Professional Documents

Culture Documents

TS PRC 8222C Layer 2 Questionnaire

Uploaded by

JOECOOL67Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS PRC 8222C Layer 2 Questionnaire

Uploaded by

JOECOOL67Copyright:

Available Formats

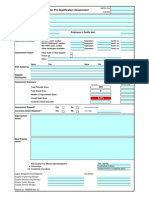

LPA LAYER 2 QUESTIONAIRRE:

AUDITOR: AUDIT AREA: DATE PART NUMBER(S) AUDITED:

Page 1 of 3

AUDIT CRITERIA

Safety:

REACTION PLANS

Does area reflect in job being performed? If not, contact supervisor immediately If not, stop production and remove any safety hazards, clean any spills, and have the operators clean the area to ensure a safe work environment. If not, STOP the job immediately and contact maintenance and engineering immediately. If not, STOP the job immediately and contact maintenance and engineering immediately. If not, STOP the job immediately and contact maintenance and engineering immediately. If not, STOP the operator immediately and contact supervision immediately.

ISSUES/COMMENTS/SUGGESTIONS

S1

Is the Area Safe and the operator wearing Safety glasses? Is the area free of oil/water on the floor, and loose cords or wires, etc. and all machines are clean, areas not cluttered, Do all safety curtains and emergency stops work effectively? Do all safety curtains have the required tool for verification? Is the safety curtain tool attached to the equipment it is to verify?

S2

S3

S4

S5

Are the operators wearing all S6 required PPE per the Work Instructions posted for the job?

Process :

P1

P2

P3

P4

P5

If not, contact supervisor immediately & Has the 1st Piece been signed off Quarantine All Parts. Look @ Inspection and available in its correct location? Checklist. Review setup sheet for correct materials. If Do Materials meet Production not, contact supervisor immediately & requirements? Quarantine Parts. If not, contact supervisor immediately & Are rejected parts identified/tagged Quarantine Parts. Look around work areas correctly and in proper container? for unidentified parts. Verify that operators are following Work Are Operators following Instructions posted at their work station. If Standardized work Instructions? not, notify supervisor and quality. If not, contact quality to develop. Ask Are boundary samples readily Operator where they keep boundary available? samples.

Look up training Matrix in Plex and Verify Are trained operators at the work all operators are trained to the job they are P6 station as per training matrix located performing. If not contact supervisor to add in Plex? the training level to Plex. P7 Is the line producing to the Appearance Standard? If not, contact supervisor immediately & Quarantine Parts. Please review Work Instructions & review how glue is being applied to verify.

P8 Is glue being applied correctly?

P9

Are all repairs processed to go back into the cell for final inspection and Please verify all repairs are going back verification over error proofing prior through normal process for inspection. to shipment? Please review the PFMEA and the consequences of shipping a nonconformance to the customer.

Are the operators aware of the P10 consequences of shipping a nonconformance to the customer?

Has the Preventive Maintenance Contact Maintenance and Supervisor to PM P11 been completed on all equipment in equipment immediately. this cell?

Error Proofing

Are there Error Proofing Devices in E1 this process? Check one "Red Rabbit" for effectiveness.

If no Error Proofing devices in cell, mark N/A. If there are Error Proofing devices, verify one works as intended, if it does not work, contact supervisor immediately & Quarantine All Parts

If no Error Proofing devices in cell, mark Are we verifying these Error Proofing N/A, if No log contact Quality Engineer to Devices and recording in a log? develop. If no Error Proofing devices in cell, mark Is there a certification sticker on the E3 N/A, if No certificate contact Quality Error proofing device? Engineer to develop. Has the error proofing device been If no Error Proofing devices in cell, mark E4 added to the Master Error Proofing N/A, if Not in the log contact Quality log? Engineer to update. E2

TS-PRC-8222C - Layer 2 questionnaire

Issue Date:06/04/11

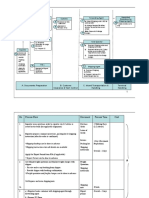

LPA LAYER 2 QUESTIONAIRRE:

AUDITOR: AUDIT AREA: DATE PART NUMBER(S) AUDITED:

Page 2 of 3

AUDIT CRITERIA

REACTION PLANS

ISSUES/COMMENTS/SUGGESTIONS

If no Error Proofing devices in cell, mark Are there additional opportunities for N/A, if Not leave this blank, if Yes, provide E5 Error Proofing? a detailed explanation in the corrective action section.

