Professional Documents

Culture Documents

NASA Facts Aeronautics Test Program

Uploaded by

Bob AndrepontOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NASA Facts Aeronautics Test Program

Uploaded by

Bob AndrepontCopyright:

Available Formats

Aeronautics Test Program

The Aeronautics Test Program, part of NASAs Aeronautics Research Mission Directorate, ensures the capability, availability and accessibility of an extensive suite of testing facilities to meet NASA and other U.S. aeronautics needs. The flight operations and test infrastructure is located at four NASA centers: Ames Research Center Mountain View, Calif. - Wind tunnels Dryden Flight Research Center Edwards, Calif. - Test bed aircraft, support aircraft, test range, simulation and flight load laboratories Glenn Research Center Cleveland - Wind tunnels, icing research tunnel, propulsion system facilities Langley Research Center Hampton, Va. - Wind tunnels, spin tunnel, aerothermodynamics testing facilities Ground and flight test capabilities are used by NASA, other government agencies and commercial customers to test and demonstrate new technologies, materials, structures and flight concepts, and to explore and understand aeronautical behaviors and phenomena.

Images (Clockwise, left to right) Hypersonic Speed: An air-breathing scramjet engine model is tested in NASAs 8-Foot High-Temperature Tunnel, which simulates flight conditions from Mach 3 to Mach 7. Support Aircraft: A view from a NASA chase plane during a test flight of the blended wing body X-48B in April 2008. Propulsion Testing: Technicians and researchers pause during a jet engine test set up in the Propulsion Systems Laboratory. Wind Tunnels: A model of the new EA-18G Navy attack aircraft being tested for aerodynamic force and moment data in the 11- by 11-Foot Transonic Wind Tunnel.

GROUND TEST FACILITIES Subsonic Wind Tunnels (Mach <1) 9- by 15-Foot Low-Speed Wind Tunnel (NASA Glenn): Aerodynamic performance and acoustic characteristics of fans, nozzles, inlets and propellers 14- by 22-Foot Subsonic Tunnel (NASA Langley): Performance testing of fixed-wing and rotorcraft configurations 20-Foot Vertical Spin Tunnel (NASA Langley): Free-spin tests to isolate potential spin modes and control techniques required for spin recovery Icing Research Tunnel (NASA Glenn): Testing of issues related to aircraft icing Transonic Wind Tunnels (Mach 0.8 1.2) National Transonic Facility (NASA Langley): Cryogenic and air testing, and configuration aerodynamics validation for both full- and half-span models of existing and new vehicle concepts Unitary Plan Facility (NASA Ames): Airframe development and aerodynamic studies, with a vital and continuing role in the U.S. crewed spaceflight program Transonic Dynamics Tunnel (NASA Langley): Testing of large aeroelastically scaled models Supersonic Wind Tunnels (Mach 1.2 5.0) 10- by 10-Foot Supersonic Wind Tunnel (NASA Glenn): Testing of supersonic aerodynamic and propulsion components such as inlets and nozzles, integrated propulsion systems, full-scale jet and rocket engines and launchvehicle concepts 9- by 7-Foot Supersonic Wind Tunnel (NASA Ames): Evaluations of domestic fixed-wing airframes; ascent and reentry aerodynamic data for crewed space vehicles 4-Foot Supersonic Unitary Plan Wind Tunnel (NASA Langley): Basic fluid dynamics research and development, assessment and optimization of advanced aerospace vehicle concepts 8- by 6-Foot Supersonic Wind Tunnel (NASA Glenn): Studies of aerodynamic and propulsion models at subsonic, transonic and supersonic speeds from Mach 0.25 to 2.0 Hypersonic Wind Tunnels (Mach 5) Aerothermodynamics Laboratory (NASA Langley): Fundamental flow-physics research, aerodynamic performance measurements and aero-heating assessments 8-Foot High-Temperature Tunnel (NASA Langley): Tests requiring flight conditions at Mach 3 to 7 for large airbreathing propulsion systems and thermal-protection system components

