Professional Documents

Culture Documents

Fb/Ek Holden Timing Gear Replacement Enthusiasts Guide: Revision Date Update

Uploaded by

andrew_harveOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fb/Ek Holden Timing Gear Replacement Enthusiasts Guide: Revision Date Update

Uploaded by

andrew_harveCopyright:

Available Formats

FB/EK HOLDEN TIMING GEAR REPLACEMENT ENTHUSIASTS GUIDE

REVISION 0

DATE June 2011

UPDATE Initial draft for review.

Table of Contents 1 2 3 4 Background .............................................................................................................................. 2 Symptoms of a Failed Timing Gear .......................................................................................... 2 Parts Required.......................................................................................................................... 3 Replacement Process .............................................................................................................. 5

Background

This document aims to provide some information regarding the process for changing a grey motor timing gear as fitted to FB and EK Holdens. It contains practical information on identification of timing gear failure, disassembly and reassembly of FB and EK Holden timing gear assemblies. It has been written to explain both workshop-type practices, and those used at the side of the road. Whilst this document is primarily related to the FB and EK Holden grey motors, much of the information is similar or identical to other early Holden motors. Much of the information below is drawn from internet forums, discussion with enthusiasts and common sense. I have used photos and other information from a wide variety of sources, particularly from the forums if anyone is offended by my use of the material, feels I have breached copyright or needs recognition, please let me know and I will correct the issue immediately. I would however like to thank Gary, Colin and Thommo for their comments on the draft a- much appreciated. Equally, I have made opinions and drawn conclusions on some of the information I have found and equipment I have owned - if anyone believes that I have made an error (or knows a better way to do something), please let me know and I will update the document... after all, the main purpose here is to help other early Holden enthusiasts. Like all things automotive, changing a timing gear comes with a risk. Leaking fuel lines can lead to fires, hands can be caught in fan blades and hot radiator water can scald (amongst other hazards). Any advice contained in this document is to be taken at the readers risk qualified mechanics should be consulted where appropriate.

Symptoms of a Failed Timing Gear

Timing gears normally show no sign of trouble until they let go normally when the car is out on the road somewhere. Cars that have been sitting for some time then started to be reused are particularly at risk, often because the timing gear oil hole has blocked with crud, and the timing gears runs dry. It is unusual for the timing gear to let go on an engine that is switched off or idling they normally fail when the engine is running on the road. The engine suddenly stops dead for no obvious reason and will not restart. The following are ways to identify a failed timing gear:

The starter motor turns over the engine more quickly than normal (because the valves are stuck in one position, with most open, and little compression occurs). Take off the rocker cover breather cap and look at the rockers when the motor is being turned over by the starter motor the rockers dont move (because the crankshaft cant turn the camshaft to drive the rockers). You can check this if you are on your own by turning the engine over with the fan blades (hold a little tension on the fan belt) whilst peering down the rocker cover. Take off the distributor cap and look at the rotor button when the motor is being turned over by the starter motor the rotor button doesnt move (because the crankshaft cant turn the camshaft to drive the distributor). You can check this if you are on your own by turning the engine over with the fan blades whilst looking at the rotor button. The fuel pump doesnt pump any fuel (because it is driven off the camshaft lobes, and the camshaft cant be driven by the crankshaft). The oil pump doesnt pump any oil (because it is driven off the distributor, which is driven off the camshaft, and the camshaft cant be driven by the crankshaft), so the red oil pressure idiot light stays lit up on the dash when the motor is being turned over by the starter motor. Not a good idea to do this for too long

Parts Required

The following parts are required to replace a timing gear: Rocker cover gasket Sideplate gasket Sideplate cork seals Fuel pump gasket Timing cover gasket

At a pinch you can reuse the existing gaskets (a smear of silicon gasket cement helps), though there is a pretty fair chance they will leak down the line (rocker cover gaskets for example you may get away with timing cover gaskets less so). There is also an oil seal in the front of the timing cover that seals against the harmonic balancer whilst you can generally get away with reusing it, now is not a bad time to replace it, especially if it is leaking. The harmonic balancer may have grooves where the seal lip runs on the balancer. Over the years the seal wears a groove in the balancer, and a new seal will sometimes leak because of this. If so, there are a number of options: you may need to try to find a better balancer with little or no groove or better still a new balancer (Rare Spares part number 7408676, American Autos part number HB17B-N, Ross tuffbond). another option is to weld the grooves and remachine, though this is not for the faint hearted! a further option is to fit a thin sleeve over the worn groove area (a kit with these sleeves and a fitment tool is available from MAHLE Clevite, see http://www.mahleclevite.com/publications/GA-5005.pdf). it may also be possible to place a washer between the harmonic balancer end and the crankshaft gear to bring the worn groove area slightly out from the normal running area of the seal on the balancer which gives the seal a unworn running surface. Note though that this will put the harmonic balancer pulley out of line with the fan and alternator pulleys, and can lead to premature fan belt failure. 3

