Professional Documents

Culture Documents

Catalouge

Uploaded by

kawalhayerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalouge

Uploaded by

kawalhayerCopyright:

Available Formats

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

WORM GEAR SCREW JACK

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

INDEX

1. 2. 3. 4. 5. 6. 7. SPECIAL FEATURES OF SFI BRAND SCREW JACKS.

SELECTION PROCEDURE OF SCREW JACK. SELECTION CHART FOR SCREW JACKS. FIGURES SHOWING TYPES AVAILABLE. DIMENSION TABLE FOR ALL TYPES AVAILABLE. SCREW HEAD VARIATIONS AVAILABLE. SAFETY AND INSTALLATION INSTRUCTIONS.

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

SPECIAL FEATURES OF SFI BRAND WORM GEAR SCREW JACKS

SFI brand Worm Gear Screw Jacks are specially designed and engineered to meet the toughest working conditions and carry the following advantages: A much higher efficiency level. Displacement speed up to 6m/min are possible. A much greater longevity Positioning is more exact. Can run continuously

All our Jacks are offered with: 4 (Four) Speed reducing ratios for each capacity Travel Length from 50mm to several meters on request. Threaded extremity of the lifting screw provided with a flange or cap. A stainless steel lifting screw can be provided (On request). End of travel switches mounted on the protection tube (On request)

All screw jacks also offers: Perfectly synchronized operation of several mechanically connected jacks. Loads are kept in the absolutely the same position by means of the self locking device. Hardly any maintenance. Precise and uniform displacement. Possibility of manual or electric controls. Operation in surrounding from -50Deg C to 90deg C.

Versions Offered: We offer a very vide range of screw jacks whose capacity varies from 0.5 Ton to 150 Tons. We offer the following versions of screw jacks. Standard : Direct or Inverse. Moving Nut With Anti-rotation keyed lifting screw. With backlash elimination system for the lifting screw.

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

SELECTION OF APPROPRIATE SCREW JACK

The technical characteristics required of each screw jacks need to be studied. While selecting the screw jack following criteria is used: 1. 2. 3. 4. Load to be displaced in Metric Tons. Speed of displacement in mm/min or mm/rev of input shaft. Utilization rate. Longevity desired.

After obtaining details on above mentioned parameters follow the process as given below to validate your selection: 1. 2. Always take a screw jack of greater capacity than actually required. Verify the buckling force on the lifting screw in case the load exerts compressive force on screw. 2*E*0.05*d4 Pc = -----------------L2 Pc = Critical Load x safety coefficient (Between 3 & 5) E = Elastic modulus of screw material (Generally = 2 x 104) L = Distance between the guiding point of lift screw where the load is guided. For Free/Unguided Loads take L = 2 x Stroke Length required. 3. Calculate the power absorbed by the Jack by applying the following formula: Load (Tons) x Lifting Speed mm/min P(HP) = ---------------------------------------------------------------------4500 x Efficiency of Jack (Refer Table-1) Verify that this power does not exceed the maximum indicated power of the screw jack. If the same is greater you need to select the greater capacity jack or else lessen the lifting speed. 4. Incase where several jacks are to be used in tandem apply the following formula to calculate power required. P absorbed by each jack x number of jacks required Total P (HP) = x -------------------------------------------------------------------------------------------------------------Overall efficiency of installation* x Efficiency of Angle Drives** 5. * For 2 Jacks = 0.95, for 3 Jacks = 0.9, for 4 Jacks = 0.85, for 6 Jacks = 0.80 ** Take 0.90 per angle drive.

Verify maximum lifting speed V in mm/min. Max power per Jack (HP) x Efficiency of Jack V (mm/min) = 4.5 x 103 x ------------------------------------------------------------------------------Load per Jack (Tons) Notes: 1. To restrain horizontal stress or to reduce the radial play of the lifting screw, optional second guide ring can be provided upon request. 2. If the jacks are to be subjected to vibrations, take a greatest reduction ratio or slower raise speed.

