Professional Documents

Culture Documents

Is 1239

Uploaded by

gopi_krishnan_29Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1239

Uploaded by

gopi_krishnan_29Copyright:

Available Formats

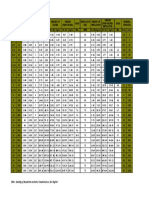

SPECIFICATION FOR MILD STEEL TUBES AND

TUBULARS CONFORMING TO IS - 1239 (PART I ) : 1990

Calculated Wt.

Mass of Black

of Galvanised

Nominal Class Outside Diameter Thickness SWG Tube Black Plain End Galvanised S & S

Tube

Bore (NB) MAX MIN P/E S/S

P/E S/S

mm Inches mm mm mm Kg/m Kg/m Mtrs/Ton Ft/Ton Pcs/Bdle Kg/m Kg/m Mtrs/Ton Ft/Ton Pcs/Bdle

L 21.40 21.00 2.00 14 0.947 0.956 1056 3465 176 0.999 1.008 992 3255 165

15 (1/2”) M 21.80 21.00 2.60 12 1.21 1.22 826 2710 138 1.264 1.274 785 2575 131

H 21.80 21.00 3.20 10 1.44 1.45 694 2277 116 1.494 1.504 665 2182 111

L 26.90 26.40 2.30 13 1.38 1.39 725 2379 121 1.441 1.451 689 2260 115

20 (3/4”) M 27.30 26.50 2.60 12 1.56 1.57 641 2103 107 1.622 1.632 613 2011 102

H 27.30 26.50 3.20 10 1.87 1.88 535 1755 89 1.923 1.933 517 1696 86

L 33.80 33.20 2.60 12 1.98 2.00 505 1657 84 2.062 2.082 480 1575 80

25 (1”) M 34.20 33.30 3.20 10 2.41 2.43 415 1362 69 2.495 2.515 398 1306 66

H 34.20 33.30 4.00 8 2.93 2.95 341 1119 57 3.028 3.048 328 1076 55

L 42.50 41.90 2.60 12 2.54 2.57 394 1293 66 2.641 2.671 374 1227 62

32 (11/4”) M 42.90 42.00 3.20 10 3.10 3.13 323 1060 54 3.207 3.237 309 1014 52

H 42.90 42.00 4.00 8 3.79 3.82 264 866 44 3.887 3.917 255 837 43

L 48.40 47.80 2.90 11 3.23 3.27 310 1017 52 3.358 3.398 294 965 49

40 (11/2”) M 48.80 47.90 3.20 10 3.56 3.60 281 922 47 3.681 3.721 269 883 45

H 48.80 47.90 4.00 8 4.37 4.41 229 751 38 4.485 4.525 221 725 37

L 60.20 59.60 2.90 11 4.08 4.15 245 804 41 4.225 4.295 233 764 39

50 (2”) M 60.80 59.70 3.60 9 5.03 5.10 199 653 33 5.166 5.236 191 627 32

H 60.80 59.70 4.50 7 6.19 6.26 162 531 27 6.349 6.419 156 512 26

L 76.00 75.20 3.20 10 5.71 5.83 175 574 29 5.898 6.018 166 545 28

65 (21/2”) M 76.60 75.30 3.60 9 6.42 6.54 156 512 26 6.621 6.741 144 486 25

H 76.60 75.30 4.50 7 7.93 8.05 126 413 21 8.095 8.215 122 400 20

L 88.70 87.90 3.20 10 6.72 6.89 149 489 25 6.925 7.122 140 459 23

80 (3”) M 89.50 88.00 4.00 8 8.36 8.53 120 394 20 8.586 8.756 114 374 19

H 89.50 88.00 4.80 6 9.90 10.40 101 331 17 10.109 10.609 97 318 16

L 113.90 113.00 3.60 9 9.75 10.00 103 338 17 10.276 10.586 94 308 16

100 (4”) M 115.00 113.10 4.50 7 12.20 12.50 82 269 14 12.758 13.258 75 246 13

H 115.00 113.10 5.40 5 14.50 14.80 69 226 12 15.252 15.552 64 210 11

M 140.80 138.50 4.80 6 15.90 16.40 63 207 11 16.649 17.149 58 190 10

125 (5”) H 140.80 138.50 5.40 5 17.90 18.40 56 184 9 18.619 19.119 52 171 9

M 166.50 163.90 4.80 6 18.90 19.50 53 174 9 19.700 20.300 49 161 8

150 (6”) H 166.50 163.90 5.40 5 21.30 21.90 47 154 8 22.322 22.922 44 144 7

TOLERANCE : Thickness : Light : + Unlimited Medium / Heavy : + Unlimited Weight : Light : ± 5%, Medium / Heavy : ± 7.5%

