Professional Documents

Culture Documents

Tru-Sonic Manual New

Uploaded by

pedropinocontrerasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tru-Sonic Manual New

Uploaded by

pedropinocontrerasCopyright:

Available Formats

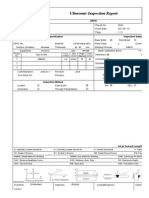

TRU-SONIC Operating Manual

INSTRUMENT FROM VIEW

INSTRUMENT BACKSIDE VIEW

CONNECTOR DESCRIPTION

Key Function

Switching the unit on and off Step Size for gain setting Freezing and storage the screen display

Recording measured value, saving data Select the function group Select the function Changing the operation level

Recording measured valued, saving data or clear back to min. setting Increasing gain Decreasing gain

LED

Symbol A R D

Description Gate alarm Function reject is active Function dual is active

Initial Start-Up

Power Supply The TRU-SONIC can be operated with an external power supply through AC/DC adaptor or with built-in Lithium-Ion battery pack. You can connect the TRU-SONIC to the main power supply if the instrument battery pack less the batteries power. Operating Use Main Power Supply Operating Use Main Power Supply The power supply unit is delivery with a 3-poles AC/DC charger Connect the TRU-SONIC to the main socket-outlet using the AC/DC power charger. The plug receptacle is at the top left of the TRU-SONIC Plus the AC/DC power supply to main power supply ( 110 or 220 VAC). The LED light on the charger will turn red into green. Then Push the AC/Dc power supply plug into the plug receptacle unit until it snaps into place with a clear audible click. (If the LED light not turns red into green, dont plug it.) Operating Use Lithium Battery Pack

The battery pack is situated at the instrument back. The battery two side built-in sliding guide Line and locked with screw. The Lithium pack also can put on the instrument charge or remove charge without instrument. The battery pack installed a DC charge receptacle connector same as instrument. See following picture shoed how to remove and install the battery pack. Battery power indicator The instrument screen right bottom side showed symbol of battery power. If the battery-pack power less than 20%, the instrument will show Low Battery. The instrument still can use approx. 20 min. when Low Battery alarm appear. The user need to switch off the unit and plug it to the main power supply or charge the battery.

Charging The Batteries You can charge the Lithium-Ion Battery either direct in the instrument or by means of an external charge from charger. Internal Charging Requirement - Lithium battery pack, our P/N - Power supply/charger unit, P/N

If a battery is located in the instrument, the charging process is start automatically when you connect the plug-in power supply unit. You can carry out ultrasonic inspection and charge a battery at the same time. The charging time is approx. 10 hours with a simultaneous ultrasonic inspection. If the instrument is not been used for ultrasonic inspectors, the charging time is approx. 8 hours. This charging time applies to ambient temperatures from 25-30 degree C, Please take into consideration that the battery pack are not charged to their full capacity at higher temperatures. The LED display on the plug-in power supply unit indicates the status of the charging process. First plug the power supply to the main power ( 220 VAC or 110 VAC ), the LED on the charger will turn red into green. Then plug the power supply plug direct to the instrument receipt socket or battery charge socket. When battery fully charged, the power supply charger LED indicator will turn red into green. External Charging Lithium-Ion batteries can be charged by means of an external charged. The Lithium battery installed a power receipt socket same as instrument. Use the same way as we charged by the previous way.. Connecting UT Probes The prepare of TRU-SONIC for operation, you have to connected a probe to it. Any brand probe can be use for the TRU-SONIC, provided the appropriate cable is available and the operating frequency is within an adequate range. The TRU-SONIC is available with the probe cable connectors Lemo 1. The probe is connected to the socket at top right on the instrument casing. Both connector socket are equally suitable ( connected in parallel) for connecting probes equipped with only one ultrasonic element (ultrasonic transducer) so that it does not matter which one of the two sockets is used. When connected dual-element (TR) probe (having one transmitter element and one receiver element), or two probes (of which one is transmitting and the other one receiving), attention should be paid to connecting the transmitter element to the right-hand sockets (transmitter, marked with black circle at the rear of the instrument case) and the receiver element to the left-hand socket (receiver, marked with red circle). Attention: If this is not taken into account, the consequence would be a mismatching which may lead to considerable power losses or even to echo waveform distortions.

Starting the TRU-SONIC Switching On TRU-SONIC To start the TRU-SONIC, press the switch on Key The start display of the Tru-Sonic appear a flash bar with instrument logo, here you will see also the current software version of the instrument.

The system carry out a self-check and then switches over to stand-by mode. The setting of all function values and the basic setting are same as before switching-on the instrument. Reset If any functions can not be operated after a warm start, or if you want to reset the instrument to the basic setup, then you should carry out a cold start by simultaneously pressing the and and Key the instrument will reset to the basic setup and clean all memory file key the instrument will reset to the basic setup and keep all memory file

Switch off the keypad Bi-Bi sound After press turn on TRU-SONIC, press again will turn off keypad sound

Principles of Operation Operators controls 0 LED

A: Gate alarm R: Rejection on D: Dual on

Screen Display The TRU-SONIC had a digital screen display of A-scan in normal mode Note: The screen display always shows the gain and the adjusted dB step value.