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

SELECTION CHART FOR WORM GEAR SCREW JACK

DESIGN-A UPWARD

Modle no. & Capacity in Metric Tonnes Lifting Screw Dia & pitch WORM GEAR RATIO Lift in mm per turn of input shaft Max. Power input (HP) Normal Slow Normal Slow Normal Slow Normal Slow At Max. Lift 0.5 18x6 10:1 20:1 0.60 0.30 0.12 0.17 26 19.0 8.8 12 1.2 0.14 0.05 2 26x6.28 6:1 24:1 1.047 0.262 0.45 0.63 26 16.0 44 36 7.3 0.32 0.09 2.5 30x6 6:1 24:1 1.0 0.250 0.55 0.77 23 14.0 60 46.5 7.3 0.45 0.1 5 40x7 6:1 24:1 1.067 0.292 1.1 1.5 21 12.0 153 92 16.2 0.82 0.25

DESIGN B INVERTED

10 58x12 23:3 24:1 1.565 0.50 2.6 3.6 23 15.0 468 195 25 1.67 0.5 20 65x12 8:1 24:1 1.5 0.5 3.7 5.2 21 13.0 1009 280 36 2.15 0.75 25 90x16 32:3 32:1 1.5 0.5 4.8 6.7 19 11.0 1725 480 70.5 4.15 1.1 35 100x16 32:3 32:1 1.5 0.5 6.0 8.4 18 11.0 2599 705 87 5.20 1.9 50 120x16 32:3 32:1 1.5 0.5 7.4 10.4 15 10.0 4236 840 176 7.70 2.5 100 160x20 12:1 36:1 1.667 0.566 12.5 17.5 15 9.0 11116 2660 538 13.82 7 538 18.6 7 150 180x25 12:1 36:1 1.41 0.47 25 11 14.1 8.6

Effcienncy Rating screw Torque (Nm)

Max.Permisslble Torque (Nm) Weight wthout screw & protection tube (kg) Weight per 100 mm screw Quantity of Lubricant (kg)

Please contact for optional gear ratios available. Specific design suiting custom requirement can also be supplied

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

TYPE 1 DESIGN A

With Protection Tube (Standaed Design) O

With 2nd Gulde Ring

O

W2 A2 T2

Lift

Lift2

NL

A4

O W B

A5

V

P

Y1

W1 NL U1 X b d

TYPE 2 DESIGN B

T2

W2

A2

With Protection Tube (Standaed Design)

X e

With 2nd Gulde Ring

TYPE 2 DESIGN A

TYPE 1DESIGN B

D L

H

Q KEY WAY K1

Q KEY WAY

H

Q KEY WAY

J

K1

K2

K1 H L K2

J L1

M N

F G

M N

L1

J

ONLY FOR MWJ-0.5

K1 L

H

E D

ONLY FOR MWJ-2

E D

ONLY FOR MWJ-2.5,5,10,20,25&35

Q KEY WAY

L H

S

K1 J

Q KEY WAY

L1

R

K2 E D

ONLY FOR MWJ-50

E D

ONLY FOR MWJ-100 & 150

T1

Y2

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

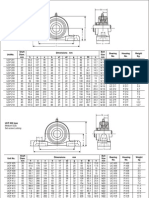

DIMENSION TABLE

Frame Size A A2 A4 A5 B C D E F G H JK6 K1 K2 L L1 M N NL O P Q R S T T1 T2 T4 U U1 U2 V W W1 W2 X Y Y1 Y2 0.5 Lift+ 20 Lift+ 44 Lift+ 166 Lift+ 188 105.5 32 81.5 115 90 9 10 27 32.5 21.5 73 120 Lift+ 72 65 75.5