- 8% - 10% (For quantities per load of 10 Tonnes Minimum)

HYDRO TEST PRESSURE : 5 MPa IS : 1239 (Part I) - 1979 Mild Steel Tubes

MAXIMUM PERMISSIBLE PRESSURE AND TEMPERATURE

FOR TUBES FOR CONVEYING STEAM

The maximum permissible pressure and temperature for tubes with screwed and socketed joints shall be as follows.

MAXIMUM PERMISSIBLE PRESSURE AND TEMPERATURE FOR TUBES

WITH STEEL COUPLINGS OR SCREWED AND SOCKETED JOINTS

Nominal Bore Maximum Permissible Maximum Permissible

Pressure Temperature

mm N/mm2 Kg/cm2 0

C

Up to and including 25 mm 1.20 12.24 260

Over 25 mm upto and including 40 mm 1.03 10.50 260

Over 40 mm upto and including 80 mm 0.86 8.77 260

Over 80 mm upto and including 100 mm 0.69 7.04 260

0.83 8.47 177

Over 100 mm up to and including 125 0.69 7.04 171

Over 125 mm up to and including 150 mm 0.50 5.10 160

You might also like

- Brides Plates A Souder PN 10Document1 pageBrides Plates A Souder PN 10www.2micNo ratings yet

- Brides Plates A Souder PN 10Document1 pageBrides Plates A Souder PN 10Mohamed ChahidNo ratings yet

- BS 1387-1985Document2 pagesBS 1387-1985Dinh Nguyen DaoNo ratings yet

- Catalogo Donghua Cadenas VariasDocument46 pagesCatalogo Donghua Cadenas Variasj.arriolaNo ratings yet

- HeaDocument1 pageHeaYorgelis LopezNo ratings yet

- Tabla Pesos IPNDocument47 pagesTabla Pesos IPNbenjaminNo ratings yet

- Brides A Collorette PN 16Document1 pageBrides A Collorette PN 16Mohamed ChahidNo ratings yet

- Brides Plates A Souder PN 16Document1 pageBrides Plates A Souder PN 16Mohamed ChahidNo ratings yet

- Flansze DIN2573 PN6Document1 pageFlansze DIN2573 PN6PawelNo ratings yet

- Square Pipe (Ok)Document4 pagesSquare Pipe (Ok)Tran Anh TuanNo ratings yet

- Torque de Pernos y Caracteristicas de PernosDocument17 pagesTorque de Pernos y Caracteristicas de PernosIvan HormazabalNo ratings yet

- Civata Sikma TorklariDocument1 pageCivata Sikma Torklarimakineci_67No ratings yet

- Acoplamiento Rígido DIN116Document2 pagesAcoplamiento Rígido DIN116dem priceNo ratings yet

- AZ SheetpileDocument2 pagesAZ SheetpiledgrantNo ratings yet

- Catalogo TTCDocument4 pagesCatalogo TTCdaniloreaNo ratings yet

- PN 6 & 10Document1 pagePN 6 & 10prabakaranNo ratings yet

- Laminate - EUROPROFILE - 2011Document10 pagesLaminate - EUROPROFILE - 2011Serban TudorNo ratings yet

- CMM-Tabla de Perfiles HEB - DIN 1026 PDFDocument1 pageCMM-Tabla de Perfiles HEB - DIN 1026 PDFJose RomeroNo ratings yet

- Tabela Comparativa de DurezasDocument4 pagesTabela Comparativa de DurezassofiaNo ratings yet

- ArmaturaDocument7 pagesArmaturaIvan KelamNo ratings yet

- Din 2503 pn25 pn40 Plate Flange PDFDocument1 pageDin 2503 pn25 pn40 Plate Flange PDFTerzimehić AlenNo ratings yet

- Pipe Weight SpanDocument1 pagePipe Weight SpanNIRMAL SINGHNo ratings yet

- 03302005A1 Torque PernosDocument8 pages03302005A1 Torque Pernosdaviii100% (1)

