Professional Documents

Culture Documents

Manage Inbound & Outbound Logistics

Uploaded by

Noopur GandhiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manage Inbound & Outbound Logistics

Uploaded by

Noopur GandhiCopyright:

Available Formats

INBOUND LOGISTICS The activities of receiving, storing, and disseminatingincoming goods or material for use.

Inbound logistics is the management of goods and materials which are arriving at your business premises. It is the opposite of outbound (or 'despatch') logistics. For example, in a tomato canning plant, inbound logistics is concerned with the receipt and storage of empty cans and raw tomatoes, which arrive separately. Outbound logistics is concerned with the storage of canned tomatoes (the finished product) and despatch to customers. INBOUND LOGISTICS Inbound side of logistics includes procurement or purchasing and the related materials management activities. It is important to note that the inbound and outbound logistics systems share common activities or process, since both involve decisions related to transportation, warehousing, materials handling, inventory management and control, and packaging, as well as some other activities. In this lecture, we will look at the materials management and procurement activities of an inbound logistics system and to discuss more fully those activities that are especially important on the inbound side, such as procurement and inventory management. The Inbound process comprises all the steps of an external procurement process that occur when the goods are received; the outbound part covers the necessary activities for preparation and shipping of goods to their destination. Goods Receipt Is a follow-on activity to a purchase order. It forms the basis for updating the financials and inventory records and can trigger warehouse management and quality management processes. With the warehouse management system, you can control the goods receipt and goods issue processes at a physical level. Goods receipts are possible from purchase order, inbound deliveries (advanced shipping notice), stock transport orders, or from production orders. Goods receipt begins the putaway process, which is supported by different advanced strategies. Determination of External Demands Determines the data describing a demand for a material that is procured externally. This data includes the quantity that is required, the release-to-supplier date of the demand, the goods receipt date for the delivery, and the location to which the material has to be shipped. Advanced Shipping Notification Comes from the vendor and contains the exact materials, quantities, and the delivery date with reference to a purchase order. This document becomes the Inbound Delivery in the

receipt process. Delivery Monitor Provides an overview of deliveries in working processes. Gives an overview of the workload in different areas, for example shipping, transportation, or invoicing, while also allowing you to collectively process documents that have the same selection criteria. Specialists in different execution areas of the organization can use this tool to gain a quick overview of their workload, drill down to single documents, and trigger follow-up activities. Yard Management Gives the warehouse an overview of stocks located on trailers, trucks, or railcars in the yard. Sequencing functions decide which stock should be received into the warehouse at which point in time. Yard Management also manages the vehicle from the check-in to check-out, including inyard activities such as sealing, weighing, and directing the vehicle to a door or parking place within the yard. Registration of the start and finish of loading or unloading activities is also supported. Yard Management is integrated with Mobile Data Entry. This process is supported by the following SAP and/or partner offerings SAP ERP

Outbound logistics The movement of material associated with storing, transporting, and distributing goods to its customers. Goods Issue The outbound delivery forms the basis for goods issue posting. The data required for goods

issue posting is copied from the outbound delivery into the goods issue document. When you post goods issue for an outbound delivery, the following functions are carried out on the basis of the goods issue document: 1. Warehouse stock is reduced by the delivery quantity. 2. Value changes are posted to the balance sheet account in inventory accounting. 3. Requirements are reduced by the delivery quantity. 4. The serial number status is updated. 5. The goods issue posting is automatically recorded in the document flow. 6. Stock determination is executed for the vendor's consignment stock. 7. A worklist for the proof of delivery is generated. After goods issue is posted for an outbound delivery, the scope for changing the delivery document becomes very limited. This prevents discrepancies between the goods issue document and the outbound delivery. Delivery Processing & Distribution Controls the actual fulfillment of sales orders and purchase orders as well as stock transport orders. The execution of logistics tasks is handled here. With delivery processing, the goods are shipped and relevant documents are printed out. The sales requirements can be distributed to alternative locations. The delivery might be shipped to the customer directly from the fulfilling locations (more than one delivery), or consolidation may occur at one location before one complete shipment is transported to the end customer. Proof of Delivery Proof of delivery (POD) is an instrument involved in business processes in which an invoice is issued only after the customer has confirmed the delivery's arrival. In addition to the POD itself, you can also record the POD date, time, actual quantity, and the reason for possible differences in quantities. This is especially important for deliveries where the delivery quantity varies because of the nature of the goods or for which the exact delivery quantity is unknown from the start. You are now in a position to issue an accurate invoice based on the customer's confirmation of goods received. You no longer need to create credit memos. The reasons for deviation that occur most frequently in real-world scenarios, such as stock shrinkage, theft, certain characteristics of goods (volatility, for example), and transportation damage, are recorded and analyzed in the system. This analysis is especially valuable when you are negotiating with forwarding agents, vendors, or customers, since all deviations can be reflected. Value-Added Services Value-Add activities in the warehouses need to be managed and monitored. Using the VAS functionality, you are able to manage and control the execution of services in the warehouse. VAS is fully integrated into Warehouse Management, Handling Unit Management, Task and Resource Management, and Mobile Data Entry.

