Professional Documents

Culture Documents

25.IJAEST Vol No 7 Issue No 2 Design Consideration of Interleaved Boost Converter For Fuel Cell Systems 322 329

Uploaded by

helpdesk9532Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25.IJAEST Vol No 7 Issue No 2 Design Consideration of Interleaved Boost Converter For Fuel Cell Systems 322 329

Uploaded by

helpdesk9532Copyright:

Available Formats

Dr.R.Seyezhai* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No.

2, 323 - 329

Design Consideration of Interleaved Boost Converter for Fuel Cell Systems

Dr.R.Seyezhai

Associate Professor, Department of EEE, SSN College of Engineering, Chennai , India. e-mail: seyezhair@ssn.edu.in

Key words PEM fuel cells, IBC, ripple, PI controller.

I.

Fuel cell is one of the most important sources of distributed energy because of its high efficiency, high energy density, plus high reliability and long life due to few moving parts. Comparison with the other types of fuel cells, PEM fuel cell shows charming attraction with its advantages such as low temperature, high power density, fast response and zero emission. Fuel cells operate at low DC voltages (typically 600 mV per cell) and therefore a number of cells are connected in series. As a long string of cells is difficult to operate, DC-DC boost converter is generally used to further boost the voltage to the required level. Various topologies such as boost, buck and series resonant full-bridge and pushpull converters have been proposed in the

IJ

ISSN: 2230-7818

A

INTRODUCTION

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

Abstract Proton Exchange Membrane (PEM) fuel cell is one of the promising technologies for the distributed power generation. For designing high efficiency fuel cell power systems, a suitable DC-DC converter is required. Among the various topologies, Interleaved Boost converter (IBC) is considered as a better solution for fuel cell systems due to improved electrical performance, reduced weight and size. Detailed analysis has been done to investigate the benefits of interleaved boost converter compared to the conventional boost converter. The design equations for IBC have been presented. In this paper, a two phase interleaved boost converter employing CoolMOS transistor and SiC diode has been suggested for fuel cells, considering variation of input voltage, inductor and switching frequency. Simulation study for the closed loop control (PI) of IBC interfaced with fuel cells has been studied using MATLAB. Theoretical analysis and hardware prototype has been performed to validate the results.

literature. But these topologies add objectionable ripples in the current flowing out of the fuel cell. To minimize the ripples, an IBC has been proposed as a suitable interface for fuel cells. In addition, interleaving provides high power capability, modularity and improved reliability [1]. A two-phase directly coupled IBC using CoolMOS and SiC diodes has been proposed in this paper compared to the conventional boost converter. The performance of IBC has been investigated over the operating range of the PEM fuel cell. The relationship between phase current ripple, input current ripple versus duty ratio has been analyzed. Mathematical analysis of overall current ripple and the design equations for IBC has been presented. The switching losses of IBC have been studied. Simulation of IBC interfaced with PEM fuel cells has been performed using MATLAB/SIMULINK. In order to get the desired value of output voltage at the interleaved boost converter stage and to get a regulated voltage at the output, a simulation study of PI controller has been studied. Hardware prototype has been built to validate the results. II. INTERLEAVED BOOST CONVERTER A two-phase interleaved boost converter is usually employed in high input-current and high input-to-output voltage conversion applications. It is used to eliminate reverse-recovery losses of the boost rectifier by operating the two boost converters at the boundary of continuous conduction mode (CCM) and discontinuousconduction mode (DCM) so that the boost switches are turned on when the current through the corresponding boost rectifier is zero. In addition, interleaving is also employed to reduce

Page 323

Dr.R.Seyezhai* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 323 - 329

the input current ripple, and therefore to minimize the size of the input filter that would be relatively large if a single boost converter was used [2].Interleaving adds additional benefits such as reduced ripple current in both input and output circuits. Higher efficiency is realized by splitting the output current into n paths, substantially reducing I2R losses and inductor losses. The circuit diagram of two-phase IBC is shown in Fig.1.

III. DESIGN CONSIDERATIONS OF IBC The interleaved boost converter design [3,4] involves the selection of the number of phases, the inductors, the output capacitor, the power switches and the output diodes. Both the inductors and diodes should be identical in all the channels of an interleaved design. In order to select these components, it is necessary to know the duty cycle range and peak currents. Since the output power is channeled through n power paths where n is the number of phases, a good starting point is to design the power path components using 1/n times the output power. Basically, the design starts with a single boost converter operating at 1/n times the power. 1) Choosing the number of phases:

Fig.1. Circuit Diagram of 2-Phase IBC

The gating pulses of the switches of the two phases are shifted by 360/n, i.e., 360/2 for n= 2, which is 180 degrees and it is shown in Fig.2.

