Professional Documents

Culture Documents

Precision Gear Pump Fast Color Change

Uploaded by

HishamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precision Gear Pump Fast Color Change

Uploaded by

HishamCopyright:

Available Formats

Gear Pump

Precision Gear Pump

Fast Color Change

ABB’s precision paint pumps are specifically designed for Modular Design

fast color change. With the unique shaft cleaning function, The modular pump design consists of four main parts:

fast and outstanding cleaning results are achieved. Pump Body - including gearwheels and pump shaft,

During flushing and loading there is a bypass function Pressure Sensor Block - including all external

around the gearwheels, in parallel to an internal flushing of connections,

gearwheels and shafts. Cleaning Adapter - including three valves for Bypass

and internal flushing of gearwheels

ABB’s Pump Technology Pump Block - including shaft sealing.

ABB's precision gear pumps are available in these models:

n 1.2 CCM/REV. Easy Maintenance

n 3.0 CCM/REV. The pump can be dismounted from the application

n 6.0 CCM/REV. without disconnecting any external hoses or cables.

The wearing parts are of hardened Stainless Steel to All external hoses and cables are connected to the

withstand a wide variety of paints. Pressure Sensor Block. By loosening four screws, the Pres-

Two different steel qualities are prepared for Water- sure Sensor Block is disconnected. Quick release of the

borne and Solvent based paints. All pump models have the pump from the system is done by loosening 2 screws. This

same outer dimensions regarding system-integration, and design allows very fast maintenance, MTTR < 15 min.

are therefore interchangeable. Since the pressure sensors are not dismounted from

the block while changing the pump, there is no need of

re-calibration.

Gear Pump

Precision Gear Pump

TECHNICAL DATA, GEAR PUMP

SPECIFICATIONS PERFORMANCE

Pump type Gear pump Pump speed Maximum 150 rpm with paint

Cleaning Cleaning of shaft, gear and in front of shaft Rotation Clockwise

packing. Built in bypass for faster cleaning. Max. fluid flow Max. pump speed x CCM/REV

Pressure sensors On fluid inlet and outlet. Min. fluid flow Min. fluid flow dependent of fluid viscosity,

system pressure, needed accuracy on coated

PUMP MODELS object and pump wear. Actual min. flow

1.2 CCM/ 3CCM / 6CCM All models are available both in flushable and should be verified with actual fluid material.

non-flushable versions. Pump design allows Accuracy ± 2%

change of pump models without other system Max. fluid pressure 20 bar. The pump is designed for accurate

modifications. dosing of fluid. Fluid input pressure should

approximately equal fluid output pressure, but

SS BY D

most accurate dosing with a little higher inlet–

than outlet-pressure at max fluid flow. Fluid

input pressure should be kept as low as pos-

IN

sible at any time in order to avoid excessive

wears.

Rec. operating

Width

fluid pressure 2-4 bar

Ø

Max. torque on pump shaft 12 Nm

Rec. air pilot pressure 5-10 bar

OUT

Max. allowable fluid temp. 60 °C

Flushing-time 7 - 10 sec

SSD D DC Solvent consumption 80 - 120 ml

Purging speed Maximum 40 rpm with cleaning agent

Length FEATURES

Integrated pressure sensors

Two pressure sensors are assembled in the block to measure

the pump input- and output pressure. In the seat for the pres-

sure sensors there is a 0.2 mm thick Teflon diaphragm. The

A

Teflon diaphragm is located directly in front of the sensors’

pressure surface. Thus the pressure sensors will not get in

contact with the paint, soiling is prevented and a better purge

Height

ability is ensured.

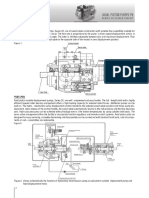

PROCESS DIAGRAM FOR FLUSHABLE PUMP SYSTEM

ABB AS, ROBOTICS, P.O BOX 265, N-4349 BRYNE, NORWAY

Model 1,2 CCM/rev 3,0 CCM/rev 6,0 CCM/rev

Length 189 200 200

Width 118 118 118

Height 138 138 146

A 50 50 50

B 91 91 91

Ø 10 10 10

Weight 3,2 3,3 4,7

PAINTYPES

Models prepared for Waterborne and Solvent based paint.

