Professional Documents

Culture Documents

9811 01 Lowfloor

Uploaded by

cgingenierosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9811 01 Lowfloor

Uploaded by

cgingenierosCopyright:

Available Formats

STRUCTURAL STEEL ACCOMODATES LOW FLOORTO-FLOOR HEIGHT floorCreative framing configuration allows for an 88

tofloor height on this five-story addition

By Thomas L. Shelmerdine, P.E.

O SATISFY THE INCREASING DEMAND FOR APARTMENTSTYLE CARE FACILITIES, THE

The addition to the Brookridge Retirement Community was designed to look as though it was built at the same time as the original building

Brookridge Retirement Community recently completed a five-story addition. The new addition to the successful upscale Continuing Care Retirement Community features a mix of independent living units and apartments, with a fivestory full service Health Center and Commons Facility nestled in a densely wooded site. The addition to the five-story building was located in a heavily wooded area, which could only be accessed by providing a new road to the building. Ray Troxell Associates, Winston-Salem, NC, provided full design services for the addition. Lead architect Kyle Troxell, AIA contracted with Structural Solutions, P.A. of Greensboro, NC, to provide structural engineering services. General Contractor Hugh G. Strickland, Inc., also of Winston-Salem, was soon brought on board to complete the team. Brookridge Retirement Community is a mix of independent living units and apartments. The existing structure consisted of load bearing masonry walls, with cast-in-place concrete flat slabs for the floors and attic. The floor to floor height was a low 8-8". The pitched roof structure was constructed of light gage metal framing, corru-

Modern Steel Construction / November 1998

gated steel decking, wood sheathing and asphalt shingles. The exterior walls were splitfaced CMU and brick. The footprint of the addition is only 1,300 sq. ft. The Owners program was to add five new two-bedroom apartments, one unit per floor. The exterior had to blend in with the existing structure as if it had always been there". Following the design process, construction of the facility had to be completed in ten months when the new tenants would arrive. STEEL FRAMING ALTERNATIVE Due to the relatively fast schedule, the design team wanted to find an alternative structural system. Constructing a load-bearing masonry and castin-place concrete structure would be too time consuming, especially since construction was to begin in September and continue through the winter. Structural steel was the obvious choice for speed and ease of construction, but the low 8-8 floor-to-floor height had to be matched, with allowance for an 8-0 ceiling height. Several years ago, Modern Steel Construction had a story about a hotel in Boston that utilized structural steel framing with a very low floor to floor height. I dug through the 8-year stack of MSCs in my office and found the September, 1993 issue. The structural engineers used 3 deep 18 gage composite steel deck to span the entire 13-4 room width. Steel beams were located only at the walls between each room. I contacted Kyle to see if the Brookridge room layout would allow this type of framing system to be used. The bedrooms were 11-2 and 12-0 wide, and the kitchen and dining areas were 12-6 wide. With the required live load being only 40 psf, this could be spanned with 3 - 18 gage composite steel deck with 3-1/4 of lightweight concrete, without the need for shoring. However, the corner of the building stepped out to cre-

Shown is a fireproofed interior steel beam. Note the double metal stud wall that will enable the beam to be hidden.

ate a 17-2 wide living room. Shoring would have to be provided in this area. DESIGN CONSIDERATIONS The framing was modeled and designed using the RamSteel computer program. Interior steel beams were centered on the wall between the two bedrooms, and the wall between the bedroom and living room. Two wythes of metal studs were used to make 9 thick interior walls, which had two distinct advantages. First, it allowed the beam with spray fireproofing to be completely hidden within the wall, eliminating the need for bulkheads on one or both sides of the wall. Secondly, it provided greater resistance to sound transmission. The perimeter steel beams were similarly hidden within a double stud wall. The columns were W8x24s, and fit within the stud wall when the web was oriented parallel to the wall. However, when the web was perpendicular to the wall, the 8 column with spray fireproofing was too deep to be hidden within the 9 wall. For this reason, these columns were offset 2 towards the interior of the building, still hidden within the 9 interior stud walls that were parallel to the web. Single angle connections were used to connect the beams to the columns at these offset conditions. The ceilings in the bathrooms were dropped to 7-0 to provide space for utilities. Close coordination was required with Consultant Engineering Service, Inc., the mechanical consultant, during the structural design process. The layout of all plumbing and exhaust lines had to be determined and coordinated with the beam locations. Holes were provided in the beam webs to allow for penetration of the mechanical and plumbing components. One opening was required through each floor to allow waste lines, vent lines, and exhaust ducts to be distributed vertically.

Web openings were utalized to accomodate many of the buildings utilities.

The underside of the composite floor deck is seen with furring channels applied for the gypsum wallboard ceiling. Beyond are the diagonal braces spread apart to accomodate the window opening.