You will also need to make a choice between a fibre, alloy or steel replacement timing gear. PRO Most quiet type of gears. Cheapest type of gears. Lightest gears. CON Least reliable type of gears (most prone to failure should the oil nozzle block). Alloy gears are two-piece (steel hub and alloy gear ring), and have been known to flog out (the steel centre separates from the alloy gear hub) over time. Can be noisier than fibre gears see Steel gears below. The steel gears have a hit-and-miss reputation for being noisy some people find no noise increase, some people find them noisy only if you change the crankshaft gear with the one that comes with the set, some people find the noise diminishes after 1000-2000 miles of use, and other people find they have gilmer belt-type whine like a supercharger. Steel gears may not "flex" even slightly when revving hard. This can cause them to shear the front of the cam clean off under heavy load. This camshaft loading has been reported anecdotally from early grey motor racers, though would be extremely rare in a road-going vehicle.

Fibre Alloy

Steel

Most reliable type of gears.

On average, most enthusiasts recommend that steel gears, followed by alloy with fibre as the least preferred option. Part Rocker cover gasket Sideplate gasket Sideplate cork seals Fuel pump gasket Timing cover gasket Timing cover seal Timing gear fibre Timing gear steel Timing gear - alloy Part number American Auto Parts JM736 KV171 KG971 92014836 TC47 PR3540 43SA MFXCAM note 2 JP5986

GMH 7411305 7415894 SP1105 7400435 7425189 7412742 note 1 7426199 7414360 -

Rare Spares H1081 7425189 VS13801 7414360 -

Permaseal JM736 KV171 KG971 JR396 -

Note1: dual lip seal. Note 2: contains both crankshaft and camshaft gears together with camshaft thrust plate.

Note that steel timing gear sets (an iron camshaft gear, a steel crankshaft gear, a camshaft thrust plate and crankshaft oil seal) are also available as (Part number GS138) from Master Engineering (12-16 Hill Street Port Elliot South Australia 5212, Telephone: (08) 85542488, Facsimile (08) 85542499, Email: nicky@masterengineering.com.au). Diecrest Engineering (Corner of Bagshaw Street and Thompsons Road Harcourt Victoria 3453, Telephone (03) 54742321, Facsimile (03) 54742536, Email info@diecrest.com.au) can also supply steel timing gears, though they generally make them on demand rather than stocking them. 4

When replacing a fibre timing gear, it is generally required to replace only the camshaft gear, leaving the original crankshaft gear intact. Timing gears are normally helically-cut, which reduces thrust on the camshaft and crankshaft. Straight-cut timing gears are available (requiring both the camshaft and crankshaft gears to be replaced together). Straight-cut gears are noisier, and offer very little performance benefit over helical cut gears they are only recommended for those seeking every last available ounce of horsepower from a grey motor (minor changes in exhaust or carburetor will make a much more noticeable power difference). You will also need to buy (or borrow) a harmonic balancer puller (from SuperCheap, Bursons, Repco etc). The puller will allow you to remove the harmonic balancer from the crankshaft without tearing the rubber bonding. The picture to the lower left shows the most common type of harmonic balancer puller available from SuperCheap, Bursons, Repco etc. The photo on the upper left and the workshop manual image below shows the original GMH type puller, which will also remove the harmonic balancer (though is a lot less common). This puller must be used for original factory harmonic balancers which do not have the holes to engage the aftermarket type puller. At a pinch, the GMH puller can be made up at home.

Replacement Process

1.

The radiator needs to come out to give access to pull the harmonic balancer and camshaft out of the motor. Allow the engine to cool. Loosen the clamp on the bottom radiator hose, and remove the radiator cap. Let the radiator drain until it is empty.

2.

3.

4.

Loosen the top radiator hose (leaving it on the thermostat housing), and loosen the bottom hose at the water pump. Undo the four AF bolts either side of the radiator. Lift the radiator up and out, taking the bottom hose with it. The fan assembly needs to come out to give access to pull the harmonic 7 balancer and camshaft out of the motor. Loosen the /16 AF bolt at the top of the generator slide. Holding under the generator, push upwards to swing it towards the motor until the fan belt is slack. Remove the fan belt. Remove the four bolts in the front of the fan blade, then remove the fan blade and pulley. The grill assembly needs to come out to give access to pull the harmonic balancer and camshaft out of the motor. Remove the front grill from the vehicle (for FB Holdens, 3 3 there are six /8 AF bolts in the front stone tray, two /8 AF bolts in the front guards, two AF bolts in the bonnet catch and three bolts which will be half seized and covered in gunk in each indicator housing tucked up behind the guards).

5.

