Professional Documents

Culture Documents

Acme Thread Designstd

Uploaded by

Filipe MartinhoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acme Thread Designstd

Uploaded by

Filipe MartinhoCopyright:

Available Formats

ACME/STUB ACME Thread Strength Calculation

-Wihaga-

Scope:

The following equations are the standard formulas for conducting Acme/Stub Acme thread strength analysis on

threaded connections. This specification contains the equations used by the Acme/Stub Acme AutoProgram. All

assumptions should be understood and applied in the proper context. In the event of actual test data, the test results

should be used in lieu of these theoretical equations. Designs are to be based at all times on sound engineering

practices and judgment.

- Thread Strength calculations that are covered in this design standard:

- Yield of the Box at the thread relief due to axial loads (tension / compression)

- Yield of the Pin at the thread relief due to axial loads (tension / compression)

- Yield of the threaded connection due to axial tension (thread strip)

- Axial load generated by an applied torque and vise versa

- Maximum allowable torque prior to yield

- Optimal thread size to minimize strength differential between the pin and box

- Thread Strength calculations that are not covered in this design standard:

- Thread jump out

- Bearing stress

- Compressive buckling in pin & box noses

It is suggested that designs take into account design considerations to account for these items.

- All stress or force values calculated below are based on static forces and they do not account for pressure-induced

loads and/or axial loads generated by hanging weight.

- Reference Documents:

o The 26

th

Edition of the Machinerys Handbook

1

o ASME B1.5-1997 for Acme

2

o ASME ANSI B1.8-1988 for Stub Acme

3

o ASME B1.1 1989 Unified Inch Screw Threads

4

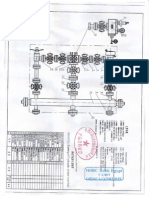

Figure 1. Acme Thread

Technical Application:

- Positive values indicate a tensile load while negative values indicate a compressive load. The designer must

identify critical compressive buckling loads at the box/pin nose. This functionality is beyond the scope of this

Standard.

- The Thread Optimization feature in the AutoProgram will allow evaluation of various thread sizes with constant

pitches. The designer must keep Design for Manufacturability and Design for Service in mind when choosing

thread pitches.

- Global Assumptions

o The materials mechanical properties are homogeneous and isotropic throughout the cross-section.

o The mechanical properties of the material are of equal magnitude in tension and compression.

o Cross-sections remain plane under loading conditions.

o The materials have ductile characteristics.

o Simple axial/shear loading results in a uniform axial/shear stress distribution across a uniform cross-

section.

o Materials obey Hookes Laws of elasticity (o = Ec).

o The minimum yield strength at .2% offset strain, rather than typical (average) yield strength of a

material, is the basis by which stress at yield is defined.

o Shear strength is 50% to 60% of the minimum yield strength. Two existing theories are the Distortion

Energy Theory (0.577 * Ys) and the Maximum Shear Stress Theory (0.5 * Ys).

o The selected material will not be used in an environment that will adversely affect its mechanical or

physical properties.

o Calculated stresses are based on static loading conditions if appropriate to the application.

Design Information:

1. Acme /Stub Acme Tensile Rating

Figure 2. Thread Reliefs and Maximum/Minimum Material Dimensions

The tensile rating for an Acme/Stub Acme Connection is the maximum value of axial tension that can be applied across

the wall thickness without the material yielding. The box (female thread) wall thickness dimension is defined by the

difference between the maximum thread relief ID and minimum OD for the box connection. The pin (male thread) wall

thickness dimension is defined by the difference between the minimum thread relief OD and maximum ID for the pin

connection. Figure 2 shows the thread reliefs and the maximum / minimum diameters. However not all Acme/Stub Acme

connections have a thread relief after the threads. In this situation the wall thickness is defined by maximum thread root

and minimum OD for the box and minimum thread root and maximum ID for the pin.