TS-PRC-8222C - Layer 2 questionnaire

Issue Date:06/04/11

LPA LAYER 2 QUESTIONAIRRE:

AUDITOR: AUDIT AREA: DATE PART NUMBER(S) AUDITED:

Page 3 of 3

AUDIT CRITERIA

Product

REACTION PLANS

Verify check sheet is filled out correctly and there is no data out of spec. If not, notify supervisor immediately. If there is data out of specification Quarantine All Parts & contact Quality.

ISSUES/COMMENTS/SUGGESTIONS

Are the operators using the part C1 gauge for all dimensional requirements?

Verify check sheet is filled out correctly and there is no data out of spec. If not, notify Are we verifying SPC as required by C2 supervisor immediately. If there is data out the customer? of specification Quarantine All Parts & contact Quality. C3 Verify correct packaging is being used and Is the correct packaging being used the labels are correct. If not, contact and is the labeling correct? supervisor immediately & Quarantine All Parts. Review parts at shipping container & verify they are good parts and meet customer needs. Verify part fits the gauge as required. If not, contact supervisor immediately & Quarantine All Parts.

Do appearance items meet C4 Customer Specs, eg. gouges, short shots, color, etc? Does the part fit the gauge for all C5 dimensional requirements as required by the customer?

Quality System

Are all ACTIVE quality alerts posted Stop Job immediately and train all current Q1 in the cell signed by operators operators to the Quality Alert. currently in the cell? Are all quality alerts posted in the cell Remove all inactive Quality Alerts and Q2 still active (not expired)? place on Quality Manager's desk. Verify Quality Alerts are still active and not expired, stop Job immediately and train all Are all active quality alerts posted in Q3 current operators to the Quality Alert and the cell being followed? contact Operations Manager and Supervisor. Q4 Q5 Are gauge calibration Tags current? Quarantine All Parts & contact Quality. Check one. Are Inspection Check Sheets being filled out completely and correctly? Are shipping containers free of debris, rocks, etc.? Notify supervisor immediately.

Remove the container and contact materials immediately and replace with a clean container. Have all Corrective Actions been Contact Manufacturing Manger to Q7 completed? determine competion timing. Is there a Job book available for the Contact Quality to develop and or print and Q8 operators. place a new job book for this cell. Are the Level 1 LPA audit being Contact the Manufacturing Manager for Q9 completed as required? resolution. Q6

Comments and suggestions for improving this audit sytem, questionnaire, or format.

Please state improvement suggestions for each area, either updates to the I1 questionnaire for layer 1 and 2, system improvements, or process changes to improve parts or reduce costs.

Non-conformance

LEGEND YES-

NO- X

TS-PRC-8222C - Layer 2 questionnaire

Issue Date:06/04/11

You might also like

- Daimler-Chrysler LPA Training at SRAFDocument27 pagesDaimler-Chrysler LPA Training at SRAFMarcela Gonçalves100% (3)

- Principle no.3 Instruction WorksheetDocument5 pagesPrinciple no.3 Instruction WorksheetBalaji BaluNo ratings yet

- Manufacturing Process Audit Excel FormDocument2 pagesManufacturing Process Audit Excel FormAri RosyadiNo ratings yet

- Manufacturing Process Audit ScorecardDocument1 pageManufacturing Process Audit ScorecardSachin Kumbhar100% (1)