The harmonic balancer needs to be slid off the end of the crankshaft to allow the timing cover to be removed. Place the harmonic balancer puller centre bolt into the crankshaft snout. Screw the three puller bolts into the three holes in the front of the harmonic balancer, making sure they are even. Use a long screwdriver to jam between the puller bolts (to stop the crankshaft turning) whilst screwing in the puller centre bolt. The harmonic balancer will slide off the end of the crankshaft.

6.

The timing cover needs to be removed to access the timing gear. Undo the seven AF bolts and six slot-head screws and remove the timing cover. The timing gear should appear to be stripped of teeth. Clear out any oil, stripped teeth and fibre sludge from the bottom of the timing gear cavity.

7.

The fuel pump needs to be removed to either hold the camshaft or to allow it to be removed. Disconnect and block the fuel lines from the fuel pump. For FB and earlier Holdens, also disconnect the vacuum motor line. Remove the two AF bolts either side of the fuel pump, then lift out the pump.

8.

It is possible to remove the old timing gear and refit a new one with the camshaft still in the car. This option is popular if you are stuck in the middle of nowhere, and cant get the car back home. To remove the gear, a grinder and/or drill is used to carefully grind off the top half of the fibre gear, then grind through the steel gear centre and front plate, taking care to avoid grinding through to the camshaft. Use a small cold chisel to split the steel gear centre. A screwdriver is then used to pry the old timing gear off. A pry bar, screwdriver or tyre iron is then put in through the fuel pump hole and held against the fuel pump cam lobe to help stop the camshaft from being knocked backwards whilst the new gear is tapped on with a hammer, using a socket as a drift. If the cam moves backwards, it will drive out the rear cam bearing plug. Note that on the timing gear there is a small dot located on a gear tooth valley. There is also a dot on the crankshaft gear above one tooth. The timing gear must be hammered on such that the crankshaft and camshaft dots line up. Once the camshaft is home, the fuel pump, timing cover, harmonic balancer, fan and radiator assemblies are reinstalled and the car is ready to go.

The replace timing gear without removing camshaft process described in step 8. above can get you out of trouble at the side of the road. However it is not recommended as the camshaft thrust 3 clearance cannot be set, there is a significant risk of driving out the 1 /8 camshaft rear plug or damaging the camshaft bearings. It is possible to drill and tap a thread in the end of the camshaft, then use a bolt and washers to pull the new gear onto the camshaft. This avoids driving the rear camshaft plug out (a similar process of drilling and tapping two holes in the crankshaft gear then using a bracket can be used to pull the crankshaft gear off). Drilling a camshaft is not for the faint hearted though. The process below assumes that the camshaft will be removed from the car, and continues from step 7. above. 9. The rocker cover needs to be removed to access the rocker gear. 5 Remove the two /8 AF nuts from the top of the rocker cover, then remove the cover, lifting it out gently around the fuel, vacuum and heater hoses.

10. The rocker gear needs to be removed to access the pushrods. Remove the ten AF bolts and two 3 AF nuts from the rocker shafts. Using a flare nut spanner, undo the /8 AF flare nut from the camshaft oil pipe. Lift off the rocker assembly.

11. The pushrods need to be removed to access the lifters. Lift out each of the twelve pushrods (one at a time!), pushing them sequentially through a piece of cardboard. Label the cardboard so that you are confident that the pushrods go back into their original holes. By putting the pushrods back into their original positions, you will probably not need to reset the tappets later. 12. The sparkplugs need to be removed to access the sideplate. Use some masking tape to label the sparkplug leads (starting with 1 at the front of the car) then remove the leads from the sparkplugs, leaving them hanging on the distributor. Also disconnect the lead from the top of the coil. Using a 13 /16 AF plug socket, remove the spark plugs.

13. The coil needs to be removed to access the sideplate. Undo the coil mounting with a flat-bladed screwdriver and lay the coil to one side on the inner fender. 7

14. The distributor needs to be removed to access the sideplate and allow the camshaft to come out. 3 Using a flare nut spanner, undo the /8 AF flare nut on the vacuum advance line on the front of the 9 distributor. Undo the /32 AF nut from the side of the distributor and disconnect the black earth lead. Undo the AF bolt from under the front of the distributor and lift the distributor assembly out of the motor. Plug the distributor hole with clean rag to prevent anything falling into the motor (like sideplate screws). 15. The sideplate needs to be removed to access the lifters. Remove the fifteen slot-head sideplate screws, and the additional screw that holds the engine breather pipe (walking stick) in place. The breather pipe screw is underneath the engine rails, and may require getting under the vehicle to get at it. If the vehicle is jacked up to access this screw, make sure that stands are used. Remove the engine side plate and breather, lifting them out carefully around the vacuum line. 16. The camshaft lifters need to be removed to allow the camshaft to slide out. Remove each of the twelve camshaft followers (one at a time!) by putting your finger into the top of them and pulling them out. Lay them out on a clean piece of paper in order, labeling the paper so that you are confident that the followers go back into their original holes. By putting the followers back into their original positions, you will probably not need to reset the tappets later. 17. There is a camshaft thrust plate that will prevent the camshaft from being pulled out of the motor. Turn the camshaft fibre timing gear around (by tapping with a drift on the camshaft fibre gear holes) until the two camshaft fibre gear holes are vertical. Use a slot-head screwdriver through the camshaft fibre gear holes to undo and remove the two slot-head bolts from the camshaft thrust plate. Pull the camshaft and attached fibre gear out of the engine, supporting the camshaft as it comes out to protect the camshaft bearings inside the motor.