1.1. Formulas

( )

or SafetyFact

ld MinimumYie * Area PinTensile

PinTensile = (lbf)

( )

or SafetyFact

ld MinimumYie * Area BoxTensile

BoxTensile = (lbf)

1.2. Intermediate Equations

( )

2 2

r ideDiamete MaximumIns ef ThreadReli MinimumPin *

4

Area PinTensile = (in

2

)

) ef ThreadReli MaximumBox ter tsideDiame (MinimumOu *

4

Area BoxTensile

2 2

= (in

2

)

1.3. User Input Variables

1.3.1. Maximum Inside Diameter (in)

1.3.2. Minimum Outside Diameter (in)

1.3.3. Thread Relief (Pin, Box, Min. & Max.) (in)

1.3.4. Minimum Yield (psi)

1.3.5. Factor of Safety

1.4. Output Variables

1.4.1. Box Tensile Rating (lbf)

1.4.2. Pin Tensile Rating (lbf)

1.4.3. Box Tensile Area (in

2

)

1.4.4. Pin Tensile Area (in

2

)

2. Acme/Stub Acme Thread Shear Rating (Thread Stripping)

Another common form of thread yielding occurs when the applied axial tension exceeds the maximum allowable thread

shear rating. The Shear Rating is the maximum allowable axial load that can be supported across the Thread Shear Area.

Thread Shear Area is defined as the total ridge cross-sectional area intersected by a specific cylinder with diameter and

length equal to the mating thread engagement. Usually the cylindrical diameter for external thread shearing is the minor

diameter of the internal thread and for the internal thread shearing it is the major diameter of the external thread

1

(see

Figure 3). Length of thread engagement of two mating threads is the axial distance over which the two threads, each

having full form at both crest and root, are designed to contact

1

. Since the location of external (pin) thread failure has a

smaller diameter than the diameter corresponding to internal (box) thread failure, the connection will fail at the external

(pin) thread, assuming that both the pin and box have the same yield strength, etc. Shear (thread stripping) strengths of

screw threads under load are dependent, in addition, on mating component relative material strengths, connection

geometry, and coefficient of friction between thread bearing surfaces. Effective shear areas are therefore somewhat less

than the geometric values calculated below

4

.

Figure 3. Acme/Stub Acme Thread Connection Length of Engagement

2.1. Formulas

or SafetyFact

ld MinimumYie * r ShearFacto * erInch ShearAreaP * LOE

ng Shear_Rati = (lbf)

2.2. Intermediate Equations (Geometric Representation)

( )

|

.

|

\

|

+ = xDia MaxMinorBo aPin MinPitchDi * ) tan(14.5 *

P

1

2

1

* xDia MaxMinorBo * erInch ShearAreaP (in)

2.3. User Input Variables

2.3.1. Length of Engagement (LOE) (in)

2.3.2. Shear Factor

2.3.3. Minimum Yield (psi)

2.3.4. Factor of Safety

2.4. Output Variables

2.4.1. Shear Rating (lbf)

2.4.2. Shear Area Per Inch (in)

2.5. Reference:

Machinerys Handbook 26

th

Edition p.1794-1795

3. Acme/Stub Acme Thread Torque and Axial Load Calculation

Once thread box/pin nose has stopped moving and the box/pin makes contact at the internal or external shoulder (see

Figure 4 and 5), additional torque is translated into tension or compression causing an axial stress applied across the

thread relief of the box for contact at the internal torque shoulder or across the thread relief in back of the pin for contact at

the external shoulder.

Once the location of contact is known the value of the axial load can be calculated from the torque applied to the joint and

vise versa. Knowing the axial load generated by an applied torque is very useful in the design of threaded connections.

An important factor in the Torque/Axial Load is the coefficient of friction used in the equation. Typically values for

coefficient of friction can be found in many engineering texts. Careful selection of the appropriate coefficient of friction is

necessary to accurately determine the corresponding calculated value. Some common factors affecting coefficient of

friction; temperature, surface finish (texture) of surfaces in contact, lubrication type and viscosity, coatings, materials in

contact, numbers of times the joint has been assembled and disassembled.