BLOCK MATERIAL

Pump Block Anodized aluminum, AlMgSi. All Recommendation When Dump line <4m, connect SSD to DC

paint-lines with Stainless Steel bush When Dump line >4m, use separate cleaning

ing (1.4571) unit (solvent & air) connected to DC

Pressure Sensor Block Stainless Steel; 12 CrNiS 18 8

Pump Body (Solvent based) Hardened Steel 90CrMoV 18 Please note Cleaning Unit is separate component

PR 10085EN_R4

Pump Body (Waterborne) Hardened Steel 6CrNiMoTi17 22K

Cleaning Adapter Plastic; PETP. All “paint lines” with

Stainless Steel bushing (1.4571)

Data and dimensions may be changed without notice.

www.abb.com/robots

You might also like

- PVS Cut SheetDocument16 pagesPVS Cut SheetBeni SaputraNo ratings yet

- Piston Pump High Pressure - HPRDocument20 pagesPiston Pump High Pressure - HPRAlawdin Grand HydraulicNo ratings yet

- Bronze Marine Pumps: Industrial DutyDocument2 pagesBronze Marine Pumps: Industrial DutyvisitabhinavNo ratings yet

- Pipeline Reinjection PumpsDocument2 pagesPipeline Reinjection PumpsManuel GimenezNo ratings yet

- Voith IPH4-5-6Document5 pagesVoith IPH4-5-6wag008No ratings yet

- Ficha Técnica Bomba PeristálticaDocument12 pagesFicha Técnica Bomba PeristálticaKEIRNENo ratings yet

- Houttuin B.V.: ProductsDocument6 pagesHouttuin B.V.: ProductspietroNo ratings yet

- Gear Pumps and Motors "B" Series Group 2,5: Technical CatalogueDocument29 pagesGear Pumps and Motors "B" Series Group 2,5: Technical CatalogueLucyan IonescuNo ratings yet

- NACHI - PUMP - SPEC - Pvs SeriesDocument57 pagesNACHI - PUMP - SPEC - Pvs SeriesTomiNo ratings yet

- Installation Manual APSDocument14 pagesInstallation Manual APSTharaka MethsaraNo ratings yet

- Catalogo Bombas NachiDocument57 pagesCatalogo Bombas NachiCesar Muñoz OssesNo ratings yet

- 094af0841fb8be15 19443EN US - TCM - 198 600017Document2 pages094af0841fb8be15 19443EN US - TCM - 198 600017li geneNo ratings yet

- Ficha Tecnica Ab01 PDFDocument6 pagesFicha Tecnica Ab01 PDFmantenimiento myagroupNo ratings yet

- LPV Hydraulic Pump Catalog PDFDocument20 pagesLPV Hydraulic Pump Catalog PDFJAGDEV PANESARNo ratings yet

- Vincke Gear Pumps CatDocument48 pagesVincke Gear Pumps CatVelibor KaranovicNo ratings yet

- High Pressure Self-Regulating Pump Technical SpecificationsDocument20 pagesHigh Pressure Self-Regulating Pump Technical Specificationsseve1No ratings yet

- Compact High-Pressure Internal Gear Pumps Dimension SheetDocument28 pagesCompact High-Pressure Internal Gear Pumps Dimension SheetcotteNo ratings yet

- Dvukhvintovye Nasosy Houttuin Serii 231.50 Prospekt Na Angliyskom YazykeDocument6 pagesDvukhvintovye Nasosy Houttuin Serii 231.50 Prospekt Na Angliyskom Yazykedindin6666No ratings yet

- 47Z-METER Truck-Mounted Concrete Boom PumpDocument6 pages47Z-METER Truck-Mounted Concrete Boom PumpJuanNo ratings yet

- Variable Displacement Axial Piston Pumps: Edition: 04/01.2012 Replaces: MVP 03 T ADocument64 pagesVariable Displacement Axial Piston Pumps: Edition: 04/01.2012 Replaces: MVP 03 T AGERALD SIMONNo ratings yet

- Vacuum Pumps and Compressors For The Electric Power IndustryDocument6 pagesVacuum Pumps and Compressors For The Electric Power IndustryPinky BasuNo ratings yet

- Page 1271Document1 pagePage 1271EmilyTheDwarfNo ratings yet

- 36ZCB4427USDocument6 pages36ZCB4427USprajjwal patidarNo ratings yet

- Variable Pumps For Closed Loop Operation Type Hv-02Document36 pagesVariable Pumps For Closed Loop Operation Type Hv-02Eric CNo ratings yet