A IJ

Fig. 2 Switching pattern for 2- phase IBC

ISSN: 2230-7818

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

2) Selection of duty ratio:

This paper utilizes two phases since the ripple content reduces with increase in the number of phases. The ripple reduces to 12% of that of a conventional boost converter. If the number of the phases is increased further, without much decrease in the ripple content, the complexity of the circuit increases very much, thereby increasing the cost of implementation. Hence, as a tradeoff between the ripple content and the cost and complexity, number of phases is chosen as two. The number of inductors, switches and diodes are same as the number of phases and switching frequency is same for all the phases [5].

The decision of the duty cycle is based on the number of phases. This is because depending upon the number of phases, the ripple is minimum at a certain duty ratio [6,7]. For two phase interleaved boost converter, the ripple is minimum at duty ratio, D = 0.45.Hence, the design value of the duty ration is chosen as 0.45.

Page 324

Dr.R.Seyezhai* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 323 - 329

3) Selection of capacitance and inductance: The selection of capacitance and inductance is done using the formulae [8,9]. C = VoDF/RVo (1)

Due to absence of reverse recovery current, there is no need of active snubber circuit for protection. The loss reduction in percentage using SiC diode is shown in Fig 3. Hence, proper choice of semiconductor device is important in improving the performance of the converter. IV.SIMULATION RESULTS

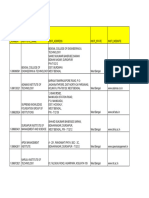

Table 1 : Simulation Parameters for 3-phase uncoupled and directly coupled IBC Parameters Values 26 -43V 70V 10kHz 0.45 3.3mH 2000uF

4) Selection of power devices: The semiconductor devices chosen for constructing the 2-phase interleaved boost converter is the Coolmos transistor and Silicon carbide (SiC) diode. The main benefits of Coolmos are lower on- state rsistance, lower conduction losses and high switching operation. The performance of CSD100060 SiC Schottky diode is compared with that of MUR1560 Si diode for IBC using PSPICE. The SiC diode has less forward voltage, high reverse breakdown voltage and less reverse recovery current which results in reduced switching loss.

IJ

ISSN: 2230-7818

Fig.3. Loss reduction in percentage using SiC diode

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

Output Voltage Switching Frequency Duty Ratio Inductance, L Capacitance

Input Voltage (PEM fuel cell)

The input current ripple, and output voltage ripple obtained from PEMFC connected to interleaved boost converter are shown in Fig. 4 and Fig. 5.

where Vo represents the output voltage (V), D represents the duty ratio, F represents frequency (Hz), R represents resistance () and Vo represents the change in the output voltage (V). L = VsD/iLF (2) where Vs represents the source voltage and iL represents the inductor current ripple.

Two phase IBC with fuel cell as power source is simulated in MATLAB with the parameters as shown in Table-I.

Page 325

Dr.R.Seyezhai* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 323 - 329

Fig. 4 Input current ripple for 2- phase IBC

Fig. 7 Output voltage ripple for Boost converter

ES

Parameters

The simulation results of IBC are compared to that of a PEMFC connected to a boost converter which is shown in Table -II.

Table II Comparison of IBC and Boost Converter Boost Converter 1.78 % 13.8 % 0.87 % Interleaved Boost Converter 0.08 % 7.35 % 0.03 %

Fig. 5 Output voltage ripple of 2-phase IBC

The input current ripple and output voltage ripple for a boost converter interfaced with the fuel cell are shown in Figs. 6 and 7.