- Vigas-de-acero-WF - (Alma-Llena) - AgoferDocument5 pagesVigas-de-acero-WF - (Alma-Llena) - AgoferCristian SolanoNo ratings yet

- Ansat Putr Bidang Cipta Karya Tahun 2022Document102 pagesAnsat Putr Bidang Cipta Karya Tahun 2022Lola AmaliyaNo ratings yet

- 08 Poutrelles HEMDocument2 pages08 Poutrelles HEMNora MazariNo ratings yet

- Métré Des ConduitesDocument15 pagesMétré Des ConduitesMANo ratings yet

- Dimenssion Des ProfilesDocument2 pagesDimenssion Des ProfilesYounes ChaaNo ratings yet

- 202 m55HJoxsaIepigel DIN933 - Bulon HexagonalDocument2 pages202 m55HJoxsaIepigel DIN933 - Bulon HexagonalIndian ChiefNo ratings yet

- Standard Steel I Beam PropertiesDocument1 pageStandard Steel I Beam PropertiesGlenda SibongaNo ratings yet

- Az Data SheetDocument2 pagesAz Data Sheetsebastian PeñalozaNo ratings yet

- Gambar Jemb. Timurung PDFDocument37 pagesGambar Jemb. Timurung PDFArielNo ratings yet

- Tableau Section D'acierDocument3 pagesTableau Section D'acierTouati BelghaliNo ratings yet

- Beams CalculationDocument6 pagesBeams Calculationsaid50% (2)

- Tabela de TorqueDocument1 pageTabela de TorqueArtur FelipeNo ratings yet

- Pipa HitamDocument1 pagePipa HitamAmadeus CocaNo ratings yet

- A1085 Dimensions and Properties Rect. HssDocument10 pagesA1085 Dimensions and Properties Rect. HssIngenieria TendNo ratings yet

- Din 272Document1 pageDin 272Ever QhNo ratings yet

- Nema 2Document9 pagesNema 2lupillorivera9981No ratings yet

- Wa0000Document7 pagesWa0000Mamadou MBAYENo ratings yet

- JIS B2220 - Flanges 5K 10K PDFDocument1 pageJIS B2220 - Flanges 5K 10K PDFLiam Choon SengNo ratings yet

- Wa0001.Document7 pagesWa0001.Jack Arjax Rutherford SaintNo ratings yet

- Piping Manhour and CostingDocument37 pagesPiping Manhour and Costingruel buntogNo ratings yet

- Apêndice B e C - Resistência Dos Materiais R. C. Hibbeler 7 EdDocument6 pagesApêndice B e C - Resistência Dos Materiais R. C. Hibbeler 7 EdStefano Taina Silva AlvesNo ratings yet

- 4 C 598 D 2 A 0 FFFD 5 BadbccDocument15 pages4 C 598 D 2 A 0 FFFD 5 Badbccapi-704419790No ratings yet

- Torque y Fuerza, MMDocument1 pageTorque y Fuerza, MMJusto AbrilNo ratings yet

- Calcule Du Réseau (Version F)Document5 pagesCalcule Du Réseau (Version F)Vatimetou EL BECHIRNo ratings yet

- Tabla Perfiles Acero LaminadoDocument12 pagesTabla Perfiles Acero LaminadoArq Paola LamasNo ratings yet

- Tabela de Peso Parafuso SXT Din 933Document1 pageTabela de Peso Parafuso SXT Din 933Patricio SouzaNo ratings yet

- Tabela de Peso Parafuso SXT Din 933Document1 pageTabela de Peso Parafuso SXT Din 933Gabrielle GrossoNo ratings yet

- 管道公称直径壁厚及压力对照表Document4 pages管道公称直径壁厚及压力对照表May LeeNo ratings yet

- A-Columns ADocument6 pagesA-Columns AAyham AbboudNo ratings yet

- PipeweightDocument24 pagesPipeweightgopaltryNo ratings yet

- RSE-Concepts de Base - QCMDocument3 pagesRSE-Concepts de Base - QCMlahoucine.ihander0% (1)

- Afficheurs Série 700Document10 pagesAfficheurs Série 700tlevageNo ratings yet

- Stabilite StructuresDocument9 pagesStabilite StructuresesselamiNo ratings yet

- III Analyse CombinatoireDocument13 pagesIII Analyse CombinatoireKat MuhongNo ratings yet

- Merged 20200609 172757.TextMarkDocument6 pagesMerged 20200609 172757.TextMarkAngeauden DidoNo ratings yet