- 2PE Salami PDFDocument35 pages2PE Salami PDFMartin MiaNo ratings yet

- Precise Flow Rate Magnetically Coupled PumpsDocument4 pagesPrecise Flow Rate Magnetically Coupled PumpsDaboiaNo ratings yet

- PV 21 PumpDocument13 pagesPV 21 PumpJayath Bogahawatte100% (1)

- CD300M Dri-Prime® Pump: Features and Benefits SpecificationsDocument2 pagesCD300M Dri-Prime® Pump: Features and Benefits Specificationsahmedomar_953724702No ratings yet

- STD Line ACE3: Product DescriptionDocument12 pagesSTD Line ACE3: Product DescriptionEugenio LombardiNo ratings yet

- Highly Accurate Piston Pumps for Precise Liquid DosingDocument4 pagesHighly Accurate Piston Pumps for Precise Liquid DosingmapalptsNo ratings yet

- Houttuin B.V.: ProductsDocument6 pagesHouttuin B.V.: ProductspietroNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- Dual Stage Pumps Type RZ: 1. GeneralDocument12 pagesDual Stage Pumps Type RZ: 1. GeneralThiago LimaNo ratings yet

- CR 0701 CH 11Document6 pagesCR 0701 CH 11Rıfat BingülNo ratings yet

- Dual Stage Pumps Type RZ: 1. GeneralDocument12 pagesDual Stage Pumps Type RZ: 1. Generaldriss echanchniNo ratings yet

- Pumps: Pacifico Ortaliza Pme 828Document32 pagesPumps: Pacifico Ortaliza Pme 828Angel Silva VicenteNo ratings yet

- How To Read A Pump CurveDocument9 pagesHow To Read A Pump CurveAhmedNo ratings yet

- Quiet Running Horizontal Multi-Stage Centrifugal Booster PumpDocument5 pagesQuiet Running Horizontal Multi-Stage Centrifugal Booster PumpthabisoNo ratings yet

- Section 06B - PumpsDocument62 pagesSection 06B - PumpsRajesh KumarNo ratings yet

- Fire Pump ChecklistDocument11 pagesFire Pump ChecklistLD Jr FrancisNo ratings yet

- Form 2208 - Page 1: Surface Pump Installation DataDocument3 pagesForm 2208 - Page 1: Surface Pump Installation DataErich ThomasNo ratings yet

- PPEC Pressure Powered Pump Selection and Sizing: Capacity LB/HDocument2 pagesPPEC Pressure Powered Pump Selection and Sizing: Capacity LB/Ht0r1t0 br4v0No ratings yet

- Metering Pumps Components ProMinent Product Catalogue 2020 Volume 1Document418 pagesMetering Pumps Components ProMinent Product Catalogue 2020 Volume 1Husif QedirzadeNo ratings yet

- Oil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetDocument4 pagesOil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetJhonNo ratings yet

- Unit 2Document22 pagesUnit 2vortofolmeNo ratings yet

- 28Z-M Brochure USDocument6 pages28Z-M Brochure USعالم الصيانة معدات ثقيلة ومعدات خرسانةNo ratings yet

- Bushing Pumps, Motors and Flow Dividers Data SheetDocument2 pagesBushing Pumps, Motors and Flow Dividers Data SheetMarinko Knezevic Crtica KarasNo ratings yet

- eHYDRO SERIESDocument6 pageseHYDRO SERIESBanupriya BalasubramanianNo ratings yet

- PV BasicsDocument45 pagesPV Basicshagg100% (2)

- Bfs ValveDocument12 pagesBfs Valverokan123No ratings yet

- Chapter 1Document6 pagesChapter 1Edgar Allende ChavezNo ratings yet

- HY29-0101-EU Hydraulic Vane Pumps Start-Up InformationDocument12 pagesHY29-0101-EU Hydraulic Vane Pumps Start-Up InformationEchipa Hydraulic-SolutionNo ratings yet

- AR Series Variable Displacement Piston Pumps Technical OverviewDocument10 pagesAR Series Variable Displacement Piston Pumps Technical OverviewArvinder SinghNo ratings yet

- Electric Submersible Pump New Design For Zug-10 Offshore North West JavaDocument9 pagesElectric Submersible Pump New Design For Zug-10 Offshore North West JavaLarasati K SadewiNo ratings yet

- 2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01Document2 pages2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01controlorNo ratings yet

- Operating Principle: PVD Sizes 25 30 37 48 45 56 72 90 115 145Document10 pagesOperating Principle: PVD Sizes 25 30 37 48 45 56 72 90 115 145ahmedNo ratings yet

