Professional Documents

Culture Documents

A Solenoid Is A Basic

Uploaded by

Somiran DasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Solenoid Is A Basic

Uploaded by

Somiran DasCopyright:

Available Formats

A solenoid is a basic, rugged device.

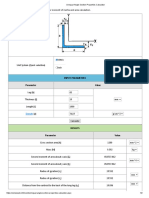

Its component parts When a solenoid consist of a coil (to carry current and generate ampere turns), an iron shell or case (to provide a magnetic circuit), and a movable plunger or pole (to act as the working element). A major objective in the design of a solenoid is to provide an iron path capable of transmitting maximum magnetic flux density with a minimum energy input. Another objective is to get the best relationship between the variable ampere turns and the working flux density in the air gap. When applying a solenoid, it is extremely important to consider the effects of heat, since for a constant voltage application, an increase in coil temperature reduces the work output. Ambient temperature range, voltage fluctuation, return is energized,the coil temperature rises. Since resistance springs and temperature rise all affect the net output varies with temperature, an increase in temperature torque/force. For preliminary calculations, we produces a proportional increase in resistance. Increased recommend that a 1.5 safety factor be applied to the resistance reduces the current flow when constant variables. voltage is applied, and decreases the effective ampere turns and torque/ force output. For each degree above or Magnetic Flux in Solenoids below 20C, the resistance of the coils copper wire Magnetic flux lines are transmitted through the iron shell changes by 0.393 percent per degree. A coil temperature and the air gap between the shell and the plunger (for rise of 80C, for example, will increase the coil linear solenoids) or the armature (for rotary solenoids). resistance by a factor of 0.314, which is equal to 80C x An iron path is much more efficient than air, but the air 0.00393/C. gap is needed to permit movement of the plunger or armature. The force or torque of a given solenoid is Rearrangement of the formula produces a ratio between inversely proportional to the square of the distance R20C and Rt2 as follows: between the pole faces. The lowest force or torque is generated when the distance is widest/longest; the strongest when the distance is smallest. Calculation of resistance at any other temperature (t2) Saturation Saturation of the iron path in a solenoid can be can be made using the following formula: considered in two ways. In the true sense it is point (a) at which the iron ceases to carry any increase in flux. In broader terms, saturation is usually considered as point (b), where the iron begins to saturate. The Resistance Factor of copper wire at temperatures from -60C (-76F) to 260C (500F) is graphed below. Once the actual coil temperature (ambient plus rise) is determined, the resistance factor can be determined as follows: A size 3E, 31 awg coil has a resistance of 31.8 ohms at 20C. After operating for a prolonged period at 10% duty, the approximate coil rise is 80C. Added to 20C, the coil temperature is 100C. The Resistance Factor As the pole pieces are moved together or when input graph indicates a 1.3 factor (point where 100C and power is increased, the flux density of the magnetic diagonal intersect). At 100C, the resistance of the 31.8 circuit increases until the iron saturates near point (b). ohm coil is increased by this factor. With a constant Beyond this point any further increase in power only voltage applied, the power decrease is proportional to the serves to add heat without an appreciable increase in resistance increase (P =E2/R). The 10% duty power of a force or torque. By changing the iron path area, the pole size 3 solenoid is 90 watts (at 20C). The decrease in shape, or the magnetic circuit material, output power at the elevated temperature is calculated by: torque/force can be increased. Ampere Turns The number of copper wire turns, the magnitude of the current, and permeance of the magnetic circuit determine the absolute value of magnetic flux within the solenoid. By interpolating between the 25% and 10% duty cycle The permissible temperature rise limits the magnitude of

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Solution Manual For Physics For Scientists and Engineers Foundations and Connections Volume 1 1st EditionDocument6 pagesSolution Manual For Physics For Scientists and Engineers Foundations and Connections Volume 1 1st EditionAnn Orozco100% (34)

- Worksheet O Levels Physics PressureDocument30 pagesWorksheet O Levels Physics PressureHZNo ratings yet

