Professional Documents

Culture Documents

Brussels01 O&M

Uploaded by

Kavin KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brussels01 O&M

Uploaded by

Kavin KumarCopyright:

Available Formats

State of the Art and Technology Trends for Offshore Wind Energy: Operation and Maintenance Issues

G.J.W. van Bussel, A.R. Henderson Section Wind Energy, Faculty Civil Engineering and Geosciences Delft University of Technology, Stevinweg 1, 2628 CN Delft, The Netherlands; C.A. Morgan (Garrad Hassan and Partners Ltd); B.Smith (Kvaerner Oil&Gas); R.Barthelmie (Ris); K. Argyriadis (GL Wind); A. Arena (ENEA); G. Niklasson (Vindkompaniet); E. Peltola (VTT).

ABSTRACT: This paper addresses the Operation and Maintenance issues that have been assembled within the Concerted Action on Offshore Wind Energy. Experience obtained so far regarding the operation and maintenenace of the existing wind farms at sea is summarised. Trends regarding access improvement, maintenance strategies and O&M modelling are addressed as well as the design modifications necessary for future offshore wind turbines. It is concluded that a further adaptation of the windturbines and of the O&M procedures has to take place in order to comply with the harsh maritime environment. Part of is in a design for increased reliability and for an offshore wind farm adapted O&M strategy. This will also include extensive remote control and monitoring facilities. In a later stage a real "farm like design approach" is needed to reduce major maintenance cost and increase availability Keywords: Offshore wind farms, O&M, Maintenance Reliability Availability, Accessibility, RAMS, Wind Farm Design. adequate environmental protection for virtually all components exposed to sea conditions.

1 INTRODUCTION 2 O&M OFFSHORE EXPERIENCE

At present a relatively small amount of wind turbines have been placed in an offshore environment. Experience started with the location of a 220kW windturbine just off the coast in Sweden. The projects that followed afterwards have all been realised at rather benign sites, with the exception of two 2 MW wind turbines located in the North Sea 2 km in front of Blyth Harbour (U.K). Future offshore wind farms will be realised both at inshore sites, mainly around Denmark and in the Baltic, at North Sea locations and at a number of sites around the UK and Ireland. These wind farms will be of a larger scale, both in the number of turbines and in their size. Operation and maintenance of offshore wind farms is more difficult and expensive than equivalent activities in onshore wind farms. Offshore conditions cause more onerous erection and commissioning operations and the accessibility for routine servicing and maintenance is a major concern. During harsh winter conditions, a complete wind farm may be inaccessible for a number of days due to sea, wind and visibility conditions. Even given favourable weather conditions, operation and maintenance tasks will be more expensive than onshore, being influenced by the distance of the OWECS from shore and harbour, the exposure of the site, the size of the OWECS, the reliability of the turbines, and the maintenance strategy under which they are operational. Offshore installations require special lifting equipment to install and to change out major components. Such lifting equipment can usually be sourced locally and at short notice for onshore wind farms. The severe weather conditions experienced by an OWECS dictate the requirement for high reliability components coupled with 2.1 O&M costs Rather then quoting the costs of O&M in terms of a percentage of the investment, it is more relevant for the overall picture of the cost break down of offshore wind electricity to present it as a percentage of the kWh costs.

I n v e s t m e n t &

O

2 5

&

-

M

3 0 %

i s s i o n i n g

7 5

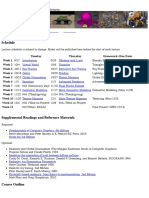

Figure 1: O&M costs as percentage of the LPC From the Opti-OWECS [1] study it came out that a percentage of around 25% of the Levelised Production Costs (LPC) [2] is a typical order of magnitude. The information obtained through questionnaires within the Concerted Action confirmed this findings for the projects that have been realised so far. 2.2 Availability The availability of a wind farm, defined as the percentage of time it is able to produce electricity, is a function of the reliability, maintainability and serviceability of the hard- and software used in the whole system. For an offshore windfarm however the accessibility of the site for O&M hardware equipment as well as the adopted maintenance strategy are of an equal importance for the achieved availability level

R eliability (failures/year)

M aintainability (ease of repair)

