Professional Documents

Culture Documents

A Servomechanism

Uploaded by

Chaitanya Kumar GOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Servomechanism

Uploaded by

Chaitanya Kumar GCopyright:

Available Formats

What is a Servo motor??

A servomechanism, or servo, is an automatic device that uses error-sensing negative feedback to correct the performance of a mechanism. The term correctly applies only to systems where the feedback or error-correction signals help control mechanical position, speed or other parameters. For example, an automotive power window control is not a servomechanism, as there is no automatic feedback that controls positionthe operator does this by observation. By contrast the car's cruise control uses closed loop feedback, which classifies it as a servomechanism. A servomechanism may or may not use a servomotor. For example, a household furnace controlled by a thermostat is a servomechanism, yet there is no motor being controlled directly by the servomechanism. A common type of servo provides position control. Servos are commonly electrical or partially electronic in nature, using an electric motor as the primary means of creating mechanical force. Other types of servos use hydraulics, pneumatics, or magnetic principles. Servos operate on the principle of negative feedback, where the control input is compared to the actual position of the mechanical system as measured by some sort of transducer at the output. Any difference between the actual and wanted values (an "error signal") is amplified and used to drive the system in the direction necessary to reduce or eliminate the error. This procedure is one widely used application of control theory. Typical servos give a rotary (angular) output. Linear types are common as well, using a leadscrew or a linear motor to give linear motion. Another device commonly referred to as a servo is used in automobiles to amplify the steering or braking force applied by the driver. However, these devices are not true servos, but rather mechanical amplifiers. (See also Power steering or Vacuum servo.) WORKING:

Servomotors are geared dc motors with a positional feedback control that allows the rotor to be positioned accurately. The specifications state that the shaft can be positioned through a minimum of 90 (45). In reality we can extend this range closer to 180 (90) by adjusting the positional control signal.

There are three wire leads to a servomotor. Two leads are for power +5v and GND. The third lead feeds a position control signal to the motor. The position control signal is a single variable width pulse. The pulse can be varied from 1 to 2 ms. The width of the pulse controls the position of the servomotor shaft.

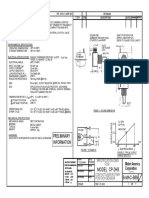

The control wire is used to communicate the angle. The angle is determined by the duration of a pulse that is applied to the control wire. This is called Pulse Coded Modulation. The servo expects to see a pulse every 20 milliseconds (.02 seconds). The length of the pulse will determine how far the motor turns. A 1.5 millisecond pulse, for example, will make the motor turn to the 90 degree position (often called the neutral position). If the pulse is shorter than 1.5 ms, then the motor will turn the shaft to closer to 0 degress. If the pulse is longer than 1.5ms, the shaft turns closer to 180 degress.

As you can see in the picture, the duration of the pulse dictates the angle of the output shaft (shown as the green circle with the arrow).

Note that the times here are illustrative, and the actual timings depend on the motor manufacturer. The principle, however, is the same.

APPLICATIONS: Positioning servomechanisms were first used in military fire-control and marine navigation equipment. Today servomechanisms are used in automatic machine tools, satellite-tracking antennas, remote control airplanes, automatic navigation systems on boats and planes, and antiaircraft-gun control systems. Other examples are fly-by-wire systems in aircraft which use servos to actuate the aircraft's control surfaces, and radio-controlled models which use RC servos for the same purpose. Many autofocus cameras also use a servomechanism to accurately move the lens, and thus adjust the focus. A modern hard disk drive has a magnetic servo system with sub-micrometre positioning accuracy. Servomotors are used in many radio-controlled model airplanes, cars, boats, and helicopters.

You might also like

- Pioneer DDJ-1000SRT DJ Controller Service Manual (RRV4696)Document51 pagesPioneer DDJ-1000SRT DJ Controller Service Manual (RRV4696)Denoraffendy Maideen67% (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- DC Servo Motor Position SystemDocument28 pagesDC Servo Motor Position SystemVincent Korie100% (2)

- ServomechanismDocument4 pagesServomechanismamuthaneceNo ratings yet

- ServomechanismDocument4 pagesServomechanismJermaine StrachanNo ratings yet

- Servo MotorDocument15 pagesServo MotorShivshankar GhugeNo ratings yet

- Servo Motors Types and ApplicationsDocument22 pagesServo Motors Types and ApplicationsJavierNo ratings yet

- Servo Motor Control Using 8051Document11 pagesServo Motor Control Using 8051Rajesh RavindranNo ratings yet

- Servo Motor Control Using 8051Document11 pagesServo Motor Control Using 8051Rajesh RavindranNo ratings yet

- Servo MotorDocument31 pagesServo Motoradiamiru25% (4)

- Servomechanism: Application of Servo MechanismDocument6 pagesServomechanism: Application of Servo MechanismJawad SandhuNo ratings yet

- Servomechanism: Industrial ServomotorDocument4 pagesServomechanism: Industrial ServomotorFarazKhanNo ratings yet

- Servomotor: Types of Motor Used in ServomotorDocument4 pagesServomotor: Types of Motor Used in ServomotorJawad SandhuNo ratings yet