- Manufacturing Process Audit Excel FormDocument1 pageManufacturing Process Audit Excel Formbhavesh_balasNo ratings yet

- Manufacturing Process AuditDocument1 pageManufacturing Process AuditEdNo ratings yet

- Supplier Audit Check ListDocument6 pagesSupplier Audit Check ListShalinMishraNo ratings yet

- Please Select The Applicable Method For Answering Each Question Qu - Questioning Ob - Observation Qu ObDocument2 pagesPlease Select The Applicable Method For Answering Each Question Qu - Questioning Ob - Observation Qu ObHamid AlilouNo ratings yet

- Daimler-Chrysler Layered Process AuditsDocument27 pagesDaimler-Chrysler Layered Process AuditsR JNo ratings yet

- Nitrogen Coiled TubingDocument2 pagesNitrogen Coiled TubingRamanamurthy PalliNo ratings yet

- Line Clearence Ravi 17oct14Document31 pagesLine Clearence Ravi 17oct14pooja singhNo ratings yet

- Process Verification Audit ChecklistDocument5 pagesProcess Verification Audit Checklistriki3xNo ratings yet

- Ac7114-5 - Rev - 0 Audit Criteria For Nondestructive Testing Facility Eddy Current SurveyDocument15 pagesAc7114-5 - Rev - 0 Audit Criteria For Nondestructive Testing Facility Eddy Current SurveyskluxNo ratings yet

- PPAP Process-Guide ExampleDocument5 pagesPPAP Process-Guide ExampleN.B.P0% (1)

- LPA Checklist Excel Table v6Document3 pagesLPA Checklist Excel Table v6Je UrdanetaNo ratings yet

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- AC7108-15 Rev ADocument29 pagesAC7108-15 Rev ACaio Fazzioli TavaresNo ratings yet

- APQP2 ADocument78 pagesAPQP2 AMukesh PathakNo ratings yet

- Ac7114-1 Rev F Audit Criteria For Nondestructive Testing Facility Penetrant SurveyDocument27 pagesAc7114-1 Rev F Audit Criteria For Nondestructive Testing Facility Penetrant SurveyskluxNo ratings yet

- Check Sheet Model SCCDocument39 pagesCheck Sheet Model SCCN.PalaniappanNo ratings yet

- 01 Supplier Pre-Qualification AssessmentDocument18 pages01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- Resolve low process capability issues quicklyDocument7 pagesResolve low process capability issues quicklytorresa10No ratings yet

- Autonomous MaintenanceDocument455 pagesAutonomous MaintenanceBrian Job Malonzo100% (4)

- Amf-P-22 Procedure For Error ProofingDocument3 pagesAmf-P-22 Procedure For Error Proofinggangadhar.patilNo ratings yet

- FM C0801 S01!02!04PFMEA ChecklistDocument1 pageFM C0801 S01!02!04PFMEA ChecklistDiego Fernando Vázquez BravoNo ratings yet

- Jig 4 SmallerAirportsJIG4 - CHECK LISTDocument26 pagesJig 4 SmallerAirportsJIG4 - CHECK LISTgulfpipinggmailcom100% (5)

- GM 1927-16a Coating Process AuditDocument16 pagesGM 1927-16a Coating Process AudithuangjlNo ratings yet

- Factory Audit Sample ReportDocument20 pagesFactory Audit Sample Reportkaveh-bahiraee100% (1)

- Daimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta RisnerDocument23 pagesDaimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta Risneralberto100% (1)

- Nonconforming Material Containment:: Designated Area Away From The Production Workflow?Document6 pagesNonconforming Material Containment:: Designated Area Away From The Production Workflow?Cande EscobedoNo ratings yet

- Motor BenzinaDocument204 pagesMotor Benzinacarlosfelix81No ratings yet

- Purpose: Radiation and Biomolecular Physics Division Quality System Guide RBPD-G-07 NonconformanceDocument3 pagesPurpose: Radiation and Biomolecular Physics Division Quality System Guide RBPD-G-07 NonconformancepannNo ratings yet