S erviceability (ease of service )

accessibility of the site

theoretical availability

maintenance strategy

actual availability

Figure 2: Availability as function of machine properties, site accessibility and maintenance strategy Vestas cite a comparison between availability rates for the Fjaldene onshore wind farm and Tuno Knob offshore wind farm [3]. The average availability for Fjaldene is quoted as 99.3% mainly due to the proximity of this windfarm to Vestas Central Service Department. Tuno Knob average availability is quoted as; 97.9%, 98.1%, and 95.2% for the years 1996 to 1998 respectively [4]. 2.3 Service and Maintenance visits The service demand of the present generation of offshore wind turbines in terms of man-hours is in the order of 40 to 80 hours [5]. Service visits are paid regularly, (except in the more demanding first year) about every six months. A more major overhaul will be undertaken every five years, and will take around 100 man-hours to complete. [6]. Experience from Tuno Knob show that the total number of service visits have been about 35 to 70 visits per year, an average of approximately 5 visits per turbine per annum. The number of cancelled visits (last moment cancellations due to weather) makes up about 15% relative to the number of service visits realised. [7]. 2.4 Component Reliability 2.4.1 Blades Current OWECS utilise a three bladed configuration, and it appears that this will continue to be the popular choice of turbine manufacturers. However, two bladed configurations incorporating alternative hub structures may see a rise in popularity given t e opportunity to operate h turbines at higher rotor speed and without visual constraints. The main advantages from a reliability perspective are the reduction in the number of components, reduced complexity of the hub and easier rotor lifting 2.4.2 Gearbox Onshore turbine manufacturers, notably Enercon and

1 kV for most turbines. Halved lifetime maintenance costs as well as arguable benefits of up to 20% higher power conversion efficiencies have been claimed [8]. Aerodyn who are currently designing the 5MW Multibrid Technology favour a drive -train consisting of single stage planetary gears, combined with a slow rotating generator, therefore eliminating fast-running components which are prone to wear. [9]. In general, induction generators require less maintenance than synchronous generators. They do not require a DC source and being inherently simpler and robust are the most common generators in onshore wind turbines. To protect standard induction generators from marine environments, the generators is totally enclosed with integral insulation to protect the internals from salt and high levels of moisture. Onshore generators rely on air-cooling, which is not recommended for offshore applications. Closed system water cooling or air -to-air heat exchange prevents the risk of corrosion from maritime cooling air. 2.4.4 Electrical and control system Electrical and control system failures account for the highest percentage of failures. For the year 2000, failures of electrical and controls systems accounted for exactly 50% of the need for wind turbine repairs [10]. Potting of electronic printed circuit boards and reduction in the number of components are necessary for offshore conditions. 2.4.5 Hydraulic systems Elimination of problematic hydraulic systems employed in yaw damping, blade pitching and breaking systems should be realised wherever possible. Electrical actuation is preferable and eliminates the possibility of oil leakage leading to secondary component failure and potential fire risks.

100%

Availability

90% 80% 70% 60% 50% 100 % (onshore) 80 % (near shore) 60 % (offshore) 40 % (remote offshore)

Offshore adapted

Vessel accessibility

Figure 3: Availability as function of vessel accessibility of a 100 unit offshore windfarm.

Lagerwey, specialise in direct drive generators therefore eliminating the need for a gearbox. Current offshore turbines manufactured by leading manufacturers favour geared drive transmissions. Being the widely recognised as the number one item for mechanical failure and servicing supervision, it would appear a progressive step to move to direct drive systems. 2.4.3 Generator ABBs Windformer is a large diameter gearless generator using permanent m agnets rather than coils or electromagnets. No transformer is required as the power is produced at 25 kV DC, compared with AC at less than

3 TRENDS IN OPERATION AND MAINTENANCE OF OWECS

3.1 Access methods The accessibility of a given offshore site can be determining in the economy of a project. A relation between accessibility and availability is shown in figure 3. The graph was taken from results of an expert system, described in [11] for a 100 unit wind farm site with offshore adapted wind turbines, for a given maintenance strategy using vessels for crew transport.

Typically Danish inshore sites, such as Vindeby and Tuno, have an average accessibility by vessel of around 85%. For harsher conditions, such as in the North Sea, the accessibility with a standard vessel may well drop to values as low as 60%. Thus there is a strong quest for improved access methods in order to improve the availability of a wind farm and hence its economic viability. Improve ments made to the base of OWECS to facilitate safe personnel access include: Fixed platforms fixed to tower above splash zone with fender posts to absorb vessel impact Flexible gangways extended from the vessel and held in the lee of the OWECS base. Installation of friction posts against which the vessel maintains a forward thrust during transfer Facility for winching the vessel out of the water during harsh sea conditions Winch / netting for personnel and equipment

Whenever remote monitoring techniques become sufficiently mature they can be used to adopt a maintenance strategy that guided by the status of the components. Maintenance visits can be paid just in time, in order to prevent failure of the windturbine and of the other monitored components of the wind farm.