10

Tru-sonic Display Sub-Menu Guide

into BASE RANGE 0250mm TRIG S MTL VEL 5920m/s D-DELY 0000mm P-DELY 0.00us

First press GATE into a GATE a START 0050mm a WIDTH 0100mm a THRESH 88.0% a LOGIC POS ab GATE OFF

Second press GATE into b GATE b START 0150mm b WIDTH 0050mm b THRESH 25.0% b LOGIC POS b GATE OFF

First press SET into DATE HORN OFF BRIGHT HIGH UNIT mm DATE 11-28-06 TIME 1528

Second press SET into COLOR GROUND WORD ECHO GRID SOLID OFF

into PULSE DAMP 100 POWER 400V DUAL REF-dB +00dB PRF-MOD 100Hz

Tru-sonic Display Sub-Menu Guide

11

AND into PK MEM PK MEM OFF ENVLOP OFF SHADOW OFF B-SCAN OFF T-SCAN OFF into SAVE NO. 000 PUSH 1 FILE NAM 0000 FILE TYP A-SCAN DATE 11-26-05 TIME 1348 into RECALL NO. 000 PUSH 1 LOAD PUSH 1 TRANSIT PUSH 1 FILE NAM 0000 FILE DEL PUSH 1 into RECV REJECT 00% FREQU 0.5-5M RF-MODE OFF AGB 50% OFF FINE G 00 into TRIG ANGLE 00.0 X-VALUE 10.0mm THICKNE 000mm DIAMET 10.0mm 34.6 into CAL MEA FP PEAK S-REF 1 50mm S-REF 2 50mm a START 0050mm b START 0150mm into DAC DAC 3C OFF DAC 4C OFF AWS OFF AVG OFF RESET PUSH 1

Functions on the display

12

The means of the 8 function group key are displayed at the bottom of the screen. The currently selected function group is display on left screen.

You can configure the four positions of the measurement line for set and measured values as required. Example of a measurement line Ha = amplitude height Gate A(%) Sa = sound path Gate A Ra= Da= Ala= Hb = Amplitude height Gate B (%) Sb = Sound path Gate B Sab= Dab= F = status indicator TOF = Flank P= peak in gate

Important Basic Setting

13

Selecting Display Unit In the function group, press key, press unit display unit right < key, use left side ^ key, change the unit display mm or inch. Setting the date In the function group, press key, press unit display date < key, use left side ^ key, change the unit display date Setting the time In the function group, press key, press unit display time < key, use left side ^ key, change the unit display time Selecting the color scheme ( normally, dont need change it )

OVERVIEW OF THE FUNCTION

14

The functions of the TRU-SONIC are combined to form function groups of three operating levels The function, operated via left 3 keys, enable to quickly and direct set the gain. Press the Press the Press the key to select the function showed left side. key to increasing the setting key to decreasing the setting

Setting the Gain

The gain control function is always directly available from left up

key.

Press select a certain incrementation for setting the gain. , dB setting choice from 1,2,6,12,20 dB 5 steps corase setting. Press To increasing or decreasing the dB set increasing/decreasing steps. , press key on right of

For the fine gain control, you can press receiver key

FINE G. use key select the Fine G setting step. FINE G setting step can set 0.1 dB increasing/decreasing steps.

15

Adjusting the Display Range ( Function Group BASE ) The function group BASE enable you to make the basic adjustment of the screen display range. The display on the screen must be adjusted for the material to be tested.( function MTLVEL) and for the probe used (function for P-DELAY). Note: In order to accurately adjust the material velocity and the probe delay, please read the section Calibration of TRU-SONIC.

RANGE 0250mm TRIG S MTL VEL 5920m/s D-DELY 0000mm P-DELY 0.00us

RANGE (Display Range) You can adjust the display range if your measurement in range. The coarse adjustment from 25, 50, 100, 200, 400, 800, 1600, 3200, 6000 mm. Press the RANGE right again from 50 change to 100,etc. Any time when press the left side one time change from 25 change to 50, press

key, the range display will return back to the 25 mm, user can press range set another display range .

The fine adjustment can press BASE Key

, press RANGE right

key, then press

key select the Fine range display.

16

MTVEL (Sound Velocity) Use MTVEL to set sound velocity within the test object. You can use sound velocity between 1000-9999m/s Coarse adjustment 5920 m/s or 3330 m/s. Direct press MTVEL right key to select 5920 m/s or 3340 m/s

Fine adjustment 1000-15000m/s in step of 1m/s through

key

17

D-DELAY ( Display Starting Point) This function allow you to shift the complete screen display and consequently also the display zero. If the display should for example start from the surface of the test object, the value in D-DELAY must be set to 0.

Press D-DELAY right

key to select D-DELAY, Use

key adjustment. Adjust the value for the display starting point.

18

P-DELAY (Probe Delay) Every probe has a delay between the transducer element and coupling face. This means that the initial pulse must first pass through this delay line before the sound wave can enter the test object. You can compensate for this influence of the delay line in the function P-DELAY If the value for P-DELAY is not known, read the section calibration in order to determine this value - Select the function P-DELAY

Adjust the value for the probe delay use

key to the right value

Probe delay measurement, see attached example

19

Adjusting the Pulser ( Function group PULS DAMPING (Probe Matching)

This function serves for matching the probe. You can use it to adjust the damping of the probes oscillating circuit and consequently change the height, width and resolution of the echo display Low ( 200), this setting has a lower damping effect and produces higher and broader echoes High (100), this setting reduces the echo height but mostly also produces narrow echoes with higher resolution Select the function DAMP,

DAMP 100 POWER 400V DUAL REF-dB +00dB PRF-MOD 100Hz

Set the required value by means of

key to the right value.