Propulsion Systems Laboratory The Propulsion Systems Laboratory (NASA Glenn): A full-scale, high-altitude, high-speed (to Mach 4) engine test facility for air-breathing propulsion systems research and development. FLIGHT OPERATIONS AND TEST INFRASTRUCTURE Located at NASA Dryden, these facilities and aircraft provide critical support to researchers, designers and manufacturers: Flight Loads Laboratory Combined mechanical-load and thermal studies of structural components and complete flight vehicles; capability to calibrate and evaluate flight-loads instrumentation under anticipated in-flight conditions Research Aircraft Integration Facility Simulations to verify and validate complex designs of aerospace vehicles and their sub-systems prior to flight Western Aeronautical Test Range Tracking, communications and data management to support technology integration, space exploration concepts, airborne remote sensing and a wide variety of science missions Support and Test Bed Aircraft NASAs fleet of support aircraftF/A-18, T-38, T-34C, B200 King Air provides video, photo and safety-chase support for NASA, the Department of Defense, the Federal Aviation Administration and other U.S. agencies and institutions. Test bed aircraftF-18, F-15B, ER-2, Global Hawks, G III can be instrumented in a variety of configurations to meet testing requirements.

Were Working on

Assessing U.S. subsonic and hypersonic wind tunnels in collaboration with the National Partnership for Aeronautical Testing Supporting the Boeing Company in ongoing flight tests of the X-48B, a remote-piloted subscale test vehicle using the blended wing body design Starting a five-year program of recapitalization and maintenance projects in all Aeronautics Test Program facilities

National Aeronautics and Space Administration Headquarters 300 E. Street, SW Washington, DC 20546

For more information about the Aeronautics Test Program and NASA aeronautics research, visit www.aeronautics. nasa.gov/atp/.

NASA Facts

NF-2009-03-486-HQ

You might also like

- Boston and The American RevolutionDocument100 pagesBoston and The American RevolutionBob Andrepont100% (2)

- The Civil War in The Trans-Mississippi Theater, 1861-1865Document60 pagesThe Civil War in The Trans-Mississippi Theater, 1861-1865Bob Andrepont100% (4)

- ChalmetteDocument64 pagesChalmetteBob Andrepont100% (1)

- Chickamauga and Chattanooga BattlefiledsDocument68 pagesChickamauga and Chattanooga BattlefiledsBob Andrepont100% (4)

- A Thunder of CannonDocument249 pagesA Thunder of CannonBob Andrepont80% (5)

- The Civil War Ends, 1865Document76 pagesThe Civil War Ends, 1865Bob Andrepont100% (2)

- CMH Pub 75-18 The Army and Reconstruction, 1865-1877Document76 pagesCMH Pub 75-18 The Army and Reconstruction, 1865-1877Bob Andrepont100% (2)

- The Maryland and Fredericksburg Campaigns, 1862-1863Document64 pagesThe Maryland and Fredericksburg Campaigns, 1862-1863Bob Andrepont100% (2)

- NASA Facts Living in SpaceDocument12 pagesNASA Facts Living in SpaceBob AndrepontNo ratings yet

- Battlefields Around Fredericksburg PDFDocument48 pagesBattlefields Around Fredericksburg PDFBob Andrepont100% (2)

- American: Here Over The British Turn The The TheDocument100 pagesAmerican: Here Over The British Turn The The TheBob Andrepont100% (1)

- Campaign For PetersburgDocument84 pagesCampaign For PetersburgBob Andrepont100% (3)

- The Petersburg and Appomattox Campaigns, 1864-1865Document72 pagesThe Petersburg and Appomattox Campaigns, 1864-1865Bob Andrepont100% (3)

- Lock Stock and BarrelDocument2 pagesLock Stock and BarrelBob Andrepont100% (3)

- Aeronautics in NACA and NASADocument80 pagesAeronautics in NACA and NASABob AndrepontNo ratings yet

- A Charming Field For An EncounterDocument76 pagesA Charming Field For An EncounterBob Andrepont100% (2)

- Castillo de San MarcosDocument70 pagesCastillo de San MarcosBob Andrepont100% (2)

