Professional Documents

Culture Documents

Inspection Checklist

Uploaded by

mechman50 ratings0% found this document useful (0 votes)

225 views6 pagesVALLEY CENTER water DISTRICT IN-CAB CHECKLIST(engine start) AIR BRAKE TEST 1.) mirrors / windshield 2.) wiper / washers 3.) turn indicators 4.) steering play(2deg or 2.) 5.) horn 6.) gauges(clutch / brake) 8.) heater / defroster 9.) gearshift 10.) seat belt / emerg. Triangles EXPLAIN in DETAIL for

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVALLEY CENTER water DISTRICT IN-CAB CHECKLIST(engine start) AIR BRAKE TEST 1.) mirrors / windshield 2.) wiper / washers 3.) turn indicators 4.) steering play(2deg or 2.) 5.) horn 6.) gauges(clutch / brake) 8.) heater / defroster 9.) gearshift 10.) seat belt / emerg. Triangles EXPLAIN in DETAIL for

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

225 views6 pagesInspection Checklist

Uploaded by

mechman5VALLEY CENTER water DISTRICT IN-CAB CHECKLIST(engine start) AIR BRAKE TEST 1.) mirrors / windshield 2.) wiper / washers 3.) turn indicators 4.) steering play(2deg or 2.) 5.) horn 6.) gauges(clutch / brake) 8.) heater / defroster 9.) gearshift 10.) seat belt / emerg. Triangles EXPLAIN in DETAIL for

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 6

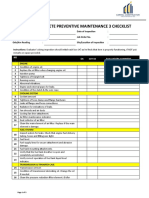

CDL PRE-TRIP INSPECTION WORKSHEET

VALLEY CENTER WATER DISTRICT

IN-CAB CHECKLIST(engine start) AIR BRAKE TEST

1.) mirrors/windshield

2.) wiper/washers

3.) turn indicators

4.) steering play(2° or 2.)

5.) horn

6.) gauges(name all)

7.) pedals(clutch/brake)

8.) heater/defroster

9.) gearshift

10.) seat belt/emerg. triangles

EXPLAIN IN DETAIL FOR EACH

ITEM NAMED WHAT YOU ARE

CHECKING FOR.

______________________________________

TRUCK/TRACTOR

Front of Vehicle Under Vehicle

Lights/turn signals Drive shaft

Steering box/hoses Exhaust system

Steering linkage Frame

Front Suspension Rear Suspension

Springs Springs/air/torque

Spring mount Spring mounts

Frame Shock absorbers

Shock absorbers

Rear Brakes

Front brake Slack adjuster

Slack adjustor Brake chamber

Brake chamber Brake hoses/lines

Brake hoses/lines Brake drum/linings

Brake drum/linings

Rear Wheels

Front Wheel Rims

Rim Tires(I-C-D)

Hub oil seal Axle seals

Lug nuts Lug nuts

Tires(I-C-D) Spacers

Driver/Fuel Area Rear of vehicle

Door, mirror Lights/reflectors

Fuel tank/leaks Doors/ties/lift

Battery box Splash guards

1.) applied psi test(3 psi in 1 min)

combination(4 psi in 1 min)

2.) governor cut out(120 psi)

3.) governor cut in(around 95 psi)

4.) low air warning device

5.) parking brake test

ENGINE COMPARTMENT

1.) oil level/coolant level

2.) power steering fluid/(belt)

3.) water pump(belt)

4.) alternator(belt)

5.) air compressor (belt)

6.) checking all hoses and for leaks

on all of the above!

___________________________________________

TRAILER

Coupling system Brakes

Air/electric lines Slack Adjustor

Mounting bolts Brake Chamber

Safety latch/pintle Brake hoses/lines

Brake drum/linings

Trailer front

Air/electric connect Wheels

Lights/reflectors Rims

Frame Tires(I.C.D.)

