Professional Documents

Culture Documents

Principal Engineer

Uploaded by

api-773444040 ratings0% found this document useful (0 votes)

24 views3 pagesPrincipal Engineer with 41 years experience looking for a Middle Management position.

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPrincipal Engineer with 41 years experience looking for a Middle Management position.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views3 pagesPrincipal Engineer

Uploaded by

api-77344404Principal Engineer with 41 years experience looking for a Middle Management position.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 3

OBJECTIVES

Senior Staff or Principal level Engineering or Managerial position, where prove

n strengths in the areas of analysis and problem solving combined with leadershi

p and design skills will help an organization scope, plan and execute through co

mpletion Engineering and/or Maintenance projects.

BACKGROUND SUMMARY

Principal Engineer with extensive petrochemical industry experience in various t

echnical and managerial positions emphasizing in Instrumentation and Control Sys

tems Maintenance and Project Engineering functions including:

- Lead Control Systems Engineer

- Dep. Head of Plant Maintenance and Engineering

- Design and Maintenance of instrument systems

- Design and troubleshooting of SIS

- Project Management

PROFESSIONAL ACCOMPLISHMENTS

Provided technical leadership to a group of local and foreign (India) engineers

in scoping, specifying, procuring and detail designing a Sulphur Recovery Unit,

a Sour Water Stripper Unit and an Amine Regeneration Unit. This resulted in acc

omplishing a successful accelerated schedule for the project.

Led the instrumentation and controls effort of PHA/HAZOP activities for a Sulfur

Recovery Unit, Amine Regeneration Unit and Sour Water Stripper Unit resulting i

n a risk reducing, safe design.

Provided instrumentation and controls consulting services for the implementation

of gas pipeline projects for customers without design standards. This resulted

in successfully guiding the customer to the usage of current and complying with

ISA standards.

Developed Process Control Strategy Documentation for a Lactic Acid Boiling Tube

Evaporators unit and detail Functional Specifications for Control Systems integr

ation of a Polyurethane R&D Reactor and an AG Products Palletizing unit This re

sulted in on-time development of control code eliminating the need to assign add

itional resources.

Led a group of in-house and contract engineers in developing scope, design, cons

truction and start-up of a multimillion-dollar overseas infrastructure project i

ncluding Power Boilers, Air Separation Plant, Incinerators and Water Treating fa

cilities. This Plant was successfully started on time.

Completed Control Systems detail design safety reviews for Safety Instrumented S

ystems (SIS) and non-SIS instrumentation projects. These reviews resulted in ri

sk reduction and hazard prevention for successful start-ups.

Evaluated and recommended design changes for upgrading safety systems in domesti

c and foreign sites to ANSI/ISA S84.01 compliance. Implementation of these syst

ems resulted in improved emergency shutdown systems for Plant protection.

Led as Subject Matter Expert (SME) in-house and contract engineers and designers

developing Readiness and Remediation Guides for PLC and other equipment with Y2

K impacted embedded devices. This work resulted in an uneventful year 2000 trans

ition for the Corporation.

Developed and implemented training programs for Control Systems Engineers in Kuw

ait. These programs resulted in successful support of the commissioning and sta

rt-up of the infrastructure of a new grass-roots multibillion-dollar petrochemic

al plant.

Successfully managed a Plant Maintenance Department consisting of engineers, spe

cialists, supervisors and hourly personnel with responsibilities over three oper

ating units plus the shops. Productivity and timeliness commitments were surpas

sed while achieving safety goals in normal operation as well as during shutdowns

.

Successfully managed a Plant Engineering Department consisting of Instrument and

Electrical Engineers and draftspersons. The Capital and Expense budget project

s were executed on time, within cost estimates and with efficient utilization of

resources.

EMPLOYMENT EXPERIENCE

Bergaila & Assoc./FLUOR Corp.

Principal Control Systems Engineer, Houston, TX. Contract work as Lead Area Eng

ineer responsible for the instrumentation and control systems on a Sulfur Recove

ry Unit, Amine Regeneration Unit and Sour Water Stripper Unit to be built in the

Republic of Tatarstan, Russia. (1/2008 to 9/2009)

Aker Kvaerner Inc.

Senior Control Systems Engineer, Belle, WV. Provided instrumentation and contro

l systems consulting support and project engineering support at a DuPont plant s

ite in the development of basic scope, functional specifications and design of v

arious utility and infrastructure projects including condensate recovery, power

boilers controls conversions and waste treatment improvements. Provided design

support on various Glycolic Acid Unit instrumentation projects. (9/2005 to 9/200

7)

AED Inc.

Senior Control Systems Engineer, South Charleston, WV. Provided instrumentation

and control systems consulting support in the development of basic scope, funct

ional specifications and design of various gas pipeline projects. (2/2005 to 9/2

005)

TAI Inc.:

Lead Process Automation Engineer, South Charleston and Cross Lanes, WV. Respons

ible for the development of Process Control Strategy Documentation and Functiona

l Specifications for a Lactic Acid Plant project, a Automotive Glass Bonding Pla

nt Upgrade project a Control Building Integration project, AG Products Bagging a

nd Palletizing project and a Polyurethane Reaction R&D project using Global Proj

ect Methodologies. (2/2001 to 2/2005)

DOW Chemicals Co.:

Lead Control Systems Engineer, South Charleston, WV. Provided technical leaders

hip in developing and implementing control systems for a Lactic Acid to Polyeth

ylene manufacturing Plant.