Figure 5: Built in crane for exchange of nacelle components. Enron 1,5S Offshore windturbines at Utgrunden, SE. 3.4 O&M modelling A thorough assessment of the operation in a large offshore windfarm cannot take place on the backside of an envelope. One of the reasons is that both the accessibility of the site as well as the occurrence of failure are of a stochastic nature. Thus methods are currently in development to predict the extent and the costs of O&M operations for planned future windfarms. These methods range from simple probabilistic methods to determine the occurrence of suitable weather windows for a given operation[13] to expert systems[11], based upon trend lines generated by an extensive Monte-Carlo simulation model.[14] In the Monte Carlo method, the site accessibility as well as the failures of the wind turbines in the OWECS are simulated stochastically upon an hour to hour basis. The response in terms of deployment of maintenance and repair crew, and equipment, is simulated simultaneously in the model. This results in the determination of the instantaneous and overall availability of the OWECS and of the instantaneous and overall costs associated with the adopted main tenance strategy under the assumed site conditions.

Figure 4: Offshore Access system using a flexible gangway

3.2 Lifting facilities Sometimes the failure of a large component requires its replacement. On land a crane of sufficient size is often available on demand. At see the mobilisation time might be significant. This will further reduce the availability of the windfarm. The use of standard offshore lifting equipment is technically possible. Crane vessels, flat bottom sheer leg barges, jack-up barges and jack-up vessels can be used. Costs of such equipment are high and will become a serious problem whenever the lifting height exceeds 80 m. [6]. Part of the adaptation of wind turbines for offshore conditions is the provision of built in lifting facilities. Large components, such as generator, gearbox and sometimes even rotor blades can be lowered to the level of transport barges by craneage facilities on the windturbine. 3.3 Maintenance strategies Current maintenance strategies are still very similar to the strategy on land. Two times a year a service and preventive maintenanc e visit is paid to each wind turbine, preferably at instants with little wind and benign sea conditions. Repair actions are carried out as soon as maintenance crew and equipment are available and weather permits a visit to the failed wind turbine. A more offshore adapted strategy can be used whenever it is possible to extend the period between two service visits. Then the opportunity of a failure of a windturbine component can be used to perform a combined repair and service action.

4. WIND TURBINE DESIGN FOR O&M

The development of adaptations for operation in the offshore environment has already been discussed. on a components and facilities basis. In general in can be seen that, driven by the higher demands with respect to loads and controllability, the design of large wind turbines tends to a higher level of complexity. Variable speed, individual blade pitch control, doubly fed generators incorporating slip rings, inverter systems etc. become more and more common for multi-megawatt designs.[15] From the viewpoint of an offshore engineer however the use of robust and simple turbines in a large scale OWECS is highly preferred. An example of a design favourable from that respect is a windturbine with a two bladed fixed pitch rotor, a standard gearbox and a completely closed induction generator. Such a wind turbine is designed specifically for use in large offshore windfarms. This also means that the O&M

demands are treated as a key aspects in all the design phases. This can for example lead to the development of the design of complete sequence of component exchange actions using internal cranes in conjunction with special maintenance vessels or to an integral exchange philosophy where a complete nacelle including rotor can be exchanged within 24 hours or so (again with a special purpose built O&M crane or jack up vessel). These issues have been addressed to some detail in [12]

5. CONCLUSIONS

Future wind turbine development for offshore wind farm use has to guided by further adaptation to the harsh maritime environment. With respect to the reduction in the lifetime costs of OWECS the following aspect have to be addressed: Improvement of access methods Development of access methods less sensitive to wind/wave conditions Reduction of time required for offshore working Wind turbine designs for reduced maintenance. This may imply: - Reduction of overall number of components and simplicity of design - Modular design of wind turbines which facilitates the interchange of faulty modules - Use of high reliability components - Re-siting of electrical units into an environmentally controlled section of the turbine - Implementation of offshore corrosion protection technology - Development of effective condition monitoring and remote control systems Development of appropriate maintenance strategies for service and repair actions Development of an integral design philosophy of a large scale OWECS, where the design of the individual wind turbines is governed by the overall OWECS targets, and not by a sequential adaptation and up scaling of onshore designs