POWER (Intensity) Use the function POWER to set the pulser voltage. You can choose between two setting ( 400V and 200V). The setting high (400V) is recommended for all Inspections in which maximum sensitivity is important, e.g. for the detection of small flaws. Choose the setting low (200V) for broadband probes or if narrow echoes are required (better latest resolution). - Select the function POWER.

Use the

key to the right value

DUAL (Pulser-Receiver Separation)

20

You can use the function DUAL to activate the pulser receiver separation. - Select the function DUAL.

DAMP 100 POWER 400V DUAL REF-dB +00dB PRF-MOD 100Hz

Use the

key to the right value

PRF-MOD ( Pulse Repetition Frequency) The pulse repetition frequency indicates the number of times an initial pulse is triggered per second. You can determine whether you need the highest possible PRF value, or whether you are satisfied with a low value. You 5 step selection (100Hz,250Hz,500Hz and 1000Hz) The larger you work piece, the smaller PRF value are needed in order avoid phantom echoes. In the case of the smaller PRF value, however, the A-scan update rate becomes lower, for this reason, high value are required if a work piece should be scanned fast. The best way to determine the suitable PRF value is by experimenting; start from the highest step and reduce the value until there are no such phantom echoes. Select the function PRF-MOD

Use the

key to the right value Angle beam mode Dual Crystal Contact mode Dual probe through-transmission mode

Single element contact mode

If the Dual crystal or dual through-transmission probe is select, the LED D (dual) is on

21

Adjusting the receiver (function group RECV) You will find all function for the adjustment of the pulser in the function group RECV. - If required, go to the first operating level Select the function group by Press RECV key REJECT 00% FREQU 0.5-5M RF-MODE The function REJECT allows you to suppress unwanted echo indications, for example structural noise from your test object. The % screen height setting indicates the minimum height that the echoes should attain in order for them to be displayed on the screen at all. The reject setting cannot be higher than the lowest threshold setting ( min 1%) of any gate. You should handle this function with great caution, as it may of course happen that you suppress echoes from flaws as well. Many test specifications expressly forbid using the reject function. - Select the function REJECT OFF AGB 50% OFF FINE G 00

REJECT

Use the

key to the right value

The LED R is therefore light with active when REJECT function on FREQU (Frequency Range) In this function, you can adjust the operating frequency according to the frequency of your probe.

22

You have a choose between 2 frequency range Narrow Band from 0.5-4.0 MHz Board Band from 4-15 MHz Select the function FREQU

Use the

key to the right value

RF-MODE ( RF=Radio Frequency) You can select the rectification mode of the echo pulses according to your application in the function RF-MODE. When RF mode on, it only applies to the display range up to 50 mm ( steel) - Select the function RF-MODE

Use the

key to turn RF on or off

AGB 80% ( Automatically increasing the gain raise the echo amplitude to 80% high ) Move Gate cross the echo Select the function AGB 80%

Use the

key to turn on the AGB 80% on, The echo amplitude will automatic increase up to 80% full screen

23

FINE G ( Fine adjustment of gain) This function serves for the fine adjustment of the current gain value. The fine adjustment is possible 0.1db per step. - - Select the function FINE G

Use the

key to increase or decrease 0.1 dB per step

24

Setting The Gates (Function Group aGAT and bGAT) Display of Gates All functions for setting the (dual) gate are arranged in the function group aGAT and bGAT. - If required, go to the first operating level - Select the function group aGAT or bGAT TASKS OF THE GATES It monitors the range of the test object where you expect to detect a flaw. If an echo exceeds or falls bellow the gate, an alarm signal is output via the LED A. The gate A and B are independent of one another. Gate A can also have the function of an echo-start gate. The gate choose the echo for the digital time-of-flight or amplitude measurement. The measured value is indicated in the measurement line. Error alarms can be triggered under certain circumstances. These are caused by intermediate conditions in instrument operation occurring when the instrument is used. i.e. when function parameters are changed. Possible alarms occurring during instrument operation (setting of function) are to be ignored.

25

To make the assignment easier, the gate are displayed in different colors. You can not vary the colors of gates because they are fixed as following Gate A yellow Gate B - Green aSTART/bSTART (Starting point of the gates) You can fix the starting point of the gates A or B within the adjustment range of 0-5999 mm. - - Select the function aSTART or bSTART

Use the

key to set right value

aWIDTH/bWIDTH (WIDTH of the gates) You can change the width of the gates A or B within the adjustment range of 0-5999 mm. - - Select the function aWIDTH or bWIDTH

Use the

key to set right value

aTHRSH/bTHRSH (Response and Measurement Threshold of the gates) You can change the threshold value of the gates A or B within the adjustment range of 10%-90% screen height for triggering the LED alarm if this value is exceeded or not reached, depending on the setting of the aLOGIC/bLOGIC function. In the RF-MODE, the threshold can be additionally set from -90% to -10%.

26

- Select the function aTHRSH or bTHRSH

Use the

key to set right value

aLOGIC/bLOGIC (Evaluation Logic of the gates) This function allows you to choose the method for triggering the gate alarm. The alarm is output to the LED A on the front panel of the TRU-SONIC. There are three setting options available off- Evaluation logic off The alarm (LED A) is on if the preset response threshold of the gate is exceeded within the displayed range Pos-Coincidence The alarm (LED A) is on if the preset response threshold of the gate is not reached within the displayed range Neg-Anticoincidence The alarm (LED A) is on if the preset response threshold of the gate is not reached within the displayed range The alarm and measurement function of the gates is only active within the display range.