Modern Steel Construction / November 1998

The existing lateral force resisting system was masonry shear walls. Since the addition was steel-framed with metal stud walls, a different lateral system would be required. Nearly every exterior wall required windows, making it difficult to locate diagonal bracing. One alternative was to utilize steel moment resisting frames. However, moment frames would be inherently more flexible that masonry shear walls. While there was an expansion joint between the old and new structures, I still wanted to minimize differential deflections. Diagonally braced frames would provide a much stiffer system. The two interior walls between the bedrooms and living room would accommodate the braces, however there were no walls in the other direction. The braces would have to be located in the exterior walls of the building. The architect established the size and location of each window to compliment the existing design. The configuration of each brace was controlled by the window dimensions. A K brace configuration was used, with the braces spread apart at the top as required to avoid interference with the window openings. The braced frames were designed using RISA 2D. DESIGNING FOR CONSTRUCTABILITY The layout of the steel framing resulted in the interior columns being braced in only one direction, since there were no beams framing into the column webs. Once the deck and concrete was installed, the slab would brace the column against weak axis buckling. Until that time, temporary struts were designed and installed between the columns to brace them laterally. This was especially important since the columns were fabricated in one piece for the full height, and all steel would be erected before any concrete was placed. The struts used bolted connections and were located 4

below the deck to facilitate removal. One area of each floor required shoring of the metal deck due to the excessive span. Typically, this would involve erecting shores beneath the deck, bearing on the level below, with reshoring below that level. Bill Allen, project manager for the general contractor, contacted me to request an alternate shoring system. Due to the small footprint of the building, Bill wanted to place concrete on more than one level at a time. This would not be possible with conventional shoring. Bill wanted to erect temporary steel beams to shore the deck, that were connected to the permanent framing. Using this scheme, the shoring did not have to bear on the level below, and concrete could be placed on all five suspended floors at one time. The beams were then removed after the concrete cured. FABRICATION AND ERECTION AISC-member Carolina Steel Corporation of Winston-Salem a fabricated the structural steel. With short spans and light loads, the steel beams and columns were relatively light, and did not involve difficult fabrication. The 3 - 18 gage composite steel deck was supplied by Consolidated Systems, Inc. , of Columbia, SC. Steel erection began in November, 1997. The winter of 1997 was especially wet, which slowed construction considerably for several weeks. Still, the main structural steel was erected in 5 days. Installation of the metal deck, screed angle, shear studs, etc. took another 3 weeks. Placement of the concrete slabs on metal deck took an additional two weeks. This six-week duration was a vast improvement over the time that load-bearing masonry and cast-in-place flat slabs would have taken. CONCLUSION Structural steel proved to be the material of choice for this project. By using a creative

approach to framing layout and slab design, the low 8-8 floor-tofloor height was achieved, and still allowed for an 8-0 ceiling in most of the rooms. Using structural steel allowed the structure to be constructed quickly and easily, even in less than ideal weather conditions, which allowed the contractor to proceed with construction through the winter. Thomas L. Shelmerdine, P.E. is president of Structural Solutions, P.A. in Greensboro, NC.

You might also like

- Hollow Sections 2nd EdtDocument240 pagesHollow Sections 2nd Edtksuscribdacct100% (2)

- SSEC 1995 Seismic Design of Bolted Steel Moment-Resisting Frames 87pDocument87 pagesSSEC 1995 Seismic Design of Bolted Steel Moment-Resisting Frames 87pcgingenierosNo ratings yet

- Complete Study Guide MIT FEM Prof BatheDocument194 pagesComplete Study Guide MIT FEM Prof BathekbdbmmNo ratings yet

- eBook-Finite Element Procedures in Engineering Analysis-Bathe - 1982Document375 pageseBook-Finite Element Procedures in Engineering Analysis-Bathe - 1982Eugenio Ferreras100% (4)

- Computer Analysis & Reinforced Concrete Design of BeamsDocument129 pagesComputer Analysis & Reinforced Concrete Design of BeamsMANDARAW100% (1)

- Fema ConexionesDocument80 pagesFema ConexionesvenezuelanNo ratings yet

- SSEC 1995 Seismic Design of Bolted Steel Moment-Resisting Frames 87pDocument87 pagesSSEC 1995 Seismic Design of Bolted Steel Moment-Resisting Frames 87pcgingenierosNo ratings yet

- An Introduction To Solving Engineering Problems With Matlab PDFDocument73 pagesAn Introduction To Solving Engineering Problems With Matlab PDFedo7474No ratings yet

- 2006 Structural Seismic Design Manual 1Document220 pages2006 Structural Seismic Design Manual 1vttrlc93% (14)

- Seismic Design of Eccentrically Braced FramesDocument32 pagesSeismic Design of Eccentrically Braced FramesMauricio RiquelmeNo ratings yet

- Solutions Manual-Dynamics of Structures (R.w. Clough and J. Penzien) - Francisco Medina-1995 118pDocument118 pagesSolutions Manual-Dynamics of Structures (R.w. Clough and J. Penzien) - Francisco Medina-1995 118pcgingenieros92% (49)

- Steel TipsDocument123 pagesSteel TipsEngr AxleNo ratings yet

- 2000-Design Applications of Raft Foundations J A Hemsley 642pDocument642 pages2000-Design Applications of Raft Foundations J A Hemsley 642pcgingenieros100% (1)

