Professional Documents

Culture Documents

Buyer Planner

Uploaded by

api-78903260Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

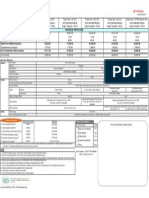

Buyer Planner

Uploaded by

api-78903260Copyright:

Available Formats

Carlos P.

Salcedo Maldonado

1275 West 29th Street Apt. #201

Los Angeles, CA 90007

Mobile: 213-220-3141

Education:

Instituto Tecnologico de Ciudad Juarez, Mexico 1991

Bachelors of Science- Business Administration

Professional Experience:

ASC Process Systems 2010 to Present

Warehouse Supervisor

* Manage the people, processes, and material, in the warehouse, stock room, and

receiving area

* Coordinate the receipt and shipment of 150 part numbers from 10 suppliers to a

n average of 30 international customers

* Work directly with suppliers to track backlogged material

* Supervise and train 5 warehouse employees

* Coordinate the kitting material process, according with new project demand

* Reduce material inventory by minimum and maximum criteria

* Identify missing material and communicate material needs to the buyer

* Close open production orders and contact suppliers for discrepances

Aerotek providing the service to Cooper Interconnect 2008 to 2010

Material Expeditor

* Coordinated the material planning of 10 suppliers and 100 part numbers, using

SAP

* Scheduled raw material and determined production plan

* Expedited finished goods shipments from Europe and North America

* Managed raw material inventories, by administering internal control processes

and inventory adjustments

* Prioritized shipments through the coordination of the different departments su

ch as quality, production and shipping.

* Provided material quotes for none productive and productive material

* Created production orders when required

* Managed warehouse and shipping when required

InjectoPlastics- Ciudad Juarez, Mexico 2006 to 2007

Material Coordinator

* Supervised and coordinated the responsibilities and development of 20 people

* Scheduled raw material and determined production plan

* Managed raw and finished goods inventories, by administering internal control

processes and approving inventory adjustments

* Negotiated supplier material prices

* Provided material quotes for the finished good price quotations

* Defined corrective actions in response to logistical errors

Robert Bosch Automotive Systems- Juarez, Mexico 2000 to 2006

Finished Goods and Raw Material Planner and Manager Development Coordinator

* Coordinated the material planning of 6 suppliers and 350 part numbers, using S

AP

* Scheduled direct material for Ford, Volkswagen, Chrysler and General Motors vi

a Electronic Demand System (EDS)

* Expedited material from Australia, Europe, Asia and North America

* Analyzed the daily inventory-on- hand report

* Determined charges to suppliers for delayed incoming material

* Coordinated technical training and Managers' development track

Ediasa III / JCI (Johnson Controls) - Juarez, Mexico 1998 to 2000

Material Expeditor

* Coordinated the material planning of 12 suppliers and 150 part numbers

* Scheduled direct material for Ford and Mazda via Materials Requirement Plannin

g (MRP) system, based on Ford's Electronic Demand Master System (EDMS)

* Expedited material from Juarez (Mexico) and the U.S.A.

* Analyzed the daily inventory-on- hand report

* Determined charges to suppliers for delayed incoming material

Rio Bravo Electricos XII (Delphi Automotive systems) - Juarez, Mexico 1995 to 1

998

Procurement Scheduler

* Directed the workload of 1 clerk

* Coordinated the material planning of 38 suppliers and 350 part numbers

* Scheduled direct material for BMW and Mercedes via Materials Requirement Plann

ing (MRP) system, based on General Motors' Electronic Demand Master System (EDMS

)

* Expedited material from Europe and the U.S.A.

* Analyzed the daily inventory- on- hand report

Production Supervisor

* Supervised and coordinated the work and training of 60 people

* Scheduled weekly production

* Analyzed changes in production requirements

* Received promotion within one year to the position of Procurement Scheduler

Professional Development:

Advancing Productivity, Innovation

& Competitive Success (APICS) September 2006- April 2007

English as a Second Language- Level 11 September 2000

Rapid Problem Solutions September 2004

Rapid Problem Solutions August 2000

Kaizen August 2000

QS-9000 February 2000

Leading the Business June 2000

Teamwork May 1998

Supervision Techniques October 1998

Managing Stress May 1997

Effective Planning July 1997

Failure Mode Experimental Analysis (FMEA) July 1996

H.R. Supervisor's Techniques November 1996

How to Delegate February 1996

Communication & Documentation of GQS March 1996

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Off Highway 24 Volt Quick Reference GuideDocument4 pagesOff Highway 24 Volt Quick Reference GuideAgus YulfizarNo ratings yet