27

Setting TRIG ANGLE=probe angle X-VALUE = Probe front side to index point distance. ( contact probe = 10 , angle beam probe need measurement by V1 bock )

MTL THK = material Thickness * DIAMET ( not available now ) 34.6 ( instrument inside temperature monitor )

Setting DAC This group function incl. set - 3 line DAC curve - 4 line DAC curve - AWS code inspection - AVG curve setting

28

DAC CURVE SETTING Prepare a 6 hole test block with different depth. Example drawing showed. 1. Calibrate the probe delay and set screen 175 mm 2. Press DAC enter the DAC submanual 3. move high-light cursor to DAC 3C and press up key turn on the DAC 3C on 4. Put probe on the test block and target to the first hole. Adjust the gain amplitude into 80%. Press * freeze key set point 1 5. Move the probe to second hole. Adjust the gate , press * set point 2 6. Move the probe to third hole. Adjust the gate , press * set point 3 7. Move the probe to no. 4 hole, adjust the gate, press * set point 4 8. Move the probe to no. 5 hole, adjust the gate, press * set point 5 9. Move the probe to no. 6 hole, adjust the gate, press * set point 6 10. press enter key completed the setting and show the setting curve 11. move high cursor set RL and EL dB. Set RL and EL dB 12. Move cursor to 6-point DAC, press up key set on, the DAC curve will display

29

30

Function Group PK.m This function incl. PK MEM ENVLOP SHADOW B-SCAN ( This function is optional accessories, not incl. in the standard package. To do the B-scan, you need encoder Scanner. Scanner and connection cable price ref. to the optional accessories ) T-SCAN

PK MEM Press PK MEM=on can hold the background echo cross the gate Put probe on 20 mm thick block to get Press PK MEM set it on, when take off the probe, the The MEM background echo will good for reference back echo cross the gate background echo display and hold on the screen. during the inspection

ENVOLOP Press ENVOLOP=on can hold the all the echoes cross the gate

31

Put probe on 20 mm thick block to get Press envlop set it on, when move the probe, the all back echo cross the gate echo cross the gate will hold and display on the screen.

SHADOW Press SHADOW=on. The initial and background echo will change color into solid display Put probe on 20 mm thick block to get Press SHADOW set it on, the echo color will change When move the probe. The show still hold on the back echo cross the gate into shadow display type display for reference

32

Time B-Scan 1. Select the probes which already calibrated the probe delay. If its a new probe, please follow the probe delay measurement procedure calibrate the probe delay 2. Press BASE key, enter probe delay ( measurement by Peak method ) 3. Press CAL set MEAS=Peak 4. Press PULS, set dual=contact 5. Press BASE, press set the screen display range to 50 mm 6. Put the probe on the step bock, make sure the gate can cover the min. and max. range 7. adjust the gain to get 75% amplitude from thick step as following 8. check the min step 20 mm back echo, see Sa=20.0 mm 9. Move the probe on the 20 mm step. Press PK MEM key, press T-SCAN right arrow key set T- scan on and start time-Bcan Move the probe from 20 mm to 10/5 mm step. After completed of the T-scan, press enter key and cal (1) key save the screen to the instrument 10. Press COPY recall key, press CAL (1) key recall the T-Bscan data 11. This Time-Bscan map showed scan the step block from 20 mm-10mm-5 mm

33

CALIBRATION: Tru-Sonic Probe Zero Auto-Calibration

1. Select the probe type ( contact or angle beam ), frequency, range and velocity Contact Probe Use V2 block 20 mm thick. Due to the probe near field resolution, please use second echo calibrate. The second echo should be 40 mm. Or, to use V1 block 100 mm Angle beam probe Target the probe to V1 R100 mm curve 2. 3. 4. 5. 6. 7. 8. Move gate cross and cover the max. response echo press CAL enter CAL mode, Press MEAS Arrow key key, now the Means/Peak will show double arrow cursor. This mean, the instrument already enter calibration procedure. Press S-REF1 arrow key, now the cursor will move to S-REF1. Use up and down key set 100 mm ( if use V1 block ) Press enter key again. Now the Tru-Sonic will auto-calibrate and the sound path will display 100.0 Press BASE key, Now the P-delay showed 2.77 us. Press Freeze key, press enter key again, Save this probe calibrate P-delay.

Example

Contact Probe Auto-Calibrate Procedure

34

1. 2. 3. 4. 5. 6. 7.

Get 4 MHz, 12 mm, 0 degree contact probe and V1 block . Press BASE key set RANGE into125 mm Press MTLVEL RIGHT ARROW KEY, MOVE CURSOR move cursor to MTLVEL. Press arrow key again Press PULS key enter PULS mode Set Probe Type- contact Press RECE key enter RECE mode, set FREQU=0.5-5.MHz Press TRIG key, enter TRIG mode Set angle 0 degree ( if now showed angel=70, press arrow key SET key select the angle=0.0 degree ) Plug probe cable to Tru-Sonic Put couplant on V2, put probe on the block to get response echo.

set MTLVEL 5920 m/s.

8. Adjust the gain until second echo raise to 80% height. 9. Press Gate, move Gate A across the second echo and cover it 10. Press CAL key, enter CAL mode, press MEAS right arrow key, the MEAS/Peak showed double arrow. 11. Press S-REF1 right arrow key, the cursor move to S-REF-1. use up/down key adjust the thickness into 100 mm 12. press enter key again. Now the probe sound path will show 100.0 mm. 13. Press BASE key. The P-delay= mm. 14. Now the probe delay already auto-calibrate. 15. Press FREEZE key, Press ENTER key enter SAVE mode. Press CAL/1 key Save the setting 16. Next time when use the same probe, press COPY key, enter recall mod, LOAD right arrow key , move cursor to Load, press CAL/1 key load the previous calibrate setting. Angle Beam Probe Auto-Calibrate Procedure

35

1. 2. 3. 4. 5. 6. 7.