- Service Manual: PVR15-30B-Flanged Series PumpDocument8 pagesService Manual: PVR15-30B-Flanged Series PumpAristideNo ratings yet

- Self Priming Centrifugal PumpsDocument9 pagesSelf Priming Centrifugal Pumpsmember1000No ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- D8R T&aDocument37 pagesD8R T&aRajan Mullappilly100% (2)

- 77-9075 DD5Document72 pages77-9075 DD5Imad AghilaNo ratings yet

- Foster Wheeler Process Engineering Practices IndexDocument86 pagesFoster Wheeler Process Engineering Practices Indexchemiesm94% (16)

- Frequency Inverter Installation & User Guide: Power 1100, Power 2200Document8 pagesFrequency Inverter Installation & User Guide: Power 1100, Power 2200Ahmed TahaNo ratings yet

- FlowtechDocument2 pagesFlowtechsurya prakashNo ratings yet

- Marketing ReportDocument45 pagesMarketing ReportSharanya HaladyNo ratings yet

- Vogel AG 1-8092-USDocument38 pagesVogel AG 1-8092-USingdaveNo ratings yet

- Technical Specification Sheet For Auxiliaries Equipment OfJ - 420Document2 pagesTechnical Specification Sheet For Auxiliaries Equipment OfJ - 420Muhammad Mujtaba TariqNo ratings yet

- Bombas de Canal Lateral - PresentaciónDocument31 pagesBombas de Canal Lateral - PresentaciónBYR SEDE BOGOTÁNo ratings yet

- CF 2500 - 3500Document16 pagesCF 2500 - 3500Freddy OrtegaNo ratings yet

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- 390 Adventure MY 20Document77 pages390 Adventure MY 20Asura GarageNo ratings yet

- Emec Product Catalogue EngDocument42 pagesEmec Product Catalogue Engtanbqtb03No ratings yet

- Leelam Industries PDFDocument13 pagesLeelam Industries PDFNILESH YADAVNo ratings yet

- MDBFPDocument21 pagesMDBFPRaja Vignesh100% (1)

- API 675 pump specification sheetDocument2 pagesAPI 675 pump specification sheetAKSHEYMEHTANo ratings yet

- HASS Manual Chapter 5Document38 pagesHASS Manual Chapter 5Victor KimNo ratings yet

- Supplying Power For Electric Fire Pumps-Pacuku-CEEDocument5 pagesSupplying Power For Electric Fire Pumps-Pacuku-CEEJOSE LUIS FALCON CHAVEZNo ratings yet

- SKF Oil PumpDocument48 pagesSKF Oil Pumpjrgonzales24No ratings yet

- 3054 3056electronicDocument110 pages3054 3056electronicMohmed Abo Elftoh100% (5)

- Pipeline Percy How I Test Field Pipes WebDocument21 pagesPipeline Percy How I Test Field Pipes WebALAA EWAIDANo ratings yet

- Function 6 MEP All Surveyors Combine Oral QuestionsDocument35 pagesFunction 6 MEP All Surveyors Combine Oral Questionsdasleo546No ratings yet

- The Ultimate Concorde X ChecklistDocument75 pagesThe Ultimate Concorde X ChecklistTomasz KubarskiNo ratings yet

- Pump Denso hp0Document63 pagesPump Denso hp0DenisEcheverri100% (3)

- Introduction of PumpsDocument10 pagesIntroduction of PumpsSudheer NairNo ratings yet

- API 610 - Renroc GroupDocument9 pagesAPI 610 - Renroc GroupSalman KhaniNo ratings yet

- "L8" Drive End: Operation - Assembly Instructions and Parts List ForDocument7 pages"L8" Drive End: Operation - Assembly Instructions and Parts List ForACCA PumpsNo ratings yet

- (Ellis H. Austin (Auth.) ) Drilling Engineering Han (B-Ok - Xyz) PDFDocument311 pages(Ellis H. Austin (Auth.) ) Drilling Engineering Han (B-Ok - Xyz) PDFRebar KakaNo ratings yet

- Update Your Oil Mist Lubrication KnowledgeDocument2 pagesUpdate Your Oil Mist Lubrication Knowledgehello17No ratings yet

- Motion Control Drives D32 Complete English 2020 01 Update 2020 07Document120 pagesMotion Control Drives D32 Complete English 2020 01 Update 2020 07Anttonio PereiraNo ratings yet