Axle seals

Side of trailer Lug nuts

Landing gear Spacers

Frame

Lights/reflectors Rear of Trailer

Load fasteners Lights/reflectors

Ramps/ties

Suspension Splash guards

Springs

Spring mounts

Shocks(if any)

ITEMS THAT ARE BEING CHECKED

APPLY TO BOTH SIDES OF VEHICLE

AND TRAILER! DURING THE TEST

YOU ARE ONLY REQUIRED TO NAME

ITEMS ON ONE SIDE ONLY!

CDL PRE-TRIP INSPECTION WORKSHEET

DETAILED CHECKLIST FOR IN-CAB AND AIR BRAKES

IN-CAB CHECKLIST(ENGINE START)

1.) Mirrors/windshield Check mirrors for fastening, proper alignment, and cleanl

iness.

(no cracks or missing pieces) Windshield must be clean and free from cracks.

2.) Wiper/washers - Check wiper blade condition and operation, and that washers

squirt

properly.(turn wipers on and apply washers)

3.) Turn indicators Check all indicators/lenses for proper operation, and that h

azards are

functional. Check indicator lever and indicator lights in dash.

4.) Steering play Check that steering play does not exceed 10° or 2. in a 20. whee

l, also

check for worn steering column bearings.

5.) Horn Check that horn(s) work properly.(physically honk the horn)

6.) Gauges Check that all gauges are visible and in proper working condition. Na

me each

gauge individually(temp., oil p.s.i., volt meter, fuel)

7.) Pedals Check clutch pedal for excessive free play, and ease, check that all

pedals are

not worn past the rubber covering.

8.) Heater/defroster Check the condition of heater and blower controls and that

both heater

and defroster are working.(physically turn on to check)

9.) Gearshift Check for excessive wear and ease of operation.

10.) Seat belt/emerg. equip. Check that seat belt is secure and latches properly

. Make sure

that there are (3) emerg. triangles, a fire extinguisher, and spare fuses are av

ailable.

AIR BRAKE TEST PROCEDURES (rear wheels must be blocked)

1.) Applied psi test This test is to determine the air leakage rate. Begin by st

arting the

engine to charge the air system fully, when full psi is reached turn engine off

and release

all brakes, after the initial psi drop, apply pressure to brake and time for one

minute, psi

cannot drop more than 3 psi in 1 min. for a single vehicle or 4 psi in 1 min. fo

r a

combination vehicle.

2.) Governor cut out This test is to determine at what psi the governor cuts out

. Re-start the

engine and let it idle, (you may raise rpm for faster charge) watch air psi gaug

e during

this time, when gauge stops(approx. 120 psi) the governor will cut off. Be sure

to state at

what pressure this occurred.

3.) Governor cut in This test is to determine at what psi the governor cuts in.

With engine

running at an idle slowly pump the brake,(waiting 3 sec. between pumps) watch ai

r psi

gauge during this time to see when the governor will cut in,(approx. 95psi) when

the

gauge starts moving upward, be sure to state the pressure that this occurred.

4.) Low air warning device This test is to check warning buzzer.(cannot be less

than 60psi)

Begin by turning the engine off, once engine has stopped turn the ignition back

to the on

position. Bleed the air out of the system by slowly pumping the brakes, watching

the air

psi gauge during this time, when the alarm sounds state the pressure that this o

ccurred.

5.) Parking brake test This test is to make sure the parking brake will lock the

wheels.

Begin this test by setting the parking brake, then remove wheel blocks, once bac

k in the

vehicle, fasten safety belt. Start the engine and charge the air system back to

full psi.

Shift vehicle into low gear, then release the parking brake. Roll forward slowly

(approx.

2mph), depress clutch and apply parking brake. Another method is to let the clut

ch out

against the parking brake being set. THIS COMPLETES THE AIR BRAKE TEST.

CDL PRE-TRIP INSPECTION WORKSHEET

DETAILED CHECKLIST FOR IN-CAB AND AIR BRAKES

FRONT OF VEHICLE

1.)