Delivery Monitor Provides an overview of deliveries in working processes. Gives an overview of the workload in different areas, for example shipping, transportation, or invoicing, while allowing you to collectively process documents that have the same selection criteria. Specialists in different execution areas of the organization can use this tool to gain a quick overview of their workload, drill down to single documents, and trigger follow-up activities. This process is supported by the following SAP and/or partner offerings

You might also like

- Internal and External Assessment PDFDocument3 pagesInternal and External Assessment PDFGieees StrecaNo ratings yet

- REsponsibilities of BODDocument4 pagesREsponsibilities of BODRizalyn Huraño MalalisNo ratings yet

- 3.3 DAGMAR Approach: HistoryDocument8 pages3.3 DAGMAR Approach: HistorySonakshi VikranthNo ratings yet

- Ration-Wale: User ID: DangwalDocument8 pagesRation-Wale: User ID: DangwalPuneet Singh Thakur100% (1)

- 4 Exam Part 2Document4 pages4 Exam Part 2RJ DAVE DURUHANo ratings yet

- EssayDocument2 pagesEssayDiana OrtegaNo ratings yet

- Edited Love by YouDocument49 pagesEdited Love by YouGElla BarRete ReQuilloNo ratings yet

- An American Tragedy: How A Good Company DiedDocument2 pagesAn American Tragedy: How A Good Company Died6028No ratings yet

- 3 Types of Business PDFDocument2 pages3 Types of Business PDFAnonymous 7VnzWHKXNo ratings yet

- Ps Module 4 Understanding Buyers Week 7-8Document35 pagesPs Module 4 Understanding Buyers Week 7-8Marian Rivera DiazNo ratings yet

- A Study On Deeds That Are Legal But UnethicalDocument7 pagesA Study On Deeds That Are Legal But UnethicalJashim UddinNo ratings yet

- Chapter 6 Class NotesDocument20 pagesChapter 6 Class NotesSarvesh BhartiNo ratings yet

- Operations Management 1Document16 pagesOperations Management 1Godfrey MkandalaNo ratings yet

- Business Combination Types GuideDocument8 pagesBusiness Combination Types GuideShanmuka NalliNo ratings yet

- Coco Chanel Case StudyDocument5 pagesCoco Chanel Case StudyArun NalamaraNo ratings yet

- Arguments For and Against Social ResponsibilityDocument2 pagesArguments For and Against Social ResponsibilityTa Thi Thu VanNo ratings yet

- Warehousing FPPGDIEDocument100 pagesWarehousing FPPGDIEGlennberg CarreonNo ratings yet

- ConclusionDocument2 pagesConclusionMuthu Kumaran100% (1)

- Who Determines Demand Levels and CompositionDocument2 pagesWho Determines Demand Levels and CompositionSean Chris Conson0% (1)

- Chapter 15Document13 pagesChapter 15Brian Duela100% (1)

- What Challenges Do You See in The OD Process When The OD Practitioner and Client Come From Different CulturesDocument1 pageWhat Challenges Do You See in The OD Process When The OD Practitioner and Client Come From Different CulturesIfra AkhlaqNo ratings yet