- Topic:-Servomechanism and Control SystemsDocument10 pagesTopic:-Servomechanism and Control SystemsHot ShotNo ratings yet

- Differences Between Stepper Motors and Servo MotorsDocument1 pageDifferences Between Stepper Motors and Servo MotorsazharzebNo ratings yet

- LAB 2-AngeladaDocument20 pagesLAB 2-AngeladaAlehamarie AngeladaNo ratings yet

- Servo Motors Types and ApplicationsDocument22 pagesServo Motors Types and ApplicationsLakshman ReddyNo ratings yet

- What Is Servo Motor Servomotor: Rotary Actuator Linear ActuatorDocument11 pagesWhat Is Servo Motor Servomotor: Rotary Actuator Linear ActuatorThe-kiros HadushNo ratings yet

- Servo MotorDocument4 pagesServo MotorWasil BabarNo ratings yet

- Servo Motor - Types, Construction, Working, Controlling & ApplicationsDocument7 pagesServo Motor - Types, Construction, Working, Controlling & ApplicationsAHMED YOUSEFNo ratings yet

- Powerpoint Presentation : Topic:-Servomechanism and Control SystemsDocument13 pagesPowerpoint Presentation : Topic:-Servomechanism and Control SystemsAhsan MalikNo ratings yet

- Unit 5Document30 pagesUnit 5kruthikaNo ratings yet

- Mechatronics Lab Assignment: Servo MotorsDocument3 pagesMechatronics Lab Assignment: Servo MotorsNavendu GuptaNo ratings yet

- Basics of Servo System and SimulationDocument45 pagesBasics of Servo System and Simulationgk_gbu100% (1)

- Servo MotorDocument3 pagesServo Motormuneeb saeedNo ratings yet

- How Do Servo Motors Work: This Little Motor Is High in Efficiency and PowerDocument8 pagesHow Do Servo Motors Work: This Little Motor Is High in Efficiency and PowerSubham GhoshNo ratings yet

- Final PresentationDocument103 pagesFinal PresentationQasir NawazNo ratings yet

- Servo MotorsDocument8 pagesServo MotorsFairos ZakariahNo ratings yet

- Chapter1 121210210811 Phpapp02Document57 pagesChapter1 121210210811 Phpapp02sharkeraNo ratings yet

- Objective: Theory:: Indian Institute of Information Technology, Design & Manufacturing, Jabalpur (M.P.)Document3 pagesObjective: Theory:: Indian Institute of Information Technology, Design & Manufacturing, Jabalpur (M.P.)Ansh NarulaNo ratings yet

- Experiment No. 02: DR D Y Patil School of Engineering & TechnologyDocument3 pagesExperiment No. 02: DR D Y Patil School of Engineering & Technologypradnya sadigaleNo ratings yet

- Experiment No. 02: DR D Y Patil School of Engineering & TechnologyDocument3 pagesExperiment No. 02: DR D Y Patil School of Engineering & Technologypradnya sadigaleNo ratings yet

- Servo Motors IntroductionDocument3 pagesServo Motors IntroductionhelloNo ratings yet

- ServoDocument7 pagesServohaaenNo ratings yet

- Servomechanism Presentation MCS 1Document38 pagesServomechanism Presentation MCS 1Vipin Ramachandran PillaiNo ratings yet

- Servomotor: Rotary ActuatorDocument2 pagesServomotor: Rotary ActuatorIan Jerome Fallarcuna BuronNo ratings yet

- Servo Motor - Servo Mechanism - Theory and Working PrincipleDocument6 pagesServo Motor - Servo Mechanism - Theory and Working PrincipleBrahmanand SinghNo ratings yet

- Introduction Robot Drive SystemsDocument17 pagesIntroduction Robot Drive SystemsTemesgen100% (2)

- Servo Motor SystemDocument8 pagesServo Motor SystemAnonymous Y7WZ3dqoXhNo ratings yet

- Servomechanism Presentation MCS - 1Document19 pagesServomechanism Presentation MCS - 1HKD89100% (3)

- University of Kirkuk College of Engineering Mechanical DepartmentDocument6 pagesUniversity of Kirkuk College of Engineering Mechanical Departmentعبدالمؤمن خالد محمودNo ratings yet

- Brushless Servomotor: Presented byDocument16 pagesBrushless Servomotor: Presented byDev KumarNo ratings yet

- Unit-II Drive SystemDocument84 pagesUnit-II Drive SystemSatheesh KumarNo ratings yet

- Unit-II: Robot Drive Systems and End EffectorsDocument81 pagesUnit-II: Robot Drive Systems and End EffectorsSatheesh KumarNo ratings yet

- DC Servomotors Assignment 02Document5 pagesDC Servomotors Assignment 02Saad BhattiNo ratings yet

- What A Servo Motor Is in Simple TermsDocument1 pageWhat A Servo Motor Is in Simple TermsRufat SafaraliyevNo ratings yet

- Giri 1Document18 pagesGiri 1GiridharNo ratings yet

- University of Kirkuk College of Engineering Mechanical DepartmentDocument6 pagesUniversity of Kirkuk College of Engineering Mechanical Departmentعبدالمؤمن خالد محمود100% (1)