3x3x20

All dimensions are in mm

35 Lift+ 20 Lift+ 60 Lift+ 535 Lift+ 580 350 115 430 360 280 210 35 38 120 135 170 80 265 430 Lift+ 205 260 250

10x8x50

2 Lift + 20 Lift+4 4 Lift+2 05 Lift+ 227 147.5 44 94 57 182 152 11 14 45.2 28.5 47 34 100 180 Lift+ 80 98 101.5

5x5x28

2.5 Lift+ 20 Lift+ 44 Lift+ 214 Lift+ 238.5 150.5 45 165 135 120 90 14 16 45.2 50 65 34.25 110.5 190 Lift+ 85 98 10.5

5x5x32

5 Lift+ 20 Lift+ 43 Lift+ 270 Lift+ 300 193 61.5 112 168 155 114 17 20 56.2 58 80 46 132 228 Lift+ 110 122 142

6x6x32

10 Lift+ 20 Lift+ 42 Lift+ 335 Lift+ 359 230 70 235 190 200 155 21 25 66.8 63.5 86 52 172 280 Lift+ 125 150 156.5

8x7x45

20 Lift+ 20 Lift+ 55 Lift+ 404 Lift+ 430 262 87 295 240 215 160 28 28 72.5 95 122.5 52 213.5 322 Lift+ 150 185 182

8x7x45

25 Lift+ 20 Lift+ 65 Lift+ 476 Lift+ 513 317 102 350 280 260 190 35 34 97 95 130 60 221 355 Lift+ 170 205 225

10x8x50

50 Lift+ 20 Lift+ 20 Lift+ 643 Lift+ 675 400 130 260 150 500 400 48 40 137 75 130 100 324 560 Lift+ 225 300 275

12x8x80

100 Lift+ 65 Lift+ 65 Lift+ 802 Lift+ 812 520 170 540 440 620 520 52 60m6 196 160 210 110 420 670 Lift+ 300 440 370

18x11x90

150 Lift+ 65 Lift+ 65 Lift+ 802 Lift+ 812 520 170 540 440 620 520 52 47-62k6 196 160 210 110 420 670 Lift+ 300 440 370

18x6x75

1.5 5.5 22.5 11.5 0 28 30 2.5 10 36 45 45 20 70 74 70

41 6 8.5 24 20 0 47 40 2 14 48 60 60 20 93 95 93

38 5.5 8.5 26.5 20 0 47 50 3 12 48 68 60 20 97 100 97

55 6 12 30 18 0 63 70 3 18 65 83 75 20 130 131 131

55 7 6.5 34 18 0 78 30 1 16 80 110 95 25 150 160 150

72 6 6 39 31 0 86 100 3 20 100 140 100 25 176 194 181

80 10 8 52 40 0 118 120 3 25 130 160 130 25 217 226 211

100 10 10 45 40 15 136 140 4 30 150 180 150 30 240 250 250

15 29 10 32 143 180 0 35 170 210 159 50 260 289 292

147 14 20 43 20 0 198 220 0 50 240 280 220 50 350 383 350

147 14 20 43 20 0 198 220 0 50 240 280 220 50 350 383 350

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

SCREW HEAD VARIATIONS

a k6

d e s

r

h k

m

c1

v n

f

Head Type I

CAPACITY IN MATRIC TONS a HEAD I b c d e f HEAD II r s x g h HEAD III I k l m n HEAD IV o H8 p u v a1 TRAVEL NUT b1 c1 d1

a1 b1

d1

Head Type III

Head Type II

0.5 12 20 30 65 45 4x7 8 20 18 30 20 M12x1.25 30 20 50 30 15 65 30 15 32 10 40 50 2 18 30 46 98 75 4x11 12 30 40 46 30 M18x1.5 46 30 70 50 20 86 48 25 40 18 50 76 2.5 20 30 45 98 75 4x14 12 30 40 45 30 M22x1 .5 45 30 70 50 25 85 50 25 45 15 50 80 5 25 40 51 122 85 4x17 18 40 50 51 59 M30x2 51 42 105 75 35 117 65 37.5 60 18 70 87 10 40 50 73.3 150 105 4x21 20 50 65 73.3 50 M40x3 73.3 60 130 100 50 153.5 90 50 75 25 90 110 20 50 60 80 185 140 4x26 20 60 90 80 60 M50x3 80 75 150 120 60 170 110 60 100 70 90 120