- The Civil War On The Atlantic Coast, 1861-1865Document64 pagesThe Civil War On The Atlantic Coast, 1861-1865Bob Andrepont100% (3)

- Dust Off Army Aeromedical Evacuation in VietnamDocument148 pagesDust Off Army Aeromedical Evacuation in VietnamBob Andrepont100% (2)

- Chief Joseph's People and Their WarDocument28 pagesChief Joseph's People and Their WarBob Andrepont100% (1)

- AntietamDocument68 pagesAntietamBob Andrepont100% (3)

- From The Golden Gate To Mexico City The U.S. Army Topographical Engineers in The Mexican War, 1846-1848Document372 pagesFrom The Golden Gate To Mexico City The U.S. Army Topographical Engineers in The Mexican War, 1846-1848Bob AndrepontNo ratings yet

- Desperate Stand The Battle of Buena VistaDocument44 pagesDesperate Stand The Battle of Buena VistaBob Andrepont100% (1)

- The Occupation of MexicoDocument48 pagesThe Occupation of MexicoBob Andrepont100% (1)

- The Gulf Theater, 1813-1815Document52 pagesThe Gulf Theater, 1813-1815Bob Andrepont100% (1)

- Introduction of The New Vito/Viano Model Series 639 With Code XZ1Document32 pagesIntroduction of The New Vito/Viano Model Series 639 With Code XZ1lartsim115No ratings yet

- 17001-03 B7R D7E CHN 115594-118654Document167 pages17001-03 B7R D7E CHN 115594-118654MAJID SADEGHIANNo ratings yet

- CMH Pub 73-1 - Mexican War - Gateway South The Campaign For MonterreyDocument36 pagesCMH Pub 73-1 - Mexican War - Gateway South The Campaign For Monterreyorabera100% (1)

- AndersonvilleDocument24 pagesAndersonvilleBob Andrepont100% (3)

- Guns Along The Rio Grand Palo Alto and Resaca de La PalmaDocument32 pagesGuns Along The Rio Grand Palo Alto and Resaca de La PalmaBob AndrepontNo ratings yet

- Before This Decade Is Out Personal Reflections On The Apollo ProgramDocument428 pagesBefore This Decade Is Out Personal Reflections On The Apollo ProgramBob AndrepontNo ratings yet

- Light Aircraft MaintenanceDocument10 pagesLight Aircraft Maintenancejoeryan6No ratings yet

- A Much Unsung Hero, The Lunar Landing Training Vehicle: And Other NASA RecollectionsFrom EverandA Much Unsung Hero, The Lunar Landing Training Vehicle: And Other NASA RecollectionsRating: 5 out of 5 stars5/5 (1)

- Nimbus-B2 Press KitDocument50 pagesNimbus-B2 Press KitBob AndrepontNo ratings yet

- NASA Facts Benefits From Apollo Giant Leaps in TechnologyDocument4 pagesNASA Facts Benefits From Apollo Giant Leaps in TechnologyBob Andrepont100% (1)

- Fifty Years of Aeronautical ResearchDocument79 pagesFifty Years of Aeronautical ResearchBob Andrepont100% (1)

- NASA Facts Interplanetary Explorer SatellitesDocument8 pagesNASA Facts Interplanetary Explorer SatellitesBob AndrepontNo ratings yet

- Dacia Duster 4x4 Aro 10 Brosura PrezentareDocument4 pagesDacia Duster 4x4 Aro 10 Brosura Prezentareadytt20005155No ratings yet

- Before This Decade Is Out: Personal Reflections on the Apollo ProgramFrom EverandBefore This Decade Is Out: Personal Reflections on the Apollo ProgramNo ratings yet

- NASA Facts X-38 Deorbit Propulsion SystemDocument4 pagesNASA Facts X-38 Deorbit Propulsion SystemBob Andrepont100% (1)

- NASA Facts Project RelayDocument9 pagesNASA Facts Project RelayBob Andrepont100% (1)

- NASA Facts The Press Site at KSC 2004Document4 pagesNASA Facts The Press Site at KSC 2004Bob AndrepontNo ratings yet