2.)

3.)

1.)

2.)

3.)

4.)

1.)

2.)

3.)

Lights/turn signals Check headlights for proper operation, cracks and condensati

on.

Make sure turn signals function properly, and are not cracked or broken.

Steering box/hoses Check steering box for proper mounting(not loose) and leaks a

round

the seals. Make sure hoses are in good condition (not cracked) and have no leaks

.

Steering Linkage Check that steering linkage is not worn cracked or loose.

FRONT SUSPENSION

1.) Springs Check that front springs are not worn, cracked, or broken and that n

o leafs are

missing from leaf spring stack. (no more than ¼ can be broken or missing)

2.) Spring mount Check that spring mount is secure to frame and has no cracks or

wear.

3.) Frame Check the frame in all locations for cracks or fatigue.

4.) Shock Absorbers Make sure shocks are not loose or hanging, and are not worn

out.

FRONT BRAKE

1.) Slack adjustor Adjustment should be 90° when brakes are released, and between

80°

and 105° when applied. The rod should not move more than with brakes released.

2.) Brake chamber Check for proper mounting and that chamber is not dented or le

aking.

3.) Brake hoses/lines Check all brake hoses/lines leading from compressor to air

tanks and

brake chamber for cracks and leaks. (basic condition)

4.) Brake drum/linings Check for cracks or holes and that the lining is not worn

to thin.

FRONT WHEEL

Rim Check condition of rim for cracks and bends, rim cannot have any welds on it

.

Hub oil seal Make sure that oil seal has no cracks or leaks in it. Check fluid l

evel.

Lug nuts Check lug nuts for rust(indicating loose),and that none are missing or

cracked.

Tires Check the inflation, condition, and depth (I.C.D.) of the front tire. You

must state

the letters I.C.D. when checking the tire condition. Make sure of proper inflati

on, check

the sidewall condition (inner and outer) for cuts and cracking, make sure that t

he tread

depth is a minimum of 4/32.

DRIVER/FUEL AREA

1.) Door, mirror Make sure that the driver door is hinged properly and latches s

ecurely,

check the mirror fastening and condition of glass.

2.) Fuel tank/leaks Make sure that tank is mounted properly and has no leaks.

3.) Battery box Check for proper mounting and that battery is secure in the box.

UNDER VEHICLE

Drive shaft Make sure drive shaft is not bent or cracked, and U joints are not w

orn.

Exhaust system Check for proper mounting and for holes or leaks in muffler and p

ipe.

Frame Check frame along the whole vehicle for cracks or broken welds.

REAR SUSPENSION

1.) Follow the same procedures as named in front suspension check.

REAR BRAKES

1.) Follow the same procedures as named in front brake check.

REAR WHEELS

1.) Rims Same as front rim.

2.) Tires Same as front with the exception of the tread depth being only 2/32.

3.) Axle seals Same as front seals.

4.) Lug nuts Same as front wheel.

5.) Spacers Check for spacers, (not equipped on our trucks) and for no debris be

tween the

rear tires. Dual wheels should be evenly separated.

CDL PRE-TRIP INSPECTION WORKSHEET

DETAILED CHECKLIST FOR IN-CAB AND AIR BRAKES

REAR OF VEHICLE

1.) Lights/reflectors Check all marker lights, tail lights and back up lights fo

r

proper operation, cracks or missing lenses. Make sure all reflectors are in plac

e

and proper color.

2.) Doors/ties/lift Check tail gate for proper fastening and locking.

3.) Splash guards Make sure mud flaps are mounted properly, not touching the

tires, and are not dragging on the ground.

COUPLING SYSTEM

1.) Air/electric lines Check air lines for leaks, cracks and that they are not c

oupled

together. Make sure electric lines are not frayed and are not tangled.

2.) Mounting bolts Check pintle hitch and hook for loose, broken, or missing bol

ts.