Head Type IV

Travel Nut

25 70 63 92 205 155 4x27 25 63 100 92 63 M70x3 92 90 175 140 70 204 130 70 120 35 130 155

35 80 80 100 260 200 4x33 30 80 130 100 80 M80x3 100 185 220 160 80 240 150 80 145 35 150 190

50 100 125 150 300 225 4x35 30 70 140 100 125 M100x5 150 120 300 200 100 325 170 100 155 50 160 225

100 140 175 200 370 280 6x52 75 125 200 150 175 M140x 6 200 160 360 280 145 385 220 140 200 80 200 260

150 150 175 225 355 280 6x48 75 125 200 200 175 M150x 6 220 180 375 300 160 400 280 150 225 65 230 395

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

Worm Gear Screw Jacks

General Instructions

Maintenance and installation recommendations In order to ensure that the actuator give good service over a period of years the following precautions should be taken. 1. 2. Select an actuator, which has a rated capacity greater than the maximum load that may be imposed on it. The structure on which the actuators are mounted have ample strength to carry the maximum load, and should be rigid enough to prevent undue deflection or distortion of the actuator supporting numbers. It is essential that the actuators be carefully aligned during installation so that the lifting screws are vertically true and the connecting shafts are exactly in the line with the worm shafts. After the actuators, shafting, gearboxes, etc., are coupled together it should be possible to turn the main drive by hand. If there are no signs of bending or misalignment, the actuator system is then ready for normal operation. The actuators should have a greater raise than is needed in the actual installation. Should it be necessary to operate the actuators at the extreme limits of travel it should be done cautiously? It is important that the lifting screws should not be closed below the specified closed height dimension of the actuators; otherwise serious damage may result to be worm gear. Lifting screw end stops are to prevent over-travel or loss of screw. These are not load supporting and should be treated as an emergency device only and must not be allowed to come into contact with the worm gears during normal working cycles otherwise serious damage will result to worm gear and bearings. The maximum worm shaft speed for these actuators should not exceed 500 R.P.M. for heavy loads. The lifting screws should not be permitted to accumulate dust and grit on the threads. If possible, lifting screw should be returned to the closed height position when not in use. A periodic check of backlash between lifting screw and worm gear is recommended to check wear on internal threads of worm gear. Backlash in excess of 50% thread thickness indicates that a replacement will be necessary to replace the worm gear and nut assembly when wear has allowed the worm gear and nut to close against each other making further adjustment impossible. The actuators are shipped packed the grease (unless otherwise called for ) which should be sufficient for one month using one of the extreme pressure grease or their equivalent.

3.

4.

5.

6. 7. 8.

9.

For severe service conditions the actuator should be lubricated with a molybdenum disulphide type of grease about once a week.

SIMRAN FLOWTECH INDUSTRIES

Plot No.: 174, Sector-24, NIT- Faridabad 121005, Haryana, India

JAS-ANZ

(AN ISO:9001 : 2000 COMPAMY)

Website : www.simranflowtech.co.in Email : simranflowtech@hotmail.com

Telefax: 91-(0129)-4028353, Mobile: 9818247353

Also please contact for other products:

HYDRAULIC CYLINDERS

HYDRAULIC JACKS

HYDRAULIC ROTARY UNIONS

For further enquiry please contact us

SIMRAN FLOWTECH INDUSTRIES

PLOT NO. 174, SECTOR-24, FARIDABAD - 121005 Telefax : 91-129-4028353 Mobile : 9818287353 Email : simranflowtech@hotmail.com Website : www.indiamart.com/simranflow-tech www.simranflowtech.in www.simranflowtech.tradeindia.com