18. The oil slinger ring fitted to the end of the crankshaft will prevent the new timing gear/camshaft assembly from sliding into the motor. Use a shifting spanner on the crankshaft (the crankshaft is round, but the spanner will catch on the key), turn the crankshaft such that the small dot on the crankshaft gear points towards the camshaft hole (about the 10 oclock position this is to help line up the camshaft later). Using a small drift, tap down one end of the crankshaft key so that the key flips up (they key is a half-moon shape). Tap the key out and remove the oil slinger ring from the end of the crankshaft.

19. The timing gear oil nozzle can often block, leading to lack of oiling (and often failure of fibre timing gears). The nozzle screws into the front of the engine (circled in the picture to the right) take note which direction it is facing, as it must point such that it oils the gears. Remove the nozzle and check that the oil gallery behind it is clear (gently with a piece of wire). Check the nozzle is clear, then reinstall it, making sure it is pointing in the right direction. Put a long flat-bladed screwdriver down the distributor hole and turn the screwdriver clockwise to engage the oil pump. Continue turning until a good flow of oil comes out of the timing gear oil nozzle, confirming it is clear. Everything is now apart time to change the gear and get it all back together again. 20. It is advisable to use a hydraulic press (and associated dies) to press the fibre timing gear off the camshaft and the new timing gear on. In the absence of a hydraulic press, many enthusiasts choose to grind the old one off, and hammer the new one on. I will describe the grind/hammer process below. Hold the camshaft fibre gear in a vice, taking care that the camshaft bearings/lobes are not touching the vice. Cover the camshaft to keep (most) of the grinding crap off the camshaft. Carefully grind off the top half of the fibre gear, then grind through the steel gear centre and front plate, taking care to avoid grinding through to the camshaft. Use a small cold chisel to split the steel gear centre. Tap the camshaft out of the fibre gear with a drift, taking care to support and catch the camshaft as it moves.

21. Using a small drift, tap down one end of the camshaft key so that the key flips up. Tap the key out. Clean the end of the camshaft and the key with emery paper. Tap the key back into the camshaft. 22. Lightly oil the camshaft, key, steel gear and keyway. Place the camshaft on the ground on a piece of softwood, and align the steel gear to the keyway. Take care that the gear is facing so that the dot side us up (concave side down). Using a 1 socket as a drift, tap on the steel gear onto the camshaft. The timing gear is driven on whilst stopping periodically to check with a feeler gauge the gap (end play) between the thrust plate and the camshaft journal see image to the right above. Drive the gear on until there is a clearance of 0.004 to 0.006 between the thrust plate and journal. Note that warming the steel timing gear (not to red hot, but warm enough to handle) will enlarge the centre hole and make it easier to drive on (especially on a frosty cold morning!). 23. Plug the camshaft hole in the front of the motor with some clean rag, then clean the timing cover gasket face. Remove the rag.