[6] G.J.W. van Bussel Reliability, availability and maintenance aspects of large-scale offshore wind farms, a concepts study, Delft University of Technology, The Netherlands, MAREC 2001 Conference Proceedings, pages 119 126. [7] Tuno Knob - Garrad Hassan questionnaire response, April 2001. [8] Competitive wind farms, does ABB have the answer? SED Aug/Sept 2000, p27 [9] Aerodyn Multibrid 5MW machine, www.multibrid.com [10] WindStats Newsletter Autumn 2000, Vol. 13 No.4, page 10 [11] G.J.W. van Bussel; The Development of an Expert System for the determination of Availability and O&M Costs for Offshore Wind Farms, Proceedings of the 1999 European Wind Energy Conference, Nice, France, March 1999, pp. 402-405 [12] M.C. Ferguson (editor); M. Khn; G.J.W. van Bussel; W.A.A.M. Bierbooms; T.T. Cockerill.; B. Gransson; L.A. Harland; J.H. Vugts; R. Hes, Opti-OWECS Final Report Vol. 4: A Typical Design Solution for an Offshore Wind Energy Conversion System, Institute for Wind Energy, TU Delft, The Netherlands, 1998, ISBN 90-7646805-2. [13] H. Braam, L.W.M.M. Rademakers, The influence of weather conditions on the strategies and costs of operation and maintenance, Proceedings of the EWEA Offshore Wind Energy Conference 2001, Brussels, December 10-12th 2001. [14] G.J.W. van Bussel, Chr. Schntag, Operation and Maintenance Aspects of Large Offshore Wind Farms Proc. EWEC 1997, Dublin, Ireland, 1998 ISBN 0-95-33922-0-1. [15] C. Morgan, State of the Art and Technology Trends for Offshore Wind Energy: Wind Turbine Technology, Proceedings of the EWEA Offshore Wind Energy Conference 2001, Brussels, December 10-12th 2001

ACKNOWLEDGEMENT

The project Concerted Action on Offshore Wind Energy in Europe [CA-OWEE] is being funded by the European Commission under contract number NNE5-1999-00562. The project's 17 partners come from 13 countries, thus covering the majority of the European Community's coastline. The partners cover a wide range of expertise and include developers, utilities, consultants, research institutes and universities. Information is available at www.offshorewindenergy.org

REFERENCES

[1] M. Khn (edt); Opti-OWECS Final Report Structural and Economic Optimisation of Bottom mounted Offshore Wind Energy Converters, Institute for Wind Energy, T.U. Delft, The Netherlands, August 1998, ISBN 90-76468-01-X [2] J.O. Tande (edt); Estimation of Cost of Energy from Wind Energy Conversion Systems, IEA Recommended Practices for Wind Turbine Testing, International Energy Agency, edition 1994. [3] T.K. Petersen Offshore wind power the operational aspects, Vestas Danish Wind Technology A/S, Lem, Denmark. [4] CADDET report 5 MW Offshore Wind Farm, September 1999, http://194.178.172.86/register/datare/ccr01855.htm [5] Chr. Schntag, Optimisation of Operation and Maintenance of Offshore Wind Farms, Report IW-96108R, Institute for Wind Energy, TU Delft, The Netherlands, November 1996

You might also like

- Sri Swami Sivananda - God Exists (90p)Document90 pagesSri Swami Sivananda - God Exists (90p)daneshnedaieNo ratings yet

- Prana and PranayamaDocument369 pagesPrana and Pranayamanytebe100% (10)

- Sri Swami Sivananda - God Exists (90p)Document90 pagesSri Swami Sivananda - God Exists (90p)daneshnedaieNo ratings yet

- ADT Stacks and QueuesDocument62 pagesADT Stacks and QueuesKavin KumarNo ratings yet

- Verb - List - Irregular (Appendix 6.10.1)Document4 pagesVerb - List - Irregular (Appendix 6.10.1)Nur AmaliaNo ratings yet

- ProgrammingDocument12 pagesProgrammingKavin KumarNo ratings yet

- Literature ReviewDocument1 pageLiterature ReviewKavin KumarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- High-Definition Multimedia Interface SpecificationDocument51 pagesHigh-Definition Multimedia Interface SpecificationwadrNo ratings yet