- Crosswind Takeoff: Effect On Tail ClearanceDocument6 pagesCrosswind Takeoff: Effect On Tail ClearancebilelNo ratings yet

- Dynafleet: Vehicle ManagementDocument14 pagesDynafleet: Vehicle ManagementHarold Robins Carbajo CarhuayanoNo ratings yet

- NASA 120294main FS-039-DFRCDocument3 pagesNASA 120294main FS-039-DFRCNASAdocumentsNo ratings yet

- Accessibility Law (BP 344)Document54 pagesAccessibility Law (BP 344)Frances Katrina M. Cortez93% (14)

- Atmosphere of Freedom Sixty Years at The NASA Ames Research CenterDocument308 pagesAtmosphere of Freedom Sixty Years at The NASA Ames Research CenterBob AndrepontNo ratings yet

- NASA Facts ER-2 High Altitude Airborne Science ProgramDocument4 pagesNASA Facts ER-2 High Altitude Airborne Science ProgramBob AndrepontNo ratings yet

- NASA Facts New Millennium ProgramDocument5 pagesNASA Facts New Millennium ProgramBob AndrepontNo ratings yet

- Nasa Facts Express Racks 1 and 2Document2 pagesNasa Facts Express Racks 1 and 2Bob AndrepontNo ratings yet

- NASA Facts Express Rack 3Document2 pagesNASA Facts Express Rack 3Bob AndrepontNo ratings yet

- NASA Facts Lightning Protection For NASA's Next Generation SpacecraftDocument2 pagesNASA Facts Lightning Protection For NASA's Next Generation SpacecraftBob AndrepontNo ratings yet

- Crew Module: European ServiceDocument6 pagesCrew Module: European ServiceUnderstanding SpaceNo ratings yet

- NASA Facts Launch Vehicle Data Center (LVDC) 2001Document2 pagesNASA Facts Launch Vehicle Data Center (LVDC) 2001Bob Andrepont100% (2)

- NASA Facts Constellation Program The Ares V Cargo Launch Vehicle 2009Document4 pagesNASA Facts Constellation Program The Ares V Cargo Launch Vehicle 2009Bob AndrepontNo ratings yet

- NASA Facts External Tank Thermal Protection System 2004Document4 pagesNASA Facts External Tank Thermal Protection System 2004Bob AndrepontNo ratings yet

- Safety in Recovery of Apollo SpacecraftDocument3 pagesSafety in Recovery of Apollo SpacecraftKanishka LankatillakeNo ratings yet

- NASA Facts PHYSX Pegasus Hyper Sonic ExperimentDocument3 pagesNASA Facts PHYSX Pegasus Hyper Sonic ExperimentBob AndrepontNo ratings yet

- Women-Space-Walk-2000000760-Article Quiz and AnswersDocument5 pagesWomen-Space-Walk-2000000760-Article Quiz and Answersapi-3028992660% (1)

- NASA Facts Biosatellite IIDocument12 pagesNASA Facts Biosatellite IIBob AndrepontNo ratings yet

- NASA Facts Constellation Program The Orion Launch Abort SystemDocument4 pagesNASA Facts Constellation Program The Orion Launch Abort SystemBob AndrepontNo ratings yet

- Development of The Apollo Launch Escape SystemDocument6 pagesDevelopment of The Apollo Launch Escape SystemKanishka LankatillakeNo ratings yet

- NASA Facts Space Shuttle Orbiter ProcessingDocument8 pagesNASA Facts Space Shuttle Orbiter ProcessingBob AndrepontNo ratings yet

- NASA Facts NASA's Orbiter Fleet 2001Document4 pagesNASA Facts NASA's Orbiter Fleet 2001Bob AndrepontNo ratings yet

- NASA Facts Space Shuttles and Sonic BoomsDocument3 pagesNASA Facts Space Shuttles and Sonic BoomsBob AndrepontNo ratings yet

- NASA Facts Forward Bipod FittingDocument3 pagesNASA Facts Forward Bipod FittingBob AndrepontNo ratings yet

- NASA Facts F-104 826 2000Document2 pagesNASA Facts F-104 826 2000Bob Andrepont0% (1)