Get 4 MHz, 8x9 mm, 60 degree contact probe and V2 block . Press BASE key set RANGE into 100 mm Press MTLVEL RIGHT ARROW KEY, MOVE CURSOR move cursor to MTLVEL. Press arrow key again Press PULS key enter PULS mode Set Probe Type-angle Press RECE key enter RECE mode, set FREQU=0.5-5.MHz Press TRIG key, enter TRIG mode Set angle 60 degree ( if now showed angel=70, press arrow key select the angle=60.0 degree ) Plug probe cable to Tru-Sonic Put couplant on V2, put probe on the block to get response echo.

set MTLVEL 5920 m/s.

8. Adjust the gain until second echo raise to 80% height. 9. Press Gate, move Gate A across the second echo and cover it 10. Press CAL key, enter CAL mode, press MEAS right arrow key, the MEAS/Peak showed double arrow. 11. Press S-REF1 right arrow key, the cursor move to S-REF-1. use up/down key adjust the sound path into 100 mm 12. press enter key again. Now the probe sound path will show 100.0 mm. 13. 14. 15. 16. Press BASE key. The P-delay= mm. Now the probe delay already auto-calibrate. Press FREEZE key, Press ENTER key enter SAVE mode. Press CAL/1 key Save the setting Next time when use the same probe, press COPY key, enter recall mod, LOAD right arrow key , move cursor to Load, press CAL/1 key load the previous calibrate setting.

36

4 MHz Contact Probe Manual Delay Measurement Select one 4 MHz contact probe connected to the cable and plug it to the TRU-SONIC Get 1 4 step thickness block ( 20, 10, 5 , 2.5mm ) Press TRU-SONIC ON/OFF switch, turn on the TRU-SONIC. Press pulser key enter pulser sub-manual. Press DUAL right key, Move cursor to DUAL, use +/- key change the display to contact probe symbol. Use Peak in Gate 1. Press BASE key enter BASE setting 2. Press RANGE key, set the display range = 25 mm 3. Press MTLVEL right key, set the velocity = 5920 m/s 4. Put the probe on the 20 mm block step 5. Press CAL set the MEAS=Peak 6. Press PULS, set DUAL=angle beam 7. Adjust the gain until echo display 80% full screen] 8. Press GATE, move gate across the display echo 9. Check the screen bottom Da=22.0 ( This show thickness is 22 mm not 20 mm.) 10. Adjust the probe delay until Da=20.0 11. The P-DEAY= 0.37 us

37

Use Flank 1. Press BASE key enter BASE setting 2. Press RANGE key, set the display range = 25 mm 3. Press MTLVEL right key, set the velocity = 5920 m/s 4. Put the probe on the 20 mm block step 5. Press CAL set the MEAS=Flank 6. Adjust the gain until echo display 80% full screen] 7. Press GATE, move gate across the display echo 8. Move the gate aTHREAD down to 7%. ( gate must acroos the echo first wave raise line ) 9. Check the screen bottom Da=21.2 ( This show thickness is 21.2 mm not 20 mm.) 10. Adjust the probe delay until Da=20.0 11. The P-DEAY= 0.22us

38

Note: Use Peak or Flank have different measurement value display. The probe delay is different. This will case inspection tolerance. Most of time, PEAK use for flaw detection and FLANK use for thickness measurement. 4 MHz, 8x9 mm, Angle Beam Probe Delay Measurement Select one 4 MHz, 8x9 mm, 70 degree probe connected to the cable and plug it to the TRU-SONIC Press TRU-SONIC ON/OFF switch, turn on the TRU-SONIC Put probe on V1 steel test block, tarket the probe to the 100 mm curve

39

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Press CAL key, select the MEAS=Peak Press BASE key, set range 200 mm Set TRIG=S Set MTL VEL=3353 m/s Press PULS,set Dual=angle beam Set gain until echo rise 80% full screen Press GATE. Move the gate b across the echo and adjust the width and thresh to 50% Press TRIG set angle =70 degree, s-VALE=12.0 mm, MTL THK = 100 mm Press BASE back BASE setting PressP-DELY right arrow key, press increasing key increasing P DELY until Sa=100.0 Move the gate across the echo check Sa=100.0. Now the P-DELY for this probe is 3.87 us

40

4 MHz Dual Crystal Contact Probe Delay Measurement Select one 4 MHz,12mm, 0 degree dualcrystal probe connected to the cable and plug it to the TRU-SONIC Press TRU-SONIC ON/OFF switch, turn on the TRU-SONIC 1. Press CAL key, select the MEAS= PEAK 2. Press BASE key, set range 25 mm 3. Set TRIG=S 4. Set MTL VEL=5920 m/s 5. Press PULS,set Dual=angle beam 6. Put probe on 20 mm step block 7. Set gain until echo rise 80% full screen 8. Press TRIG set angle = 0 degree, s-VALE=0.0 mm, MTL THK =20.0 mm 9. Press GATE. Move the gate across the echo and adjust the width and thresh to 50% 10. Press BASE back BASE setting 11. Move the gate across the echo 12. PressP-DELY right arrow key, press increasing key increasing P DELY until Sa=20.0 13. check Sa=20.0. Now the P-DELY for this probe is 3.39 us

41

Its very important to calibrate the probes delay and record it. If you didnt calibrate the probes delay and entry to the parameter. The inspection result will generate big tolerance. Each probes have different probe dealy. Single Probe Thickness measurement Select one 4 MHz,12mm, 0 degree dual crystal probe connected to the cable and plug it to the TRU-SONIC Press TRU-SONIC ON/OFF switch, turn on the TRU-SONIC

42

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15.