IJ

Fig. 6 Input current ripple for boost converter

ISSN: 2230-7818

Input current ripple Inductor current ripple Output voltage ripple

The combination of CoolMOS transistor and SiC diode for the proposed IBC topology results in a reduced switching loss compared to IRFP460A MOSFET and Si diode. Switching loss for the main power device is calculated based on the equation given below:

1 I Psw Vo in ton tr toff t f f s 2 N

T

(3)

Page 326

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

Dr.R.Seyezhai* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 323 - 329

Table III Comparison of turn-on, turn-off tim and switching energy for CoolMOS and IRFP460A MOSFET (simulation results) Parameter IRFP460A MOSFET 120ns 550ns 500uJ CoolMOS Transistor 120ns 400ns 310uJ

IJ

Parameter Si Diode 100A Reverse recovery current (Irr) Reverse recovery time (trr) 60ns

ISSN: 2230-7818

Table IV Comparison of Irr and trr for Si and SiC diode SiC Diode 20A Fig. 8 Hardware prototype for 2-phase IBC Figs. 9 and 10 shows the ripple in output voltage and input current for IBC.

A

20ns

Turn-on time Turn-off time Switching Energy From TableIII, the simulation results shows that CoolMOS transistor has lower switching energy compared to MOSFET. The SiC diode chosen for IBC has high reverse breakdown voltage, less reverse recovery current, less reverse recovery time and the simulated results are shown in Table IV.

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

where, Psw represents the switching loss of the main power semiconductor device, N represents the number of phases, fs represents the switching frequency, Iin represents the current through the device, Vo represents the voltage, ton represents the turn-on time of the device, toff represents the turn-off time of the device, tr represents the current rise time, tf represents the voltage fall time.The simulated turn-on time, turn-off time and switching energy for CoolMOS transistor and IRFP460A MOSFET is shown in Table III.

Table IV shows that SiC Schottky diode has less reverse recovery time compared to the conventional Si diode. V. EXPERIMENTAL PROTOTYPE OF 2PHASE IBC A prototype of a 2- phase IBC has been designed as shown in Fig.8 in order to verify the simulation results. The hardware set-up consists of the main power circuit, PIC microcontroller board for pulse generation and power supply circuit for optocouplers. The main power circuit consists of three boost converters in parallel with CoolMOS transistors and SiC diodes. The optocoupler 6N137 is used to isolate the power circuit from the PIC microcontroller circuit. PIC18F4550 is employed to generate the pulses required to trigger the CoolMOS transistor .

Page 327

Dr.R.Seyezhai* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 323 - 329

A suitable PI controller has been designed to regulate the output voltage of IBC .The PI controller has been tuned using Zeiglers Nichols method to determine the values of Kp and Ki .The simulation has been carried out using MATLAB/SIMULINK and the closed loop output voltage response is shown in Fig.12.

Fig.9 Ripple factor for output voltage ripple

Fig 11 shows the inductor current ripple which is below the designed value (10.2%).

IJ

Fig 11 Ripple factor for inductor current ripple

ISSN: 2230-7818

Fig. 10 Ripple factor for input current ripple

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

Acknowledgements

Fig.12.Closed loop output voltage response of IBC using PI controller. VI.CONCLUSION

This paper has investigated the performance of two-phase IBC and conventional boost converter for fuel cells. The relationship between phase current ripple, input current ripple versus duty ratio is analyzed. The design equations for IBC have been presented. It is found that IBC effectively reduces the overall current ripple compared to that of boost converter. The choice of SiC diode and CoolMOS transistor for IBC has led to reduced switching losses. From these results, two-phase IBC with CoolMOS transistor and SiC diode proves to be a good candidate for fuel cell interface.

The author wish to thank the management of SSN College of Engineering, for providing the computational and laboratory facilities to carry out this work.

T

Page 328

Dr.R.Seyezhai* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 323 - 329

REFERENCES

1. Gyu-Yeong Choe, Hyun-Soo Kang, Byoung-Kuk Lee and Won-Yong Lee, Design Consideration of Interleaved Converters for Fuel Cell Applications, in Proceedings of International Conference on Electrical Machines and Systems 2007, 8-11 Oct. 2007,Seoul, Korea, pp.238-243. P.A.Dahono, S.Riyadi , A.Mudawari and Y.Haroen,O utput ripple analysis of multiphase DCDC converter. IEEE Int. Conf. Power Electrical and Drive Systems, Hong Kong, pp. 626631, 1999. H.Kosai, S.McNeal, Austin Page, Brett Jordan, Jim Scofield and B.Ray , Characterizing the effects of inductor coupling on the performance of an interleaved boost converter, Proc. CARTS USA 2009, pp. 237251, 2009. H.Xu, E.Qiao, X.Guo, X.Wen and L.Kong , Analysis and Design of High Power Interleaved Boost Converters for Fuel Cell Distributed Generation System, Int. Conf. IEEE Power Electronics Specialists Conference (PESC), pp. 140 145, 2005.