Figure 4. Acme/Stub Acme Thread connection with an internal load shoulder

Figure 5. Acme/Stub Acme Thread connection with an external load shoulder

3.1. Formulas

( )

( )

12

* dius MidPointRa

cos * 2

* PitchDia

2

P

* AxialLoad

Torque

|

|

.

|

\

|

+

|

|

.

|

\

|

+ |

.

|

\

|

= (ft-lbf)

( )

( )

( )

|

|

.

|

\

|

+

|

|

.

|

\

|

+

=

* dius MidPointRa

cos * 2

* PitchDia

2

P

12 * Torque

AxialLoad (lbf)

3.1.1. External Torque Shoulder

elief) BoxThreadR (MinOD * (1/4) dius MidPointRa + = (in)

Mid-Point Radius is the assumed location of applied force

3.1.2. Internal Torque Shoulder

elief) PinThreadR (MaxID * (1/4) dius MidPointRa + = (in)

Mid-Point Radius is the assumed location of applied force

3.1.3. User Input Variables

3.1.3.1. Coefficient of Friction (u)

3.1.3.2. Maximum Inside Diameter (in)

3.1.3.3. Minimum Outside Diameter (in)

3.1.3.4. Minimum Yield (psi)

3.2. Constants

Phi (o) = 14.5 degrees

3.3. Output Variables

3.3.1. Torque (ft-lbf)

3.3.2. Axial Load (lbf)

3.3.3. Pin Tensile Rating (lbf)

3.3.4. Box Tensile Rating (lbf)

3.3.5. Thread Shear Rating (lbf)

3.4. Reference

Machinery's Handbook, 26

th

Edition, p. 1486-1487

4. Acme/Stub Acme Thread Torque To Yield Calculation

If an excessive torque is used to generate an axial load, the connection could yield before the desired axial load has

been achieved. To determine whether the load will cause the threaded connection to yield, the minimum of the {box

tensile rating, pin tensile rating, & shear rating} is determined. Those values are used in the equation found in

section 4.1 to determine the torque to yield the threaded connection. Ideally, the axial load should be less than the

box/pin tensile and shear ratings to prevent and plastic deformation to the threaded joint.

4.1. Formulas

( )

( )

12

* dius MidPointRa

cos * 2

* PitchDia

2

P

* AxialLoad

Torque

|

|

.

|

\

|

+

|

|

.

|

\

|

+ |

.

|

\

|

= (ft-lbf)

4.1.1. External Torque Shoulder

elief) BoxThreadR (MinOD * (1/4) dius MidPointRa + = (in)

Axial Load = Min. of {PinTensileRating, BoxTensileRating, ThreadShearRating}

4.1.2. Internal Torque Shoulder

elief) PinThreadR (MaxID * (1/4) dius MidPointRa + = (in)

Axial Load = Min. of {BoxTensileRating, PinTensileRating, ThreadShearRating}

4.2. User Input Variables

4.2.1. Coefficient of Friction (u)

4.2.2. Maximum Inside Diameter (in.)

4.2.3. Minimum Outside Diameter (in.)

4.2.4. Min. Yield (psi)

4.2.5. Factor of Safety

4.2.6. Length of Engagement (LOE) (in.)

4.2.7. Shear Factor

4.3. Constants

Phi (o) = 14.5 degrees

4.4. Output Variables

4.4.1. Torque To Yield (ft-lbf)

4.4.2. Axial Load To Yield (lbf)

4.4.3. Pin Tensile Rating (lbf)

4.4.4. Box Tensile Rating (lbf)

4.4.5. Thread Shear Rating (lbf)

4.5. Reference

Machinery's Handbook, 26

th

Edition, p. 1486-1487

5. Thread Size Optimization (Acme/Stub Acme Threads)

The procedure outlined in Section 5.1 searches for the optimal size thread that will minimize the difference between the

box and pin tensile rating. To use the search algorithm, the user must enter the OD, ID, Pitch, and Yield Strength. The

program then takes over and performs the search based on the constraints input by the user. After performing the

algorithm, the program then displays the results in order of increasing maximum allowable tensile strength difference.

5.1. Algorithm

1. Calculate the midpoint between the Max. ID and Min. OD rounded to the closest 1/32 of an inch.

2. Start with first thread size that is equal to or greater than the average value found in step 1.

3. Calculate the Box Tensile Rating and the Pin Tensile Rating and the absolute difference between the Box Tensile

Rating and the Pin Tensile Rating. Box tensile will generally be larger than Pin Tensile.