- SMT Generic Control PlanDocument3 pagesSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- Procedure For Traffic Light Quality System-LibreDocument8 pagesProcedure For Traffic Light Quality System-LibreAnonymous wA6NGuyklDNo ratings yet

- Certified Labview Developer Examination: InstructionsDocument8 pagesCertified Labview Developer Examination: InstructionsAugustineEsperonParondaNo ratings yet

- Agilent 6400 Series Preventive Maintenance Checklist - April2020Document13 pagesAgilent 6400 Series Preventive Maintenance Checklist - April2020christianNo ratings yet

- Vendour Evaluation Report - JSL PDFDocument3 pagesVendour Evaluation Report - JSL PDFMitesh SinghNo ratings yet

- Template Process Optimization Check ListDocument1 pageTemplate Process Optimization Check ListNithiyakumar.PNo ratings yet

- Grand Rapids Controls LPA Checksheet AuditDocument7 pagesGrand Rapids Controls LPA Checksheet Auditalliceyew100% (3)

- Foxconn Line Leader ResponsibilitiesDocument13 pagesFoxconn Line Leader ResponsibilitieskkNo ratings yet

- EPACK HSE MANAGEMENT SYSTEM AUDITDocument3 pagesEPACK HSE MANAGEMENT SYSTEM AUDITJyotiranjan RoutNo ratings yet

- 1n GM 1927 16 Process Control Plan Audit April 2005Document12 pages1n GM 1927 16 Process Control Plan Audit April 2005kunjan2165100% (2)

- 01Document7 pages01robertNo ratings yet

- Zero Defects Implementation ManualDocument8 pagesZero Defects Implementation ManualCleber RochaNo ratings yet

- Layered Audit Check SheetsDocument5 pagesLayered Audit Check Sheetsdeepak sharmaNo ratings yet

- 5S ChecklistDocument4 pages5S ChecklistMohdAzhanBinIshakNo ratings yet

- TDP15GN108 CPGDocument5 pagesTDP15GN108 CPGpurnamaoriginalNo ratings yet

- 6sigma - Control PhaseDocument130 pages6sigma - Control Phasesathya_145No ratings yet

- TPG-AC7114 - Audit Criteria For Nondestructive Testing (NDT) Suppliers Accreditation ProgramDocument37 pagesTPG-AC7114 - Audit Criteria For Nondestructive Testing (NDT) Suppliers Accreditation ProgramNayan VyasNo ratings yet

- Fault Tracing IntroductionDocument4 pagesFault Tracing IntroductionjgkuchhadiyaNo ratings yet

- LPA Procedure2Document6 pagesLPA Procedure2Iram ChaviraNo ratings yet

- GM 1927-87 Special Nonconforming Material AuditDocument6 pagesGM 1927-87 Special Nonconforming Material AuditMichael HicksNo ratings yet

- Facility Inspection ChecklistDocument9 pagesFacility Inspection ChecklistdesignselvaNo ratings yet

- 1992 APC MistakesDocument13 pages1992 APC MistakesabrahamkalilNo ratings yet

- LEV Weekly ChecklistDocument2 pagesLEV Weekly ChecklistOussama OuardaniNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- ISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012From EverandISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012No ratings yet

- ISTQB Certified Tester Foundation Level Practice Exam QuestionsFrom EverandISTQB Certified Tester Foundation Level Practice Exam QuestionsRating: 5 out of 5 stars5/5 (1)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- GMW15777Document40 pagesGMW15777JOECOOL67No ratings yet

- AS10169Document11 pagesAS10169JOECOOL67No ratings yet

- Buhler Global Quality Manual V1.0Document35 pagesBuhler Global Quality Manual V1.0JOECOOL67No ratings yet