24. Lightly oil the lobes and bearings of the camshaft. Support the camshaft as it slides into the block, taking care not to mark the bearings inside the motor. Note that on the camshaft gear there is a small dot located on a gear tooth valley. There is also a dot on the crankshaft gear above one tooth. As the camshaft slides home, turn the camshaft so that the crankshaft and camshaft dots line up. 25. Clean the crankshaft key with some emery paper. Slide on the oil slinger ring, then tap the crankshaft key in place with a small drift until it is level. 26. Use a shifting spanner on the crankshaft (it will catch on the key), turn the crankshaft until the camshaft gear holes are vertical. Insert and tighten the camshaft thrustplate screws. Note that it can be difficult getting the screws into the holes in the camshaft gear. One trick is to use a large blade screwdriver, and stick the screws to the screwdriver with a dollop of grease. If you do drop the screws behind the gear, a magnet will help fish them out. 27. Install the camshaft followers, taking care that they are each put back into their original holes. Give the followers a light squirt of oil before putting them in. 28. Cover the camshaft followers with some clean paper/rag to stop anything falling into them. Clean the side plate and gasket face. The side plate cork gasket can be fiddly to get in place one trick is to use a smear of gasket cement (silicon) or grease to stick it to the sideplate, using the sideplate screws to align it. Also install the six spark plug hole cork gaskets onto the side plate. Install the sideplate and engine breather pipe. 29. Cover the fuel pump hole in the engine to stop anything falling in, then clean the fuel pump and gasket face. Install the fuel pump and gasket, taking care that the fuel pump arm slides up above the camshaft lobe. 30. Reinstall the spark plugs and coil. 31. Reinstall the pushrods, taking care that they are each put back into their original holes. 32. Place the rocker shafts back onto the two rocker cover studs. As the rocker shafts lower, ensure the rockers sit onto their pushrods. Connect the camshaft oil pipe with a flare nut spanner, then tighten the rocker bolts to 15-20 ftlb torque. 33. Clean the timing cover and gasket face. Put the timing cover and new gasket in place with the screws/bolts loose. There is a fair bit of slop in the timing cover, which can lead to the crankshaft oil seal not sitting right. Oil the crankshaft and key, then fit up the harmonic balancer. Place a piece of wood packing in front of the harmonic balance, then use a hammer to drive the balancer onto the crankshaft. As the balance drives home, the oil seal will centre. Tighten the screws and bolts that are accessible, then use the puller to remove the harmonic balancer. Tighten the remaining screws/bolts, then reinstall the harmonic balancer, tapping it home until it is flush with the end of the crankshaft. Note that like the steel timing gear, warming the harmonic balancer will enlarge the centre hole and make it easier to drive on, especially on a cold morning. 34. Install the fan pulley, fan and fan belt. Push the generator away from the motor then tighten the generator slide bolt. 35. Install the radiator and radiator hoses. Fill the radiator with coolant. 36. Install the grill. 37. Using the fan, turn the motor over until cylinder #1 is in the firing position. This can be seen by looking at cylinder #6 (the one closest to the firewall). Watch carefully until you can see one of the cylinder #6 rockers rising (and just stopping), and the other cylinder #6 rocker just starting to fall. This is referred to as cylinder #6 rocking (i.e. one rocker just finishing and one just starting). As you are turning the motor over, you should hear the fuel pump wheezing, and the glass fuel bowl filling with fuel. 10

38. Check the timing mark by looking at the back of the motor under the distributor. In the timing window you should be able to see a white mark on the flywheel (this is the timing ball it is often marked with white paint to make it easier to see). Use the fan to move the motor backwards or forwards (just a touch) until the timing ball is directly under the timing window pointer.

39. With the distributor in your hands or on a bench, take the distributor cap off the distributor and look carefully at the steel rim where the cap sits. There is a small mark on the rim near the vacuum advance module (you may need to clean the last fifty years of crap off the rim to see the mark it is faint). The image to the right shows roughly where to look. This mark is where the rotor button points when it is firing cylinder #1. Turn the rotor button around (which spins the distributor shaft) until the rotor button is pointing to the mark. 40. Look at how the oil pump drive tang at the bottom of the distributor is pointing. Imagine the distributor in the motor, and how the oil pump tang would face (side to side across the block). Using a long screwdriver down the camshaft hole, engage the oil pump and turn it until it is side-to-side, ready to engage the distributor. 41. Reconnect the black earth lead to the distributor, then gently lower the distributor down the distributor hole, allowing it to turn very slightly as the gear engages. It may be necessary to turn the motor (via the fan) slightly until the distributor drops (dont force it). You can see the distributor has dropped when the advance/retard plate at the base of the distributor is sitting on the block. Once the distributor has dropped, check the white timing mark is still under the pointer in the timing window, and that the rotor button is still pointing to the mark on the distributor rim. If you missed the drive gear by one tooth, the rotor button wont be pointing correctly to the mark take it out and try again. Once it is aligned (white mark in the timing window pointer, cylinder # 6 rocking and rotor pointing to the mark), install the bolt in the distributor advance/retard plate. Connect the vacuum advance line flare nut. 42. Install the distributor cap and leads, taking care to get the right lead to its cylinder (use the labels you made earlier. Remember that the distributor spins clockwise (viewed from above), and the firing order is 1-5-3-6-2-4. 43. Install the rocker cover and new gasket. 44. Test start the motor it may not run as easily as normal, as the timing is probably out. Set the motor timing with a timing light until the timing ball is directly under the timing window pointer.