10

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 100 Pushups PocketMod (Black and White)Document1 page100 Pushups PocketMod (Black and White)wiredpsycheNo ratings yet

- Professional Engineer Summary StatementDocument3 pagesProfessional Engineer Summary StatementkawalhayerNo ratings yet

- IELTS Speaking Band DescriptorsDocument1 pageIELTS Speaking Band DescriptorsIELTS Online Practice67% (3)

- Nothing Just A Blank DocumentDocument4 pagesNothing Just A Blank DocumentkawalhayerNo ratings yet

- K-Factor Sheet MetalDocument3 pagesK-Factor Sheet MetalkawalhayerNo ratings yet

- String Properties: Property DescriptionDocument5 pagesString Properties: Property DescriptionkawalhayerNo ratings yet

- K-Factor Sheet MetalDocument3 pagesK-Factor Sheet MetalkawalhayerNo ratings yet

- Analysis Basis Base PlateDocument11 pagesAnalysis Basis Base PlatekawalhayerNo ratings yet

- Indian Lok SabhaDocument1 pageIndian Lok SabhakawalhayerNo ratings yet

- Ik Baba Nanak Si Bai Jeenay Tur Ke Duniya Gaa TiDocument1 pageIk Baba Nanak Si Bai Jeenay Tur Ke Duniya Gaa TikawalhayerNo ratings yet

- Writing Your Three Career EpisodesDocument2 pagesWriting Your Three Career EpisodesizharkhanNo ratings yet

- Welding SymbolsDocument9 pagesWelding Symbolsjojo_323100% (3)

- Ror StringDocument1 pageRor StringkawalhayerNo ratings yet

- Proposed Changes For Baghouse Structure-ModelDocument1 pageProposed Changes For Baghouse Structure-ModelkawalhayerNo ratings yet

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdNo ratings yet

- Form 19Document2 pagesForm 19kawalhayerNo ratings yet

- Brochure PtcpvdeDocument2 pagesBrochure PtcpvdekawalhayerNo ratings yet

- Take ChancesDocument1 pageTake ChanceskawalhayerNo ratings yet

- Analysis Basis Base PlateDocument11 pagesAnalysis Basis Base PlatekawalhayerNo ratings yet

- SinghDocument1 pageSinghkawalhayerNo ratings yet

- That's LifeDocument1 pageThat's LifekawalhayerNo ratings yet

- Tuyere Handling Equipment for Blast FurnacesDocument1 pageTuyere Handling Equipment for Blast FurnaceskawalhayerNo ratings yet

- UCPs of AsahiDocument4 pagesUCPs of AsahikawalhayerNo ratings yet

- Defectos de LaminadoDocument0 pagesDefectos de Laminadoאבימיי דור אבימיי דורNo ratings yet

- Ias Mechanical EnggDocument2 pagesIas Mechanical EnggkawalhayerNo ratings yet

- Total Water Management in Thermal Power StationsDocument8 pagesTotal Water Management in Thermal Power StationsSarah FrazierNo ratings yet

- 19 - Wartsila - Turbocharging 2 Stroke Engine - Existing & Future DemandsDocument18 pages19 - Wartsila - Turbocharging 2 Stroke Engine - Existing & Future DemandsCháu Bác HồNo ratings yet

- KNOC - Surface Pre and Painting ProcedureDocument32 pagesKNOC - Surface Pre and Painting Procedureminhhieu.qc100% (1)

- Advances in Thermochemical Conversion of Woody Biomass To Energy, Fuels and ChemicalsDocument9 pagesAdvances in Thermochemical Conversion of Woody Biomass To Energy, Fuels and ChemicalsAsem AmairyhNo ratings yet