- GM 1927-43 Supplier Launch Audit - XLSX-GM ConfidentialDocument8 pagesGM 1927-43 Supplier Launch Audit - XLSX-GM ConfidentialJOECOOL670% (1)

- GM1738NA Rev 2.0Document35 pagesGM1738NA Rev 2.0JOECOOL67No ratings yet

- GMW 14669 Table CDocument1 pageGMW 14669 Table CJOECOOL67No ratings yet

- Buhler Global Quality Manual V1.0Document35 pagesBuhler Global Quality Manual V1.0JOECOOL67No ratings yet

- GMW6076MDocument3 pagesGMW6076MJOECOOL67No ratings yet

- Buhler Global Quality Manual V1.0Document35 pagesBuhler Global Quality Manual V1.0JOECOOL67No ratings yet

- GMW 14669 Table CDocument1 pageGMW 14669 Table CJOECOOL67No ratings yet

- BuehlerMotor Supplier Code of ConductDocument4 pagesBuehlerMotor Supplier Code of ConductJOECOOL67No ratings yet

- GMW16215Document7 pagesGMW16215JOECOOL67100% (1)

- Gm1738na 4.0Document39 pagesGm1738na 4.0JOECOOL67No ratings yet

- Supplier Readiness Check List T1XXHeavyDocument9 pagesSupplier Readiness Check List T1XXHeavyJOECOOL67No ratings yet

- GRA2092 Projection Weld Nut EP WorkbookDocument69 pagesGRA2092 Projection Weld Nut EP WorkbookJOECOOL67No ratings yet

- GMW 14057Document10 pagesGMW 14057JOECOOL67No ratings yet

- Astm d1654 08 New PDFDocument4 pagesAstm d1654 08 New PDFKhan ShahzebNo ratings yet

- Fairfax Contact ListDocument1 pageFairfax Contact ListJOECOOL67No ratings yet

- GMW16215Document7 pagesGMW16215JOECOOL67100% (1)

- Protect Your Customers: Supplier's Shutdown Audit TitleDocument32 pagesProtect Your Customers: Supplier's Shutdown Audit TitleJOECOOL670% (1)

- Suppliers - How To Upload A Document Into APQP 06jul15 (English) PDFDocument11 pagesSuppliers - How To Upload A Document Into APQP 06jul15 (English) PDFJOECOOL67No ratings yet

- Process To Request Cost Recovery SubpackageDocument29 pagesProcess To Request Cost Recovery SubpackageJOECOOL67No ratings yet

- Plex Control Panel Plant 1 Rev.3Document39 pagesPlex Control Panel Plant 1 Rev.3JOECOOL67No ratings yet

- GMW16215Document7 pagesGMW16215JOECOOL67100% (1)

- IATF 16949 GM CSR Sept 2017Document26 pagesIATF 16949 GM CSR Sept 2017Selvaraj SNo ratings yet

- Bopp-Busch Quality ManualDocument50 pagesBopp-Busch Quality ManualJOECOOL67No ratings yet

- GMW 14057Document10 pagesGMW 14057JOECOOL67No ratings yet

- Non Standard Part HandlingDocument1 pageNon Standard Part HandlingJOECOOL67No ratings yet

- Corrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01Document1 pageCorrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01JOECOOL67No ratings yet

- F-870-001 Process Alarm LimitsDocument2 pagesF-870-001 Process Alarm LimitsJOECOOL67No ratings yet

- Uniform Customs and Practices For Documentary Credit UCPDCDocument17 pagesUniform Customs and Practices For Documentary Credit UCPDCSudershan ThaibaNo ratings yet

- Baron G58Document11 pagesBaron G58oof o100% (1)

- Amazon Fulfillment ProcessDocument1 pageAmazon Fulfillment ProcessRAHUL RNAIRNo ratings yet

- Frane Bogdan - Resume - Deck OfficerDocument3 pagesFrane Bogdan - Resume - Deck OfficerFrane BogdanNo ratings yet