11

45. It is possible when replacing the timing gear that you cannot get the timing ball directly under the timing gear window. The symptoms of this are: the timing mark appears to the far right of the window no matter how far you advance the distributor. It feels like you have the distributor off by one tooth. However, if you move the distributor around one tooth, the timing mark appears to the far left of the window no matter how far you retard the distributor. It feels like you are stuck between too much advance, and too much retard, and can be caused by the old timing fibre timing gear having had a lot of slop. If this is the case: with the engine stopped, move the engine around until the until the timing ball is directly under the timing window pointer and the distributor is pointing to cylinder #1. loosen the bolt in the distributor advance/retard plate and set the distributor to about way between full advance and full retard (i.e. zero advance and zero retard) on the advance/retard plate. slacken the slot-headed clamp around the distributor body. with the engine and a timing light running, turn the distributor body until the timing ball is directly under the timing window pointer. tighten the slot-headed clamp around the distributor body. 46. Run the motor up to temperature, looking for any oil leaks. Allow the motor to cool then topup the radiator coolant.

12

You might also like

- 1999 Isuzu Rodeo UE US Version Service ManualDocument2,613 pages1999 Isuzu Rodeo UE US Version Service ManualRichard Tani100% (7)

- SM - 47 Hemi Engines Repair Manual Easy WayDocument449 pagesSM - 47 Hemi Engines Repair Manual Easy WayΜιχάλης Χατζηαντρέας50% (6)

- NV5600 Repair ManualDocument152 pagesNV5600 Repair ManualLarry Bloodworth10% (20)

- 2500HD Wiring 2004Document83 pages2500HD Wiring 2004vixentd100% (3)

- Motor 5.7 HemiDocument3,268 pagesMotor 5.7 HemiAlex Maceira GraterolNo ratings yet

- Ford Bronco Workshop Manual (V8-351 5.8L VIN G 2-Bbl (1982) )Document3,163 pagesFord Bronco Workshop Manual (V8-351 5.8L VIN G 2-Bbl (1982) )Marcos RomeroNo ratings yet

- 2001manualdetallerranger 131209153120 Phpapp02 PDFDocument547 pages2001manualdetallerranger 131209153120 Phpapp02 PDFiñaki100% (2)

- LR Tech IntroDocument432 pagesLR Tech Intromagellan_phineas100% (11)

- 1984 GMC Light Duty Trucks Service ManualDocument1,746 pages1984 GMC Light Duty Trucks Service ManualRoberto Stefani94% (17)

- ST 330-87-1987 Chevrolet Light Duty Truck Service ManualDocument1,382 pagesST 330-87-1987 Chevrolet Light Duty Truck Service Manualmanuel100% (9)

- 2000 Chevrolet Camaro & Pontiac Firebird Service Manual Volume 1Document764 pages2000 Chevrolet Camaro & Pontiac Firebird Service Manual Volume 1Sean100% (9)

- Download Free Manuals from www.mispdf.com.arDocument401 pagesDownload Free Manuals from www.mispdf.com.arMauricio AmadorNo ratings yet

- 50-65 Ford Interchange PDFDocument155 pages50-65 Ford Interchange PDFVincent LoVerde100% (6)

- 1949-1950-1951 Ford Passenger Car Shop ManualDocument321 pages1949-1950-1951 Ford Passenger Car Shop Manualtattooeddood98% (41)

- BorgWarner 35 ManualDocument76 pagesBorgWarner 35 ManualMattH3100% (2)

- Ford Coyote Engines - Revised Edition: How to Build Max Performance: How to Build Max PerformanceFrom EverandFord Coyote Engines - Revised Edition: How to Build Max Performance: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (1)

- How To Rebuild Your Small-Block FordDocument163 pagesHow To Rebuild Your Small-Block Fordcatalin9494100% (4)

- Ls1 Engine Installation Guide: Design and NotesDocument36 pagesLs1 Engine Installation Guide: Design and NotesHelimenes De Jesús100% (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Volvo 940 1994 Wiring DiagramDocument173 pagesVolvo 940 1994 Wiring DiagramQuercus288% (8)

- 2003 Chevy Suburban Wiring DiagramsDocument152 pages2003 Chevy Suburban Wiring Diagramsmike80% (5)

- 98 Jeep Cherokee Repair ManualDocument1,947 pages98 Jeep Cherokee Repair ManualTodd Gregoire85% (13)

- NV3500 - 5LM60 - HM290 - STYLE REPLACES CHEVY C/K 1500/2500 - 1988-98 - S10 1990-98 Dodge DAKOTA, RAM, R1500 1994-98Document11 pagesNV3500 - 5LM60 - HM290 - STYLE REPLACES CHEVY C/K 1500/2500 - 1988-98 - S10 1990-98 Dodge DAKOTA, RAM, R1500 1994-98Roberto Nolasco100% (2)

- LQ4 LQ9 Engine Manual L510016Document229 pagesLQ4 LQ9 Engine Manual L510016Kyle Dubay100% (3)

- Detroit 8.2 v8Document25 pagesDetroit 8.2 v8Jose Juan Davila100% (3)

- Ford 351 Cleveland Engines: How to Build for Max PerformanceFrom EverandFord 351 Cleveland Engines: How to Build for Max PerformanceRating: 5 out of 5 stars5/5 (8)