3.) Safety latch/pintle Make sure safety latch on pintle hitch locks securely, a

nd that

safety chains are not worn or dragging on the ground.

TRAILER FRONT

1.) Air/electric connect Check that glad hands are connected properly and are no

t

leaking. Make sure electric plug is connected firmly in place.

2.) Lights/reflectors Make sure that all lights are working and lenses are not b

roken.

Check reflectors for proper color and that they are not broken or missing.

3.) Frame Check tongue area for cracks and broken welds.

SIDE OF TRAILER

1.) Landing gear Make sure landing gear is fully retracted and secure.

2.) Frame Continue to check the frame for cracks or broken welds.

3.) Lights/reflectors Continue to check lights and reflectors as done on front.

4.) Load fasteners Check load fasteners for wear and cracked welds.

SUSPENSION

1.) Springs Check springs for cracks broken or missing leafs.

2.) Spring mounts Make sure mounts are secure and have no cracks or broken welds

.

3.) Shocks Check that shocks are mounted properly and are not worn out.

BRAKES

5.) Slack adjustor Adjustment should be 90° when brakes are released, and between

80°

and 105° when applied. The rod should not move more than with brakes released.

6.) Brake chamber Check for proper mounting and that chamber is not dented or le

aking.

7.) Brake hoses/lines Check all brake hoses/lines leading from compressor to air

tanks and

brake chamber for cracks and leaks. (basic condition)

8.) Brake drum/linings Check for cracks or holes and that the lining is not worn

to thin.

WHEELS

1.) Rim Check the condition of the rim for cracks and bends, the rim cannot have

any

welds or repairs on them.

2.) Tires Check the (I.C.D.) of the tires as done on the rear of the truck. (2/3

2 tread)

3.) Axle seals Make sure that oil seal has no cracks or leaks in it. Check fluid

level.

4.) Lug nuts Check lug nuts for rust (indicating loose), and that none are missi

ng or cracked.

5.) Spacers Check spacers (if equipped) and for no debris between the tires. Dua

l wheels

should be evenly separated.

REAR OF TRAILER

4.) 1.) Lights/reflectors Check all marker lights, and tail lights for proper op

eration,

cracks or missing lenses. Make sure all reflectors are in place and proper color

.

5.) Ramps/ties Check ramps for proper fastening and locking.

6.) Splash guards Make sure mud flaps are mounted properly, not touching the

tires, and are not dragging on the ground.

You might also like

- Excavator Pre-Use Inspection ChecklistDocument1 pageExcavator Pre-Use Inspection ChecklistFyan SaputraNo ratings yet

- TA-2 Visual & Technical Inspection for Wheeled ExcavatorsDocument24 pagesTA-2 Visual & Technical Inspection for Wheeled Excavatorscarlos angelNo ratings yet

- Required Manuals and Documentation: Honda Certified Used Cars 150 Point Inspection ChecklistDocument2 pagesRequired Manuals and Documentation: Honda Certified Used Cars 150 Point Inspection ChecklistKaiser Shaikh100% (2)

- Excavator Pre-Use Inspection ChecklistDocument1 pageExcavator Pre-Use Inspection ChecklistMd. Ashraful Islama100% (1)

- SotBPlayersGuide v1.0.1Document20 pagesSotBPlayersGuide v1.0.1Asen100% (3)

- Vehicle Inspection Form 01Document1 pageVehicle Inspection Form 01GuruNo ratings yet

- Safety & Maintenance Inspection (902-938) : Wheel LoaderDocument2 pagesSafety & Maintenance Inspection (902-938) : Wheel LoaderRossman Mejicanos100% (1)

- Guideline For Examining Failed Parts (1000, 7000) : Applied Failure AnalysisDocument70 pagesGuideline For Examining Failed Parts (1000, 7000) : Applied Failure AnalysisKusuma Jaya100% (1)