- Selection and Placement Chapter OverviewDocument3 pagesSelection and Placement Chapter OverviewJoshua100% (1)

- Burger King Satisfries Case Study CBDocument2 pagesBurger King Satisfries Case Study CBAtul Mishra0% (1)

- New Product Development and Product Life-Cycle Strategies: A Global PerspectiveDocument33 pagesNew Product Development and Product Life-Cycle Strategies: A Global PerspectiveLakshmikanthBalasubramanianNo ratings yet

- Inventory Management SystemDocument30 pagesInventory Management Systemmulte123No ratings yet

- Unit 2 Philosophical Aspects of ManagementDocument42 pagesUnit 2 Philosophical Aspects of ManagementarbindshrNo ratings yet

- Simon's Negative Attitude Affects Employee Job SatisfactionDocument2 pagesSimon's Negative Attitude Affects Employee Job SatisfactionRizqikha Hanung Ciptayukas100% (1)

- Assignment On Strategic Evaluation & ControlDocument13 pagesAssignment On Strategic Evaluation & ControlShubhamNo ratings yet

- Value Chain vs Supply ChainDocument2 pagesValue Chain vs Supply ChainSagar100% (2)

- Consumer Behavior and Marketing StrategyDocument17 pagesConsumer Behavior and Marketing StrategySuman PoudelNo ratings yet

- Business Communication AssignmentsDocument4 pagesBusiness Communication AssignmentsAtul RishiNo ratings yet

- Module 4 - Marketing ResearchDocument4 pagesModule 4 - Marketing ResearchBhaskar SaileshNo ratings yet

- Yea 4Document3 pagesYea 4api-334748891No ratings yet

- Job Satisfaction and Attitudes: Cognitive, Affective, and Behavioral ComponentsDocument17 pagesJob Satisfaction and Attitudes: Cognitive, Affective, and Behavioral ComponentsAbdullah JuttNo ratings yet

- Strategic TrainingDocument22 pagesStrategic TrainingNina HooperNo ratings yet

- Basic Accounting Principles and ConceptsDocument2 pagesBasic Accounting Principles and ConceptsSukhjinder Singh100% (1)

- Mob-Case Study PDFDocument11 pagesMob-Case Study PDFGreeshmani GreeshNo ratings yet

- What Are Business Ethics, and Why Is This An Important Topic?Document2 pagesWhat Are Business Ethics, and Why Is This An Important Topic?Juliana CabreraNo ratings yet

- What Is Market ResearchDocument13 pagesWhat Is Market ResearchJudy Ann VicenteNo ratings yet

- Advantages and Qualities of EntrepreneurshipDocument7 pagesAdvantages and Qualities of EntrepreneurshipChandra RaviNo ratings yet

- New Product DevelopmentDocument20 pagesNew Product DevelopmentAbhinav SachdevaNo ratings yet

- Analysis of Sources, Technological Innovation Capabilities and PerformanceDocument7 pagesAnalysis of Sources, Technological Innovation Capabilities and Performancethrowawayasdfzxcv100% (1)

- What are Internal ControlsDocument3 pagesWhat are Internal Controlssome_one372No ratings yet

- Marketing Management TasksDocument6 pagesMarketing Management TasksJalad MukerjeeNo ratings yet

- Managing Financial Resources and DecisionsDocument28 pagesManaging Financial Resources and DecisionsamyNo ratings yet

- Evaluating A Billboard AdDocument2 pagesEvaluating A Billboard AdLucas satosNo ratings yet

- Specialized Fields and Branches of AccountingDocument2 pagesSpecialized Fields and Branches of AccountingElla Simone100% (2)

- Obligations To The FirmDocument2 pagesObligations To The FirmAngel Pearl DeneroNo ratings yet

- Business Entity Guide - Compare Types, Advantages & DisadvantagesDocument13 pagesBusiness Entity Guide - Compare Types, Advantages & DisadvantagesmanjuashokNo ratings yet

- Introduction To International Marketing ResearchDocument7 pagesIntroduction To International Marketing ResearchPrem Zip Zap ZoomNo ratings yet

