continuously Hot-Dip Coated Strip and Sheet of Structural Steels - Technical Delivery ConditionsDocument24 pagesContinuously Hot-Dip Coated Strip and Sheet of Structural Steels - Technical Delivery ConditionsPraveen SinghNo ratings yet

- Mainhole and EtcDocument44 pagesMainhole and Etcameera nabihaNo ratings yet

- Paper On Harmonization Eac - August 2011Document7 pagesPaper On Harmonization Eac - August 2011Jared MakoriNo ratings yet

- DM1111 Railways Africa Issue 5Document32 pagesDM1111 Railways Africa Issue 5rferrel2010No ratings yet

- ICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side MountDocument44 pagesICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side Mountvisva scgNo ratings yet

- Wirtgen HM 4500 Esp TecDocument4 pagesWirtgen HM 4500 Esp TecJohn GarciaNo ratings yet

- Manual Track Beam Eng Japan Monorail AssociationDocument159 pagesManual Track Beam Eng Japan Monorail AssociationJames ChangNo ratings yet

- 1307078105903-TSC - 81-RBOrders FinalDocument100 pages1307078105903-TSC - 81-RBOrders FinalSatish DmNo ratings yet

- Planning Parameters for High Speed RailDocument40 pagesPlanning Parameters for High Speed Railmkashkooli_scribdNo ratings yet

- Part 03 Cement PDFDocument5 pagesPart 03 Cement PDFRotsapNayrbNo ratings yet

- Bds en 15827 2011Document83 pagesBds en 15827 2011Konstantin ShcherbanNo ratings yet

- International Steel Grade EquivalencyDocument6 pagesInternational Steel Grade EquivalencyAhmadreza AminianNo ratings yet

- Tungum Tubes & Their SpecificationsDocument9 pagesTungum Tubes & Their SpecificationsASPERA2No ratings yet

- ThyssenKrupp Steel Data Sheet P235GHDocument4 pagesThyssenKrupp Steel Data Sheet P235GHjaseerkannothNo ratings yet

- Datasheet DMV 304 HCu 20081118Document4 pagesDatasheet DMV 304 HCu 20081118Anuj ShahiNo ratings yet

- Wire Mesh Steel Reinforcement BarsDocument6 pagesWire Mesh Steel Reinforcement Barssattar12345No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Imphal EasaaDocument1 pageImphal EasaaKosygin LeishangthemNo ratings yet

- ES0153-75440100-DBR-0003 Dust ExtractionDocument19 pagesES0153-75440100-DBR-0003 Dust Extractionraaj bharathNo ratings yet

- Direct Shear Test: Measuring Soil Shear StrengthDocument4 pagesDirect Shear Test: Measuring Soil Shear StrengthQUEIZNo ratings yet

- Series LFN45B-M1 Specification SheetDocument2 pagesSeries LFN45B-M1 Specification SheetWattsNo ratings yet

- Piping OverviewDocument28 pagesPiping Overviewعزت عبد المنعمNo ratings yet

- Engineering Design of Lifting LugsDocument1 pageEngineering Design of Lifting LugsadammzjinNo ratings yet

- High rigidity HDPE grade for 20L lubricant containersDocument1 pageHigh rigidity HDPE grade for 20L lubricant containersStella KazanciNo ratings yet

- Boiler Basics, Operation and MaintenanceDocument121 pagesBoiler Basics, Operation and MaintenanceCosmin IulianNo ratings yet

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDocument10 pagesSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedNo ratings yet

- B-1050 EL Resilient 2012-08Document24 pagesB-1050 EL Resilient 2012-08Karthick VenkateshNo ratings yet

- Serving The World in Pneumatic and Vacuum Conveying ProductsDocument8 pagesServing The World in Pneumatic and Vacuum Conveying ProductsoganuluNo ratings yet

- Sikadur - 43 FSMY: High Strength Epoxy Bedding MortarDocument3 pagesSikadur - 43 FSMY: High Strength Epoxy Bedding MortarChee Soon LeeNo ratings yet

- Laurie Baker Works and IdeasDocument14 pagesLaurie Baker Works and IdeasCebo DharuNo ratings yet

- Chapter 7 Others Construction MaterialsDocument61 pagesChapter 7 Others Construction MaterialsNabil FarhanNo ratings yet

- Module 1 - National Building Code of The Philippines - Part 1Document37 pagesModule 1 - National Building Code of The Philippines - Part 1Rovic VincentNo ratings yet

- Soft Sealing Gate Valve PN25Document2 pagesSoft Sealing Gate Valve PN25Emran HaniniNo ratings yet

- Reference List 1983-1995Document23 pagesReference List 1983-1995Đi Để ĐếnNo ratings yet

- U-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSDocument8 pagesU-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSFakeNo ratings yet

- Yanmar - 3tna72lDocument194 pagesYanmar - 3tna72lTiago Campos100% (1)

- Cable-Stayed Bridge Final and Construction Stage Analysis TutorialDocument69 pagesCable-Stayed Bridge Final and Construction Stage Analysis TutorialHafiz DoyoxNo ratings yet

- Villa Ottolenghi by Carlo ScarpaDocument6 pagesVilla Ottolenghi by Carlo ScarpaOana ZavoianuNo ratings yet

- Specification Sheets 50100 5202BN TR571Document3 pagesSpecification Sheets 50100 5202BN TR571MZY Commercial EnterprisesNo ratings yet

- Maintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyDocument1 pageMaintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyAneesh ConstantineNo ratings yet

- 0.12 M, 0.36 M, and The Depth of The FoundationDocument1 page0.12 M, 0.36 M, and The Depth of The FoundationMomen AdilNo ratings yet

- Plastering Techniques and MethodsDocument6 pagesPlastering Techniques and MethodsYazhisai SelviNo ratings yet

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Document14 pagesSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNo ratings yet

- Memo RA 9514Document351 pagesMemo RA 9514VergillerMisaGomezNo ratings yet

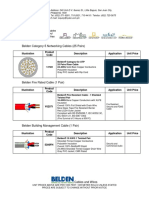

- Sytec Belden Cables and Accessories List 2016 Eff May 1Document15 pagesSytec Belden Cables and Accessories List 2016 Eff May 1Mitch PareñoNo ratings yet

- SEISMIC ISOLATORSDocument16 pagesSEISMIC ISOLATORSWillygan PmNo ratings yet