- Annual Vehicle Inspection Form: Area Item Inspection Focus of Inspection Finding CommentsDocument9 pagesAnnual Vehicle Inspection Form: Area Item Inspection Focus of Inspection Finding CommentsrickyNo ratings yet

- Safety & Maintenance Checklist-Wheel HarvesterDocument1 pageSafety & Maintenance Checklist-Wheel HarvesterParth PatelNo ratings yet

- Vehicle inspection checklistDocument1 pageVehicle inspection checklistChaudhary Wasim MurtazaNo ratings yet

- Vehicle TIDocument2 pagesVehicle TIBacolod PS SevenNo ratings yet

- TA1 English - Wheel LoaderDocument20 pagesTA1 English - Wheel Loadercarlos angel100% (2)

- Daily Pre-Operationla Check List (Excavator)Document1 pageDaily Pre-Operationla Check List (Excavator)Soufian BahmadNo ratings yet

- Front End Loader Preventive Maintenance ChecklistDocument1 pageFront End Loader Preventive Maintenance ChecklistNamron AicragNo ratings yet

- Kmoch 05Document7 pagesKmoch 05SnajhngtNo ratings yet

- MASTER Monthly Vehicle Inspection ReportDocument2 pagesMASTER Monthly Vehicle Inspection Reportrahul kavirajNo ratings yet

- Truck Inspection FormDocument1 pageTruck Inspection FormMOHAMED RADYNo ratings yet

- Equipment/Vehicle Checklist: Name of Company: Date/Time: Machine Make & Model: Unit #: Mileage: Km/milesDocument2 pagesEquipment/Vehicle Checklist: Name of Company: Date/Time: Machine Make & Model: Unit #: Mileage: Km/milesJack PNo ratings yet

- C10836843 PDFDocument1 pageC10836843 PDFsandrobhaNo ratings yet

- Safety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Document1 pageSafety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Abdellatef HossamNo ratings yet

- Road Grader Daily Inspection by OperatorDocument1 pageRoad Grader Daily Inspection by OperatorNasrullah Khan Yousafzai100% (1)

- Backhoe-Rock Breaker Inspection ChecklistDocument1 pageBackhoe-Rock Breaker Inspection ChecklistAlok Singh100% (1)

- Safety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFDocument1 pageSafety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFcherifNo ratings yet

- Backhoe Preventive Maintenance ChecklistDocument1 pageBackhoe Preventive Maintenance ChecklistJoshua CastroNo ratings yet

- Cat PlannerDocument1 pageCat PlannerSidhartha MallickNo ratings yet

- Safety & Maintenance Checklist Underground LoadersDocument1 pageSafety & Maintenance Checklist Underground LoadersGustavoNo ratings yet

- Backhoe English PDFDocument1 pageBackhoe English PDFGino AndersonNo ratings yet

- Service Report: GraderDocument3 pagesService Report: Graderainul arifNo ratings yet

- TA1 English - Articulated TruckDocument15 pagesTA1 English - Articulated Truckcarlos angelNo ratings yet

- Safety & Maintenance Checklist - Waste Industry-Landfill CompactorsDocument1 pageSafety & Maintenance Checklist - Waste Industry-Landfill CompactorskkmechNo ratings yet

- TA1 English - Backhoe LoaderDocument35 pagesTA1 English - Backhoe Loadercristian chuquicondor torresNo ratings yet

- Manitowoc 18000: Product GuideDocument64 pagesManitowoc 18000: Product Guideluciano GarciaNo ratings yet

- Front-End Loader Safety ProceduresDocument15 pagesFront-End Loader Safety Proceduresreda mesbahNo ratings yet

- Tyre Inspection ChecklistDocument2 pagesTyre Inspection ChecklistElgrego Wayne Swartz100% (1)

- Safety & Maintenance Checklist Underground Trucks PDFDocument1 pageSafety & Maintenance Checklist Underground Trucks PDFGustavoNo ratings yet

- Crane Preventive Maintenance ChecklistDocument3 pagesCrane Preventive Maintenance ChecklistAbdul HalimNo ratings yet