- TDR64 RebuildingTheNV5600Document6 pagesTDR64 RebuildingTheNV5600Matthew Burkhalter100% (2)

- HD Maintenance and LubricationDocument42 pagesHD Maintenance and LubricationCarloVanZylNo ratings yet

- Ford AODDocument10 pagesFord AODDrisy Garcia100% (3)

- Jeep Cherokee Service Manual 2000Document1,528 pagesJeep Cherokee Service Manual 2000pitchao1100% (9)

- Eldred AnecdoteDocument14 pagesEldred Anecdoteandrew_harve100% (1)

- 2012.0 Ranger P375 Body Equipment Mounting Manual July 2014Document86 pages2012.0 Ranger P375 Body Equipment Mounting Manual July 2014Matthew Hutchins100% (1)

- Chevy 6.5 DieselDocument17 pagesChevy 6.5 DieselJerad Bixler75% (4)

- Chevrolet Cruze BCMDocument4 pagesChevrolet Cruze BCMAndrés Caleb Blanco GuzmanNo ratings yet

- FB/EK Holden Holley 350 GuideDocument66 pagesFB/EK Holden Holley 350 Guideandrew_harve100% (1)

- FORD Falcon XA Repair ManualDocument770 pagesFORD Falcon XA Repair ManualMark Kenzie100% (10)

- Ford Flathead Engines: How to Rebuild & ModifyFrom EverandFord Flathead Engines: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (5)

- Workshop Manual 1999 - 3000ppDocument3,265 pagesWorkshop Manual 1999 - 3000ppKatsaras Sotiris100% (5)

- Chevy/GMC Trucks 1973-1987: How to Build & ModifyFrom EverandChevy/GMC Trucks 1973-1987: How to Build & ModifyRating: 3 out of 5 stars3/5 (1)

- Check Chart Common - Specs - English - All BRIGGS & STRATTON - Engines PDFDocument1 pageCheck Chart Common - Specs - English - All BRIGGS & STRATTON - Engines PDFigrekqa67% (9)

- Carburettor GuideDocument148 pagesCarburettor Guideandrew_harve95% (43)

- Oil FilterDocument30 pagesOil Filterandrew_harve100% (5)

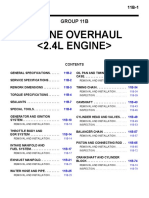

- Engine Overhaul : Group 11BDocument80 pagesEngine Overhaul : Group 11BДмитрийNo ratings yet

- S14 Silvia With SR20DET Factory Service ManualDocument815 pagesS14 Silvia With SR20DET Factory Service ManualMuZaChi100% (1)

- 1998 XJ Jeep Cherokee PDFDocument582 pages1998 XJ Jeep Cherokee PDFMeryori Lara de Villarroel100% (3)

- 3 Stromberg SingleDocument7 pages3 Stromberg SinglevanapeerNo ratings yet

- 3.5L EngineDocument795 pages3.5L EngineCarlos Sanchez NajeraNo ratings yet

- Holden Commodore VZ Fault CodesDocument5 pagesHolden Commodore VZ Fault Codesashleyshaw0% (1)

- FB/EK Holden Stromberg Carburettion Enthusiasts Guide Addendum 1Document24 pagesFB/EK Holden Stromberg Carburettion Enthusiasts Guide Addendum 1andrew_harve86% (7)

- Nissan Murano CVTDocument234 pagesNissan Murano CVTtroublezaur100% (10)

- CVTDocument25 pagesCVTBen George100% (1)

- Holley 2 Barrell Carb 350cfmDocument12 pagesHolley 2 Barrell Carb 350cfmjaydooNo ratings yet

- SU Carbs TuningDocument13 pagesSU Carbs TuningXDBDNo ratings yet

- Turner Compact Plus Transmission ManualDocument74 pagesTurner Compact Plus Transmission Manualbeto06100% (8)

- 1988 g30 Chevy Van Repair ManualDocument178 pages1988 g30 Chevy Van Repair Manualwwwebcat75% (8)

- Fb/ek Holden Three-Speed Crashbox Enthusiasts GuideDocument215 pagesFb/ek Holden Three-Speed Crashbox Enthusiasts Guideandrew_harve89% (18)

- Obd Ii Pids: From Wikipedia, The Free EncyclopediaDocument18 pagesObd Ii Pids: From Wikipedia, The Free EncyclopediacocorocaraNo ratings yet

- ECM Calibration Transmission Software Enhancements Lexus 570 2016 2017 CanadaDocument7 pagesECM Calibration Transmission Software Enhancements Lexus 570 2016 2017 CanadaSajjad HussainNo ratings yet

- Caterpillar Diagrama Electrico Cargador 950fiiDocument2 pagesCaterpillar Diagrama Electrico Cargador 950fiiDiego Pizarro100% (1)