- Servo MotorDocument41 pagesServo MotorVaibhav Patil100% (1)

- Servo Motor Speed and Direction ControlDocument7 pagesServo Motor Speed and Direction Controltazeb100% (1)

- Insight Stepper MotorDocument8 pagesInsight Stepper MotorKarri AmarnathNo ratings yet

- Servo Motor ControlDocument72 pagesServo Motor ControlTien-Thinh NguyenNo ratings yet

- DC Motor Control Using Arduino: 1) IntroductionDocument10 pagesDC Motor Control Using Arduino: 1) IntroductionSoeAyeNo ratings yet

- Control System - by Rakesh KumarDocument6 pagesControl System - by Rakesh KumarRakesh KumarNo ratings yet

- ServomechanismsDocument22 pagesServomechanismsYuvanesh Prabakaran100% (1)

- Servo Motor Selection For UAVDocument9 pagesServo Motor Selection For UAVUAV Society100% (1)

- Assignment On Servo Motor: January 2018Document4 pagesAssignment On Servo Motor: January 2018Simagn BekeleNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Infineon Bts3408g Ds v01 05 enDocument14 pagesInfineon Bts3408g Ds v01 05 enblessingj19it018No ratings yet

- Mina TEG SpecDocument3 pagesMina TEG SpecPamela SandersinNo ratings yet

- 85TO3GHDocument6 pages85TO3GHVictor BondarenkoNo ratings yet

- Agni College of Technology Department of Ece Notice Board DetailsDocument1 pageAgni College of Technology Department of Ece Notice Board DetailsDevill DavajNo ratings yet

- "Final Year Ece Projects in Chennai, Bangalore, Vijayawada, Kakinada." GoodDocument18 pages"Final Year Ece Projects in Chennai, Bangalore, Vijayawada, Kakinada." Goodwondi BETNo ratings yet

- FInal Year Projects List - MEMS and SensorsDocument3 pagesFInal Year Projects List - MEMS and SensorsEnsemble Technologies100% (3)

- TOA WM-4210 ManualDocument4 pagesTOA WM-4210 ManualwkfanNo ratings yet

- PV Curve For Voltage StabilityDocument1 pagePV Curve For Voltage Stabilityveeru_puppalaNo ratings yet

- ARL-300 EU-Type Examination CertificateDocument1 pageARL-300 EU-Type Examination CertificateSamir Ben RomdhaneNo ratings yet

- GST-C-9202 Conventional Manual Call Point Issue1.06 PDFDocument2 pagesGST-C-9202 Conventional Manual Call Point Issue1.06 PDFwayeb andoremNo ratings yet

- Instrument Landing SystemDocument7 pagesInstrument Landing Systemchayan_m_shahNo ratings yet

- 10 - Serie 63 SolenoideDocument2 pages10 - Serie 63 SolenoideoscarNo ratings yet

- Preliminary Information: B-MAC-B69 Model Cp-2HbDocument1 pagePreliminary Information: B-MAC-B69 Model Cp-2HbCykhong KhongNo ratings yet

- Pine Labs Q2 ManualDocument10 pagesPine Labs Q2 ManualAli WarsiNo ratings yet

- SM-A730F DS SVC Guide - F PDFDocument27 pagesSM-A730F DS SVC Guide - F PDFsafi alsafiNo ratings yet

- Electronic Devices and Circuit An Introduction by Allen Mottershead 1356Document1 pageElectronic Devices and Circuit An Introduction by Allen Mottershead 1356DHAMODHARAN0% (7)

- Ir2318l U2 PRT en GB RDocument44 pagesIr2318l U2 PRT en GB RNaseer AhmedNo ratings yet

- Xilinx XC 3000Document21 pagesXilinx XC 3000shabbir470100% (1)

- SS16 CPGK DC60Document4 pagesSS16 CPGK DC60Benjie CallantaNo ratings yet

- DDocument47 pagesDSusheel RajNo ratings yet

- 05501lm-90 (F) - Sensor Wind Tracker Crane - YoungDocument8 pages05501lm-90 (F) - Sensor Wind Tracker Crane - Youngsuhaili pedroNo ratings yet

- Telecommunication Network Design - Design of Optical Fiber SystemsDocument37 pagesTelecommunication Network Design - Design of Optical Fiber SystemsJorma Kekalainen100% (2)

- Question BankDocument3 pagesQuestion BankDivyaNo ratings yet

- Large Horizontal Machining Center: HM 1000 HM 1250 HM 1250WDocument20 pagesLarge Horizontal Machining Center: HM 1000 HM 1250 HM 1250WRAJIV GandhiNo ratings yet

- REPORT Ecd Lab 9Document3 pagesREPORT Ecd Lab 9ayazNo ratings yet

- Dynamic Logic CircuitsDocument61 pagesDynamic Logic Circuitsbirla_sNo ratings yet

- IM ch04Document8 pagesIM ch04Edbert CatapangNo ratings yet

- Siemens Profiset 3030 enDocument11 pagesSiemens Profiset 3030 enBoasu FlorinNo ratings yet