- NASA Facts Bolt Catcher Modifications On The Solid RocketDocument2 pagesNASA Facts Bolt Catcher Modifications On The Solid RocketBob AndrepontNo ratings yet

- NASA Facts Shuttle Carrier AircraftDocument2 pagesNASA Facts Shuttle Carrier AircraftBob AndrepontNo ratings yet

- The Jovian Beet: Un H CC Mpli NTDocument6 pagesThe Jovian Beet: Un H CC Mpli NTBob Andrepont100% (1)

- NASA Facts X-37 Demonstrator To Test Future Launch Technologies in Orbit and Reentry Environments 2001Document2 pagesNASA Facts X-37 Demonstrator To Test Future Launch Technologies in Orbit and Reentry Environments 2001Bob AndrepontNo ratings yet

- NASA Facts Constellation Program Ares I-X Flight Test Vehicle 2009Document4 pagesNASA Facts Constellation Program Ares I-X Flight Test Vehicle 2009Bob AndrepontNo ratings yet

- NASA Facts Orbits and RevolutionsDocument4 pagesNASA Facts Orbits and RevolutionsBob AndrepontNo ratings yet

- Step-by-Step Assembly Diagram: To Learn More About Human Spaceflight at NASA VisitDocument8 pagesStep-by-Step Assembly Diagram: To Learn More About Human Spaceflight at NASA VisitMuhammad RubiyanorNo ratings yet

- Nasa Facts Altus II How High Is High 2003Document3 pagesNasa Facts Altus II How High Is High 2003Bob AndrepontNo ratings yet

- NASA: 84985main DebusDocument25 pagesNASA: 84985main DebusNASAdocumentsNo ratings yet

- The High-Speed Frontier. Case Histories of Four NACA Programs, 1920 - 1950Document196 pagesThe High-Speed Frontier. Case Histories of Four NACA Programs, 1920 - 1950Bob AndrepontNo ratings yet

- Bio Medical Results of ApolloDocument576 pagesBio Medical Results of ApolloBob AndrepontNo ratings yet

- Nasa-Gendered-Spacesuits-2001011260-Article Quiz and AnswersDocument5 pagesNasa-Gendered-Spacesuits-2001011260-Article Quiz and Answersapi-302899266No ratings yet

- NASA Facts Earth ResourcesDocument6 pagesNASA Facts Earth ResourcesBob Andrepont100% (1)

- NASA Facts Spacecraft Tracking and CommunicationDocument4 pagesNASA Facts Spacecraft Tracking and CommunicationBob AndrepontNo ratings yet

- Viking Lander SterilizationDocument2 pagesViking Lander SterilizationBob Andrepont100% (1)

- NASA Facts Galileo Mission To JupiterDocument9 pagesNASA Facts Galileo Mission To JupiterBob Andrepont100% (1)

- NASA Facts Parachute Refurbishment Facility 2001Document2 pagesNASA Facts Parachute Refurbishment Facility 2001Bob AndrepontNo ratings yet

- Comet Nucleus Tour (CONTOUR) Mishap Investigation Board ReportDocument64 pagesComet Nucleus Tour (CONTOUR) Mishap Investigation Board ReportBob AndrepontNo ratings yet

- Eigth Scout Development Flight Press KitDocument6 pagesEigth Scout Development Flight Press KitBob AndrepontNo ratings yet

- The Search For Extraterrestrial Intelligence (SETI)Document293 pagesThe Search For Extraterrestrial Intelligence (SETI)Bob Andrepont100% (2)

- Russian Docking Compartment and Airlock PirsDocument1 pageRussian Docking Compartment and Airlock PirsBob Andrepont100% (1)

- STS-70 Press KitDocument48 pagesSTS-70 Press KitBob AndrepontNo ratings yet

- STS-51F Press KitDocument44 pagesSTS-51F Press KitBob AndrepontNo ratings yet

- NASA Facts Robert H Goddard American Rocket PioneerDocument3 pagesNASA Facts Robert H Goddard American Rocket PioneerBob AndrepontNo ratings yet