BIOGRAPHY

Dr. R.Seyezhai obtained her B.E. (Electronics & Communication Engineering) from Noorul Islam College of Engineering, Nagercoil in 1996 and her M.E in Power Electronics & Drives from Shanmugha College of Engineering, Thanjavur in 1998. She has been working in the teaching field for about 12 Years. She has published 65 papers in the area of Power Electronics & Drives. Her areas of interest include SiC Power Devices & Multilevel Inverters. Dr.B.L.Mathur obtained his B.E. (Electrical Engineering) from University of Rajasthan, in 1962 and his M.Tech in Power Systems from IIT, Bombay in 1964.He completed his Ph.D. in 1979 from IISc, Bangalore. His Ph.D. thesis was adjudged as the best for application to industries in the year 1979 and won gold medal. He has been working in the teaching field for about 44 Years. He takes immense interest in designing Electronic circuits. He has published 50 papers in National and International journals and 100 in National and International conferences. His areas of interest include Power Devices, Power Converters, Computer Architecture and FACTS.

2.

3.

4.

5.

6.

R.J.Wai and R.Y.Duan , High step-up converter with coupled-inductor, IEEE Trans. Power Electronics, Vol. 20, No.5, pp. 1025-1035, 2005. Laszlo Huber, T.Brian Irving and M.Milan Jovanovi, Closed-Loop Control Methods for Interleaved DCM/CCM Boundary Boost PFC Converters, Int. Conf. IEEE Applied Power Electronics , Washington, pp. 991-997, 2009.

IJ

8. 9.

7.

P.Thounthong, P.Sethakul, S.Rael and B.Davat , Design and implementation of 2- phase interleaved boost converter for fuel cell power source, Int. Conf. Power Electronics, Machines, and Drives,PEMD 2008, pp. 9195, 2008.

M.Veerachary, T.Senjyu and K.Uezato , Modeling and analysis of interleaved dual boost converter, Int. Conf. IEEE International Symposium on Industrial Electronics,Vol. 2, pp 718 722, 2001.

ISSN: 2230-7818

P.Lee, Y.Lee, D.K.W. Cheng and X.Liu , Steadystate analysis of an interleaved boost converter with coupled inductors. IEEE Trans. Industrial Electronics, pp. 787795, 2000.

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

Page 329

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Ijaest: Adaptation of Watt's Indicator Mechanism in Altitude MeasurementDocument4 pagesIjaest: Adaptation of Watt's Indicator Mechanism in Altitude Measurementhelpdesk9532No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 8.ijaest Vol No 8 Issue No 1 Synthesis of Nano Particle 054 057Document4 pages8.ijaest Vol No 8 Issue No 1 Synthesis of Nano Particle 054 057helpdesk9532No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354Document8 pages29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354helpdesk9532No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 6.ijaest Vol No 8 Issue No 1 Water Audit 039 048Document10 pages6.ijaest Vol No 8 Issue No 1 Water Audit 039 048helpdesk9532No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 1.IJAEST Vol No 8 Issue No 1 "Biomethanation of Dairy Waste Water Through UASB at Mesophilic Temperature Range" 001 009Document9 pages1.IJAEST Vol No 8 Issue No 1 "Biomethanation of Dairy Waste Water Through UASB at Mesophilic Temperature Range" 001 009helpdesk9532No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364Document10 pages30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364helpdesk9532No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354Document8 pages29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354helpdesk9532No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 22.IJAEST Vol No 7 Issue No 2 Simulation Studies On Dynamic Contact Force Between Mobile Robot Manipulator and Surrounding Environment 305 312Document8 pages22.IJAEST Vol No 7 Issue No 2 Simulation Studies On Dynamic Contact Force Between Mobile Robot Manipulator and Surrounding Environment 305 312helpdesk9532No ratings yet