- Travaux Dirigés - Série 1Document2 pagesTravaux Dirigés - Série 1MOHAND ES - SAADANYNo ratings yet

- Cahier Sommet Corrigé ch4Document6 pagesCahier Sommet Corrigé ch4Yuxiang YuanNo ratings yet

- DEVIS QUANTITATIF CENTRE D'ALPHABETISATION - ST - VideDocument7 pagesDEVIS QUANTITATIF CENTRE D'ALPHABETISATION - ST - VideBadara NdiayeNo ratings yet

- PNEU - Les Pré-Actionneurs - Les Distributeurs - TP1.V2 (AP 1 À 5) - Nv4Document5 pagesPNEU - Les Pré-Actionneurs - Les Distributeurs - TP1.V2 (AP 1 À 5) - Nv4Maxime PeridyNo ratings yet

- Guide ORIAS Conformité Modalites de Contact VFDocument8 pagesGuide ORIAS Conformité Modalites de Contact VFBenjamin ChabrierNo ratings yet

- Chapitre 5 - Le Traitement Et L'épuration Des EauxDocument5 pagesChapitre 5 - Le Traitement Et L'épuration Des Eauxرضا بونعاسNo ratings yet

- L2 Lac Ana NumDocument7 pagesL2 Lac Ana NumReyririNo ratings yet

- Mostafa Ami - Fiches 4 A.P - Séquence 2 - Projet 1 - Je Vais Chez MadjidDocument31 pagesMostafa Ami - Fiches 4 A.P - Séquence 2 - Projet 1 - Je Vais Chez MadjidNädïne Fërhätï100% (3)

- Commence Ici: Guide en Bref: Détails Sur Les Piles: +: On DanseDocument1 pageCommence Ici: Guide en Bref: Détails Sur Les Piles: +: On DansephigeramNo ratings yet

- Comparatif Et Configuration HSRP, VRRP, GLBP - Blog Sur Les Technologies RésDocument9 pagesComparatif Et Configuration HSRP, VRRP, GLBP - Blog Sur Les Technologies RésslimanovNo ratings yet

- Chapitre 1 Normalisation Reperage Installation Electrique PDFDocument23 pagesChapitre 1 Normalisation Reperage Installation Electrique PDFstoufa73No ratings yet

- Ite Missa Est, Op6-FS, VS, PX-PML PDFDocument28 pagesIte Missa Est, Op6-FS, VS, PX-PML PDFbry kaligayahanNo ratings yet

- Annexe 2 Identifiez Les Facteurs Déterminants La Position Concurrentielle D'essilor Avant L'opération de RapprochementDocument4 pagesAnnexe 2 Identifiez Les Facteurs Déterminants La Position Concurrentielle D'essilor Avant L'opération de RapprochementS.A O.CNo ratings yet

- 9 GuebayaDocument10 pages9 GuebayaYassine RabhiNo ratings yet

- GCPaout19 SommaireDocument13 pagesGCPaout19 Sommairelouveau.antoineNo ratings yet

- Respect Des Règles de Stockage 1Document7 pagesRespect Des Règles de Stockage 1Junior DossoNo ratings yet

- Pratique de L'entretienDocument22 pagesPratique de L'entretienDhia Eddine AbedNo ratings yet

- Processus Recrutement.2 PDFDocument3 pagesProcessus Recrutement.2 PDFAna RotaruNo ratings yet

- Theorie de LarchitectureDocument11 pagesTheorie de LarchitecturemohammedNo ratings yet

- 2022mulh5427 These ColardDocument190 pages2022mulh5427 These ColardReda AveNo ratings yet

- Compte-Rendu 2 POODocument3 pagesCompte-Rendu 2 POOAbdelbaki MissaouiNo ratings yet

- Quels Sont Les Différents Acteurs Intervenants en Milieu Pénitentiaire - VieDocument2 pagesQuels Sont Les Différents Acteurs Intervenants en Milieu Pénitentiaire - VieAmane ImaneNo ratings yet

- Schematique Psa 2Document36 pagesSchematique Psa 2Anonymous 7VmObaA7sL100% (1)

- L Orthographe Du PulaarDocument6 pagesL Orthographe Du PulaarBah AbrahamNo ratings yet

- Bouchireb, NassimaDocument1 pageBouchireb, NassimaMbarka ManelNo ratings yet