- Monthly Crane Inspection ChecklistDocument2 pagesMonthly Crane Inspection Checklistslamet4riadiNo ratings yet

- Safety & Maintenance Checklist - Landfill Compactors V0611.2Document1 pageSafety & Maintenance Checklist - Landfill Compactors V0611.2cherifNo ratings yet

- Mobile Crane Monthly ChecklistDocument3 pagesMobile Crane Monthly ChecklistDAOUMY YOUNESSNo ratings yet

- Excavator FormsDocument5 pagesExcavator FormsMarc ChuttooNo ratings yet

- Safety & Maintenance Checklist - Motor GradersDocument1 pageSafety & Maintenance Checklist - Motor Graderskkmech83% (6)

- Mobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncDocument5 pagesMobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncCarwill TesdaNo ratings yet

- The NamesakeDocument3 pagesThe Namesakenilanjan_chatterje_2100% (2)

- Grader ChecklistDocument16 pagesGrader ChecklistJhun Aquino100% (1)

- RDDPartyPack2017 1498827866Document24 pagesRDDPartyPack2017 1498827866Cameron SmithNo ratings yet

- Front End Loader SafetyDocument32 pagesFront End Loader SafetyAshraful AlamNo ratings yet

- Operator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsDocument1 pageOperator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsPradeep ShindeNo ratings yet

- Drum Rooller Daily ChecklistDocument1 pageDrum Rooller Daily ChecklistMD AbdullahNo ratings yet

- CME CPQ PDF-enDocument1,015 pagesCME CPQ PDF-enmarcin lipiecNo ratings yet

- Asahi Pentax Spotmatic Shutter and Film Mechanism ManualDocument51 pagesAsahi Pentax Spotmatic Shutter and Film Mechanism Manualmamamojo100% (1)

- Multi-channel formats in electroacoustic compositionDocument4 pagesMulti-channel formats in electroacoustic compositionNikos StavropoulosNo ratings yet

- Astra D.truck ChecklistDocument9 pagesAstra D.truck ChecklistEyobNo ratings yet

- Weekly Lift Truck Safety ChecksDocument2 pagesWeekly Lift Truck Safety Checkstemter gandaNo ratings yet

- Excavator Pre-Use InspectionDocument1 pageExcavator Pre-Use Inspectionshabban4uNo ratings yet

- D4 - Vehicle Inspection ReportDocument1 pageD4 - Vehicle Inspection ReportPolycarp Danson SigaiNo ratings yet

- Bus Inspection ChecklistDocument1 pageBus Inspection ChecklistRuzaini MohamedNo ratings yet

- Crane Daily Inspection Checklist-Sa 9466Document1 pageCrane Daily Inspection Checklist-Sa 9466Ricardo DalisayNo ratings yet

- Annual Vehicle Inspection ReportDocument1 pageAnnual Vehicle Inspection ReportAdolphe HotereshiNo ratings yet

- TA2 English - Wheel Tractor ScraperDocument32 pagesTA2 English - Wheel Tractor Scrapercarlos angelNo ratings yet

- Tangguh LNG Operation Equipment Inspection ChecklistsDocument7 pagesTangguh LNG Operation Equipment Inspection ChecklistsadinugrohoNo ratings yet

- TA2 English - Excavator (Terminado)Document41 pagesTA2 English - Excavator (Terminado)Efrain DYNo ratings yet

- L - (MG) - FRM - 111 - R1 Vehicle Daily ChecklistDocument1 pageL - (MG) - FRM - 111 - R1 Vehicle Daily ChecklistEdhz Bilog100% (1)

- Forklift Service Report: Form No.: Rev: Effective Date: Prepared byDocument1 pageForklift Service Report: Form No.: Rev: Effective Date: Prepared byBarath100% (1)

- Weekly Standard InspectionDocument3 pagesWeekly Standard InspectionFrancis Salonga100% (1)