- 10.IJAEST Vol No 7 Issue No 2 Human Protein Function Prediction An Overview 239 244Document6 pages10.IJAEST Vol No 7 Issue No 2 Human Protein Function Prediction An Overview 239 244helpdesk9532No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 8.ijaest Vol No 7 Issue No 2 Designing Aspects Using Various Uml Diagrams in Resource Pool Management 228 233Document6 pages8.ijaest Vol No 7 Issue No 2 Designing Aspects Using Various Uml Diagrams in Resource Pool Management 228 233helpdesk9532No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 5.IJAEST Vol No 7 Issue No 2 APaaS Technology To Build Workflow Based Applications 212 216Document5 pages5.IJAEST Vol No 7 Issue No 2 APaaS Technology To Build Workflow Based Applications 212 216helpdesk9532No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Evolution Army 3 R DadDocument341 pagesEvolution Army 3 R DadStanisław DisęNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pityriasis VersicolorDocument10 pagesPityriasis Versicolorketty putriNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Week 4 - Theoretical Framework - LectureDocument13 pagesWeek 4 - Theoretical Framework - LectureRayan Al-ShibliNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 2016 Closing The Gap ReportDocument64 pages2016 Closing The Gap ReportAllan ClarkeNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pg2022 ResultDocument86 pagesPg2022 ResultkapilNo ratings yet

- Sample Resume For Supply Chain Logistics PersonDocument2 pagesSample Resume For Supply Chain Logistics PersonAmmar AbbasNo ratings yet

- Impact of Pantawid Pamilyang Pilipino Program On EducationDocument10 pagesImpact of Pantawid Pamilyang Pilipino Program On EducationEllyssa Erika MabayagNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Acute Appendicitis in Children - Diagnostic Imaging - UpToDateDocument28 pagesAcute Appendicitis in Children - Diagnostic Imaging - UpToDateHafiz Hari NugrahaNo ratings yet

- CHAPTER 1 SBL NotesDocument13 pagesCHAPTER 1 SBL NotesPrieiya WilliamNo ratings yet

- Chapter 4 Achieving Clarity and Limiting Paragraph LengthDocument1 pageChapter 4 Achieving Clarity and Limiting Paragraph Lengthapi-550339812No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Cisco BGP ASPATH FilterDocument115 pagesCisco BGP ASPATH FilterHalison SantosNo ratings yet

- Latched, Flip-Flops, and TimersDocument36 pagesLatched, Flip-Flops, and TimersMuhammad Umair AslamNo ratings yet

- Miniature Daisy: Crochet Pattern & InstructionsDocument8 pagesMiniature Daisy: Crochet Pattern & Instructionscaitlyn g100% (1)

- Canon Powershot S50 Repair Manual (CHAPTER 4. PARTS CATALOG) PDFDocument13 pagesCanon Powershot S50 Repair Manual (CHAPTER 4. PARTS CATALOG) PDFRita CaselliNo ratings yet

- WBDocument59 pagesWBsahil.singhNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 1 - 2020-CAP Surveys CatalogDocument356 pages1 - 2020-CAP Surveys CatalogCristiane AokiNo ratings yet

- Sveba Dahlen - SRP240Document16 pagesSveba Dahlen - SRP240Paola MendozaNo ratings yet

- Measurement Assignment EssayDocument31 pagesMeasurement Assignment EssayBihanChathuranga100% (2)

- Fundaciones Con PilotesDocument48 pagesFundaciones Con PilotesReddy M.Ch.No ratings yet

- Sandstorm Absorbent SkyscraperDocument4 pagesSandstorm Absorbent SkyscraperPardisNo ratings yet

- Applied Economics 2Document8 pagesApplied Economics 2Sayra HidalgoNo ratings yet

- Iguana Joe's Lawsuit - September 11, 2014Document14 pagesIguana Joe's Lawsuit - September 11, 2014cindy_georgeNo ratings yet

- Resume: Mr. Shubham Mohan Deokar E-MailDocument2 pagesResume: Mr. Shubham Mohan Deokar E-MailAdv Ranjit Shedge PatilNo ratings yet

- Lecture2 GranulopoiesisDocument9 pagesLecture2 GranulopoiesisAfifa Prima GittaNo ratings yet

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionDocument10 pagesMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyNo ratings yet

- Quiz 140322224412 Phpapp02Document26 pagesQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriNo ratings yet

- 2011-2012 - Medical - DirectoryDocument112 pages2011-2012 - Medical - DirectoryЈелена КошевићNo ratings yet

- Sem4 Complete FileDocument42 pagesSem4 Complete Fileghufra baqiNo ratings yet

- Quarter 1 - Module 1Document31 pagesQuarter 1 - Module 1Roger Santos Peña75% (4)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AMULDocument11 pagesAMULkeshav956No ratings yet