Press CAL key, select the MEAS= PEAK Press BASE key, set range 25 mm Set TRIG=S Set MTL VEL=5920 m/s Press PULS,set Dual=angle beam Put probe on 20 mm step block Set gain until echo rise 80% full screen Press TRIG set angle = 0 degree, s-VALE=0.0 mm, MTL THK =20.0 mm Press GATE. Move the gate across the echo and adjust the width and thresh to 50% Press BASE back BASE setting Move the gate across the echo PressP-DELY right arrow key, press increasing key increasing P DELY until Sa=20.0 check Sa=20.0. Now the P-DELY for this probe is 3.39 us Move the probe to 10 mm step, move gate across back echo, the Sa=10.0 and Da=10.0 Move the probe to 10 mm step, move gate across back echo, the Sa=5.0 and Da5.0

43

Note: When use Flank, the probe delay calibrate is different. Dual Probe Thinckness measurement Select one 4 MHz,12mm, 0 degree dual crystal probe connected to the cable and plug it to the TRU-SONIC Press TRU-SONIC ON/OFF switch, turn on the TRU-SONIC 16. Press CAL key, select the MEAS= PEAK 17. Press BASE key, set range 25 mm 18. Set TRIG=S 19. Set MTL VEL=5920 m/s 20. Press PULS,set Dual=angle beam 21. Put probe on 20 mm step block 22. Set gain until echo rise 80% full screen 23. Press TRIG set angle = 0 degree, s-VALE=0.0 mm, MTL THK =20.0 mm 24. Press GATE. Move the gate across the echo and adjust the width and thresh to 50% 25. Press BASE back BASE setting 26. Move the gate across the echo 27. PressP-DELY right arrow key, press increasing key increasing P DELY until Sa=20.0 28. check Sa=20.0. Now the P-DELY for this probe is 3.39 us

44

29. Move the probe to 10 mm step, move gate across back echo, the Sa=10.0 and Da=10.0 30. Move the probe to 10 mm step, move gate across back echo, the Sa=5.0 and Da5.0

Note: When use Flank, the probe delay calibrate is different.

45

Echo to Echo Measurement Select one 4 MHz contact probe connected to the cable and plug it to the TRU-SONIC Get 1 4 step thickness block ( 20, 10, 5 , 2.5mm ) Press TRU-SONIC ON/OFF switch, turn on the TRU-SONIC. Press pulser key enter pulser sub-manual. Press DUAL right key, Move cursor to DUAL, use +/- key change the display to contact probe symbol. 1. Press BASE key enter BASE setting 2. Press RANGE key, set the display range = 25 mm 3. Press MTLVEL right key, set the velocity = 5920 m/s 4. Put the probe on the 20 mm block step 5. Press CAL set the MEAS=Peak 6. Press PULS, set DUAL=angle beam 7. Adjust the gain until echo display 80% full screen] 8. Press GATE, move gate across the display echo 9. Check the screen bottom Da=22.0 ( This show thickness is 22 mm not 20 mm.) 10. Adjust the probe delay until Da=20.0 11. The P-DEAY= 0.37 us 12. Press BASE set the range=50 mm 13. Press GATE, move a Gate to cross first back echo 14. Press GATE again, set bGATE=on. Move bGATE cross second echo 15. Press GATE set abGATE=on 16. The screen bottom display Sab=20.00, Dab=20.00

46

If use FLANK, The probe delay calibrate same as before. Just take care set the aGATE and bGATE down cross echo wave first rise line. This will give you more precision measurement. Dual contact probe echo-echo do the same way.

47

You might also like

- DIO-562 - Brief Manual PDFDocument12 pagesDIO-562 - Brief Manual PDFDylkanWingsNo ratings yet

- Ultrasonic Flow Meter User Manual MU SeriesDocument43 pagesUltrasonic Flow Meter User Manual MU SeriesRameez IrfanNo ratings yet

- Techsonic EZ III Rev 4 092010 PDFDocument70 pagesTechsonic EZ III Rev 4 092010 PDFandresgomez10No ratings yet

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDocument21 pagesMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNo ratings yet

- Certificate of Origin Form F For China-Chile FTADocument2 pagesCertificate of Origin Form F For China-Chile FTAinspectormetNo ratings yet

- Defect / Non Compliance ReportDocument12 pagesDefect / Non Compliance ReportMichael OkwuwaNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Iplex GX-GT en Boroscopio OlympusDocument4 pagesIplex GX-GT en Boroscopio OlympusVICENTE CHAPARRONo ratings yet

- Pressure Vessel Inspection PlanDocument8 pagesPressure Vessel Inspection Plansuratno 25100% (1)

- Weld History SheetDocument2 pagesWeld History SheetAjin S100% (1)

- Status of power plant equipment testing June 2022Document2 pagesStatus of power plant equipment testing June 2022SureshYarlagaddaNo ratings yet

- Document: NO.:: Ultrasonic ExaminationDocument41 pagesDocument: NO.:: Ultrasonic ExaminationDamar WardhanaNo ratings yet