- YOKOGAWA Exa Fc400g (Ing)Document91 pagesYOKOGAWA Exa Fc400g (Ing)biotech666No ratings yet

- Elastomer - WikipediaDocument15 pagesElastomer - WikipediaM Irfan KhanNo ratings yet

- Sno Pro Diagnostic Troubleshooting Guide 72 520 1Document72 pagesSno Pro Diagnostic Troubleshooting Guide 72 520 1papamatt100% (1)

- DM0412 Manual EspanolDocument21 pagesDM0412 Manual EspanolkaliNo ratings yet

- CKC Guidance Manual Jan 10 2008 PDFDocument34 pagesCKC Guidance Manual Jan 10 2008 PDFamk2009No ratings yet

- SOP of Destruction of Culture MediaDocument6 pagesSOP of Destruction of Culture MediaaKureishiNo ratings yet

- Hydrogen-Bonded Supramolecular Liquid Crystal Polymers: Smart Materials With Stimuli-Responsive, Self-Healing, and Recyclable PropertiesDocument30 pagesHydrogen-Bonded Supramolecular Liquid Crystal Polymers: Smart Materials With Stimuli-Responsive, Self-Healing, and Recyclable PropertiesNadi NaderiNo ratings yet

- Drying Shrinkage of ConcreteDocument6 pagesDrying Shrinkage of Concretecrownguard100% (1)

- Byk Bykjet 9170Document2 pagesByk Bykjet 9170ankitleedsNo ratings yet

- Gas Chromatography Troubleshooting GuideDocument12 pagesGas Chromatography Troubleshooting GuideAbhishek Banerjee100% (1)

- Mba Pom Exam 122019Document6 pagesMba Pom Exam 122019Ped SalvadorNo ratings yet

- 8.1prob Sheet Vapor Power CyclesDocument3 pages8.1prob Sheet Vapor Power CyclesAnonymous mXicTi8hB100% (1)

- Proceso: Lummus Application: Improved Technology To Produce Highest Quality Phenol andDocument5 pagesProceso: Lummus Application: Improved Technology To Produce Highest Quality Phenol andAdrian Copa JNo ratings yet

- Webasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedDocument8 pagesWebasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedAlexanderNo ratings yet

- ASHRAE Recommend 2 PDFDocument6 pagesASHRAE Recommend 2 PDFAhmed LabibNo ratings yet

- Ie 12 Lec Act IiiDocument2 pagesIe 12 Lec Act IiiLance JayomaNo ratings yet

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationVedachalam ManiNo ratings yet

- Foundry Shop Tools and ProcessesDocument37 pagesFoundry Shop Tools and ProcessesAsmitaNo ratings yet

- Rusting Chapter 3Document4 pagesRusting Chapter 3Maries San PedroNo ratings yet

- Time: 03 Hours Maximum Marks: 100 Instructions To CandidatesDocument2 pagesTime: 03 Hours Maximum Marks: 100 Instructions To CandidatesMohammed ShamsuddinNo ratings yet

- Danby Premiere Dehumidifier User's ManualDocument39 pagesDanby Premiere Dehumidifier User's ManualRick AndersonNo ratings yet

- Process of P-Xylene Production by Highly Selective Methylation of Toluene PDFDocument8 pagesProcess of P-Xylene Production by Highly Selective Methylation of Toluene PDFMarco Antonio FeriaNo ratings yet

- QIS College Engineering & Tech Session Plan Metal CuttingDocument13 pagesQIS College Engineering & Tech Session Plan Metal CuttingKalai ArasanNo ratings yet

- Electro-mechanical broaching machine modelDocument16 pagesElectro-mechanical broaching machine modelStefanNo ratings yet

- 3M Prestige 70 Exterior PBDocument3 pages3M Prestige 70 Exterior PBDiego Ramirez FuentesNo ratings yet

- Underground Cables - 010954Document23 pagesUnderground Cables - 010954lawrence momanyiNo ratings yet