- 2010 Honda Fit PDIDocument7 pages2010 Honda Fit PDIclicqNo ratings yet

- ECM Trucks PDFDocument23 pagesECM Trucks PDFMarco Melchor100% (5)

- DDC DieselDocument2 pagesDDC Dieseldolphingroup100% (1)

- MINI Cooper Repair Manual - 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, and 2010Document1 pageMINI Cooper Repair Manual - 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, and 2010sultan_1430% (5)

- Nissan RB EngineDocument9 pagesNissan RB EngineNaufal Rizqur RahmanNo ratings yet

- 2008 Dodge Nitro 30980 PDFDocument434 pages2008 Dodge Nitro 30980 PDFRoms CuevasNo ratings yet

- Stromberg NeedleDocument2 pagesStromberg Needlevanapeer100% (2)

- Assessment Cover Sheet: Student UseDocument11 pagesAssessment Cover Sheet: Student UseARSHAD TURINo ratings yet

- Timing Gear PDFDocument12 pagesTiming Gear PDFTriyonoNo ratings yet

- Fb/Ek Holden Nasco Warmaride Heaters Enthusiasts Guide: Revision Date UpdateDocument63 pagesFb/Ek Holden Nasco Warmaride Heaters Enthusiasts Guide: Revision Date Updateandrewbower280% (5)

- Stromberg Carburettor Model BXV-2 Single Barrel Downdraft Parts and OperationDocument36 pagesStromberg Carburettor Model BXV-2 Single Barrel Downdraft Parts and OperationMeteorite Khan100% (1)

- Holden Commodore VR Fault Codes & InstructionsDocument4 pagesHolden Commodore VR Fault Codes & InstructionsShareeNo ratings yet

- Mercruiser Technical DataDocument45 pagesMercruiser Technical Datajose antonio MelladoNo ratings yet

- Land Speed Record Norman SuperchargersDocument5 pagesLand Speed Record Norman Superchargersandrew_harveNo ratings yet

- cm284 j843 Engine PDFDocument219 pagescm284 j843 Engine PDFкостя костяNo ratings yet

- Rough Terrain Vehicle Using Rocker Bogie MechanismDocument7 pagesRough Terrain Vehicle Using Rocker Bogie MechanismKalai SelvanNo ratings yet

- L36GSI: VGF Series Gas EngineDocument2 pagesL36GSI: VGF Series Gas EngineferyNo ratings yet

- IRC 30D New Qualified Plug-In Electric Drive Motor Vehicle Credit Internal Revenue ServiceDocument1 pageIRC 30D New Qualified Plug-In Electric Drive Motor Vehicle Credit Internal Revenue ServiceJohnNo ratings yet

- A Brief Study of Cylinder DeactivationDocument21 pagesA Brief Study of Cylinder DeactivationwarcellNo ratings yet

- The Stinger BrochureDocument17 pagesThe Stinger BrochureYang Y.No ratings yet

- Kepb032804 D61ex-15e0Document654 pagesKepb032804 D61ex-15e0Matheus FraguasNo ratings yet

- GOLDEN 60-65-75-85 Compatto 60V-75VDocument184 pagesGOLDEN 60-65-75-85 Compatto 60V-75VgkyankielNo ratings yet

- Mercedes-Benz 300SL W 198: Assembly Manual & User's GuideDocument8 pagesMercedes-Benz 300SL W 198: Assembly Manual & User's GuidematerpcNo ratings yet

- Water Jacket Curves - C7.1 Marine Propulsion EngineDocument3 pagesWater Jacket Curves - C7.1 Marine Propulsion EnginejudarangocaNo ratings yet

- Detroit S60 SpecsDocument2 pagesDetroit S60 Specsgrgramm50% (2)

- How Tata Made the World's Cheapest Car PossibleDocument11 pagesHow Tata Made the World's Cheapest Car PossibleAkash KarakNo ratings yet

- Focus ItemsDocument4 pagesFocus Itemsvishal jaatNo ratings yet

- ServiceBrochure 8.5x11 EN PDFDocument4 pagesServiceBrochure 8.5x11 EN PDFSantiago Rodríguez CantoNo ratings yet

- MG Tuning and MaintenanceDocument109 pagesMG Tuning and Maintenanceclaytoncnc100% (1)

- Explorer ManualDocument545 pagesExplorer ManualWilfer Castaño ToroNo ratings yet

- OFFER DEUTZ BF4L1011F Hernedez Reyes PDFDocument3 pagesOFFER DEUTZ BF4L1011F Hernedez Reyes PDFjorge adalberto hernandez reyesNo ratings yet

- DAF Retarder Systems 64739 enDocument2 pagesDAF Retarder Systems 64739 enDardan HusiNo ratings yet