4. Go to the next larger available size with an index of 1/32

5. Recalculate the Box Tensile Rating, Pin Tensile Rating and the absolute difference

6. Continue until Box Tensile Rating is less than the Pin Tensile Rating (this will be thread size B)

7. Recalculate the Box Tensile Rating, Pin Tensile Rating and the absolute difference for the previous and next size

(A and C respectively)

8. Compare the absolute difference for thread sizes A, B and C

9. The thread size with the lowest absolute difference is the 1

st

(optimal) option

10. The remaining are then listed 2, 3, 4 and 5 in order of increasing absolute difference values

5.2. User Input Values

5.2.1. Thread Type

5.2.2. Max. OD (in)

5.2.3. Min. ID (in)

5.2.4. Pitch

5.2.5. Min. Yield (psi)

5.3. Outputs

5.3.1. Thread Size (in)

5.3.2. Pin Tensile Rating (lbf)

5.3.3. Box Tensile Rating (lbf)

5.3.4. Absolute Difference (lbf) -- Absolute Difference = ABSOLUTE ([Box Tensile Rating] - [Pin Tensile Rating])

You might also like

- Casing Friendly Hardbanding Facts and MythsDocument3 pagesCasing Friendly Hardbanding Facts and Mythssdb158No ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Acme Thread-Inch enDocument6 pagesAcme Thread-Inch enscrewtech100% (3)

- Arrow-Pak 7.0 X 4Document9 pagesArrow-Pak 7.0 X 4Tech AlfaNo ratings yet

- NCS Liner HangersDocument5 pagesNCS Liner Hangerssmithyry2014No ratings yet

- 0620000008Document6 pages0620000008mahsaNo ratings yet

- NOV Grant Prideco Drilling Connection Inspection GuideDocument4 pagesNOV Grant Prideco Drilling Connection Inspection GuidetheinmoeNo ratings yet

- Grant Prideco™ Mechanical Property Requirements For Drill PDFDocument4 pagesGrant Prideco™ Mechanical Property Requirements For Drill PDFChristian Matteo100% (1)

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965From EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNo ratings yet

- 5276Document52 pages5276Sean PorterNo ratings yet

- Bop Es406 15K WeatherfordDocument53 pagesBop Es406 15K WeatherfordWill CastellanosNo ratings yet

- Set A Drill Collars-Drillpipe-HeviwateDocument44 pagesSet A Drill Collars-Drillpipe-HeviwateMuhammad Shahzad0% (1)

- Casing API ConnectionsDocument3 pagesCasing API ConnectionsBrahim Letaief100% (1)

- 2012 Thread Profile Data SheetDocument2 pages2012 Thread Profile Data Sheetflasher_for_nokiaNo ratings yet

- Pump Out Plug Operating InstructionsDocument6 pagesPump Out Plug Operating InstructionsEvolution Oil ToolsNo ratings yet

- RP Insp Rep 01Document8 pagesRP Insp Rep 01advantage025No ratings yet

- API Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure, Gerdes, 2010Document8 pagesAPI Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure, Gerdes, 2010Ryan Fenyves100% (1)

- SPE-198397-MS DrillPlan Fatigue Implementation PDFDocument10 pagesSPE-198397-MS DrillPlan Fatigue Implementation PDFДенис ЖангауловNo ratings yet

- NXT-M Bop TMSDocument1 pageNXT-M Bop TMSSasan Abbasi100% (1)

- Te ValveDocument30 pagesTe Valvecrni roko100% (2)

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDocument2 pagesD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNo ratings yet

- Autoclave Engineers - Valves Fittings and Tubing - Condensed CatalogDocument16 pagesAutoclave Engineers - Valves Fittings and Tubing - Condensed Catalogchristophedepaepe100% (1)

- API Extreme Line Casing Metal-to-Metal Seal ConnectionsDocument1 pageAPI Extreme Line Casing Metal-to-Metal Seal ConnectionsEleonora LetorNo ratings yet

- SB Drill CollarDocument51 pagesSB Drill CollarJeff ZhangNo ratings yet

- TMK Up™: Field ManualDocument84 pagesTMK Up™: Field Manualcorsini999No ratings yet

- Heshka Oil Catalog 2019Document16 pagesHeshka Oil Catalog 2019Michael PerschkeNo ratings yet

- Fabritech Globular® GBOP User Manual REV.1Document50 pagesFabritech Globular® GBOP User Manual REV.1Joel S100% (1)

- Remdial & StimulationDocument55 pagesRemdial & StimulationAutumn NunezNo ratings yet

- Tenaris HSR Handbook Eng. V3Document20 pagesTenaris HSR Handbook Eng. V3Mecnun SevindikNo ratings yet