- Christmas Is Coming - All The Way From China: AdvancedDocument3 pagesChristmas Is Coming - All The Way From China: AdvancedMartín AlonsoNo ratings yet

- Checklist for CTPAT/Security/SCAN Audit DocumentsDocument1 pageChecklist for CTPAT/Security/SCAN Audit DocumentsFaruque Uddin100% (1)

- Export Process Flow-RoRo PDFDocument5 pagesExport Process Flow-RoRo PDFTuan LuqmanNo ratings yet

- Transportation Assignment - WK 1Document2 pagesTransportation Assignment - WK 1Fedoua Lat100% (2)

- Siemens PLM John Shuttleworth Yacht Designs Cs Z9Document5 pagesSiemens PLM John Shuttleworth Yacht Designs Cs Z9rasgeetsinghNo ratings yet

- CHAPTER 7 Freight RatesDocument11 pagesCHAPTER 7 Freight Ratesshaji100% (1)

- A Project Report ON Industry VisitsDocument54 pagesA Project Report ON Industry VisitsAdriya Fellis FurnandaceNo ratings yet

- Drop Ship BlackDocument37 pagesDrop Ship BlackphanindhraNo ratings yet

- Offshore Vessel Inspection Database FAQsDocument4 pagesOffshore Vessel Inspection Database FAQsNorman Sasongko100% (1)

- LS QuestionsDocument56 pagesLS QuestionsJoy Supanika0% (1)

- Oracle Accounts Receivables 1Document431 pagesOracle Accounts Receivables 1dataset123No ratings yet

- Reflection PAPER in REO WEBINARDocument4 pagesReflection PAPER in REO WEBINARKyla Joy T. SanchezNo ratings yet

- Challenging of Commercial Shipping in Pakistan, Case Study PNSC. NEWDocument14 pagesChallenging of Commercial Shipping in Pakistan, Case Study PNSC. NEWMazhar HussainNo ratings yet

- SCM Topic 15 AssigmentDocument3 pagesSCM Topic 15 Assigmentapteryx100% (1)

- Standard For Wood Containers 2012Document51 pagesStandard For Wood Containers 2012Cristina Garcia100% (1)

- 08 BSCM v3.2 MasterDocument74 pages08 BSCM v3.2 MasterMostafaNo ratings yet

- #297 04-10-15 Nc-Mi PDFDocument3 pages#297 04-10-15 Nc-Mi PDFDanica Danka SekularacNo ratings yet

- Freight Charges-No NCFDocument30 pagesFreight Charges-No NCFChiến NguyễnNo ratings yet

- Transport LogisticDocument85 pagesTransport LogisticamfipolitisNo ratings yet

- WMSHL Annual Report 2017 2018 For WebsiteDocument117 pagesWMSHL Annual Report 2017 2018 For WebsitemdabujahidNo ratings yet

- Understanding FMCSA's Cargo Securement RulesDocument44 pagesUnderstanding FMCSA's Cargo Securement RulesPatrick DuffNo ratings yet

- Transpo Midterms ReviewerDocument10 pagesTranspo Midterms ReviewereieipayadNo ratings yet

- ISO 9001 CERTIFIED B-SCHOOL CORPORATE LAW MARKSDocument6 pagesISO 9001 CERTIFIED B-SCHOOL CORPORATE LAW MARKSPhanindra GollapalliNo ratings yet

- Paper-8 Indirect Tax LawsDocument16 pagesPaper-8 Indirect Tax LawsSouryaNo ratings yet

- Elearning-Chapter 4-Carriage of Goods by Air - RVDocument106 pagesElearning-Chapter 4-Carriage of Goods by Air - RVLê Tiểu BăngNo ratings yet

- Table of Contents for ULD RegulationsDocument8 pagesTable of Contents for ULD RegulationsMahmood Mushtaq100% (1)