- Mobile Crane Checklist EssentialsDocument6 pagesMobile Crane Checklist EssentialsBanesco TemplarisNo ratings yet

- Bs 1806 1989Document22 pagesBs 1806 1989Kishor Jadhav100% (2)

- Flocat LB45A Manual Version 1 4Document48 pagesFlocat LB45A Manual Version 1 4JimBoringNo ratings yet

- OmniSX MX2 Training 17B HydroForm Setup Raster ScanDocument32 pagesOmniSX MX2 Training 17B HydroForm Setup Raster ScanOussama KhelilNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- Hardness Test Quality Control and Inspection Report FormDocument17 pagesHardness Test Quality Control and Inspection Report FormAlif Rahmat Febrianto0% (1)

- Ultrasonic Report: Probe Details and Position (Fig 1)Document2 pagesUltrasonic Report: Probe Details and Position (Fig 1)BALA GANESH100% (1)

- Cuel CPT ReportDocument103 pagesCuel CPT ReportIkhsan Ly100% (1)

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDocument6 pagesLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANo ratings yet

- Hydrotest - 333 AG FW 0001 - Rev03 PDFDocument26 pagesHydrotest - 333 AG FW 0001 - Rev03 PDFIhsan IchwansyahNo ratings yet

- Calibration Methods and Reference Standards in Ultrasonic TestingDocument4 pagesCalibration Methods and Reference Standards in Ultrasonic TestingKevin HuangNo ratings yet

- 16 - SGU - RT - ASME - 16 - Radiographic - REV - 00Document53 pages16 - SGU - RT - ASME - 16 - Radiographic - REV - 00pankrasius herbudiNo ratings yet

- PHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor BoltDocument14 pagesPHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor Boltchristian210789No ratings yet

- Astm d3044 PDFDocument3 pagesAstm d3044 PDFJose Manuel GaliciaNo ratings yet

- APL-C7!22!109 Ultrasonic Flow Detector Quality InspectorsDocument2 pagesAPL-C7!22!109 Ultrasonic Flow Detector Quality InspectorsSTEPHEN MIGWINo ratings yet

- PMI Ferrite Measurement ProcedureDocument7 pagesPMI Ferrite Measurement ProcedureAbd Rahman AliasNo ratings yet

- Replacement of Drum Screens & LCP ValvesDocument1 pageReplacement of Drum Screens & LCP ValvesAli Akbar100% (1)

- Assessing linearity of phased array instrumentsDocument20 pagesAssessing linearity of phased array instrumentsKevin HuangNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Copper WeldingDocument13 pagesCopper Weldingkatchani123No ratings yet

- 41.water Cum Foam Monitor-Trailer MountedDocument2 pages41.water Cum Foam Monitor-Trailer MountedSimbu ArasanNo ratings yet

- Elbow Trimming ProcedureDocument5 pagesElbow Trimming ProcedureMechanical Static WRKNo ratings yet

- PROCEDURE - Centrifuge Test For Oil BS&W CutDocument3 pagesPROCEDURE - Centrifuge Test For Oil BS&W CutHalanEnNo ratings yet

- Welding machine checklist inspectionDocument1 pageWelding machine checklist inspectionAshraf shaikhNo ratings yet

- TEST & REPAIR EQUIPMENT FOR VALVES AND ACTUATORSDocument44 pagesTEST & REPAIR EQUIPMENT FOR VALVES AND ACTUATORSBouzaida Maher100% (1)

- Appendix G Crane Safety Attachment A Pre Lift PlanDocument2 pagesAppendix G Crane Safety Attachment A Pre Lift PlanSyed Waqhas0% (1)

- VSSC Phased ArrayDocument140 pagesVSSC Phased Arraysentamil vigneshwaranNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Manual Apollo AnalysisDocument114 pagesManual Apollo AnalysisvrapciudorianNo ratings yet

- Astm E797Document7 pagesAstm E797Jimmy MárquezNo ratings yet

- Ultrasonic Wall Thickness Report Feb.27-28,20062 - 2Document32 pagesUltrasonic Wall Thickness Report Feb.27-28,20062 - 2Endickk Screamo PoreperrNo ratings yet

- ASME Sección V - Artículo 6Document9 pagesASME Sección V - Artículo 6Jhonathan ST100% (1)

- Reporting: Report Manager Generator (P11)Document31 pagesReporting: Report Manager Generator (P11)PrakashNo ratings yet

- TDS - Hardtop XP - English (Uk) - Azad Jotun Ras TanuraDocument4 pagesTDS - Hardtop XP - English (Uk) - Azad Jotun Ras TanuraAzadAhmadNo ratings yet

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- ASTM E10-14 Standard Test Method For Brinell Hardness of Metallic MaterialsDocument32 pagesASTM E10-14 Standard Test Method For Brinell Hardness of Metallic MaterialsSaya Santorno100% (2)

- NCDOT WPS for Double Bevel Groove WeldsDocument3 pagesNCDOT WPS for Double Bevel Groove Weldsfarshid KarpasandNo ratings yet

- Cutting PLan Pipe & Ducting PDFDocument91 pagesCutting PLan Pipe & Ducting PDFHaGun Gantry100% (1)

- SS Pipe Welding ProcedureDocument5 pagesSS Pipe Welding Procedureamit rajputNo ratings yet

- Foam InductorDocument6 pagesFoam InductorDipanjan Chakrabarti100% (1)