- Operations Strategy and Competitiveness-Ch02Document38 pagesOperations Strategy and Competitiveness-Ch02Rob Christian100% (1)

- Unit 1 EihrmDocument55 pagesUnit 1 EihrmShivamNo ratings yet

- Introduction to Finance Functions and PrinciplesDocument20 pagesIntroduction to Finance Functions and PrinciplesNuruzzaman Md Sheikh100% (1)

- BRM NotesDocument24 pagesBRM NotesBuraq KhanNo ratings yet

- Crafting A Business Plan and Building A Solid Strategic PlanDocument29 pagesCrafting A Business Plan and Building A Solid Strategic PlanNusrat IslamNo ratings yet

- Cap 1Document19 pagesCap 1Tina CRNo ratings yet

- Entrepreneurship Development - Unit 5Document27 pagesEntrepreneurship Development - Unit 5Ajit JainNo ratings yet

- Inbound Delivery SapDocument1 pageInbound Delivery SapKumar AjitNo ratings yet

- Determination of External Demands: Goods IssueDocument2 pagesDetermination of External Demands: Goods IssueLovely Angell FermanNo ratings yet

- Dot Net MVC Course ContentDocument6 pagesDot Net MVC Course ContentNoopur GandhiNo ratings yet

- Levittown & NJ apartment communities guideDocument2 pagesLevittown & NJ apartment communities guideNoopur GandhiNo ratings yet

- Fin 500 Q&aDocument4 pagesFin 500 Q&aNoopur GandhiNo ratings yet

- AnalysisDocument2 pagesAnalysisNoopur GandhiNo ratings yet

- Labor productivity and outsourcing calculationsDocument6 pagesLabor productivity and outsourcing calculationsNoopur GandhiNo ratings yet

- Metabical CaseDocument3 pagesMetabical CaseNoopur GandhiNo ratings yet

- Toyota Presentation 2Document5 pagesToyota Presentation 2Noopur GandhiNo ratings yet

- Hjkweek 7 ResearchDocument1 pageHjkweek 7 ResearchNoopur GandhiNo ratings yet

- Question 31Document2 pagesQuestion 31Noopur Gandhi0% (2)

- PP Chap 5 FX MarketsDocument59 pagesPP Chap 5 FX MarketsNoopur GandhiNo ratings yet

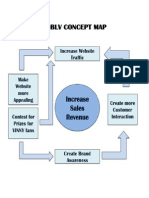

- Concept MapDocument1 pageConcept MapNoopur GandhiNo ratings yet

- Transaction Exposure - A Detailed Example PDFDocument16 pagesTransaction Exposure - A Detailed Example PDFNoopur GandhiNo ratings yet

- Concept MapDocument1 pageConcept MapNoopur GandhiNo ratings yet

- 1Document14 pages1Noopur GandhiNo ratings yet

- Fairchild Water TechDocument2 pagesFairchild Water TechNoopur Gandhi0% (1)

- Application LetterDocument1 pageApplication LetterNoopur GandhiNo ratings yet

- Howard Mba AddmiDocument2 pagesHoward Mba AddmiDhairya BajariaNo ratings yet

- Assistant Auditor Brown UniversityDocument1 pageAssistant Auditor Brown UniversityNoopur GandhiNo ratings yet

- HondaDocument127 pagesHondaNoopur GandhiNo ratings yet

- Azim PremjiDocument1 pageAzim PremjiNoopur GandhiNo ratings yet

- CCCCCCCDocument1 pageCCCCCCCNoopur GandhiNo ratings yet

- Definitions of Occupational DiseasesDocument2 pagesDefinitions of Occupational DiseasesNoopur GandhiNo ratings yet

- Factors Influencing Bank Selection Decisions of Indian CustomersDocument2 pagesFactors Influencing Bank Selection Decisions of Indian CustomersNoopur GandhiNo ratings yet

- Seven Key MessagesDocument16 pagesSeven Key MessagesMartijn Planken100% (1)

- A Project Report On Comparison Between HDFC Bank & ICICI BankDocument75 pagesA Project Report On Comparison Between HDFC Bank & ICICI Bankvarun_bawa25191592% (12)