- Hydraulic Locke Valve Testing ReportDocument30 pagesHydraulic Locke Valve Testing Reportjamil voraNo ratings yet

- Shearing Blind Rams SBRDocument8 pagesShearing Blind Rams SBRDavid OrtegaNo ratings yet

- Cold Rolling Info GuideDocument11 pagesCold Rolling Info Guide72espoNo ratings yet

- Tenaris ConnDocument12 pagesTenaris ConnDanielNo ratings yet

- Bdmi SM-6013 1 PDFDocument27 pagesBdmi SM-6013 1 PDFFatoni Gea AirlanggaNo ratings yet

- DLH Packer: DescriptionDocument6 pagesDLH Packer: DescriptionDEATH ASSASSIN GAMERNo ratings yet

- Tapon Mecanico Iron Bridge Plug TSSDocument11 pagesTapon Mecanico Iron Bridge Plug TSSAaron Vazquez MartinezNo ratings yet

- DL Catalog 080419Document119 pagesDL Catalog 080419Dmitry Gal100% (1)

- Scrugrab 05-03-10 PDFDocument2 pagesScrugrab 05-03-10 PDFfabisysNo ratings yet

- 10 37 00 1110 NS 1 A4 WatermarkedDocument7 pages10 37 00 1110 NS 1 A4 Watermarkedislam atif100% (1)

- Drillquip MLS Ssystem Catalog ms15 - Mudline PDFDocument20 pagesDrillquip MLS Ssystem Catalog ms15 - Mudline PDFMoisesNo ratings yet

- H4 Connector - Reference OnlyDocument117 pagesH4 Connector - Reference OnlyDanielle Vasconcelos ParraNo ratings yet

- Drill Stem Testing RD Sampler: SmartstarDocument1 pageDrill Stem Testing RD Sampler: SmartstarDenier RubianoNo ratings yet

- Schematics BOP Triple RamDocument2 pagesSchematics BOP Triple RamDidik SafdaliNo ratings yet

- MRP Gage Operation Manual Models 1000/2000/3000Document62 pagesMRP Gage Operation Manual Models 1000/2000/3000jose abaNo ratings yet

- Maintain Single Shear Seal BOPDocument22 pagesMaintain Single Shear Seal BOPDEATH ASSASSIN GAMERNo ratings yet

- Thread Make-Up ProcedureDocument5 pagesThread Make-Up ProcedureVova PanchenkoNo ratings yet

- Hydril Annular BOP1Document2 pagesHydril Annular BOP1Abde EsselamNo ratings yet

- Flanges PDFDocument9 pagesFlanges PDFDGG2010No ratings yet

- Liner PackersDocument1 pageLiner PackersMohamed ElabbasyNo ratings yet

- M "EA" R C P P N - 25.214: Odel Etrievamatic Ementer Acker Roduct ODocument2 pagesM "EA" R C P P N - 25.214: Odel Etrievamatic Ementer Acker Roduct ORodolfo Rider100% (1)

- Parveen Stabilizers Guide Drilling ToolsDocument2 pagesParveen Stabilizers Guide Drilling ToolsGonzalo Guzman Jaimes100% (1)

- GuibersonCatalog PDFDocument66 pagesGuibersonCatalog PDFtictacal100% (2)

- Cementing Plugs AND Ancillary EquipmentDocument16 pagesCementing Plugs AND Ancillary EquipmentTeguh Akbar HarahapNo ratings yet

- Drilco Spiral Drill Collar PsDocument1 pageDrilco Spiral Drill Collar Psyojan35No ratings yet

- 003 Casing & Tubing Hanger PDFDocument4 pages003 Casing & Tubing Hanger PDFalaliali88No ratings yet

- Field inspection criteria for Fox thread connectionsDocument5 pagesField inspection criteria for Fox thread connectionsJoseph MidouNo ratings yet

- Tenaris Running Manual 01Document20 pagesTenaris Running Manual 01advantage025No ratings yet

- Indian Codes - Concrete Design PerDocument7 pagesIndian Codes - Concrete Design Peribrahim100% (1)

- He So Nen UonDocument7 pagesHe So Nen UonTran Van DaiNo ratings yet

- Design Aids For Tension Members As Per Revised Is: 800-2007Document7 pagesDesign Aids For Tension Members As Per Revised Is: 800-2007dev_1989No ratings yet