- Non-Destructive Testing of Steel Forgings - Part 2: Penetrant Testing (BS EN 10228-2:1998) 1 ScopeDocument7 pagesNon-Destructive Testing of Steel Forgings - Part 2: Penetrant Testing (BS EN 10228-2:1998) 1 ScopeKeng LengNo ratings yet

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Document3 pagesPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- WIKA Calibration Certificate for Process CalibratorDocument3 pagesWIKA Calibration Certificate for Process CalibratorBalaji BobadeNo ratings yet

- Tru Sonic Manual New PDFDocument47 pagesTru Sonic Manual New PDFStephen Rincon GonzalezNo ratings yet

- Zoll M, E Defibrillator - Service GuidelineDocument3 pagesZoll M, E Defibrillator - Service GuidelinePaul Levi NkahNo ratings yet

- RT 21 FB 55 MDocument29 pagesRT 21 FB 55 MHanif Rathore PrinceNo ratings yet

- Satlook Micro+ Operation ManualDocument12 pagesSatlook Micro+ Operation ManualgargiamoliNo ratings yet

- User'S Manual: Digital Satellite Meter SH-500Document8 pagesUser'S Manual: Digital Satellite Meter SH-500josewanNo ratings yet

- 19 Lecture PPTDocument47 pages19 Lecture PPTFrederick DugayNo ratings yet

- Mechanical Systems (Vibration and Control) - Roger F GansDocument448 pagesMechanical Systems (Vibration and Control) - Roger F GansBig FloresNo ratings yet

- System Dynamics and Respinse Kelly SolutionsDocument447 pagesSystem Dynamics and Respinse Kelly SolutionsSteve Karkenny100% (6)

- Chp3 SlidesDocument75 pagesChp3 Slideschristoalexw99No ratings yet

- Coursenotes Control Aero 4308Document10 pagesCoursenotes Control Aero 4308Phil GuerinNo ratings yet

- A Procedure To Predict Influence of Acceleration and Damping of Blades Passing Through Critical Speeds On Fatigue LifeDocument21 pagesA Procedure To Predict Influence of Acceleration and Damping of Blades Passing Through Critical Speeds On Fatigue LifeAltairEnlightenNo ratings yet

- Mcqs Based On Definitions, Time Equations, Place Equations, Maximum Values and PeriodDocument5 pagesMcqs Based On Definitions, Time Equations, Place Equations, Maximum Values and PeriodPon Adityan JeyamuruganNo ratings yet

- Kumpulan SoalDocument34 pagesKumpulan SoalDaraFelisiaArdhityasariNo ratings yet

- Basic Theory of Cavity Optomechanics PDFDocument20 pagesBasic Theory of Cavity Optomechanics PDFpsiholama27No ratings yet

- 05083Document284 pages05083chimpmbNo ratings yet

- FTIR MethodologyDocument12 pagesFTIR MethodologyArshia NazirNo ratings yet

- Differential Equations of PhysicsDocument28 pagesDifferential Equations of PhysicsRamesh MishraNo ratings yet

- PowerFactory WhatsNew 15.1 en r1225Document33 pagesPowerFactory WhatsNew 15.1 en r1225shengnaNo ratings yet

- User ManualDocument32 pagesUser ManualAljun LumbaoNo ratings yet

- Physics Formulas and ConceptsDocument23 pagesPhysics Formulas and Conceptschand7790No ratings yet

- BSC Physics Syllabus PDFDocument39 pagesBSC Physics Syllabus PDFFaizan KhanNo ratings yet

- Review of NZ Building Codes for Earthquake ResistanceDocument59 pagesReview of NZ Building Codes for Earthquake ResistanceMarcelo Zapata MuñozNo ratings yet

- Resonance PDFDocument160 pagesResonance PDFJustin Le BlancNo ratings yet

- Torre MayorDocument6 pagesTorre MayorTomislav ŠimagNo ratings yet

- M. Kramer - Propagation and Damping of M +1 and M - 1 Helicon Modes in An Inhomogeneous Plasma ColumnDocument4 pagesM. Kramer - Propagation and Damping of M +1 and M - 1 Helicon Modes in An Inhomogeneous Plasma ColumnHimaszNo ratings yet

- Bentley RM Bridge Advanced Detalii Module AditionaleDocument4 pagesBentley RM Bridge Advanced Detalii Module AditionalephanoanhgtvtNo ratings yet

- Vibration of Single Degree of Freedom SystemDocument31 pagesVibration of Single Degree of Freedom SystemEnriqueGDNo ratings yet

- TMC Setup Guide Lab Table 20 SeriesDocument24 pagesTMC Setup Guide Lab Table 20 SeriesDiabloNo ratings yet

- Pendulum Lab Report 3 (Final Rough Copy 1)Document15 pagesPendulum Lab Report 3 (Final Rough Copy 1)joe zouNo ratings yet

- Input Filter Design For SMPSDocument21 pagesInput Filter Design For SMPSsenkum812002No ratings yet

- Machine - Foundation - Vibrations-Vertical Dynamic Response of Foundation RestingDocument7 pagesMachine - Foundation - Vibrations-Vertical Dynamic Response of Foundation RestingRajendra S. RautNo ratings yet

- CE-5113 Lecture Notes 1Document19 pagesCE-5113 Lecture Notes 1Qaiser IqbalNo ratings yet

- Force VibrationDocument15 pagesForce Vibrationmohdanis53yahoocomNo ratings yet

- Vibration BySK MondalDocument25 pagesVibration BySK MondalRahul KumarNo ratings yet