- Space Shuttle Solid Rocket Booster Frangible Nut Crossover SystemDocument2 pagesSpace Shuttle Solid Rocket Booster Frangible Nut Crossover SystemBob AndrepontNo ratings yet

- STS-109 HST Servicing Mission 3B Media Reference GuideDocument113 pagesSTS-109 HST Servicing Mission 3B Media Reference GuideBob AndrepontNo ratings yet

- Arkansas Post National MemorialDocument2 pagesArkansas Post National MemorialBob Andrepont100% (1)

- Their Stories Women in The U.S.-mexican WarDocument2 pagesTheir Stories Women in The U.S.-mexican WarBob AndrepontNo ratings yet

- Advanced Redoubt of Fort BarrancasDocument2 pagesAdvanced Redoubt of Fort BarrancasBob AndrepontNo ratings yet

- A House DividedDocument1 pageA House DividedBob AndrepontNo ratings yet

- Toolbox Talks: Forklift FatalitiesDocument1 pageToolbox Talks: Forklift Fatalitiesserdar yücelNo ratings yet

- Preliminary Study of Pedestrian Movement Over Foot Over BridgesDocument20 pagesPreliminary Study of Pedestrian Movement Over Foot Over BridgesAshis karmakarNo ratings yet

- On Highway Vehicles Off-Highway MachineryDocument8 pagesOn Highway Vehicles Off-Highway MachinerykarthegreNo ratings yet

- Pre-owned vehicle auction listDocument1 pagePre-owned vehicle auction listGeorge PamaNo ratings yet

- Indian Railways-Case StudyDocument4 pagesIndian Railways-Case Studyanusris1850% (2)

- Nissan Urvan PromoDocument2 pagesNissan Urvan Promovanesabautista100% (2)

- ID CardDocument2 pagesID CardJennifer MerloNo ratings yet

- History of AviationDocument104 pagesHistory of Aviationsiranjeevi21100% (1)

- 1PL, 2PL, 3PL, 4PL, and 5PLDocument2 pages1PL, 2PL, 3PL, 4PL, and 5PLMoozi Baloch unofficalNo ratings yet

- ReplyDocument NHAIDocument1 pageReplyDocument NHAIvishal gargNo ratings yet

- 7 - STUs - Profile and Performance (2018-19)Document268 pages7 - STUs - Profile and Performance (2018-19)Abhigyan PatraNo ratings yet

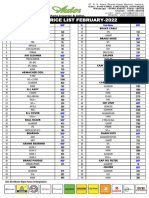

- HERO Price List February-2022Document5 pagesHERO Price List February-2022Md. Salim UddinNo ratings yet

- Katalog Radja ElevatorDocument4 pagesKatalog Radja ElevatorAdita Rian PradanaNo ratings yet

- Module 2 Elective TUICODocument4 pagesModule 2 Elective TUICOkentong compraNo ratings yet

- Technological Institute of The Philippines Quezon City: Final Examination in CE 012 - Highway and Railroad EngineeringDocument22 pagesTechnological Institute of The Philippines Quezon City: Final Examination in CE 012 - Highway and Railroad EngineeringKaty PerryNo ratings yet

- Manitou M 26 M 30 M 40 M 50 ENDocument12 pagesManitou M 26 M 30 M 40 M 50 ENwill wuNo ratings yet

- Travel and Tourism Products and ServicesDocument25 pagesTravel and Tourism Products and ServicesAbdul Basit KhanNo ratings yet

- Tandem Dump Truck SpecificationsDocument4 pagesTandem Dump Truck SpecificationsdeadbirdsNo ratings yet

- Aspects of Defensive DrivingDocument73 pagesAspects of Defensive DrivingGerald Joseph Malit100% (1)

- British Airways Advance Ticketing RuleDocument1 pageBritish Airways Advance Ticketing RuleAhmad MansourNo ratings yet

- Manual Raptor - 350Document150 pagesManual Raptor - 350jere aquinoNo ratings yet

- TrackingDocument4 pagesTrackingapi-261853178No ratings yet

- Global Transportation DocumentsDocument18 pagesGlobal Transportation DocumentsImanghaff 03No ratings yet