- On Fracture MechanicsDocument81 pagesOn Fracture MechanicsDEEPAK100% (1)

- PLLV Client Consent FormDocument4 pagesPLLV Client Consent Formapi-237715517No ratings yet

- DPWH Cost EstimationDocument67 pagesDPWH Cost EstimationAj Abe92% (12)

- Review On A Protective Scheme For Wind Power Plant Using Co-Ordination of Overcurrent Relay-NOTA TECNICADocument5 pagesReview On A Protective Scheme For Wind Power Plant Using Co-Ordination of Overcurrent Relay-NOTA TECNICAEdgardo Kat ReyesNo ratings yet

- CS 148 - Introduction To Computer Graphics and ImagingDocument3 pagesCS 148 - Introduction To Computer Graphics and ImagingMurtaza TajNo ratings yet

- Discovering Computers 2016: Operating SystemsDocument34 pagesDiscovering Computers 2016: Operating SystemsAnonymous gNHrb0sVYNo ratings yet

- Presentation The New Condominium Rules 9 1 2018 PDFDocument35 pagesPresentation The New Condominium Rules 9 1 2018 PDFYe AungNo ratings yet

- Sampling PowerpointDocument21 pagesSampling PowerpointMuhammad Furqan Aslam AwanNo ratings yet

- NammalvarDocument22 pagesNammalvarPranesh Brisingr100% (1)

- REID CatalogDocument54 pagesREID Catalogzhaoye maoNo ratings yet

- Retail Marketing Course Work 11Document5 pagesRetail Marketing Course Work 11Ceacer Julio SsekatawaNo ratings yet

- Taller Sobre Preposiciones y Vocabulario - Exhibición Comercial SergioDocument5 pagesTaller Sobre Preposiciones y Vocabulario - Exhibición Comercial SergioYovanny Peña Pinzon100% (2)

- Spectrochem Chemindex 2016 17Document122 pagesSpectrochem Chemindex 2016 17Nivedita Dube0% (1)

- BSC IT SyllabusDocument32 pagesBSC IT Syllabusஜூலியன் சத்தியதாசன்No ratings yet

- Choosing The Right HF Welding Process For Api Large Pipe MillsDocument5 pagesChoosing The Right HF Welding Process For Api Large Pipe MillsNia KurniaNo ratings yet

- EPM Cloud Tax Reporting Overview - EMEA Training May 2020Document25 pagesEPM Cloud Tax Reporting Overview - EMEA Training May 2020zaymounNo ratings yet

- Chapter 3 SampleDocument12 pagesChapter 3 Samplesyarifah53No ratings yet

- Crystallization of Para-Xylene in Scraped-Surface CrystallizersDocument11 pagesCrystallization of Para-Xylene in Scraped-Surface Crystallizersanax22No ratings yet

- Consolidated Digests - Part 2Document314 pagesConsolidated Digests - Part 2Neil Patrick Pepito ErmacNo ratings yet

- Model: The Most Accepted and Respected Engine-Driven Cooler in The Gas Compression IndustryDocument2 pagesModel: The Most Accepted and Respected Engine-Driven Cooler in The Gas Compression IndustryparathasiNo ratings yet

- TFTV3225 Service Manual 102010 Coby 26-32Document21 pagesTFTV3225 Service Manual 102010 Coby 26-32bigbrother4275% (4)

- Review of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)Document12 pagesReview of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)RHIAN B.No ratings yet

- Introduction and Instructions: ForewordDocument20 pagesIntroduction and Instructions: ForewordDanang WidoyokoNo ratings yet

- Timken Bearing Damage PosterDocument1 pageTimken Bearing Damage Postera04205100% (5)

- FinTech RegTech and SupTech - What They Mean For Financial Supervision FINALDocument19 pagesFinTech RegTech and SupTech - What They Mean For Financial Supervision FINALirvandi syahputraNo ratings yet

- FAA PUBLICATIONS May Be Purchased or Downloaded For FreeDocument4 pagesFAA PUBLICATIONS May Be Purchased or Downloaded For FreeFlávio AlibertiNo ratings yet

- VAT (Chapter 8 Compilation of Summary)Document36 pagesVAT (Chapter 8 Compilation of Summary)Dianne LontacNo ratings yet

- DSP Unit V ObjectiveDocument4 pagesDSP Unit V Objectiveshashi dharNo ratings yet

- 2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP GlycerinDocument1 page2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP Glycerinchristian muñozNo ratings yet