- (2000) Matrix Structural Analysis McGuire Gallagher Ziemian 474pDocument474 pages(2000) Matrix Structural Analysis McGuire Gallagher Ziemian 474pcgingenieros100% (2)

- NAVFAC-DM-7.2 Foundation & Earth Structure PDFDocument280 pagesNAVFAC-DM-7.2 Foundation & Earth Structure PDFFauzankalibata100% (1)

- 1974 Analytical and Computer Methods in Foundation Engineering J Bowles 519pDocument519 pages1974 Analytical and Computer Methods in Foundation Engineering J Bowles 519pcgingenieros100% (3)

- BallTank Foundation Design Guide Using AFES 21pDocument51 pagesBallTank Foundation Design Guide Using AFES 21pcgingenieros100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DB 200 SLDocument2 pagesDB 200 SLkanchanabalajiNo ratings yet

- Focus 2 2ed Vocabulary Quiz Unit4 GroupADocument1 pageFocus 2 2ed Vocabulary Quiz Unit4 GroupAAntoni Antoni100% (1)

- Padmanabhapuram Palace BookDocument23 pagesPadmanabhapuram Palace Bookosheen guptaNo ratings yet

- Heat Load Plus FormulaeDocument4 pagesHeat Load Plus FormulaeKaushikNo ratings yet

- Possible Solutions To Clogged NozzleDocument1 pagePossible Solutions To Clogged NozzleAsphystraszaNo ratings yet

- Etabs GuidelinesDocument2 pagesEtabs GuidelinesMudit GandhiNo ratings yet

- FacadeDocument5 pagesFacadeAvinash Mahajan100% (1)

- UBBL Application of Fire Safety ProvisionsDocument25 pagesUBBL Application of Fire Safety ProvisionsChen YishengNo ratings yet

- Airbus Structural Design ProjectsDocument2 pagesAirbus Structural Design ProjectsHugues de PayensNo ratings yet

- Unit 7. HousingDocument6 pagesUnit 7. HousingUyên ĐàoNo ratings yet

- Fire Stopping ManualDocument98 pagesFire Stopping Manualq linNo ratings yet

- Easy Arch ManualDocument49 pagesEasy Arch ManualDerzsi Elthes Andras100% (1)

- Aldar ProjectDocument19 pagesAldar ProjectmediamachansNo ratings yet

- The English Home - November 2015Document148 pagesThe English Home - November 2015Hussain ElarabiNo ratings yet

- NTN Ultage Ball BearingsDocument5 pagesNTN Ultage Ball Bearingsa04205No ratings yet

- Shigeru BanDocument44 pagesShigeru BanRicardo100% (1)

- Meadow BrochureDocument31 pagesMeadow BrochureShamilNo ratings yet

- A Temperature Difference Between The Outside and Inside Air Will Create ADocument5 pagesA Temperature Difference Between The Outside and Inside Air Will Create ASAKDA MAPRADITKULNo ratings yet

- Summary of Master Programme - 30.05Document9 pagesSummary of Master Programme - 30.05hmdineshNo ratings yet

- Ground Floor Plan 2 StoreyDocument1 pageGround Floor Plan 2 StoreyMa. Janina CincoNo ratings yet

- Spray Plaster Combined 28 July 2011Document8 pagesSpray Plaster Combined 28 July 2011gsebrenmaniNo ratings yet

- Ahuja Towers Worli - MumbaiDocument22 pagesAhuja Towers Worli - Mumbaimohammed.irfan@newprojectdeals.comNo ratings yet

- Hull InspectionDocument9 pagesHull InspectionTulen CabuldinNo ratings yet

- Bill of Quantities For POP False Ceiling No. Area Name Punning Area Didaction Total Ground FloorDocument6 pagesBill of Quantities For POP False Ceiling No. Area Name Punning Area Didaction Total Ground FloorAvinesh KumarNo ratings yet

- Set Sail 1 & 2Document24 pagesSet Sail 1 & 2jaccaz0% (1)

- 4 Fasteners: Hybrid Wood and Steel Details-Builder's GuideDocument24 pages4 Fasteners: Hybrid Wood and Steel Details-Builder's GuidetribleprinceNo ratings yet

- Giacomini - Modelo A61 - Valvula de Prueba y DrenageDocument8 pagesGiacomini - Modelo A61 - Valvula de Prueba y DrenageelpelaracingNo ratings yet

- Air Conditioning Installation CertificationDocument13 pagesAir Conditioning Installation Certificationeng_amin1239449No ratings yet

- School Building DesignDocument42 pagesSchool Building DesignKawaii Crafts100% (4)

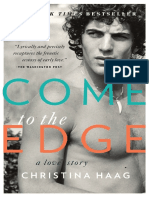

- Come To The Edge: The Love Story of JFK Jr. and Christina Haag (Excerpt)Document38 pagesCome To The Edge: The Love Story of JFK Jr. and Christina Haag (Excerpt)Random House Publishing Group22% (9)