- Navi Star Supplier GuidelinesDocument104 pagesNavi Star Supplier GuidelinesEduardo UscangaNo ratings yet

- SRD-vehicle Traction Applications PDFDocument20 pagesSRD-vehicle Traction Applications PDFEduardo BittencourtNo ratings yet

- Gearbox PPT (Repaired)Document11 pagesGearbox PPT (Repaired)Siddharth BalekarNo ratings yet

- Struktur Astra BahasaDocument3 pagesStruktur Astra BahasaMayaKusumawatiWijayaNo ratings yet

- D4505 & D4005Document6 pagesD4505 & D4005Philippine Bus Enthusiasts SocietyNo ratings yet

- ARAI Regulations For Electric Vehicle-Three WheelerDocument10 pagesARAI Regulations For Electric Vehicle-Three WheelerMuraliKrishna0% (3)

- DD Calibration Tool PDFDocument6 pagesDD Calibration Tool PDFRichard Centeno100% (1)

- Retro Marketing: By: - Ritender Pal Singh Roll No: - 08 Reg No: - 3020070133Document33 pagesRetro Marketing: By: - Ritender Pal Singh Roll No: - 08 Reg No: - 3020070133nawabrp100% (1)

- Honda Atlas: Vision StatementDocument3 pagesHonda Atlas: Vision StatementSaad ZiaNo ratings yet

- Omax Ar 09Document80 pagesOmax Ar 09jughead201985No ratings yet

- Installation and Removal of High MastDocument3 pagesInstallation and Removal of High MastMohd Hafiz Muhamed100% (1)

- YZ400WR400FDocument9 pagesYZ400WR400FhackstamNo ratings yet

- BIW Welding Fixture Design Domain TrainingDocument21 pagesBIW Welding Fixture Design Domain Trainingmohammad touffique100% (1)

- 27th International Conference On Flexible Automation and Intelligent ManufacturingDocument3 pages27th International Conference On Flexible Automation and Intelligent ManufacturingDokajanNo ratings yet

- Is 14812 2005Document12 pagesIs 14812 2005JayDeep KhajureNo ratings yet

- ALEXIS A BORISY - Comprehensive Report - 2013-08-30Document17 pagesALEXIS A BORISY - Comprehensive Report - 2013-08-30fatwa2No ratings yet

- ZF6 GEN2 Vac LocationsDocument4 pagesZF6 GEN2 Vac LocationsDavid LacunesNo ratings yet

- Trail/Beaver Valley/Rossland Pennywise June 6, 2017Document40 pagesTrail/Beaver Valley/Rossland Pennywise June 6, 2017Pennywise PublishingNo ratings yet

- Manual Bot CatDocument440 pagesManual Bot CatFranco Korn100% (1)

- MBA Project Report On Dividend PolicyDocument67 pagesMBA Project Report On Dividend PolicyMohit Kumar33% (3)

- Opel Range BrochureDocument17 pagesOpel Range Brochureapi-306904956No ratings yet

- Toyota Vios PamphleteDocument1 pageToyota Vios PamphleteNajiyah OneStopNo ratings yet

- Brevini Power Transmission Products 2008 UKDocument14 pagesBrevini Power Transmission Products 2008 UKSabith MohammedNo ratings yet

- Mechanical System Tests: Stall TestDocument8 pagesMechanical System Tests: Stall TestMayobanex Moya MartinezNo ratings yet

- SHOCK ABSORBERS - A PresentationDocument30 pagesSHOCK ABSORBERS - A PresentationRaja Sekaran SajjaNo ratings yet

- Directory 566Document210 pagesDirectory 566Anna LaClair0% (1)

- Travel Policy - India W IDC PDFDocument30 pagesTravel Policy - India W IDC PDFmahakagrawal3No ratings yet

- Consumer Behaviour Regarding BMW, Audi, MercedesDocument3 pagesConsumer Behaviour Regarding BMW, Audi, MercedesChinmayee ChoudhuryNo ratings yet

- Vehicles ListDocument9 pagesVehicles ListjohnmalanaNo ratings yet