- Sheet 1 PDFDocument5 pagesSheet 1 PDFAnonymous hdjbt4waj7No ratings yet

- Chapter One: Fluid Properties by Ahmed YASHARDocument37 pagesChapter One: Fluid Properties by Ahmed YASHARSogolNo ratings yet

- PHY098Document9 pagesPHY098Syarifah Anis AqilaNo ratings yet

- List of Derivations Part-1 XiiDocument2 pagesList of Derivations Part-1 XiiTanishq VermaNo ratings yet

- Bead and Ring ProblemDocument4 pagesBead and Ring ProblemsayanNo ratings yet

- Applied Fluid MechanicsDocument27 pagesApplied Fluid Mechanicsdodoy kangkongNo ratings yet

- Equal Angle Section Properties CalculatorDocument2 pagesEqual Angle Section Properties CalculatorPinku Maiti100% (1)

- 161 SFT3023 Test 1 Question PDFDocument6 pages161 SFT3023 Test 1 Question PDFNur RynahNo ratings yet

- Coordinated Control of Distributed Energy Storage System With Tap Changer Transformers For Voltage Rise Mitigation Under High Photovoltaic PenetrationDocument10 pagesCoordinated Control of Distributed Energy Storage System With Tap Changer Transformers For Voltage Rise Mitigation Under High Photovoltaic PenetrationEvellyne ChrisNo ratings yet

- 3 Motion in One DimensionDocument43 pages3 Motion in One DimensionYoojin KimNo ratings yet

- CHE 2202 Module1 - Evaluation of Enthalpy Diference Part 1 - StudentDocument18 pagesCHE 2202 Module1 - Evaluation of Enthalpy Diference Part 1 - StudentKing Antonio AbellaNo ratings yet

- PPBFullbookDocument217 pagesPPBFullbookJovanie EstrellaNo ratings yet

- ATG - Gen. Physics 2Document11 pagesATG - Gen. Physics 2Grophel MesaNo ratings yet

- Diccionario CientíficoDocument440 pagesDiccionario CientíficoCamb LysNo ratings yet

- Forces On Curved Surfaces PDFDocument9 pagesForces On Curved Surfaces PDFSunny MaitangNo ratings yet

- RC CircuitsDocument4 pagesRC Circuitsjack daniels0% (1)

- Neet Test Series 2022 Test Code: NT - 02: Biology Physics ChemistryDocument16 pagesNeet Test Series 2022 Test Code: NT - 02: Biology Physics Chemistry6 months AgoNo ratings yet

- Type A Power Generating Modules: Engineering Recommendation G99 Form A2-3Document13 pagesType A Power Generating Modules: Engineering Recommendation G99 Form A2-3David GarciaNo ratings yet

- Tabla de Conversiones para Ingenieros Quimicos PDFDocument2 pagesTabla de Conversiones para Ingenieros Quimicos PDFElder ReyesNo ratings yet

- Class Xi Motion Along A Straight LineDocument3 pagesClass Xi Motion Along A Straight LineCHANDERBATISH MOHANNo ratings yet

- Partha Q3Document2 pagesPartha Q3ujjwal sahaNo ratings yet

- SHM HomeWorkSheet-1Document2 pagesSHM HomeWorkSheet-1Technology MediaNo ratings yet

- Dimensional Analysis Part 1 v3Document7 pagesDimensional Analysis Part 1 v3tahadostmushtaqNo ratings yet

- 197 eDocument6 pages197 eTians SkyNo ratings yet

- ENVIRONMENTAL CONTROL SYSTEM-III AssignmentDocument4 pagesENVIRONMENTAL CONTROL SYSTEM-III Assignmentmehak mahmoodNo ratings yet

- Mine Ventilation PDFDocument29 pagesMine Ventilation PDFLMNo ratings yet

- Industrial Products: Experts in Motion ControlDocument63 pagesIndustrial Products: Experts in Motion ControlMark JuhrigNo ratings yet

- Physics Revision ChecklistDocument36 pagesPhysics Revision Checklistapi-3723991100% (5)