(1/2000 to 2/2001)

Union Carbide Corp.:

Worked in various domestic and international locations as Project Manager, Maint

enance Department Head, Engineering Department Head, Area Lead Maintenance Engin

eer and Lead Control Systems Engineer supporting Plants operations. (1969 to 1/2

000)

EDUCATIONAL BACKGROUND

BS Electrical Engineering, Cum Laude, University of Puerto Rico

Fully Bilingual, English - Spanish

Training Programs:

- Six Sigma Green Belt - Analyzer Project Engineering

- TRICONIX, Tricon SIS Implementation

- HONEYWELL, TDC 3000 Universal Station

- Puffer-Sweiven, MODICON PLC

- Fred Pryor, Project Management

- AMA, Project Manager Managerial Skills

- AMA, Supervision and Administrative Skills

- UPR, Chemical Engineering Fundamentals

- MICRSOFT, Word, Excel and Power Point

- Rockwell, Device Net

- VEI Inc., Value Engineering 1 and 2

- ISA, Control Valve Sizing and Selection

- Bently Nevada, Vibration Monitoring Systems

- ISA, Flow Meter Engineering

- GE, Speedtronic Gas Turbine Controls

- Others

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- LED LCD TV Repair Guide: WWW - Television-Magazine - Co.ukDocument47 pagesLED LCD TV Repair Guide: WWW - Television-Magazine - Co.ukShauna WhelanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Smart Sketch GuideDocument690 pagesSmart Sketch Guidesenthilsp3d100% (1)

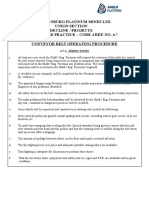

- 4.7 Conveyor Belt Operating ProcedureDocument3 pages4.7 Conveyor Belt Operating Procedurejohnson OlubiNo ratings yet

- 1 ODI LessonsDocument234 pages1 ODI LessonsAhmed AliNo ratings yet

- Cookbook Measuring StrategiesDocument27 pagesCookbook Measuring StrategiesArzillo Salvatore50% (2)

- Timber-framed homes guideDocument44 pagesTimber-framed homes guideMtkNo ratings yet

- CERT-In Empanel OrgDocument141 pagesCERT-In Empanel OrgavinashrajsumanNo ratings yet

- Flipkart's Big Billion Day Sale IT FailuresDocument21 pagesFlipkart's Big Billion Day Sale IT FailuresManisha KumariNo ratings yet

- Shale ShakerDocument3 pagesShale ShakerkosunlucyNo ratings yet

- Strategic Management g9 Elon Musk BetsDocument5 pagesStrategic Management g9 Elon Musk BetsJaya Neelanshi SethNo ratings yet

- Rotex Poly-Norm: Torsionally Flexible CouplingsDocument27 pagesRotex Poly-Norm: Torsionally Flexible CouplingsAngelica Ochoa FlorezNo ratings yet

- Mohamed Badr CVDocument2 pagesMohamed Badr CVMohamed BadrNo ratings yet

- Minimum Equipment List (MEL) - SKYbrary Aviation SafetyDocument1 pageMinimum Equipment List (MEL) - SKYbrary Aviation SafetyhmmnksyNo ratings yet

- Project Management For Construction - The Design and Construction ProcessDocument3 pagesProject Management For Construction - The Design and Construction ProcessMark Alvin L. AcordaNo ratings yet

- Urban Planning With GisDocument9 pagesUrban Planning With GisMostaque AhmedNo ratings yet

- SCHLENKER Katalog 2022 EN - WEBDocument136 pagesSCHLENKER Katalog 2022 EN - WEBhosseinNo ratings yet

- Cam350 810Document4 pagesCam350 810Frank ZamoraNo ratings yet

- SOP Sample SubmissionDocument9 pagesSOP Sample SubmissionMUDASSAR AFZAL100% (1)

- Designsolutions 2010springDocument68 pagesDesignsolutions 2010springjkarpitskiyNo ratings yet

- Engineering Economics Chapter 2 & 3Document14 pagesEngineering Economics Chapter 2 & 3byun baekNo ratings yet

- Ch11Integer Goal ProgrammingDocument54 pagesCh11Integer Goal ProgrammingAngelina WattssNo ratings yet

- D9 MG GensetDocument4 pagesD9 MG GensetAji HandokoNo ratings yet

- Electronic Government - Concepts, Tools, Methodologies, and Applications - Introductory ChapterDocument35 pagesElectronic Government - Concepts, Tools, Methodologies, and Applications - Introductory ChapterСтаменић МаринаNo ratings yet

- Alcatel Extension CodesDocument2 pagesAlcatel Extension Codesranma_ptNo ratings yet

- Richa Industries Wins First Rail Over Bridge Project For Railways (Company Update)Document2 pagesRicha Industries Wins First Rail Over Bridge Project For Railways (Company Update)Shyam SunderNo ratings yet

- Philips: Failure Mode and Effect AnalysisDocument74 pagesPhilips: Failure Mode and Effect AnalysisBunga MelurNo ratings yet

- Infineon FS30R06XL4 IGBT DatasheetDocument10 pagesInfineon FS30R06XL4 IGBT Datasheetmv_gearNo ratings yet

- Crossing The Bridge The Effects of Time Varying Tolls On Curbing Congestion 2016 Transportation Research Part A Policy and PracticeDocument19 pagesCrossing The Bridge The Effects of Time Varying Tolls On Curbing Congestion 2016 Transportation Research Part A Policy and PracticeZen ZeeNo ratings yet

- Honda Sales ProjectDocument72 pagesHonda Sales Projectsurendar100% (2)

- ISO 6346 - Wikipedia, The Free EncyclopediaDocument10 pagesISO 6346 - Wikipedia, The Free EncyclopediaJogi Oscar SinagaNo ratings yet