- Vehicle Inspection Study Guide Straight Truck/School Bus: Department of Motor VehiclesDocument2 pagesVehicle Inspection Study Guide Straight Truck/School Bus: Department of Motor VehiclesJohn HamiltonNo ratings yet

- Inspection: 1. Tighten Bolts and Nuts On Chassis and BodyDocument8 pagesInspection: 1. Tighten Bolts and Nuts On Chassis and BodyTomas DominguezNo ratings yet

- Ejercicios Pasado SimpleDocument2 pagesEjercicios Pasado Simplenuevavida35No ratings yet

- En - HDL20-A Spec SheetDocument4 pagesEn - HDL20-A Spec SheetNiviNo ratings yet

- DT 104 BrochDocument2 pagesDT 104 BrochSony ZebuaNo ratings yet

- Add Audacity Soundtrack to SlideshowDocument15 pagesAdd Audacity Soundtrack to SlideshowMarija LuloNo ratings yet

- Breakfast (Morning) Lunch or Dinner (Noon To Evening) Drinks DessertsDocument4 pagesBreakfast (Morning) Lunch or Dinner (Noon To Evening) Drinks DessertsJa CkiNo ratings yet

- Hostel B Menu From 16 March To 31 March'2024Document4 pagesHostel B Menu From 16 March To 31 March'2024govindkauNo ratings yet

- Cultural Diversity and Influences Shaped Indonesian MusicDocument12 pagesCultural Diversity and Influences Shaped Indonesian MusicjhokenNo ratings yet

- Book ReviewDocument2 pagesBook ReviewEricko MarvinNo ratings yet

- MPAA Ex Parte Communication MB Docket No 08-82 (November 4, 2009)Document7 pagesMPAA Ex Parte Communication MB Docket No 08-82 (November 4, 2009)sperlingreichNo ratings yet

- AS 119336 XG-X LineScan SG A21GB WW GB 2033 3Document164 pagesAS 119336 XG-X LineScan SG A21GB WW GB 2033 3DeaNo ratings yet

- Kasut You 2.3Document21 pagesKasut You 2.3AdamZain788No ratings yet

- Datasheet of THC-D320-VF V1.0.1 20181008 PDFDocument3 pagesDatasheet of THC-D320-VF V1.0.1 20181008 PDFIT.COMPany Intelligent SolutionsNo ratings yet

- Wireless World 1950 12Document41 pagesWireless World 1950 12Jan PranNo ratings yet

- SMO Project On MI PhoneDocument67 pagesSMO Project On MI PhoneVishalNo ratings yet

- GolgothansDocument2 pagesGolgothansMike UrsuNo ratings yet

- Future Time ClausesDocument3 pagesFuture Time ClausesLisania Maria Jimenez MendozaNo ratings yet

- NLSC - Officiaggggl Pba 2k14 v2Document33 pagesNLSC - Officiaggggl Pba 2k14 v2JongardsOllirumNo ratings yet

- Disney Luxury Homes in Hyderabad's Financial DistrictDocument21 pagesDisney Luxury Homes in Hyderabad's Financial DistrictKota RavichandNo ratings yet

- New York Tourist Map PDFDocument1 pageNew York Tourist Map PDFRaquelNo ratings yet

- SwordDocument47 pagesSwordPlaymaker DhimasNo ratings yet

- I. Directions: Give The Two Original Words That Were Combined To Form The Following Blended Words. An Example Given To Help Guide YouDocument1 pageI. Directions: Give The Two Original Words That Were Combined To Form The Following Blended Words. An Example Given To Help Guide YouMarisa LeeNo ratings yet

- Hm75 Mobile Chipset BriefDocument4 pagesHm75 Mobile Chipset BriefAjit KumarNo ratings yet

- Chef John's Calabrian Chicken RecipeDocument2 pagesChef John's Calabrian Chicken RecipearkcaverNo ratings yet