- University of Mumbai Bachelor of Management Studies (B.M.S)Document18 pagesUniversity of Mumbai Bachelor of Management Studies (B.M.S)Noopur GandhiNo ratings yet

- Economic Evaluation of Hot Chocklet Reports FinalDocument12 pagesEconomic Evaluation of Hot Chocklet Reports FinalShahriar AzgarNo ratings yet

- Task EnvironmentDocument3 pagesTask EnvironmentlesNo ratings yet

- Clean Spritz 02Document45 pagesClean Spritz 02fiqa50% (2)

- Bubble TeaDocument9 pagesBubble TeaDania UzairNo ratings yet

- 16 ZaraDocument2 pages16 ZaraFauzangetsu Tensou100% (1)

- Discussions On L'OrealDocument3 pagesDiscussions On L'OrealAsim Dasgupta100% (1)

- Marketing Management 3104Document6 pagesMarketing Management 3104Jennifer WillardNo ratings yet

- Overall Trends in IT Spending by IndustryDocument262 pagesOverall Trends in IT Spending by Industrynaveenkumarvr0% (1)

- Business CaseDocument26 pagesBusiness CaseujiwaraNo ratings yet

- Selling Fairness Creams in IndiaDocument18 pagesSelling Fairness Creams in IndiaswatikukNo ratings yet

- 1.1.1 The Dynamic Nature of BusinessDocument6 pages1.1.1 The Dynamic Nature of BusinessryanNo ratings yet

- COSMETICSDocument20 pagesCOSMETICSCARDIAC8No ratings yet

- Pelican Cases Catalog PDFDocument22 pagesPelican Cases Catalog PDFRicardo Peña EcheverriaNo ratings yet

- Chapter - 2 Theory of Demand and SupplyDocument16 pagesChapter - 2 Theory of Demand and SupplySohail Ahmed KhiljiNo ratings yet

- SynopsisDocument43 pagesSynopsisvlaparna1100% (1)

- Situation AnalysisDocument6 pagesSituation AnalysisLim Vi VienNo ratings yet

- case-study-Amazon.comDocument8 pagescase-study-Amazon.comBaldeep Kaur100% (1)

- Coordination in Supply ChainDocument22 pagesCoordination in Supply ChainVipulGoelNo ratings yet

- Hide SignDocument35 pagesHide Signagga1111No ratings yet

- Administración de Ventas - Chapter 3Document61 pagesAdministración de Ventas - Chapter 3albgatmtyNo ratings yet

- Individual, family and combination brand names explainedDocument3 pagesIndividual, family and combination brand names explainedMuhammad Zain ImtiyazNo ratings yet

- MCB Focus: Mauritius Inc.: Engaging and Partnering With Africa On Its Transformative JourneyDocument120 pagesMCB Focus: Mauritius Inc.: Engaging and Partnering With Africa On Its Transformative JourneyL'express MauriceNo ratings yet

- Day 4 - Solve and Interpret The Supply ElasticityDocument3 pagesDay 4 - Solve and Interpret The Supply ElasticityVolefe UKNo ratings yet

- Demand Analysis (Meaning, Types and Determinants of Demand)Document12 pagesDemand Analysis (Meaning, Types and Determinants of Demand)PAYEL MAZINDER BORUAHNo ratings yet

- Commodore International - Wikipedia, The Free EncyclopediaDocument10 pagesCommodore International - Wikipedia, The Free EncyclopediaHisyam MawardieNo ratings yet

- Industry Segmentation and Competitive AdvantageDocument25 pagesIndustry Segmentation and Competitive AdvantageVikasSharmaNo ratings yet

- What Is Acceptable Quality Level PDFDocument4 pagesWhat Is Acceptable Quality Level PDFمصطفى عبدالرحيمNo ratings yet

- Study On Customer Preferences in Choosing Big BazaarDocument71 pagesStudy On Customer Preferences in Choosing Big Bazaarsumit91% (11)

- NCVT NotesDocument10 pagesNCVT NotesDeepali Singhai JainNo ratings yet

- Economy of ScaleDocument7 pagesEconomy of ScaleVananh NguyenNo ratings yet