- Carrfoster 2Document5 pagesCarrfoster 2SauravNo ratings yet

- SosthenesDocument396 pagesSosthenesAthiesh KumarNo ratings yet

- Math at Grade 4Document9 pagesMath at Grade 4api-239942675No ratings yet

- MAVEN: Motion Analysis and Visualization of Elastic Networks and Structure Ensembles Version 1.1 User's Manual ContentsDocument30 pagesMAVEN: Motion Analysis and Visualization of Elastic Networks and Structure Ensembles Version 1.1 User's Manual ContentsOscar DedNo ratings yet

- AASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Document17 pagesAASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Laurence Arcon Banal0% (1)

- Martin Hermann, Masoud Saravi - Nonlinear Ordinary Differential Equations - Analytical Approximation and Numerical Methods-Springer (2016) PDFDocument320 pagesMartin Hermann, Masoud Saravi - Nonlinear Ordinary Differential Equations - Analytical Approximation and Numerical Methods-Springer (2016) PDFHugo Mayorga100% (1)

- Polar Moment of Inertia ExperimentDocument17 pagesPolar Moment of Inertia Experimentsohail parachaNo ratings yet

- Calorimetry - Specific Heat and Latent Heat: 3.1 PurposeDocument6 pagesCalorimetry - Specific Heat and Latent Heat: 3.1 PurposeRajesh JadhavNo ratings yet

- Separation and Purification of Triacylglycerols From Nyamplung (Calophyllum Inophyllum) Oil by Batchwise Solvent ExtractionDocument24 pagesSeparation and Purification of Triacylglycerols From Nyamplung (Calophyllum Inophyllum) Oil by Batchwise Solvent ExtractionAfifatul JannahNo ratings yet

- CGR 16050 2019 2020 1Document1 pageCGR 16050 2019 2020 1Chandan Prasad KushwahaNo ratings yet

- Group Plant BrochureDocument52 pagesGroup Plant BrochureAnonymous AdofXEYAgE100% (1)

- Free Electron Theory 2015-16 (VTU) PDFDocument14 pagesFree Electron Theory 2015-16 (VTU) PDFU and me SNo ratings yet

- Fastners Modeling For MSC - Nastran Finite Element AnalysisDocument20 pagesFastners Modeling For MSC - Nastran Finite Element Analysisabo029No ratings yet

- D Mec Frac Fatigue Part IIDocument38 pagesD Mec Frac Fatigue Part IIsure516vNo ratings yet

- PhoneticsDocument5 pagesPhoneticsKarensita Totty' HerreraNo ratings yet

- Load CalculationsDocument5 pagesLoad Calculationsarif_rubinNo ratings yet

- Cracking Moment Analysis of Prestressed Concrete BeamDocument18 pagesCracking Moment Analysis of Prestressed Concrete Beamharshil gandhiNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19SURAJ NAKUMNo ratings yet

- Mock C4 Paper Key ConceptsDocument4 pagesMock C4 Paper Key ConceptsWojtek BażantNo ratings yet

- Diaphragm Design PDFDocument50 pagesDiaphragm Design PDFManoj JaiswalNo ratings yet

- POLYMERIZATION PROCESSESDocument0 pagesPOLYMERIZATION PROCESSESmajesticdharma1985No ratings yet

- Equilibrium Stage Processes - Docx CetDocument25 pagesEquilibrium Stage Processes - Docx CetPortia ShilengeNo ratings yet

- Alloy ZN Ni PDFDocument8 pagesAlloy ZN Ni PDFElenaNo ratings yet

- Design of 10m Span RCC Slab CulvertDocument105 pagesDesign of 10m Span RCC Slab CulvertD.V.Srinivasa Rao100% (4)

- Numerical MethodsDocument9 pagesNumerical Methodsshaz_donNo ratings yet

- Influence of Dirt Accumulation On Performance of PV Panels: SciencedirectDocument7 pagesInfluence of Dirt Accumulation On Performance of PV Panels: SciencedirectEsra AbdulhaleemNo ratings yet

- Berco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inDocument1 pageBerco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inrameshNo ratings yet

- Chocolate RheologyDocument7 pagesChocolate RheologyAdil AnwarNo ratings yet

- CE 3310 Assignment 2Document1 pageCE 3310 Assignment 2SSNo ratings yet